Precision Testing Made Easier: Applications of Double Ridged Flexible Waveguide

In today's demanding microwave testing environment, engineers face mounting challenges with signal integrity, measurement accuracy, and system flexibility. Traditional waveguide solutions often fall short when dealing with complex installation geometries, vibration-prone environments, and the need for precise high-frequency measurements. The Double Ridged Flexible Waveguide emerges as a revolutionary solution, transforming how precision testing is conducted across satellite communications, defense systems, and advanced radar applications. This advanced transmission line technology addresses critical pain points while delivering unparalleled performance in scenarios where traditional rigid waveguides simply cannot function effectively.

Understanding Double Ridged Flexible Waveguide Technology

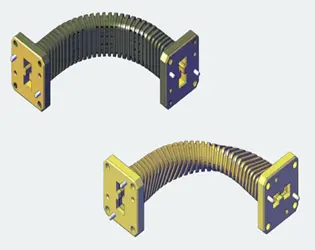

Double Ridged Flexible Waveguide represents a significant advancement in microwave transmission technology, combining the superior electromagnetic performance of ridge waveguides with the mechanical flexibility required for demanding applications. The innovative dual-ridge design dramatically expands operational frequency ranges while maintaining exceptional precision across measurements. Unlike conventional waveguides, the Double Ridged Flexible Waveguide incorporates two metallic ridges positioned opposite each other within the waveguide cross-section, effectively reducing the cutoff frequency and enabling broader bandwidth operation. The fundamental advantage lies in its ability to support much wider frequency ranges compared to standard rectangular waveguides of similar dimensions. The ridge configuration modifies the electromagnetic field distribution, allowing for efficient signal propagation across extended frequency bands while maintaining low insertion loss characteristics. This design innovation makes Double Ridged Flexible Waveguide particularly valuable for applications requiring versatility and high-performance signal transmission across multiple frequency bands.

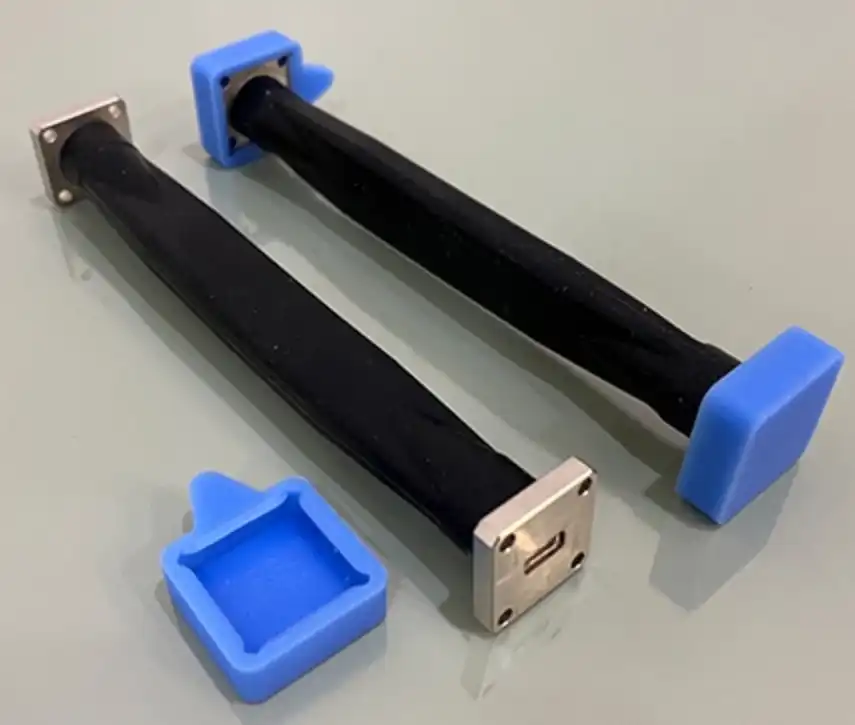

Engineering Excellence in Flexible Construction

The flexible construction of Double Ridged Flexible Waveguide utilizes advanced materials engineering to achieve optimal performance under mechanical stress. The waveguide structure incorporates corrugated metal construction with specialized coatings that maintain electrical continuity while allowing for bending and twisting motions. This flexibility enables installation in confined spaces, routing around obstacles, and accommodation of thermal expansion without compromising signal integrity. Advanced manufacturing techniques ensure that the Double Ridged Flexible Waveguide maintains consistent impedance characteristics throughout its length, even when subjected to mechanical deformation. The corrugated outer conductor provides mechanical flexibility while the internal ridge structure preserves electromagnetic performance. This combination results in a transmission line capable of handling dynamic environments while delivering stable, repeatable measurements essential for precision testing applications.

Critical Applications in Precision Testing Environments

Double Ridged Flexible Waveguide technology has revolutionized precision testing across multiple industries, providing solutions where traditional rigid waveguides prove inadequate. In satellite communication testing, these waveguides enable accurate characterization of antenna systems, allowing engineers to perform comprehensive pattern measurements and gain calibrations with unprecedented accuracy. The flexibility factor becomes crucial when testing large satellite structures where rigid connections would be impractical or impossible to implement effectively. Aerospace testing environments particularly benefit from Double Ridged Flexible Waveguide applications, where vibration isolation and thermal cycling requirements demand robust, flexible interconnections. The waveguides maintain measurement accuracy while withstanding the harsh conditions typical of aerospace testing facilities. Their ability to accommodate mechanical movement while preserving electrical performance makes them indispensable for testing aircraft radar systems, navigation equipment, and communication arrays.

Laboratory and Field Measurement Applications

Modern microwave laboratories increasingly rely on Double Ridged Flexible Waveguide for network analyzer calibration and verification procedures. The broad frequency coverage enables single-setup measurements across multiple bands, reducing test complexity and improving measurement efficiency. The flexibility allows for easy reconfiguration of test setups, enabling rapid switching between different measurement configurations without compromising calibration accuracy. Field testing applications demonstrate the true value of Double Ridged Flexible Waveguide technology. Military radar systems, mobile communication platforms, and remote sensing equipment all require reliable, flexible interconnections capable of maintaining performance under field conditions. The waveguides provide the necessary mechanical durability while ensuring measurement integrity in challenging environmental conditions where precision remains paramount.

Advanced Technical Features and Performance Characteristics

The technical sophistication of Double Ridged Flexible Waveguide extends beyond basic flexibility, incorporating advanced engineering features that optimize performance across demanding applications. The dual-ridge configuration enables operation across frequency ranges extending from 0.5 GHz to over 110 GHz, providing exceptional bandwidth coverage that surpasses traditional waveguide designs. This extended frequency range eliminates the need for multiple waveguide types in broadband testing applications, simplifying test setups while improving measurement accuracy. The waveguide construction utilizes precision manufacturing techniques that ensure consistent electrical performance throughout the flexible structure. Internal surface treatments and specialized plating provide low-loss characteristics essential for high-frequency applications. The corrugated external structure maintains mechanical flexibility while preserving the internal electromagnetic environment, resulting in stable impedance characteristics regardless of physical configuration.

Material Engineering and Durability Considerations

Advanced material selection plays a crucial role in Double Ridged Flexible Waveguide performance and longevity. The waveguide construction incorporates corrosion-resistant materials and specialized coatings that withstand environmental exposure while maintaining electrical performance. The flexible construction materials are selected for their ability to withstand repeated bending cycles without degradation, ensuring long-term reliability in dynamic applications. The standard Neoprene jacket provides pressure retention and environmental protection while maintaining flexibility characteristics. This protective covering shields the internal waveguide structure from moisture, dust, and mechanical damage while allowing full range of motion. The jacket design incorporates features that prevent kinking and maintain proper bend radius limits, protecting the internal waveguide structure from damage during installation and operation.

Customization and OEM Integration Solutions

Advanced Microwave Technologies Co., Ltd. recognizes that precision testing applications often require specialized solutions tailored to specific requirements. The company's comprehensive customization capabilities enable modification of Double Ridged Flexible Waveguide dimensions, materials, and frequency ranges to match exact application needs. This flexibility in manufacturing allows integration into existing test systems while optimizing performance for specific measurement requirements. The customization process begins with detailed analysis of application requirements, including frequency range, power handling, environmental conditions, and mechanical constraints. Engineering teams work closely with customers to develop optimized solutions that maximize performance while meeting specific installation and operational requirements. This collaborative approach ensures that each Double Ridged Flexible Waveguide solution delivers optimal performance for its intended application.

Quality Assurance and Testing Protocols

Every Double Ridged Flexible Waveguide undergoes rigorous testing procedures that verify electrical performance, mechanical integrity, and environmental compliance. The testing protocols include comprehensive network analyzer measurements to verify insertion loss, return loss, and impedance characteristics across the specified frequency range. Mechanical testing ensures that flexibility specifications are met without compromising electrical performance. Environmental testing validates performance under temperature cycling, humidity exposure, and vibration conditions typical of field applications. These comprehensive testing procedures ensure that each waveguide meets or exceeds specified performance criteria, providing customers with reliable, predictable performance in their precision testing applications. The quality assurance process includes documentation of all test results, providing complete traceability for critical applications.

Conclusion

Double Ridged Flexible Waveguide technology represents a paradigm shift in precision testing capabilities, offering unprecedented combination of performance, flexibility, and reliability. These advanced transmission lines solve critical challenges in modern microwave testing while enabling new possibilities for system design and implementation. The technology's broad frequency coverage, mechanical flexibility, and superior electrical performance make it indispensable for applications requiring precision and adaptability.

Cooperate with Advanced Microwave Technologies Co., Ltd.

Advanced Microwave Technologies Co., Ltd. stands as the premier China Double Ridged Flexible Waveguide manufacturer, offering comprehensive solutions backed by over two decades of microwave expertise. Our state-of-the-art 24m Microwave Darkroom and ISO-certified quality systems ensure every High Quality Double Ridged Flexible Waveguide meets stringent performance standards. As a leading China Double Ridged Flexible Waveguide supplier, we provide competitive Double Ridged Flexible Waveguide price options with rapid prototyping and global delivery capabilities. Our China Double Ridged Flexible Waveguide factory offers wholesale solutions and customization services. Contact craig@admicrowave.com for Double Ridged Flexible Waveguide for sale inquiries and discover why industry leaders choose our precision solutions.

FAQ

Q: What frequency range does Double Ridged Flexible Waveguide support?

A: Double Ridged Flexible Waveguide typically operates from 0.5 GHz to 110 GHz, providing exceptional bandwidth coverage for diverse testing applications.

Q: How does flexibility affect electrical performance?

A: Advanced engineering maintains consistent electrical characteristics during bending, with minimal impact on insertion loss and return loss specifications.

Q: What are the main advantages over standard rectangular waveguides?

A: Double Ridged Flexible Waveguide offers broader bandwidth, mechanical flexibility, and easier installation in complex geometries while maintaining precision performance.

Q: Can these waveguides be customized for specific applications?

A: Yes, dimensions, materials, flange types, and frequency ranges can be customized to meet specific technical requirements and installation constraints.

References

1. "Microwave Engineering: Passive Circuits" - David M. Pozar, focusing on advanced waveguide technologies and their applications in precision measurements

2. "Ridge Waveguides and Passive Microwave Components" - Sheel Aditya, examining the theoretical foundations and practical implementations of ridge waveguide systems

3. "Handbook of Microwave Component Measurements" - Joel P. Dunsmore, providing comprehensive coverage of measurement techniques using advanced waveguide technologies

4. "Microwave and RF Design: A Systems Approach" - Michael Steer, detailing the integration of flexible waveguide components in modern microwave systems

_1733738410152.webp)