Waveguide Couplers for Precise Design Needs

In high-frequency microwave systems, signal integrity can deteriorate rapidly without proper coupling mechanisms, leading to power loss, interference, and compromised system performance. Engineers designing satellite ground stations, radar installations, and defense communication networks face mounting pressure to achieve precise power distribution while maintaining signal quality across broad frequency ranges. The Double-Ridged Waveguide Broadwall Directional Coupler emerges as a critical solution, addressing these challenges through specialized structural design that enables controlled electromagnetic wave coupling with minimal insertion loss and maximum directivity.

Understanding Double-Ridged Waveguide Broadwall Directional Coupler Technology

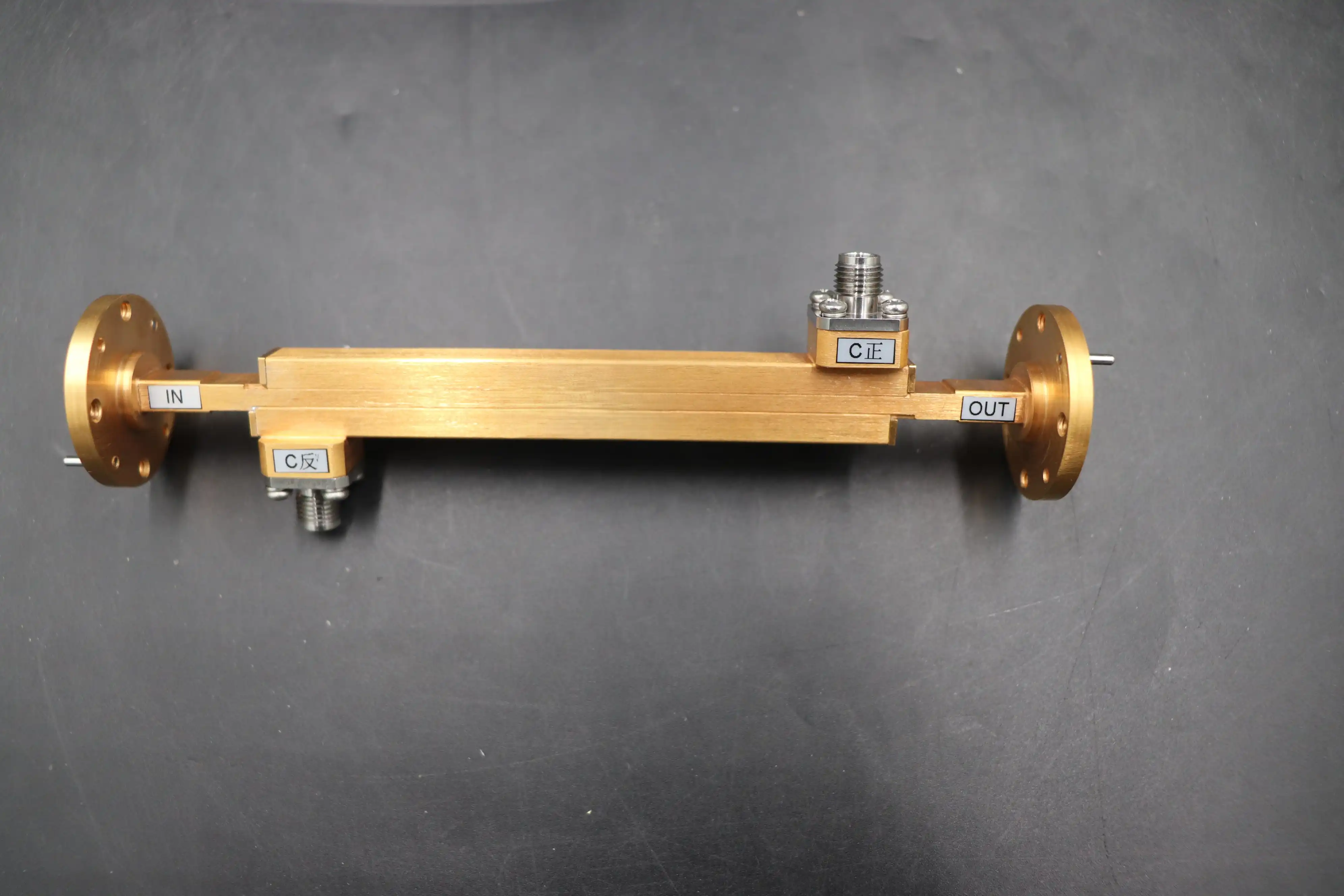

The Double-Ridged Waveguide Broadwall Directional Coupler represents a sophisticated evolution in microwave component design, featuring two opposing ridge-like protrusions on its broad wall that fundamentally alter electromagnetic wave propagation characteristics. When electromagnetic energy enters through one port of this specialized waveguide structure, the ridges create a unique field distribution pattern that differs markedly from conventional rectangular waveguides. This distinctive geometry enables the coupler to achieve broadband performance across frequencies ranging from 1 GHz to 40 GHz, making it exceptionally versatile for applications spanning legacy communication systems to cutting-edge 5G and future 6G technologies. The operational principle relies on controlled coupling through the waveguide's broad wall, where electromagnetic waves traveling through the primary path induce coupled energy to a secondary port. The ridge structures enhance this coupling mechanism by concentrating electromagnetic fields in specific regions, resulting in superior directivity and coupling flatness compared to standard waveguide designs. This configuration proves particularly advantageous in high-power applications, where the Double-Ridged Waveguide Broadwall Directional Coupler can handle up to 1 kilowatt of continuous power while maintaining insertion losses below 0.5 dB. The precision-machined coupling holes follow a Tchebyscheff distribution pattern, optimizing the coupling coefficient across the entire operating bandwidth and ensuring consistent performance that meets the demanding requirements of satellite transponders, military radar systems, and telecommunications infrastructure.

Key Performance Characteristics

Modern Double-Ridged Waveguide Broadwall Directional Couplers manufactured by Advanced Microwave Technologies Co., Ltd. incorporate multiple performance enhancements that address critical design challenges. The broad frequency coverage from 1 GHz through 40 GHz accommodates diverse application requirements, from L-band satellite communications to Ka-band radar systems. Coupling factors are customizable across a range of 10 dB, 20 dB, and 30 dB, allowing system designers to precisely tailor power division ratios to specific signal distribution architectures. The directivity specification typically exceeds 15 dB across the full bandwidth, ensuring that coupled signals maintain proper phase relationships and minimize unwanted reflections that could degrade system performance. The mechanical construction employs rugged materials including aluminum alloys, stainless steel, and brass, selected based on application-specific environmental conditions and power handling requirements. Advanced manufacturing techniques such as CNC precision machining and dip-brazing create hermetically sealed assemblies capable of withstanding extreme temperature variations, humidity exposure, and mechanical shock encountered in aerospace and defense deployments. The compact form factor optimizes space utilization within crowded equipment racks and antenna feed systems, while standard flange configurations ensure compatibility with existing waveguide infrastructure. These physical characteristics combine with electrical performance specifications to deliver a reliable, field-proven solution that maintains calibration accuracy throughout extended operational lifetimes.

Application Domains for Precision Waveguide Coupling

The Double-Ridged Waveguide Broadwall Directional Coupler finds extensive deployment across multiple high-stakes industries where signal integrity directly impacts mission success. In satellite communications infrastructure, these couplers enable ground station operators to monitor transmitted and received power levels without interrupting signal flow, facilitating real-time adjustments that optimize link budgets and maximize data throughput. The ability to sample high-definition video streams, telemetry data, and voice communications simultaneously across multiple frequency bands makes the Double-Ridged Waveguide Broadwall Directional Coupler indispensable for commercial satellite operators and government space agencies managing complex orbital constellations. Defense applications leverage the coupler's high power handling and wide bandwidth capabilities for sophisticated radar systems requiring precise target discrimination and long-range detection. Military surveillance platforms integrate these components into phased array antennas where accurate amplitude and phase control across numerous radiating elements determines beam steering precision and target resolution. Electronic warfare systems utilize Double-Ridged Waveguide Broadwall Directional Couplers for signal injection and monitoring functions, enabling operators to analyze adversary emissions while simultaneously jamming hostile communications. The component's rugged construction and reliable performance under harsh environmental conditions make it suitable for shipboard installations, airborne platforms, and ground-based tactical systems operating in contested electromagnetic environments.

Telecommunications Infrastructure Integration

Modern telecommunications networks increasingly rely on waveguide coupling technology to support expanding bandwidth demands and coverage requirements. Base station installations serving 5G networks incorporate Double-Ridged Waveguide Broadwall Directional Couplers within their feed systems to distribute signals among multiple antenna sectors while maintaining the low noise figures essential for maximizing cell edge performance. Rural connectivity initiatives benefit from the coupler's efficiency in long-distance signal propagation scenarios, where every fraction of a decibel in insertion loss translates directly to extended coverage footprints and improved quality of service for underserved populations. Industrial Internet of Things deployments represent another growing application domain, with manufacturing facilities, logistics centers, and energy production sites requiring robust wireless connectivity across expansive physical areas. The Double-Ridged Waveguide Broadwall Directional Coupler's ability to maintain signal integrity across temperature extremes and in the presence of electromagnetic interference makes it ideally suited for these challenging industrial environments. Research laboratories conducting experimental work on advanced modulation schemes, cognitive radio architectures, and millimeter-wave propagation studies depend on the measurement accuracy that precision-engineered waveguide couplers provide, enabling scientists to validate theoretical models and advance the state of the art in wireless communications technology.

Design Considerations and Customization Options

Selecting the optimal Double-Ridged Waveguide Broadwall Directional Coupler configuration requires careful analysis of system-level requirements including frequency range, power handling capacity, coupling factor, physical envelope constraints, and environmental operating conditions. Engineers must balance competing design tradeoffs such as directivity versus bandwidth, coupling flatness versus insertion loss, and size versus power rating. Advanced Microwave Technologies Co., Ltd. addresses these challenges through comprehensive OEM services that enable customer-specific customization of critical parameters. Frequency range optimization begins with waveguide size selection, with WRD-series configurations spanning from WRD-840 for lower frequency applications through WRD-180 for high-frequency Ka-band systems. The coupling factor selection directly impacts dynamic range in measurement applications, with tighter coupling values providing stronger coupled signals for sensitive detection equipment while looser coupling minimizes loading effects on the main transmission path. Material choices influence both electrical performance and environmental resilience, with copper and brass offering superior conductivity for low-loss performance while aluminum alloys reduce weight for aerospace applications and stainless steel provides maximum corrosion resistance for maritime deployments.

Manufacturing Excellence and Quality Assurance

The production of high-performance Double-Ridged Waveguide Broadwall Directional Couplers demands exacting manufacturing standards and comprehensive quality control protocols. Advanced Microwave Technologies Co., Ltd. operates ISO 9001:2015 certified manufacturing facilities equipped with state-of-the-art CNC machining centers capable of achieving dimensional tolerances measured in micrometers. Each waveguide component undergoes multiple inspection stages using coordinate measuring machines and optical comparators to verify conformance with engineering drawings before assembly operations commence. The company's 24-meter microwave darkroom facility enables full characterization of coupler performance across the 0.5 to 110 GHz frequency spectrum, providing comprehensive validation of insertion loss, coupling factor, directivity, and voltage standing wave ratio parameters. This antenna plane near and far field measuring recombination chamber allows engineers to identify and correct subtle design anomalies that might escape detection in smaller test environments, ensuring that production units consistently meet published specifications. Environmental testing capabilities including temperature cycling, humidity exposure, and vibration qualification verify product reliability under the harsh conditions encountered in real-world deployments. These quality assurance processes, combined with ISO 14001:2015 environmental management and ISO 45001:2018 occupational safety certifications, demonstrate Advanced Microwave's commitment to manufacturing excellence and corporate responsibility.

Technical Support and Engineering Collaboration

Successful integration of Double-Ridged Waveguide Broadwall Directional Couplers into complex microwave systems often requires close collaboration between component suppliers and end-user engineering teams. Advanced Microwave Technologies Co., Ltd. provides comprehensive technical support services throughout the product lifecycle, beginning with initial design consultations where experienced RF engineers help customers define optimal specifications based on system-level requirements. Electromagnetic simulation capabilities enable pre-production validation of custom configurations, reducing development risk and accelerating time-to-market for new platform designs. Prototyping services offer rapid turnaround on evaluation units, allowing customers to perform hands-on testing and verification before committing to production quantities. Installation guidance documentation provides detailed mechanical interface specifications, torque requirements for flange hardware, and best practices for waveguide system assembly that prevent common installation errors. Troubleshooting support addresses field issues through systematic diagnostic procedures, with factory engineers available to analyze returned units and recommend corrective actions when performance anomalies occur. This comprehensive support infrastructure ensures that customers can confidently specify Double-Ridged Waveguide Broadwall Directional Couplers for mission-critical applications where system reliability directly impacts operational success.

Conclusion

Double-Ridged Waveguide Broadwall Directional Couplers deliver essential performance capabilities for precision microwave system designs across satellite communications, defense, aerospace, and telecommunications applications, combining broadband frequency coverage with exceptional power handling and signal integrity.

Cooperate with Advanced Microwave Technologies Co., Ltd.

As a China Double-Ridged Waveguide Broadwall Directional Coupler manufacturer, China Double-Ridged Waveguide Broadwall Directional Coupler supplier, and China Double-Ridged Waveguide Broadwall Directional Coupler factory offering High Quality Double-Ridged Waveguide Broadwall Directional Coupler for sale at competitive Double-Ridged Waveguide Broadwall Directional Coupler price points, Advanced Microwave Technologies Co., Ltd. stands ready to support your most demanding applications. Our China Double-Ridged Waveguide Broadwall Directional Coupler wholesale programs deliver cost-effective solutions backed by over 20 years of microwave expertise, ISO certifications, and comprehensive OEM customization capabilities. Contact craig@admicrowave.com today to discuss your specific requirements and discover how our precision-engineered components can enhance your system performance.

References

1. Montgomery, C. G., Dicke, R. H., & Purcell, E. M. (Editors). Principles of Microwave Circuits. McGraw-Hill Book Company, Radiation Laboratory Series Volume 8.

2. Collin, R. E. Foundations for Microwave Engineering. IEEE Press Series on Electromagnetic Wave Theory, Second Edition.

3. Pozar, D. M. Microwave Engineering. John Wiley & Sons, Fourth Edition.

4. Matthaei, G. L., Young, L., & Jones, E. M. T. Microwave Filters, Impedance-Matching Networks, and Coupling Structures. Artech House Publishers.