Parabolic Antenna Components: Reflector, Feed, and Support

When your satellite communication suddenly experiences significant signal degradation during critical operations, or your radar system fails to detect distant targets accurately, the problem often traces back to poorly designed or mismatched parabolic antenna components. Understanding the three fundamental elements—reflector, feed, and support structures—is essential for anyone working in telecommunications, defense, aerospace, or satellite communications. This comprehensive guide explores how these components work together to deliver the high-gain, directional performance that modern microwave applications demand, helping engineers and procurement specialists make informed decisions that prevent costly system failures and ensure mission-critical reliability.

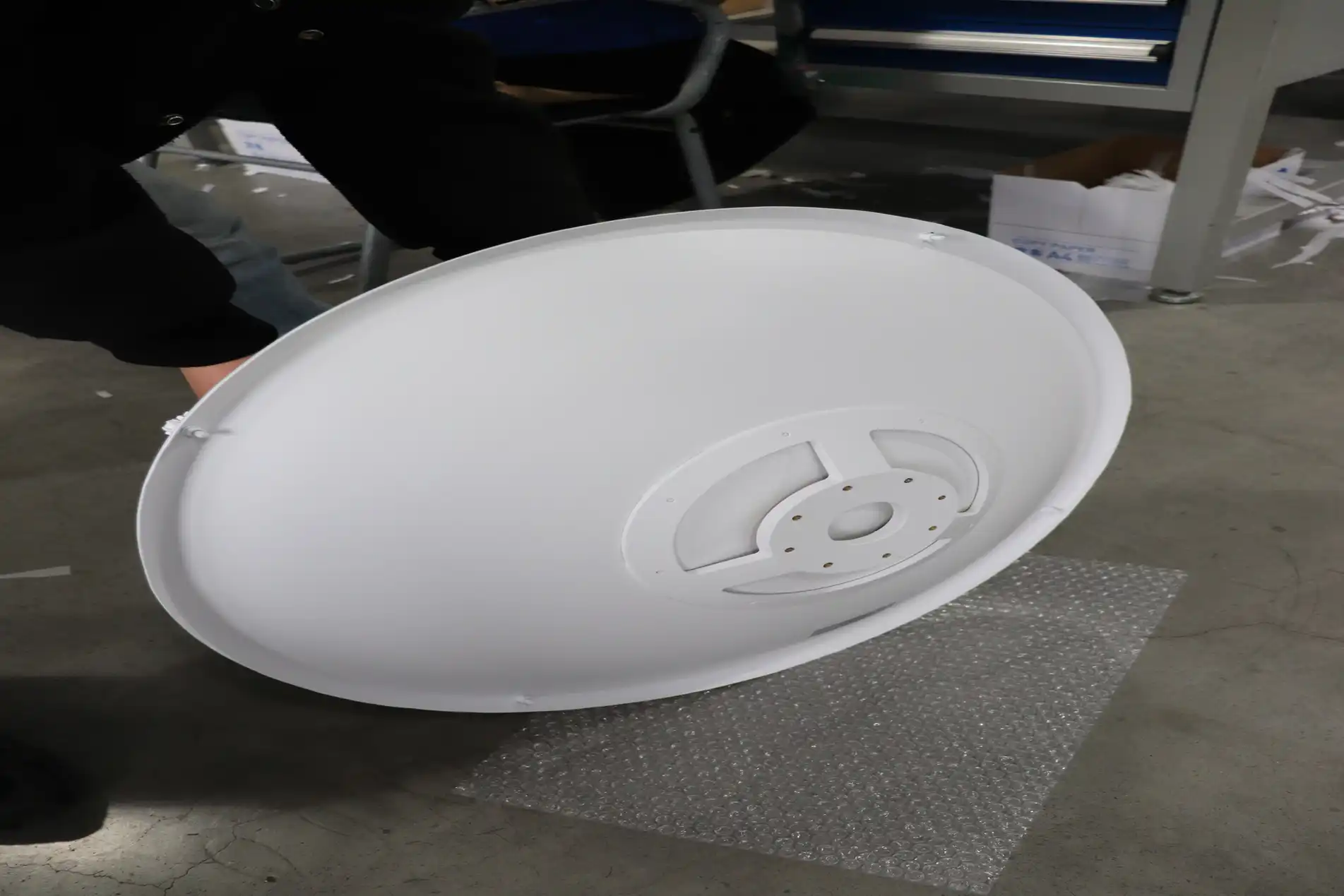

Understanding the Parabolic Antenna Reflector Design

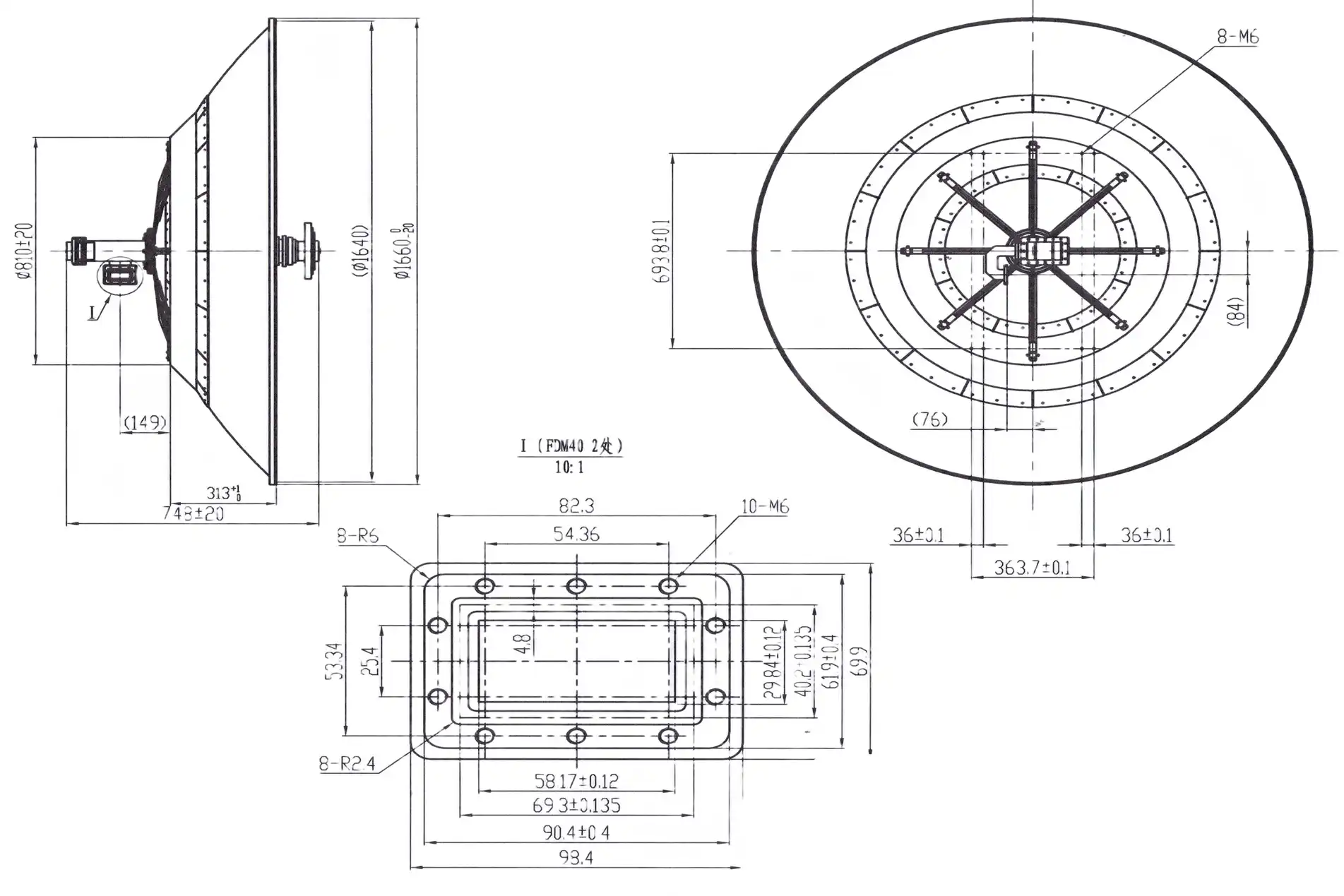

The parabolic reflector stands as the most recognizable and critical component of any parabolic antenna system. This curved metallic surface follows a precise mathematical paraboloid shape, where every point on the surface maintains a specific geometric relationship to the focal point. The reflector's primary function is to collect electromagnetic waves and redirect them toward a single focal point during reception, or conversely, to transform diverging waves from the feed into a parallel, collimated beam during transmission. The parabolic geometry ensures that all reflected signals travel equal path lengths, maintaining phase coherence and enabling the high directivity that makes these antennas indispensable for long-distance communication. Advanced Microwave Technologies Co., Ltd. manufactures parabolic reflectors using premium materials including aluminum, steel, and advanced composites, each selected based on specific application requirements. Aluminum reflectors offer an excellent balance of lightweight construction and high conductivity, making them ideal for applications where weight is a critical factor, such as aerospace and UAV systems. Steel reflectors provide superior mechanical strength and durability for ground-based installations exposed to harsh environmental conditions. The surface accuracy of these reflectors is maintained within one-sixteenth of a wavelength to ensure optimal phase coherence across the entire aperture, a specification that becomes increasingly challenging as operating frequencies extend into the millimeter-wave spectrum up to 110 GHz. The aperture diameter of the parabolic antenna directly influences both gain and beamwidth characteristics. Larger aperture diameters produce higher gain and narrower beamwidths, essential for applications requiring precise directional control such as satellite ground stations and deep-space communication. Advanced Microwave offers customizable aperture diameters ranging from 30 centimeters to 12 meters, accommodating everything from compact portable systems to large fixed installations. The relationship between aperture size and wavelength determines the antenna's electrical performance, with larger apertures relative to wavelength yielding superior directivity and reduced side lobe levels.

Reflector Surface Treatments and Coatings

The electrical performance of a parabolic antenna reflector depends significantly on surface treatments and protective coatings applied during manufacturing. High-conductivity metallic coatings, often incorporating silver or gold plating, minimize resistive losses and enhance signal reflection efficiency across the operating frequency range. These specialized coatings are particularly important for millimeter-wave applications where even small surface losses can significantly degrade overall system performance. Environmental protection coatings are strategically layered over the conductive surfaces to prevent oxidation, corrosion, and degradation from ultraviolet exposure, ensuring long-term performance stability in outdoor installations. Surface finish quality affects both electrical performance and resistance to environmental factors. Smooth, precision-machined surfaces minimize scattering losses and maintain the parabolic geometry required for optimal focusing. Advanced manufacturing techniques employed by leading manufacturers ensure surface irregularities remain well below critical thresholds, typically less than one-sixteenth wavelength at the highest operating frequency. This level of precision becomes increasingly challenging for large-aperture antennas operating at millimeter-wave frequencies, requiring sophisticated fabrication methods and rigorous quality control throughout the production process.

Feed System Configurations for Parabolic Antennas

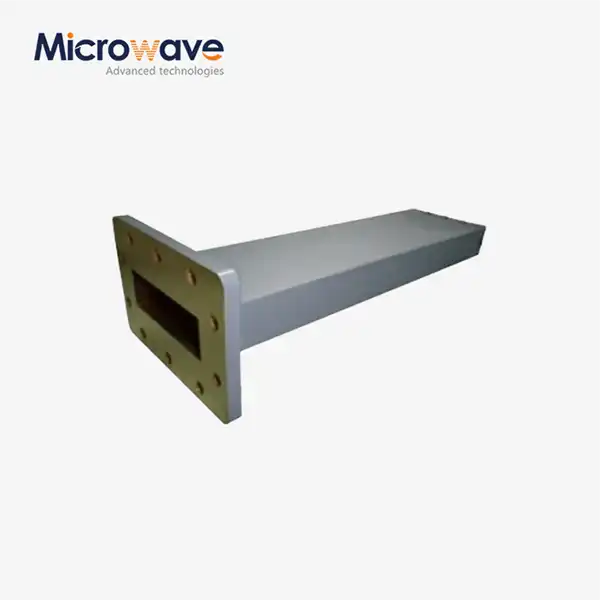

The feed system serves as the active radiating element of the parabolic antenna, converting guided electromagnetic energy from transmission lines or waveguides into free-space propagating waves, and vice versa during reception. Advanced Microwave Technologies Co., Ltd. offers parabolic reflector antennas with both primary focus feed type and back-fed type configurations, each optimized for specific application requirements. The feed system's radiation pattern must be carefully matched to the reflector geometry to achieve efficient illumination across the entire reflector surface while minimizing spillover losses and maximizing aperture efficiency. Primary focus or axial feed configurations position the feed antenna directly at the focal point of the parabolic reflector, pointed back toward the reflector surface. This straightforward arrangement is widely used due to its simplicity and effectiveness, though it does introduce some aperture blockage from the feed structure and its supporting struts. Horn antennas are commonly employed as feed elements in this configuration, offering excellent directivity and polarization control across wide bandwidth. The feed horn's aperture dimensions and flare angle are optimized to provide the appropriate illumination taper across the reflector surface, balancing edge illumination against spillover losses to maximize overall antenna efficiency. Cassegrain feed systems employ a secondary hyperboloidal reflector positioned between the primary parabolic reflector and the focal point, redirecting the electromagnetic energy to a feed located at the vertex of the main reflector. This dual-reflector configuration offers several advantages, including shorter overall antenna length, convenient feed placement for reduced transmission line losses, and improved illumination efficiency. The secondary reflector can be shaped and positioned to optimize the amplitude and phase distribution across the main reflector aperture, achieving higher aperture efficiencies typically ranging from 65 to 70 percent compared to 55 to 60 percent for simple front-fed designs.

Feed Polarization and Frequency Considerations

Polarization characteristics of the feed system determine the overall antenna polarization, which must be matched to the application requirements. Advanced Microwave parabolic antennas support both linear and circular polarization configurations, with dual-polarization feed systems available for applications requiring simultaneous operation on orthogonal polarizations. Linear polarization is commonly employed in terrestrial microwave links and radar applications, while circular polarization finds extensive use in satellite communications where it offers advantages in mitigating propagation effects and enabling frequency reuse through orthogonal polarization isolation. The frequency range from 1 GHz to 110 GHz covered by Advanced Microwave's parabolic antenna portfolio demands careful feed design optimization across different frequency bands. At lower frequencies, dipole-based feeds with splash plate reflectors may be suitable for compact systems, while waveguide horn feeds become necessary as frequencies increase into the microwave and millimeter-wave regimes. Broadband feed designs must maintain consistent radiation patterns and impedance matching across the entire operating bandwidth, requiring sophisticated electromagnetic design and optimization. Custom feed networks can be engineered to support specific frequency allocations, ensuring optimal performance for telecommunications, radar, satellite communications, and research applications.

Support Structure Engineering and Mounting Systems

The mechanical support structure plays a crucial yet often underappreciated role in maintaining parabolic antenna performance across varying environmental conditions and operational scenarios. Support structures must maintain the precise geometric alignment between the reflector and feed system while withstanding static loads from the antenna mass, dynamic loads from wind and ice accumulation, and thermal stresses from temperature variations. Advanced Microwave Technologies Co., Ltd. engineers support structures using finite element analysis and sophisticated structural optimization to minimize weight while ensuring adequate stiffness and strength for the application environment. Fixed mounting configurations provide the most rigid and stable antenna installations for applications where the target direction remains constant, such as point-to-point microwave links and fixed satellite ground terminals. These mounting systems typically incorporate adjustment mechanisms for initial alignment and periodic maintenance, allowing precise azimuth and elevation positioning during installation. The mounting hardware is fabricated from corrosion-resistant materials with protective coatings to ensure long service life in outdoor environments. Proper installation of fixed mounting systems requires careful site survey and precise alignment to achieve the narrow beamwidths characteristic of high-gain parabolic antennas. Adjustable mounting systems incorporate mechanical or electromechanical positioning mechanisms enabling real-time antenna pointing adjustments. These systems range from simple manual adjustment mechanisms for periodic repositioning to sophisticated servo-driven positioners supporting automated tracking of moving satellites or targets. Two-axis positioners provide azimuth and elevation control, with precision gearing and encoder feedback enabling accurate pointing even with large, heavy antenna structures. Advanced tracking systems integrate with satellite ephemeris data or radar tracking information to maintain continuous alignment with moving targets, essential for applications including satellite communication on mobile platforms, radar surveillance systems, and radio astronomy observations.

Environmental Protection and Durability

Parabolic antennas deployed in outdoor environments must withstand exposure to rain, snow, ice, ultraviolet radiation, temperature extremes, and corrosive atmospheres. Support structure materials are selected based on the specific deployment environment, with options including powder-coated steel, anodized aluminum, and stainless steel for marine or highly corrosive environments. Proper drainage design prevents water accumulation on reflector surfaces that could add weight and affect electrical performance. Radomes or protective covers may be specified for installations in severe weather environments, though these add cost and may introduce slight performance degradation. Thermal expansion and contraction from diurnal temperature cycling can introduce mechanical stresses and geometric distortions in large antenna structures. Support structure design must account for differential thermal expansion between dissimilar materials to prevent stress concentrations that could lead to fatigue failures over extended service life. Temperature-induced distortions of the reflector surface must remain within acceptable tolerances to maintain electrical performance, particularly for precision applications operating at millimeter-wave frequencies where small geometric errors significantly impact antenna patterns and gain.

Integration of Components for Optimal Performance

Achieving optimal parabolic antenna performance requires careful integration of the reflector, feed system, and support structure as a complete system rather than independent components. The relationship between focal length and aperture diameter, known as the f/D ratio, fundamentally affects feed design requirements and achievable aperture efficiency. Lower f/D ratios produce deeper dish profiles requiring feeds with wider beamwidths to adequately illuminate the reflector, while higher f/D ratios result in shallower dishes that can be efficiently illuminated with narrower feed patterns. Advanced Microwave's engineering team optimizes these parameters for each application to balance performance requirements against practical constraints including available space, weight limitations, and manufacturing considerations. Impedance matching between the feed system and associated transmission lines or waveguides is critical for minimizing reflected power and maximizing radiation efficiency. Advanced Microwave designs incorporate impedance transformation networks when necessary to achieve the standard 50-ohm impedance referenced in the product specifications, ensuring compatibility with standard RF and microwave transmission systems. VSWR performance is carefully controlled across the operating bandwidth through electromagnetic simulation and prototype testing, with production antennas verified through comprehensive measurement in Advanced Microwave's state-of-the-art antenna measurement facilities including the 24-meter microwave darkroom. The Antenna Plane Near and Far Field Measuring Recombination Chamber enables complete characterization of antenna radiation patterns, gain, polarization, and impedance characteristics across the full frequency range from 0.5 to 110 GHz. Near-field measurement techniques are employed for electrically large antennas where far-field measurement distances would be impractical, with mathematical transformation converting near-field data to equivalent far-field patterns. This comprehensive testing capability ensures every parabolic antenna meets rigorous performance specifications before delivery, providing customers confidence in system performance for their critical applications.

Application-Specific Optimization

Different applications impose varying requirements on parabolic antenna design, necessitating customization of component specifications to match operational needs. Telecommunications applications including satellite ground stations and microwave backhaul links prioritize high gain and narrow beamwidth for maximum link budget and spectral efficiency. Aerospace and defense applications may require lightweight construction, ruggedized designs for harsh environments, and specialized polarization or frequency characteristics for radar or electronic warfare systems. Deep-space communication applications demand the highest possible gain and lowest noise temperatures, often requiring cryogenically cooled feed systems and ultra-precise reflector surface accuracy. Advanced Microwave Technologies Co., Ltd. provides comprehensive OEM services to develop customized parabolic antenna solutions tailored to specific customer requirements. Design customization includes optimization of frequency range, aperture diameter, polarization configuration, and material selection based on performance objectives and environmental conditions. Rapid prototyping capabilities enable quick iteration and testing of custom designs before committing to full-scale production, reducing development risk and time-to-market for new applications. The combination of over 20 years of manufacturing experience, ISO 9001:2015 certified quality management systems, and advanced testing facilities positions Advanced Microwave as a trusted partner for demanding parabolic antenna applications worldwide.

Conclusion

Parabolic antenna components—reflector, feed, and support—must work in precise harmony to deliver the high-gain, directional performance required for modern microwave applications across telecommunications, aerospace, defense, and research sectors.

Cooperate with Advanced Microwave Technologies Co., Ltd.

Partner with Advanced Microwave Technologies Co., Ltd., a leading China parabolic antenna manufacturer, supplier, and factory offering high-quality parabolic antennas for sale at competitive prices. Our China parabolic antenna wholesale solutions combine over 20 years of expertise with ISO 9001:2008 certification and RoHS compliance. From our 24-meter microwave darkroom to comprehensive OEM services, we deliver customized solutions with rapid prototyping, expert technical support, and fast turnaround. Whether you need primary focus or Cassegrain configurations spanning 1 GHz to 110 GHz, our experienced team ensures your project succeeds. Contact us today at craig@admicrowave.com to discuss your requirements and experience the reliability that comes from working with a trusted high-quality parabolic antenna provider serving global markets.

References

1. Balanis, Constantine A. "Antenna Theory: Analysis and Design." Fourth Edition, John Wiley & Sons.

2. Milligan, Thomas A. "Modern Antenna Design." Second Edition, Institute of Electrical and Electronics Engineers Press.

3. Stutzman, Warren L. and Thiele, Gary A. "Antenna Theory and Design." Third Edition, John Wiley & Sons.

4. Rudge, Alan W., Milne, K., Olver, A. D., and Knight, P. "The Handbook of Antenna Design." Volumes 1 and 2, Peter Peregrinus Ltd.

5. Silver, Samuel. "Microwave Antenna Theory and Design." MIT Radiation Laboratory Series, McGraw-Hill Book Company.

YOU MAY LIKE

VIEW MOREHigh Power Waveguide to Coaxial Adapter

VIEW MOREHigh Power Waveguide to Coaxial Adapter VIEW MOREWaveguide Loop Coupler

VIEW MOREWaveguide Loop Coupler VIEW MOREEnd Launch Double Ridged WG To Coaxial Adapter

VIEW MOREEnd Launch Double Ridged WG To Coaxial Adapter VIEW MOREEnd Launch Waveguide to Microstrip Adapter

VIEW MOREEnd Launch Waveguide to Microstrip Adapter VIEW MOREWaveguide Sliding Termination

VIEW MOREWaveguide Sliding Termination VIEW MOREWaveguide Unmatched Termination

VIEW MOREWaveguide Unmatched Termination VIEW MOREMagic Hybrid Tee

VIEW MOREMagic Hybrid Tee VIEW MOREH-Plane Tee

VIEW MOREH-Plane Tee