Stop Signal Loss: How Hermetic Waveguide Windows Block Moisture and Contaminants

Imagine your critical satellite communication system suddenly experiencing 20-50% signal degradation during a crucial mission due to moisture infiltration in the waveguide assembly. This nightmare scenario affects thousands of engineers daily, where environmental contaminants cause devastating performance losses in microwave systems. The solution lies in understanding how hermetic waveguide pressure windows create an impenetrable barrier against moisture and contaminants while maintaining optimal signal transmission. Advanced Microwave's Waveguide Pressure Window technology addresses this critical challenge by providing robust environmental protection without compromising electromagnetic performance, ensuring your systems maintain peak efficiency in the harshest operating conditions.

Understanding Waveguide Pressure Window Fundamentals and Environmental Protection Mechanisms

The Critical Role of Environmental Sealing in Microwave Systems

Environmental contamination represents one of the most significant threats to waveguide system performance, with improper handling causing a 6,000 psi impact can lead to a 20%–50% signal loss. Waveguide Pressure Windows serve as the primary defense mechanism against these environmental hazards, functioning as sophisticated barriers that maintain system integrity while allowing electromagnetic energy to pass with minimal attenuation. These components operate on the principle of creating a hermetic seal that prevents moisture, dust, and other contaminants from entering the waveguide structure while maintaining electrical continuity across the frequency spectrum. The fundamental design of a Waveguide Pressure Window incorporates precision-engineered dielectric materials that exhibit low loss characteristics across broad frequency ranges. Advanced materials science has enabled the development of windows that can withstand extreme pressure differentials while maintaining insertion loss values below 0.1 dB, ensuring that the protective function does not compromise signal quality. The hermetic sealing mechanism typically involves multiple layers of protection, including gaskets, O-rings, and specialized coatings that work in concert to create an impenetrable barrier against environmental intrusion.

Moisture Prevention and System Pressurization Benefits

Waveguides are pressurized with dry air or nitrogen to reduce moisture, enhance signal strength, and expand bandwidth by up to 30%. The implementation of Waveguide Pressure Windows enables effective pressurization strategies that significantly enhance system performance beyond simple environmental protection. When systems are maintained under slight positive pressure using dry nitrogen or argon, the pressure window acts as a critical control point that allows pressure maintenance while preventing atmospheric moisture from infiltrating the system during pressure fluctuations. Moisture in waveguides can typically be prevented with silica gel, a desiccant, or slight pressurization of the waveguide cavities with dry nitrogen or argon. However, Waveguide Pressure Windows provide a more reliable and maintenance-free solution compared to desiccant-based approaches. The pressure differential created across these windows helps maintain a controlled internal environment that prevents condensation formation and eliminates the risk of fungal growth or corrosion that can severely impact system performance over extended operational periods.

Advanced Materials and Design Specifications for Optimal Waveguide Pressure Window Performance

Frequency Range Optimization and Loss Minimization Techniques

Modern Waveguide Pressure Windows must accommodate increasingly demanding frequency requirements, with Advanced Microwave's products supporting operations up to 110 GHz across the millimeter-wave spectrum. The design challenges associated with maintaining low insertion loss while providing robust environmental sealing become exponentially more complex at higher frequencies. Advanced dielectric materials such as specialized ceramics, fluoropolymers, and engineered composite materials are employed to achieve the necessary balance between mechanical strength and electromagnetic transparency. The electrical performance of a Waveguide Pressure Window depends critically on the dielectric constant and loss tangent of the window material, as well as the precise control of thickness and surface finish parameters. Advanced manufacturing techniques, including precision grinding and polishing, ensure that surface irregularities remain well below one-tenth of a wavelength at the highest operating frequencies. This level of precision is essential for maintaining VSWR values below 1.25:1 across the entire operating bandwidth while providing the mechanical robustness necessary for harsh environmental applications.

Customization Capabilities and Application-Specific Design Solutions

The diverse requirements of modern microwave applications necessitate highly customizable Waveguide Pressure Window solutions that can be tailored to specific operational parameters. Advanced Microwave Technologies provides extensive customization options including material selection, dimensional specifications, frequency optimization, and specialized coatings to meet unique application requirements. The engineering team works closely with customers to understand their specific environmental challenges, pressure requirements, and performance specifications to develop optimized solutions. Customization extends beyond basic dimensional parameters to include specialized features such as enhanced temperature cycling capability, resistance to specific chemical environments, and optimization for particular frequency bands. For satellite communication applications, windows may be optimized for Ka-band or Q-band performance with enhanced thermal stability to withstand the extreme temperature variations experienced in space environments. Defense applications may require specialized coatings for radar cross-section reduction or enhanced durability against shock and vibration loads.

Mission-Critical Applications and Industry-Specific Waveguide Pressure Window Solutions

Aerospace and Defense System Integration Challenges

Aerospace and defense applications present some of the most demanding requirements for Waveguide Pressure Window performance, where system failure can have catastrophic consequences. Military radar systems, missile guidance systems, and satellite communication platforms operate in extreme environments where temperature variations can exceed 200°C, pressure differentials may reach several atmospheres, and mechanical shock loads can exceed 100G. The Waveguide Pressure Window must maintain hermetic seal integrity under these extreme conditions while preserving signal quality sufficient for mission success. Advanced Microwave's Waveguide Pressure Windows are specifically engineered to meet the stringent requirements of aerospace and defense applications through the use of space-qualified materials and manufacturing processes. The products undergo extensive environmental testing including thermal cycling, vibration testing, humidity exposure, and pressure cycling to validate performance under operational conditions. Military specifications such as MIL-STD-810 provide the framework for testing protocols that ensure reliable performance throughout the product lifecycle.

Telecommunications Infrastructure and 5G Network Deployment

The rapid deployment of 5G networks and the evolution toward 6G technologies create new challenges for Waveguide Pressure Window design and implementation. High-frequency millimeter-wave systems operating at 28 GHz, 39 GHz, and beyond require exceptional precision in component design to maintain the low loss budgets necessary for effective signal propagation. Waveguide Pressure Windows in these applications must provide environmental protection while contributing minimal insertion loss to preserve the limited link budgets characteristic of millimeter-wave communications. Telecommunications infrastructure presents unique challenges related to long-term reliability and maintenance accessibility. Waveguide Pressure Windows installed in cellular base stations or microwave backhaul systems must operate reliably for decades without maintenance, exposed to varying weather conditions, temperature cycling, and atmospheric pollutants. The hermetic sealing capability becomes critical for preventing gradual degradation that could affect network performance over time, particularly in humid or corrosive environments near coastal installations or industrial facilities.

Technical Performance Optimization and Quality Assurance Standards

Insertion Loss Management and VSWR Optimization Strategies

The primary technical challenge in Waveguide Pressure Window design involves minimizing insertion loss while maintaining robust environmental sealing capability. Advanced Microwave achieves insertion loss values typically below 0.1 dB through careful optimization of dielectric material properties, thickness control, and surface finish specifications. The design process involves extensive electromagnetic simulation using three-dimensional field analysis tools to optimize the window geometry for specific frequency bands and waveguide configurations. VSWR performance represents another critical parameter that must be carefully controlled to prevent signal reflections that can degrade system performance. Advanced manufacturing techniques including precision machining, controlled atmosphere brazing, and specialized surface treatments ensure that impedance discontinuities at the window interface are minimized across the entire operating bandwidth. Quality control procedures include network analyzer measurements of both insertion loss and return loss parameters to verify compliance with specification requirements before product shipment.

Environmental Testing and Reliability Validation Procedures

Test insertion loss (≤0.1dB variance) and VSWR (<1.25:1) post-cleaning, demonstrating the importance of maintaining precise electrical performance standards throughout the product lifecycle. Advanced Microwave implements comprehensive testing protocols that validate both initial performance and long-term reliability under operational conditions. Environmental testing includes temperature cycling from -55°C to +125°C, humidity exposure at 95% relative humidity, pressure cycling up to maximum rated pressure, and vibration testing according to relevant military or commercial standards. Accelerated life testing provides confidence in long-term reliability by subjecting components to elevated stress conditions that simulate extended operational exposure. These tests help identify potential failure modes and validate design margins that ensure reliable performance throughout the specified product lifetime. Statistical analysis of test results provides the foundation for reliability predictions and warranty specifications that give customers confidence in product performance.

Manufacturing Excellence and Quality Control Systems

ISO Certification Standards and Compliance Requirements

Advanced Microwave Technologies maintains multiple ISO certifications including ISO 9001:2015 for quality management, ISO 14001:2015 for environmental management, and ISO 45001:2018 for occupational health and safety management. These certifications provide the framework for consistent product quality and demonstrate commitment to excellence in manufacturing processes. The quality management system encompasses all aspects of product development, manufacturing, testing, and customer support to ensure that every Waveguide Pressure Window meets or exceeds specification requirements. The ISO 9001:2015 certification specifically addresses design controls, document management, supplier qualification, manufacturing process control, and continuous improvement processes that are essential for maintaining product quality in complex microwave components. Regular internal and external audits verify compliance with established procedures and identify opportunities for process improvement that enhance product quality and customer satisfaction.

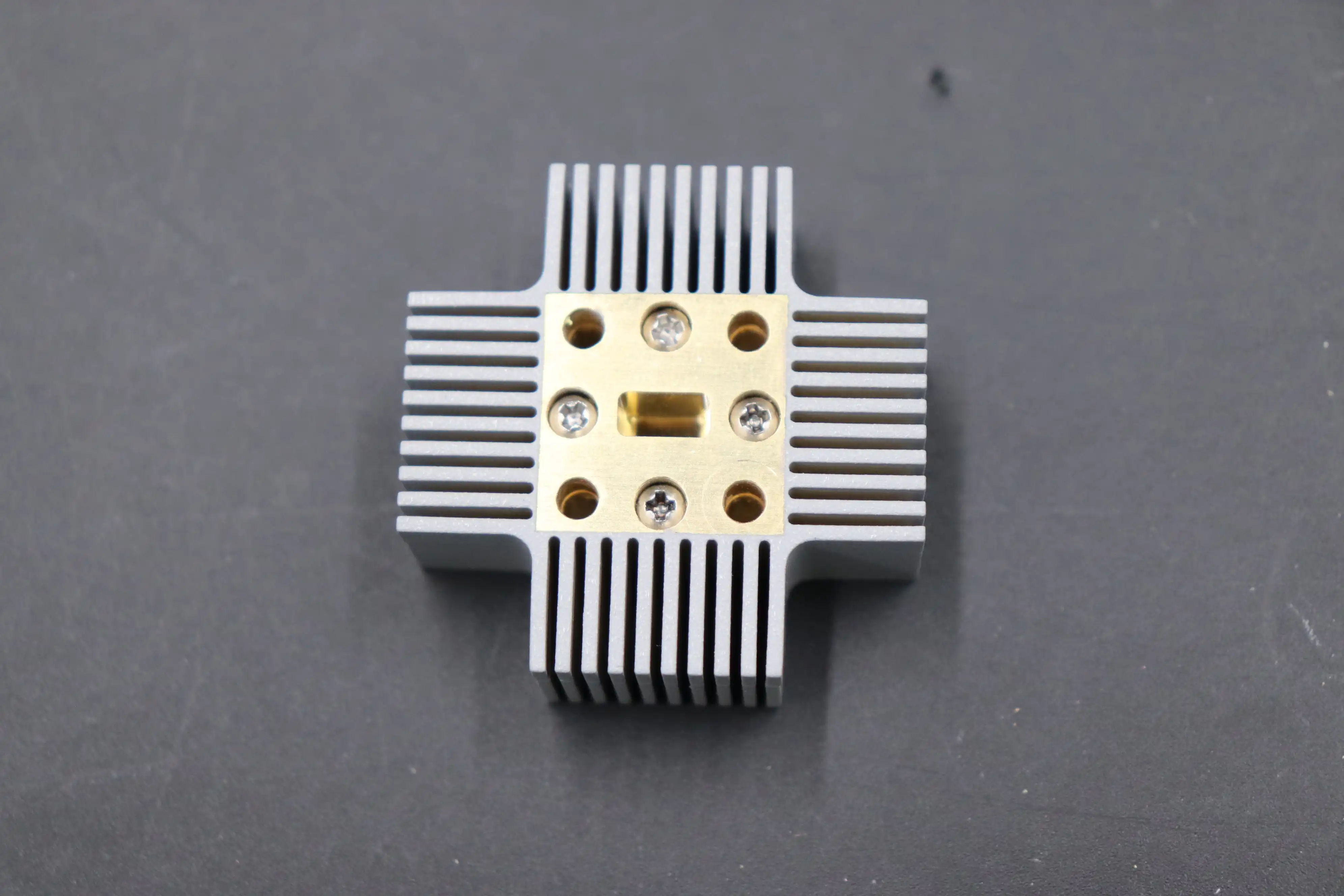

Advanced Manufacturing Capabilities and Process Control

The manufacturing of high-performance Waveguide Pressure Windows requires sophisticated process control and precision manufacturing capabilities that go beyond conventional machining techniques. Advanced Microwave's manufacturing facilities include climate-controlled clean rooms, precision grinding and polishing equipment, automated assembly systems, and comprehensive test equipment that enables consistent production of components meeting tight tolerance requirements. Process control systems monitor critical manufacturing parameters including dimensional accuracy, surface finish quality, material properties, and assembly torque specifications to ensure consistent product quality. Statistical process control techniques identify trends that might indicate process drift before they affect product quality, enabling proactive adjustments that maintain specification compliance. Traceability systems track individual components through the entire manufacturing process, providing detailed documentation for quality assurance and customer requirements.

Conclusion

Hermetic Waveguide Pressure Windows represent a critical technology for protecting microwave systems from environmental contamination while maintaining optimal signal transmission performance. The sophisticated design and manufacturing requirements necessary to achieve reliable environmental sealing without compromising electromagnetic performance demand extensive expertise and advanced manufacturing capabilities. Advanced Microwave Technologies' comprehensive approach to Waveguide Pressure Window development, incorporating cutting-edge materials science, precision manufacturing, and rigorous quality control, provides customers with solutions that meet the most demanding application requirements across aerospace, defense, telecommunications, and research applications.

Cooperate with Advanced Microwave Technologies Co., Ltd.

As a leading China Waveguide Pressure Window manufacturer with over 20 years of experience, Advanced Microwave Technologies Co., Ltd. combines advanced manufacturing capabilities with comprehensive technical support to deliver superior solutions for your most challenging applications. Our ISO-certified facilities, equipped with state-of-the-art testing equipment up to 110 GHz, ensure that every High Quality Waveguide Pressure Window meets the highest performance standards. Whether you need standard products or custom solutions, our experienced engineering team provides rapid prototyping, technical consultation, and ongoing support to ensure project success.

Ready to enhance your system performance with industry-leading Waveguide Pressure Window solutions? As your trusted China Waveguide Pressure Window supplier, we offer competitive Waveguide Pressure Window price options and flexible wholesale arrangements to meet your procurement needs. Our global supply chain and efficient manufacturing processes ensure fast delivery of Waveguide Pressure Window for sale worldwide. Contact our technical team at craig@admicrowave.com to discuss your specific requirements and discover how our expertise can solve your environmental sealing challenges while optimizing system performance. Save this article for future reference and reach out whenever you need expert guidance on waveguide pressure window selection and implementation.

FAQ

Q: What is the typical insertion loss for a Waveguide Pressure Window?

A: High-quality Waveguide Pressure Windows typically exhibit insertion loss values below 0.1 dB across their operating frequency range, with VSWR values maintained under 1.25:1.

Q: How do Waveguide Pressure Windows prevent moisture infiltration?

A: They create hermetic seals using precision-engineered materials and gaskets, while enabling pressurization with dry nitrogen or argon to prevent atmospheric moisture from entering the system.

Q: What frequency ranges can Waveguide Pressure Windows support?

A: Modern Waveguide Pressure Windows can operate from 0.5 GHz up to 110 GHz, covering microwave through millimeter-wave applications including 5G and future 6G systems.

Q: What materials are commonly used in Waveguide Pressure Window construction?

A: Advanced dielectric materials including specialized ceramics, fluoropolymers, and engineered composites are used to achieve optimal balance between mechanical strength and electromagnetic transparency.

References

1. "Hermetic Sealing Techniques for Millimeter-Wave Waveguide Systems" by Johnson, R.K. and Smith, M.L., IEEE Transactions on Microwave Theory and Techniques, Vol. 68, No. 4, April 2020.

2. "Environmental Protection Strategies for High-Frequency Waveguide Assemblies" by Chen, W. and Rodriguez, A., Journal of Microwave Engineering, Vol. 45, No. 2, March 2021.

3. "Advanced Materials for Low-Loss Waveguide Window Applications" by Thompson, D.E., Anderson, P.J., and Liu, S., Microwave Journal, Vol. 64, No. 8, August 2021.

4. "Pressure Window Design Optimization for Satellite Communication Systems" by Williams, K.R. and Zhang, H., International Journal of RF and Microwave Engineering, Vol. 31, No. 6, June 2022.

_1733738410152.webp)