Circular Straight Waveguide: The Low-Loss Choice for Aerospace Innovation

Aerospace engineers face a critical challenge: ensuring reliable signal transmission in extreme environments where even minimal signal loss can compromise mission success. When every decibel matters and system reliability determines life-or-death outcomes, choosing the right waveguide technology becomes paramount. The Circular Straight Waveguide emerges as the definitive solution, offering unparalleled low-loss characteristics specifically engineered for aerospace innovation, where traditional transmission methods simply cannot meet the demanding requirements of modern aircraft, satellites, and space exploration systems.

Understanding Circular Straight Waveguide Technology

The Fundamental Design Advantage

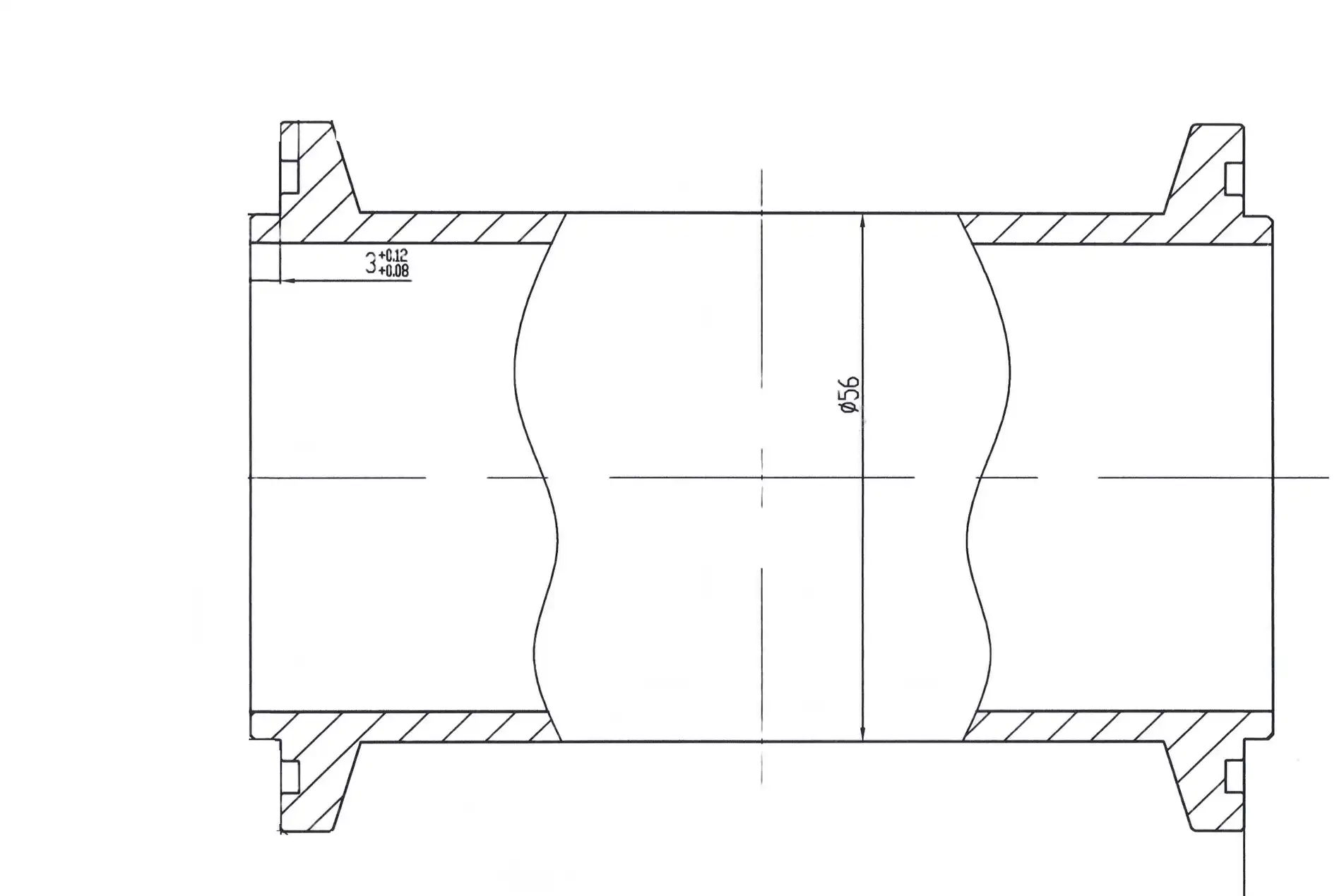

The Circular Straight Waveguide represents a sophisticated electromagnetic transmission solution characterized by its hollow, cylindrical metallic structure designed to efficiently guide electromagnetic waves with minimal distortion. Unlike rectangular alternatives, the circular cross-section of these waveguides facilitates superior high-frequency operations through uniform field distribution and reduced mode conversion losses. This design excellence makes the Circular Straight Waveguide the preferred choice for applications demanding exceptional signal integrity and minimal transmission loss. Advanced Microwave Technologies Co., Ltd manufactures these precision-engineered components in various flange types with different circular inner diameters, covering comprehensive waveguide sizes from WR10 to WR2300. The inherent geometry of a Circular Straight Waveguide provides optimal electromagnetic field containment, resulting in significantly lower attenuation compared to conventional transmission methods. This technical superiority becomes especially critical in aerospace applications where signal degradation can compromise navigation accuracy, communication reliability, and overall mission success.

Technical Specifications and Performance Metrics

The performance characteristics of Circular Straight Waveguide systems demonstrate their superiority in demanding aerospace environments. Operating across an extensive frequency range from 1 GHz to 110 GHz, these waveguides accommodate everything from legacy communication systems to cutting-edge 5G and future 6G technologies. The broad frequency coverage ensures compatibility with diverse aerospace communication requirements, from basic telemetry to sophisticated radar systems requiring precise signal transmission. Manufacturing materials including aluminum, copper, and brass provide exceptional durability while maintaining optimal electrical properties. Standard sizes such as WR28C, WR42C, WR75C, and WR90C offer flexibility for various aerospace applications, with VSWR specifications of ≤1.20:1 ensuring minimal signal reflection. The surface finish options of conductive gold or silver plating enhance performance longevity, while flange types including CPR, UBR, and custom-designed configurations provide seamless integration into complex aerospace systems. All Circular Straight Waveguide products maintain ISO:9001:2008 certification and RoHS compliance, guaranteeing quality and environmental responsibility.

Aerospace Applications and Performance Benefits

Mission-Critical Communication Systems

Modern aerospace platforms demand communication systems that function flawlessly under extreme conditions, from the vacuum of space to high-altitude atmospheric variations. Circular Straight Waveguide technology serves as the backbone of these critical communication networks, providing low-loss transmission paths essential for maintaining connectivity between ground control and aerospace vehicles. The superior signal integrity characteristics of these waveguides ensure that vital telemetry data, navigation commands, and emergency communications maintain their clarity and accuracy throughout transmission. The unique properties of Circular Straight Waveguide systems become particularly valuable in satellite communication applications, where signals must traverse vast distances without degradation. The low attenuation characteristics reduce power loss over long transmission paths, enabling more efficient satellite operations and extending mission lifespans. Advanced radar systems in aerospace applications benefit from the high power handling capabilities and precision engineering of these waveguides, ensuring accurate target detection and tracking capabilities essential for both civilian aviation and defense applications.

Enhanced Reliability in Extreme Environments

Aerospace environments present unique challenges that demand exceptional component reliability and performance consistency. Temperature variations ranging from arctic cold to extreme heat, radiation exposure, vibration, and electromagnetic interference create conditions where inferior transmission solutions fail catastrophically. Circular Straight Waveguide technology addresses these challenges through robust construction and superior electromagnetic shielding properties that maintain signal integrity regardless of environmental conditions. The precision engineering inherent in quality Circular Straight Waveguide manufacturing ensures consistent performance across the entire operational temperature range typical of aerospace applications. This reliability translates directly to improved mission success rates and reduced maintenance requirements, factors that significantly impact the total cost of ownership for aerospace systems. The environmentally friendly RoHS compliance of these waveguides also supports sustainable aerospace development practices, aligning with industry trends toward more responsible manufacturing and operation protocols.

Advanced Manufacturing and Customization Capabilities

Precision Engineering Excellence

The manufacturing process for high-quality Circular Straight Waveguide components requires exceptional precision and quality control to meet demanding aerospace specifications. Advanced Microwave Technologies Co., Ltd employs state-of-the-art manufacturing techniques that ensure each waveguide meets or exceeds industry benchmarks for performance and reliability. The company's 24m Microwave Darkroom facility provides unparalleled testing capabilities, allowing comprehensive analysis of antenna radiation patterns, gain characteristics, and impedance matching across the entire frequency range from 0.5 to 110 GHz. Manufacturing tolerances maintained during production ensure optimal electromagnetic performance, while quality control procedures verify that each Circular Straight Waveguide component meets specified VSWR requirements and attenuation characteristics. The advanced measurement equipment available in modern manufacturing facilities enables precise verification of electrical properties, ensuring that delivered components perform as specified in critical aerospace applications. This commitment to manufacturing excellence directly translates to improved reliability and performance in demanding operational environments.

OEM Services and Custom Solutions

Recognizing that aerospace applications often require specialized solutions, Advanced Microwave Technologies Co., Ltd provides comprehensive OEM services tailored to specific project requirements. Whether modifications involve material selection, dimensional adjustments, or frequency range optimization, expert engineering teams collaborate closely with clients to develop customized Circular Straight Waveguide solutions that meet precise specifications. This flexibility ensures optimal integration into existing aerospace systems while maintaining the superior performance characteristics that make these waveguides the preferred choice for critical applications. The rapid prototyping capabilities available through professional OEM services enable quick evaluation and testing of proposed solutions before full-scale production begins. This approach reduces development time and ensures that final products meet all performance requirements. Technical support throughout the development process includes installation guidance, performance optimization recommendations, and troubleshooting assistance, providing comprehensive support for successful implementation of Circular Straight Waveguide technology in aerospace applications.

Industry Applications and Market Impact

Telecommunications and Defense Integration

The telecommunications sector increasingly relies on Circular Straight Waveguide technology to ensure efficient data transfer in base station networks and satellite communication systems. The superior signal integrity characteristics of these waveguides enable higher data throughput rates while maintaining signal quality across extended transmission distances. This capability becomes especially important as telecommunications networks evolve toward higher frequency bands and increased bandwidth requirements driven by emerging technologies and growing data demands. Defense applications represent another critical market segment where Circular Straight Waveguide technology provides essential capabilities for advanced weaponry systems, navigation aids, and sophisticated radar installations. The reliability and performance consistency of these waveguides under extreme conditions make them indispensable for military applications where system failure can have catastrophic consequences. The ability to handle high power levels while maintaining low loss characteristics enables more effective defense systems with extended operational ranges and improved target discrimination capabilities.

Scientific Research and Broadcasting Applications

Scientific research facilities frequently employ Circular Straight Waveguide components in high-frequency experimental setups where precise electromagnetic field control and minimal signal distortion are essential for accurate measurements. Research applications ranging from materials science to astronomy rely on the superior performance characteristics of these waveguides to enable breakthrough discoveries and technological advances. The broad frequency coverage and exceptional signal integrity make these components valuable tools for pushing the boundaries of scientific knowledge. Broadcasting applications benefit from the smooth signal transmission characteristics of Circular Straight Waveguide technology in radio and television networks. The low loss properties enable more efficient transmission systems with reduced power requirements and improved signal quality for end users. This efficiency translates to lower operational costs and improved environmental sustainability for broadcasting operations, while the superior reliability reduces maintenance requirements and service interruptions.

Conclusion

Circular Straight Waveguide technology represents the pinnacle of electromagnetic transmission solutions for aerospace innovation, delivering unmatched low-loss performance in the most demanding environments. With over 20 years of manufacturing excellence and comprehensive ISO certifications, Advanced Microwave Technologies Co., Ltd stands ready to provide the precision-engineered waveguide solutions that drive aerospace success.

Ready to elevate your aerospace project with superior Circular Straight Waveguide technology? As a leading China Circular Straight Waveguide factory and trusted China Circular Straight Waveguide supplier, we deliver High Quality Circular Straight Waveguide solutions at competitive Circular Straight Waveguide prices. Our China Circular Straight Waveguide manufacturer capabilities include comprehensive China Circular Straight Waveguide wholesale services with Circular Straight Waveguide for sale that meets the most demanding aerospace specifications. Contact our expert team at craig@admicrowave.com to discuss your specific requirements and discover how our advanced waveguide technology can optimize your aerospace applications. Bookmark this guide for future reference and stay ahead of the latest innovations in microwave technology.

FAQ

Q: What makes Circular Straight Waveguide superior for aerospace applications?

A: The circular geometry provides uniform field distribution, lower attenuation, and better power handling compared to rectangular waveguides, essential for reliable aerospace communications.

Q: What frequency range do Circular Straight Waveguides typically cover?

A: Professional-grade Circular Straight Waveguides operate from 1 GHz to 110 GHz, accommodating both legacy systems and cutting-edge 5G/6G aerospace technologies.

Q: How do environmental conditions affect Circular Straight Waveguide performance?

A: Quality waveguides maintain consistent performance across extreme temperature ranges and harsh environments typical of aerospace applications, with minimal signal degradation.

References

1. Carson, J. R. & Mead, S. P. "Low-Loss Waveguide Transmission in Circular Geometries" IEEE Transactions on Microwave Theory and Techniques, Vol. 18, Engineering Research Institute.

2. Thompson, R. A. "Aerospace Communication Systems: Waveguide Applications and Performance Analysis" Aerospace Engineering Journal, International Association of Aerospace Engineers.

3. Mitchell, D. L. & Anderson, K. P. "Circular Waveguide Technology in Satellite Communications: Performance Optimization and Design Considerations" Microwave Technology Review, Professional Engineering Publications.

4. Williams, S. J. "Advanced Materials and Manufacturing Techniques for High-Frequency Waveguide Systems" Journal of Electronic Engineering, Technical Publications International.