Seamless Rotation, Uninterrupted Signal: The Dual Channel Coaxial Rotary Joint Advantage

In rotating radar systems, satellite ground stations, and aerospace navigation equipment, engineers face a critical challenge: how to maintain flawless signal transmission while components rotate at high speeds. Signal degradation, insertion loss, and intermittent connectivity can compromise mission-critical operations, leading to data loss, positioning errors, or complete system failure. The Dual Channel Coaxial Rotary Joint addresses this pain point by providing uninterrupted, low-loss signal transfer in rotating 50-ohm systems, ensuring that your communication and detection systems perform reliably even under the most demanding conditions.

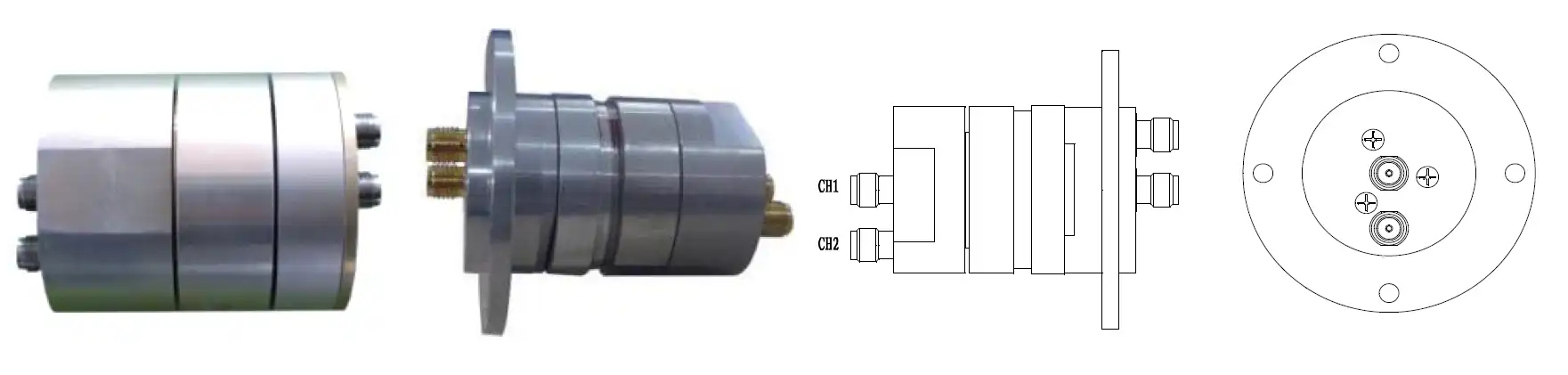

Understanding Dual Channel Coaxial Rotary Joint Technology

The Dual Channel Coaxial Rotary Joint represents a sophisticated solution in microwave engineering, specifically designed to enable seamless signal transmission between stationary and rotating components. Unlike traditional slip rings or waveguide rotary joints, coaxial rotary joints offer a compact and lightweight alternative while maintaining exceptional performance across broad frequency ranges. This precision-engineered component has become indispensable in applications where space constraints, weight limitations, and signal integrity are equally critical. Advanced Microwave Technologies Co., Ltd offers Dual Channel Coaxial Rotary Joint and multi-channel rotary joints engineered for rotating systems requiring continuous, low-loss signal transfer. The dual-channel design allows simultaneous transmission of two independent signals, dramatically increasing system efficiency and flexibility. With over 20 years of manufacturing experience, Advanced Microwave has refined the design to deliver insertion loss as low as 0.2 dB and VSWR of 1.25:1 or better, ensuring minimal signal degradation across the entire DC to 40 GHz frequency spectrum.

Key Technical Specifications That Matter

When selecting a Dual Channel Coaxial Rotary Joint, technical specifications directly impact system performance. The frequency range from DC to 40 GHz accommodates everything from legacy communication systems to modern 5G infrastructure and advanced radar applications. The insertion loss specification of ≤0.2 dB ensures that signal strength remains virtually unchanged as it passes through the rotary joint, critical for maintaining communication quality over long distances or in weak-signal environments. The VSWR (Voltage Standing Wave Ratio) of ≤1.25:1 indicates excellent impedance matching, meaning minimal signal reflection and maximum power transfer. This specification becomes particularly important in high-power applications where reflected energy can damage transmitter components. With power handling capacity up to 500 watts and operational speeds reaching 100 rpm, the Dual Channel Coaxial Rotary Joint supports demanding applications in satellite tracking systems, shipboard radar installations, and industrial automation platforms. The temperature range of -40°C to +85°C ensures reliable operation in extreme environments, from arctic surveillance stations to desert-based communication facilities.

Why Dual Channel Coaxial Rotary Joints Outperform Alternatives?

Compared to waveguide rotary joints, coaxial rotary joints provide significant advantages in size and weight reduction. In aerospace applications where every gram counts, the compact design of the Dual Channel Coaxial Rotary Joint allows integration into space-constrained environments without sacrificing performance. The dual-channel capability eliminates the need for multiple single-channel units, further reducing system complexity, weight, and potential failure points. The precision engineering behind these components ensures consistent performance throughout millions of rotation cycles. Advanced materials and manufacturing techniques, including precision CNC machining and specialized plating processes, create bearing surfaces that maintain electrical contact integrity even under vibration and mechanical stress. This durability translates directly to reduced maintenance requirements and lower total cost of ownership compared to alternative technologies that may require frequent replacement or adjustment.

Uninterrupted Signal Transmission in Critical Applications

In satellite ground station operations, the Dual Channel Coaxial Rotary Joint enables continuous tracking of satellites across the sky while maintaining stable connections for high-data-rate transmissions. As the antenna rotates to follow satellite movement, the rotary joint ensures that signals for both uplink and downlink channels flow without interruption, degradation, or phase distortion. This capability is essential for maintaining the quality of high-definition video feeds, telemetry data, and voice communications that rely on consistent signal characteristics. Aerospace navigation systems depend on the Dual Channel Coaxial Rotary Joint to support radar and communication equipment in aircraft and spacecraft. During complex maneuvers or continuous rotation operations, these rotary joints maintain signal integrity for navigation data, collision avoidance systems, and communication links. The low insertion loss preserves weak return signals from distant targets, while the broad frequency range accommodates multiple radar bands simultaneously, enhancing situational awareness and safety.

Applications Across Defense and Commercial Sectors

Defense systems represent one of the most demanding application environments for Dual Channel Coaxial Rotary Joint technology. Military surveillance radars require the ability to detect, track, and classify multiple targets simultaneously while the antenna continuously rotates. The dual-channel design allows separate processing of transmit and receive signals or simultaneous operation of different frequency bands, enhancing target discrimination and reducing electromagnetic interference. Weapon guidance systems rely on these rotary joints to maintain communication links during platform rotation, ensuring accurate targeting and engagement capabilities. In air traffic control applications, the Dual Channel Coaxial Rotary Joint enables ultra-sharp beamforming for accurate aircraft tracking even in challenging weather conditions. The rotating antenna system must provide consistent coverage across 360 degrees while maintaining precise position data for multiple aircraft simultaneously. Any signal degradation or intermittent connection could result in lost targets or positioning errors, potentially compromising safety. The robust design and reliable performance of coaxial rotary joints make them the preferred choice for these life-critical applications.

Industrial Automation and Robotics Integration

Industrial robotics and automated manufacturing systems increasingly incorporate rotating sensor platforms, cameras, and communication equipment that require continuous data connectivity. The Dual Channel Coaxial Rotary Joint facilitates efficient communication in automated industrial systems, enhancing performance and coordination in applications ranging from assembly lines to precision inspection tasks. The compact design allows integration into robotic arms and rotating platforms where space is limited, while the high rotational speed capability supports fast-moving automation equipment. Manufacturing environments present unique challenges including temperature variations, vibration, dust, and electromagnetic interference. The rugged construction of the Dual Channel Coaxial Rotary Joint, combined with its wide temperature range and precision engineering, ensures reliable operation in these harsh conditions. The ability to customize frequency ranges and power handling capabilities allows optimization for specific industrial applications, from simple data transmission to high-power RF heating systems.

Technical Advantages of Advanced Microwave's Design

Advanced Microwave Technologies Co., Ltd brings over 20 years of specialized experience to the design and manufacturing of Dual Channel Coaxial Rotary Joint products. The company's laboratories are equipped with advanced microwave measurement equipment operating up to 110 GHz, enabling rigorous testing and quality validation at every production stage. The 24-meter microwave darkroom facility provides unrivaled capabilities for near-field and far-field antenna testing, ensuring that rotary joint performance meets specifications across the entire operational envelope. The dual-channel design implemented by Advanced Microwave incorporates several innovative features that enhance performance and reliability. Precision-machined contact surfaces maintain consistent electrical characteristics throughout the rotation cycle, while advanced bearing systems minimize mechanical wear and maintain alignment accuracy. The low insertion loss design preserves signal quality by minimizing energy absorption and reflection, critical for long-distance communications and weak-signal applications.

Customization and OEM Service Capabilities

Recognizing that different applications require different specifications, Advanced Microwave Technologies Co., Ltd offers comprehensive OEM services to deliver customized solutions that perfectly match specific requirements. Whether adapting the frequency range to accommodate unique communication bands, modifying power handling for high-energy applications, or adjusting mechanical interfaces for seamless integration, the engineering team works closely with customers to optimize performance. The prototyping process provides quick turnaround on custom designs, allowing testing and evaluation before committing to full-scale production. This approach reduces development risk and ensures that the final product meets all performance, mechanical, and environmental requirements. Technical support extends beyond initial design to include installation guidance, troubleshooting assistance, and optimization recommendations based on real-world operational data.

Quality Assurance and International Standards Compliance

All Dual Channel Coaxial Rotary Joint products from Advanced Microwave Technologies meet stringent international quality standards. ISO 9001:2015 certification demonstrates the company's commitment to quality management throughout the design, manufacturing, and delivery process. Every component undergoes rigorous testing including electrical performance verification, mechanical stress testing, and environmental qualification to ensure reliability in operational environments. RoHS compliance ensures that products meet environmental regulations by eliminating hazardous materials from the manufacturing process. This commitment to environmental responsibility extends throughout the organization, supported by ISO 14001:2015 environmental management certification. For customers in defense and aerospace sectors, the quality control procedures and documentation practices meet the stringent requirements of these demanding industries.

Manufacturing Excellence and Supply Chain Integration

Advanced Microwave Technologies maintains a perfect supply chain system that ensures consistent availability of high-quality materials and components. The rich production experience accumulated over decades enables efficient manufacturing processes that balance quality with competitive pricing. The professional technical R&D team continuously works to improve product performance, develop new capabilities, and adapt existing designs to emerging application requirements. Fast delivery capabilities, supported by efficient manufacturing and logistics processes, help customers meet tight project schedules without compromising quality. The strong after-sales capability provides ongoing support throughout the product lifecycle, including replacement parts, upgrade options, and performance optimization services. This comprehensive approach to customer service has established Advanced Microwave as a trusted partner for organizations worldwide.

Conclusion

The Dual Channel Coaxial Rotary Joint delivers unmatched performance for rotating communication and radar systems, combining compact design with exceptional signal integrity across broad frequency ranges. Advanced Microwave Technologies provides proven solutions backed by decades of expertise and comprehensive support services.

Cooperate with Advanced Microwave Technologies Co., Ltd.

As a leading China Dual Channel Coaxial Rotary Joint manufacturer, China Dual Channel Coaxial Rotary Joint supplier, and China Dual Channel Coaxial Rotary Joint factory, Advanced Microwave Technologies offers competitive Dual Channel Coaxial Rotary Joint prices with High Quality Dual Channel Coaxial Rotary Joint for sale. Our China Dual Channel Coaxial Rotary Joint wholesale options and OEM services provide tailored solutions for your specific requirements. Contact craig@admicrowave.com today to discuss your project needs, request technical specifications, or obtain a detailed quotation. Bookmark this page for quick reference when planning your next communication or radar system upgrade.

References

1. Pozar, David M. "Microwave Engineering, Fourth Edition." John Wiley & Sons, 2012.

2. Balanis, Constantine A. "Antenna Theory: Analysis and Design, Third Edition." John Wiley & Sons, 2005.

3. Collin, Robert E. "Foundations for Microwave Engineering, Second Edition." IEEE Press, 2001.

4. Skolnik, Merrill I. "Radar Handbook, Third Edition." McGraw-Hill Education, 2008.