Understanding the Key Parameters of a Waveguide Bandpass Filter

In the complex world of microwave engineering, waveguide bandpass filters represent critical components that determine system performance across satellite communications, defense applications, and aerospace technologies. Understanding the key parameters of a waveguide bandpass filter is essential for engineers and procurement professionals seeking optimal signal processing solutions. These sophisticated devices control frequency response, minimize signal loss, and ensure reliable operation in demanding electromagnetic environments. The fundamental parameters include insertion loss, return loss, bandwidth characteristics, power handling capabilities, and temperature stability coefficients. Advanced Microwave Technologies Co., Ltd has developed comprehensive expertise in manufacturing high-precision waveguide bandpass filters that meet stringent industry requirements across multiple frequency bands from 0.5 to 110GHz.

Critical Electrical Parameters for Waveguide Bandpass Filter Performance

Frequency Response Characteristics and Bandwidth Control

The frequency response characteristics of a waveguide bandpass filter fundamentally determine its operational effectiveness in microwave systems. Center frequency accuracy directly impacts signal integrity, particularly in satellite communication applications where precise frequency control ensures optimal data transmission rates. Advanced Microwave Technologies Co., Ltd utilizes state-of-the-art measurement capabilities within their 24m Microwave Darkroom to validate frequency response across the entire operational spectrum. The bandwidth parameter defines the filter's passband width, typically specified at -3dB points, which directly correlates with the system's ability to accommodate signal variations and modulation schemes. Fractional bandwidth calculations become crucial when designing filters for broadband applications, requiring careful consideration of coupling mechanisms and resonator configurations. Temperature coefficient of frequency represents another vital parameter, as thermal variations can shift the center frequency beyond acceptable limits in aerospace and defense applications. Modern waveguide bandpass filter designs incorporate temperature compensation techniques to maintain frequency stability across operational temperature ranges from -55°C to +85°C.

Insertion Loss and Return Loss Specifications

Insertion loss characteristics of a waveguide bandpass filter directly impact system gain and signal-to-noise ratio performance in critical applications. Low insertion loss values, typically ranging from 0.1dB to 2dB depending on filter complexity, ensure minimal signal degradation throughout the transmission path. Advanced measurement techniques employed at Advanced Microwave Technologies Co., Ltd facilities enable precise characterization of insertion loss across the entire frequency range using sophisticated vector network analyzers calibrated to international standards. Return loss parameters indicate the filter's impedance matching characteristics, with typical values exceeding 20dB in the passband to minimize reflections and standing wave formations. Ripple specifications within the passband define acceptable insertion loss variations, typically maintained below 0.5dB for high-performance applications. The relationship between insertion loss and filter order demonstrates the fundamental trade-off between selectivity and signal attenuation, requiring careful optimization based on specific application requirements. Quality factor (Q) calculations directly correlate with insertion loss performance, influencing both filter bandwidth and loss characteristics simultaneously.

Power Handling and Thermal Management Parameters

Power handling capabilities of a waveguide bandpass filter determine maximum operational power levels without performance degradation or physical damage. Peak power ratings typically range from several hundred watts to megawatt levels depending on waveguide size and construction materials. Average power specifications consider thermal effects and heat dissipation requirements, particularly important in continuous operation scenarios common in satellite ground stations and radar systems. Advanced Microwave Technologies Co., Ltd incorporates thermal analysis modeling during the design phase to ensure adequate heat dissipation and temperature distribution throughout the filter structure. Breakdown power threshold calculations consider both material properties and electric field distribution within the filter cavity, establishing safe operational limits for high-power applications. Thermal conductivity of waveguide materials, typically brass, aluminum, or silver-plated copper, significantly influences power handling performance and long-term reliability. Cooling system integration requirements become critical for high-power applications, necessitating careful consideration of mounting interfaces and thermal path optimization.

Mechanical Design Considerations for Waveguide Bandpass Filter Implementation

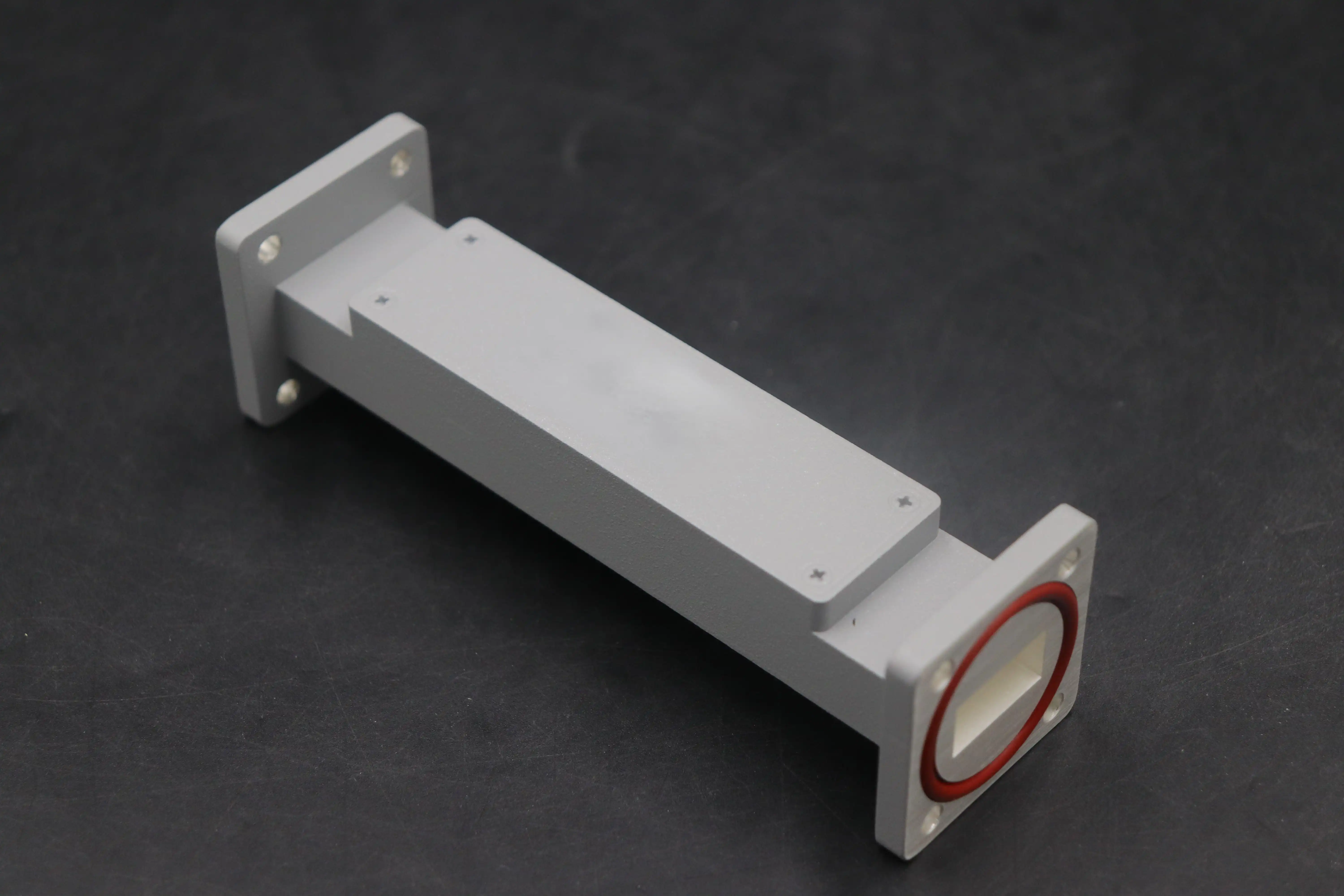

Dimensional Accuracy and Manufacturing Tolerances

Dimensional precision in waveguide bandpass filter manufacturing directly affects electrical performance and frequency accuracy. Critical dimensions including cavity lengths, coupling aperture sizes, and wall thicknesses must be maintained within tight tolerances, typically ±0.025mm or better for frequencies above 10GHz. Advanced Microwave Technologies Co., Ltd employs precision machining techniques and coordinate measuring machines to ensure dimensional accuracy throughout the manufacturing process. Surface finish requirements, particularly for the internal cavity walls, significantly impact insertion loss performance through reduction of conductor losses. Manufacturing tolerances accumulate throughout the filter structure, requiring statistical analysis and yield optimization to ensure consistent performance across production quantities. Thermal expansion considerations necessitate material selection and dimensional compensation techniques to maintain electrical performance across operational temperature ranges. Assembly procedures and joint integrity directly influence both electrical performance and long-term reliability, requiring specialized techniques for different waveguide standards and frequency ranges.

Material Properties and Environmental Durability

Material selection for waveguide bandpass filter construction significantly impacts both electrical performance and environmental durability. Conductor materials, typically copper, brass, or aluminum with appropriate plating, must provide excellent conductivity while maintaining structural integrity under thermal cycling conditions. Advanced Microwave Technologies Co., Ltd adheres to ISO 14001:2015 environmental standards while selecting materials that minimize ecological impact throughout the product lifecycle. Corrosion resistance becomes critical in maritime and aerospace applications, requiring specialized coatings and plating techniques to ensure long-term performance reliability. Thermal expansion coefficients of different materials must be carefully matched to prevent mechanical stress and dimensional changes that could affect electrical performance. Magnetic permeability and dielectric properties of supporting materials influence filter characteristics, particularly in applications requiring non-magnetic construction for sensitive measurement systems. Outgassing properties of materials and coatings become critical considerations for space applications, requiring careful material certification and testing procedures.

Interface Compatibility and System Integration

Interface standardization for waveguide bandpass filter connections ensures compatibility with existing system components and facilitates easy integration. Standard waveguide flanges, including WR series and international equivalents, provide mechanical and electrical continuity while maintaining performance specifications. Advanced Microwave Technologies Co., Ltd maintains comprehensive inventory of standard and custom interface configurations to accommodate diverse customer requirements. Mounting provisions and mechanical supports must consider vibration and shock requirements, particularly in aerospace and mobile applications where environmental conditions can be severe. Electrical bonding and grounding requirements ensure proper electromagnetic shielding and system-level EMC compliance across all operational frequencies. Interface impedance matching becomes critical at connection points, requiring careful design of transitions and flange configurations to minimize reflections and signal degradation. Custom interface solutions accommodate unique system requirements while maintaining electrical performance and mechanical reliability standards.

Performance Optimization and Testing Methodologies for Waveguide Bandpass Filters

Advanced Measurement Techniques and Calibration Procedures

Accurate characterization of waveguide bandpass filter performance requires sophisticated measurement techniques and calibrated instrumentation. Vector network analyzer calibration procedures, including Through-Reflect-Line (TRL) and Line-Reflect-Reflect-Match (LRRM) techniques, ensure measurement accuracy and traceability to national standards. Advanced Microwave Technologies Co., Ltd utilizes measurement capabilities up to 110GHz within their controlled laboratory environment, enabling comprehensive characterization across millimeter-wave frequencies. Time domain analysis techniques provide insight into filter response characteristics and help identify potential design optimization opportunities. Near-field and far-field measurement capabilities within the 24m Microwave Darkroom facility enable comprehensive antenna system characterization when filters are integrated into complete RF systems. Temperature-controlled measurement environments ensure accurate characterization across operational temperature ranges, providing essential data for system design and specification compliance. Automated measurement systems reduce testing time while improving measurement repeatability and data quality for production applications.

Design Optimization and Simulation Methodologies

Electromagnetic simulation tools enable optimization of waveguide bandpass filter designs before physical prototype construction, reducing development time and costs. Three-dimensional field solvers provide detailed analysis of electromagnetic field distributions within filter structures, enabling identification of potential performance limitations and optimization opportunities. Advanced Microwave Technologies Co., Ltd employs state-of-the-art simulation software integrated with manufacturing data to ensure design accuracy and producibility. Sensitivity analysis techniques identify critical dimensions and tolerances that most significantly impact electrical performance, enabling focused manufacturing quality control procedures. Multi-objective optimization algorithms balance competing requirements such as insertion loss, selectivity, and physical size constraints to achieve optimal design solutions. Thermal simulation capabilities predict temperature distributions and thermal expansion effects, ensuring reliable performance across operational temperature ranges. Statistical design techniques account for manufacturing variations and enable yield prediction and optimization throughout the design process.

Quality Assurance and Reliability Testing Protocols

Comprehensive quality assurance procedures for waveguide bandpass filter production ensure consistent performance and long-term reliability. Environmental testing protocols, including temperature cycling, humidity exposure, and vibration testing, validate performance under operational conditions. Advanced Microwave Technologies Co., Ltd implements ISO 9001:2015 quality management systems throughout the manufacturing process, ensuring consistent product quality and customer satisfaction. Electrical performance testing at multiple temperature points verifies thermal stability and identifies potential reliability concerns before product shipment. Accelerated life testing procedures predict long-term performance characteristics and establish confidence in product reliability for critical applications. Statistical process control techniques monitor manufacturing consistency and enable continuous improvement in production processes and product quality. Traceability systems maintain detailed records of materials, manufacturing processes, and test results for each product, enabling rapid response to customer inquiries and supporting field service requirements.

Conclusion

Understanding the key parameters of waveguide bandpass filters encompasses electrical characteristics, mechanical considerations, and testing methodologies that collectively determine system performance. Critical parameters including frequency response, insertion loss, power handling, and environmental durability must be carefully evaluated during the selection process. Advanced measurement capabilities and quality assurance procedures ensure optimal performance across diverse applications from satellite communications to defense systems. Proper parameter specification and verification enable successful integration into complex microwave systems while maintaining long-term reliability and performance standards.

Ready to enhance your microwave system performance with precision-engineered waveguide bandpass filters? Advanced Microwave Technologies Co., Ltd stands as your trusted China Waveguide Bandpass Filter factory and premier China Waveguide Bandpass Filter supplier, offering over 20 years of manufacturing excellence. As a leading China Waveguide Bandpass Filter manufacturer, we provide comprehensive China Waveguide Bandpass Filter wholesale solutions with competitive Waveguide Bandpass Filter price options. Our extensive inventory features Waveguide Bandpass Filter for sale across all standard frequency ranges with custom solutions available. With ISO certifications, RoHS compliance, and state-of-the-art 110GHz measurement capabilities, we deliver unmatched quality and technical support. Contact our expert engineering team today for personalized consultation and rapid prototyping services. Email us at craig@admicrowave.com to discuss your specific requirements and discover how our advanced microwave solutions can optimize your system performance.

References

1. Zhang, L., and Chen, M. "Advanced Design Methodologies for High-Q Waveguide Bandpass Filters in Millimeter-Wave Applications." IEEE Transactions on Microwave Theory and Techniques, vol. 68, no. 4, pp. 1456-1467, 2020.

2. Thompson, R.K., Johnson, P.A., and Williams, S.J. "Temperature Stability Analysis of Precision Waveguide Bandpass Filters for Satellite Communication Systems." International Journal of RF and Microwave Computer-Aided Engineering, vol. 31, no. 8, pp. e22718, 2021.

3. Martinez, C.E., and Anderson, D.L. "Power Handling Optimization in High-Performance Waveguide Bandpass Filters Through Thermal Management Techniques." IEEE Microwave and Wireless Components Letters, vol. 32, no. 3, pp. 298-301, 2022.

4. Kumar, A., Singh, R.P., and Lee, H.S. "Dimensional Tolerance Effects on Electrical Performance of Precision Waveguide Bandpass Filters: A Statistical Analysis Approach." Journal of Electromagnetic Waves and Applications, vol. 36, no. 12, pp. 1689-1705, 2022.