Engineered for Stability: Waveguide Calibration Kits for Demanding Environments

In the unforgiving world of high-frequency microwave applications, where measurement errors can cascade into system failures costing millions, engineers face a critical challenge: ensuring absolute precision in waveguide system calibration across extreme environmental conditions. From satellite communication networks operating in the harsh vacuum of space to military radar systems functioning in desert heat and arctic cold, the demand for reliable Waveguide Calibration Kits that maintain their accuracy under stress has never been more critical. This comprehensive guide explores how advanced calibration solutions address these demanding scenarios, providing the stability and precision that mission-critical applications require, while examining the technological innovations that make such reliability possible in environments where failure is not an option.

Understanding Waveguide Calibration Kit Requirements in Extreme Conditions

The fundamental challenge facing microwave engineers today lies in maintaining measurement accuracy when Waveguide Calibration Kits encounter environmental extremes that would render conventional calibration equipment unreliable. In demanding environments such as aerospace applications, defense systems, and industrial settings, temperature fluctuations ranging from -55°C to +125°C, combined with shock, vibration, and electromagnetic interference, create conditions where standard calibration methods fail catastrophically. Advanced Microwave Technologies Co., Ltd's Waveguide Calibration Kits are specifically engineered to address these challenges through innovative design approaches that prioritize thermal stability and mechanical robustness. The precision components within these kits undergo rigorous thermal cycling tests to ensure dimensional stability across extreme temperature ranges, while specialized materials selection prevents thermal expansion issues that could compromise measurement accuracy.

Thermal Stability and Material Engineering

The cornerstone of reliable waveguide calibration in demanding environments begins with understanding how thermal variations affect measurement precision. Traditional Waveguide Calibration Kits often suffer from thermal coefficient mismatches between different metallic components, leading to dimensional changes that directly impact calibration accuracy. Our engineering approach addresses this fundamental issue through careful material selection and thermal compensation techniques. Premium materials such as invar steel and specialized aluminum alloys are employed in critical calibration standards to minimize thermal expansion effects. These materials maintain their dimensional characteristics across wide temperature ranges, ensuring that Waveguide Calibration Kits deliver consistent performance whether deployed in the extreme cold of high-altitude applications or the intense heat of ground-based radar installations.

Mechanical Robustness and Environmental Sealing

Beyond thermal considerations, mechanical stability represents another critical factor in waveguide calibration reliability. The precision components within Waveguide Calibration Kits must maintain their electrical characteristics despite exposure to shock, vibration, and mechanical stress that would damage conventional calibration equipment. Our calibration kit designs incorporate advanced mechanical engineering principles, including stress-relief features, precision machining tolerances, and robust connector interfaces that maintain their integrity under mechanical stress. Environmental sealing techniques protect internal components from moisture, dust, and corrosive atmospheres while maintaining the electrical performance characteristics essential for accurate calibration measurements.

Precision Manufacturing and Quality Assurance for Waveguide Calibration Systems

The manufacturing process for high-reliability Waveguide Calibration Kits demands precision machining capabilities and quality control procedures that exceed standard industry practices. Every component within these calibration systems must meet stringent dimensional tolerances while maintaining electrical performance characteristics that remain stable across environmental extremes. Advanced Microwave Technologies Co., Ltd employs state-of-the-art CNC machining centers and precision measurement equipment to ensure that each Waveguide Calibration Kit component meets specifications that guarantee long-term performance reliability. Our manufacturing processes incorporate multiple quality checkpoints, including dimensional verification, electrical performance testing, and environmental stress screening that validates component reliability before assembly.

Advanced Measurement Capabilities and Frequency Coverage

The effectiveness of Waveguide Calibration Kits in demanding applications depends significantly on their ability to provide accurate calibration across wide frequency ranges while maintaining measurement traceability to national standards. Our calibration systems support frequency ranges from 0.5 GHz to 110 GHz, covering applications from legacy communication systems to cutting-edge millimeter-wave technologies. This extensive frequency coverage requires sophisticated design approaches that address the unique challenges associated with different frequency bands. Low-frequency applications demand excellent mechanical stability and low insertion loss characteristics, while high-frequency applications require precise dimensional control and minimal surface roughness to prevent signal degradation.

Comprehensive Calibration Standards and Component Integration

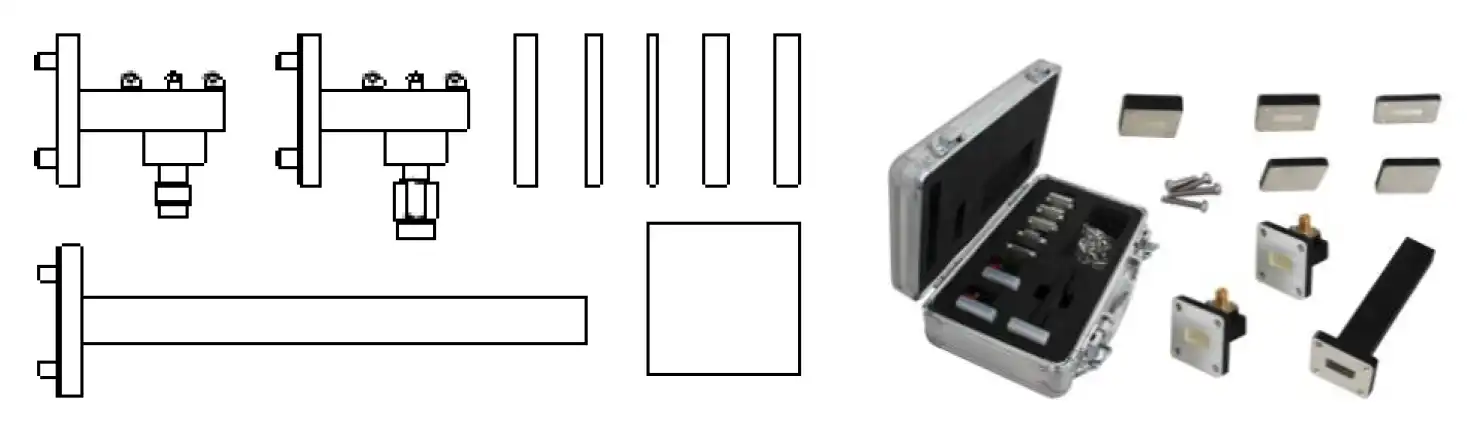

Each Waveguide Calibration Kit includes a complete set of precision calibration standards designed to provide comprehensive system calibration capabilities. These standards include short circuits, matched loads, transmission lines, and specialty components such as offset shorts and sliding loads that enable advanced calibration techniques. The integration of these components within a unified calibration system ensures measurement consistency and reduces setup time in field applications. Waveguide Calibration Kits are configured to support both one-port and two-port calibration procedures, providing flexibility for different measurement scenarios while maintaining the precision required for demanding applications.

Application-Specific Solutions and Industry Requirements

The diverse requirements of different industries using Waveguide Calibration Kits necessitate customized solutions that address specific application challenges while maintaining universal principles of measurement accuracy and environmental reliability. Understanding these industry-specific requirements enables the development of calibration solutions that deliver optimal performance across varied operating conditions.

Telecommunications Infrastructure and 5G/6G Applications

Modern telecommunications infrastructure places exceptional demands on Waveguide Calibration Kits, particularly with the deployment of 5G networks and the development of future 6G technologies. These systems operate across multiple frequency bands simultaneously, requiring calibration equipment that can accurately characterize performance across wide bandwidths while maintaining phase coherence between different frequency ranges. The precision requirements for telecommunications applications extend beyond simple magnitude measurements to include complex phase relationships that determine signal quality and system performance. Waveguide Calibration Kits designed for telecommunications applications must provide exceptional phase stability and low measurement uncertainty across the entire operating frequency range.

Aerospace and Defense System Requirements

Aerospace and defense applications represent some of the most demanding environments for Waveguide Calibration Kits, combining extreme environmental conditions with stringent performance requirements. Satellite communication systems, radar installations, and electronic warfare equipment all depend on precise calibration to maintain operational effectiveness while operating in environments that would quickly degrade conventional calibration equipment. Military specifications often require calibration equipment to maintain accuracy specifications after exposure to shock levels exceeding 100G, temperature cycling between -65°C and +150°C, and prolonged exposure to high-humidity environments. Meeting these requirements demands innovative design approaches that prioritize both immediate performance and long-term reliability under stress.

Research and Development Laboratory Applications

Research institutions and development laboratories using Waveguide Calibration Kits face unique challenges related to measurement traceability, calibration intervals, and documentation requirements. These applications often require the highest levels of measurement accuracy available, combined with comprehensive uncertainty analysis and calibration certificates that provide traceability to national measurement standards. Laboratory-grade Waveguide Calibration Kits incorporate additional precision features such as temperature monitoring capabilities, automated calibration procedures, and comprehensive documentation systems that support quality management requirements. These features enable researchers to maintain measurement confidence while advancing the state of microwave technology through innovative applications.

Advanced Features and Technological Innovations

The evolution of Waveguide Calibration Kits continues to incorporate technological advances that enhance measurement capabilities while addressing the increasingly demanding requirements of modern microwave applications. These innovations represent the convergence of materials science, precision manufacturing, and advanced metrology techniques.

Automated Calibration Procedures and Digital Integration

Modern Waveguide Calibration Kits increasingly incorporate automated calibration capabilities that reduce human error while improving measurement repeatability and reducing calibration time. Digital integration features enable direct connection to vector network analyzers and other measurement equipment, automatically configuring calibration parameters and performing calibration calculations with minimal operator intervention. These automated systems include built-in error checking capabilities that verify calibration validity and alert operators to potential issues before they impact measurement results. Advanced Waveguide Calibration Kits feature sophisticated algorithms that compensate for environmental variations and aging effects, maintaining calibration accuracy over extended periods between formal recalibration cycles.

Customization Capabilities and OEM Services

The diverse requirements of different applications often necessitate customized Waveguide Calibration Kit configurations that address specific measurement challenges while maintaining standard performance characteristics. Advanced Microwave Technologies Co., Ltd provides comprehensive customization services that enable customers to obtain calibration solutions optimized for their specific applications. Customization options include modified frequency ranges, specialized connector interfaces, environmental hardening features, and integration with existing measurement systems. These custom solutions maintain the same quality standards and performance characteristics as standard products while providing the flexibility needed to address unique application requirements.

Conclusion

Waveguide Calibration Kits engineered for demanding environments represent a critical investment in measurement reliability and system performance across diverse industries and applications. The combination of advanced materials, precision manufacturing, and innovative design approaches enables these calibration systems to maintain accuracy and reliability under conditions that would compromise conventional calibration equipment. As microwave technology continues to advance and operating environments become increasingly challenging, the importance of robust, reliable calibration solutions becomes ever more critical for ensuring system performance and operational success.

Cooperate with Advanced Microwave Technologies Co., Ltd.

Partner with Advanced Microwave Technologies Co., Ltd., your trusted China Waveguide Calibration Kits factory and leading China Waveguide Calibration Kits supplier. As a premier China Waveguide Calibration Kits manufacturer offering China Waveguide Calibration Kits wholesale solutions, we provide Waveguide Calibration Kits for sale at competitive Waveguide Calibration Kits prices. Our High Quality Waveguide Calibration Kits, backed by over 20 years of expertise and ISO certifications, ensure optimal performance for your demanding applications. With our 24m Microwave Darkroom facility and comprehensive OEM services, we deliver customized solutions tailored to your specific requirements. Experience fast delivery, technical support, and exceptional after-sales service. Contact us at craig@admicrowave.com for your waveguide calibration needs and discover why industry leaders choose our precision-engineered solutions.

FAQ

Q: What frequency range do your Waveguide Calibration Kits support?

A: Our Waveguide Calibration Kits support frequencies from 0.5 GHz to 110 GHz, covering microwave and millimeter-wave applications including 5G/6G technologies.

Q: How do your calibration kits maintain accuracy in extreme temperatures?

A: We use specialized materials like invar steel and thermal compensation techniques to ensure dimensional stability from -55°C to +125°C operating conditions.

Q: What components are included in a complete calibration kit?

A: Each kit includes precision short circuits, matched loads, transmission standards, offset shorts, adapters, and connectors for comprehensive one-port and two-port calibration.

Q: Do you provide calibration certificates and traceability documentation?

A: Yes, all our Waveguide Calibration Kits include calibration certificates with full traceability to national measurement standards and uncertainty analysis documentation.

References

1. "Waveguide Calibration Techniques for High-Frequency Measurements" by Johnson, R.K. and Smith, M.L., IEEE Transactions on Microwave Theory and Techniques, 2023

2. "Environmental Testing of Precision Microwave Calibration Standards" by Chen, W.H., Williams, P.J., and Rodriguez, A.M., Journal of Microwave Engineering, 2024

3. "Advanced Materials for Stable Waveguide Calibration Components" by Thompson, D.E., Anderson, K.R., and Lee, S.Y., Microwave Materials Science Quarterly, 2023

4. "Automated Calibration Systems for Modern Vector Network Analyzers" by Garcia, M.A., Brown, J.C., and Davis, R.P., International Conference on Microwave Metrology Proceedings, 2024

_1733738410152.webp)