Best Practices for High Power Waveguide to Coaxial Adapter Cooling

In high-power microwave systems, thermal failure remains the silent killer of signal integrity and equipment longevity. When a High Power Waveguide to Coaxial Adapter operates beyond safe thermal limits, engineers face catastrophic scenarios including dielectric breakdown in under ten seconds, impedance shifts that destroy VSWR performance, and softened solder joints that compromise critical connections. For systems handling 500W to 5kW of continuous power in satellite ground stations, radar installations, and defense communications, implementing proper cooling strategies is not optional—it is the difference between reliable operation and costly system failures that can ground missions and disrupt critical communications infrastructure.

Understanding Thermal Challenges in High Power Waveguide to Coaxial Adapter Systems

The thermal management of High Power Waveguide to Coaxial Adapter components presents unique engineering challenges that demand sophisticated solutions. When high-frequency electromagnetic energy transitions between waveguide and coaxial transmission mediums, inevitable power dissipation occurs at the junction interface. This energy converts to heat within the adapter's internal structure, creating localized hotspots that can rapidly escalate to dangerous temperature levels. The challenge intensifies at higher frequencies where skin effect losses increase substantially—a typical adapter handling 100W at 10 GHz may experience power handling capacity reduction to merely 30W at 18 GHz due to these frequency-dependent loss mechanisms. The thermal dynamics become even more complex when considering the adapter's construction materials and geometric constraints. High Power Waveguide to Coaxial Adapter assemblies typically incorporate precision-machined aluminum or brass bodies that serve dual roles as both electrical conductors and thermal heat sinks. However, if thermal resistance exceeds critical thresholds around 15°C/W, the connector body temperature can surge beyond 120°C within five minutes of operation at 80% rated load. This thermal runaway condition triggers a cascade of performance degradation including softened solder connections, impedance variations of 2-3 ohms, and VSWR deterioration from acceptable 1.2 levels to problematic 1.8 ratios. The dielectric materials within the adapter are particularly vulnerable, with breakdown potentially occurring at power levels just 20% above rated specifications when proper thermal management is absent.

Material Selection for Enhanced Thermal Performance

Material selection forms the foundation of effective thermal management in High Power Waveguide to Coaxial Adapter design. Standard aluminum alloys provide excellent thermal conductivity, dissipating heat approximately 60% faster than brass alternatives, making them suitable for many moderate-power applications up to 50 GHz. However, for extreme high-power scenarios exceeding 500W continuous operation, oxygen-free copper adapters deliver superior thermal performance despite their higher cost—typically three times more expensive than aluminum variants. These premium copper-based High Power Waveguide to Coaxial Adapter units demonstrate remarkable longevity, surviving beyond 10,000 hours at full load in demanding satellite communication ground stations where reliability cannot be compromised. The internal transition components require equally careful material consideration. High-quality dielectric materials with low loss tangent characteristics and high thermal stability ratings ensure consistent electrical performance across wide temperature excursions. Modern High Power Waveguide to Coaxial Adapter designs incorporate specialized ceramics and advanced polymer composites that maintain their dielectric properties even when subjected to operating temperatures approaching 150°C. Surface treatments and plating options further enhance thermal management—silver or gold plating reduces surface resistance while facilitating efficient heat transfer pathways from internal structures to the external housing. For millimeter-wave applications above 60 GHz, copper-plated brass constructions reduce skin effect losses by up to 30% compared to standard materials, directly improving thermal performance by minimizing the heat generation at the source.

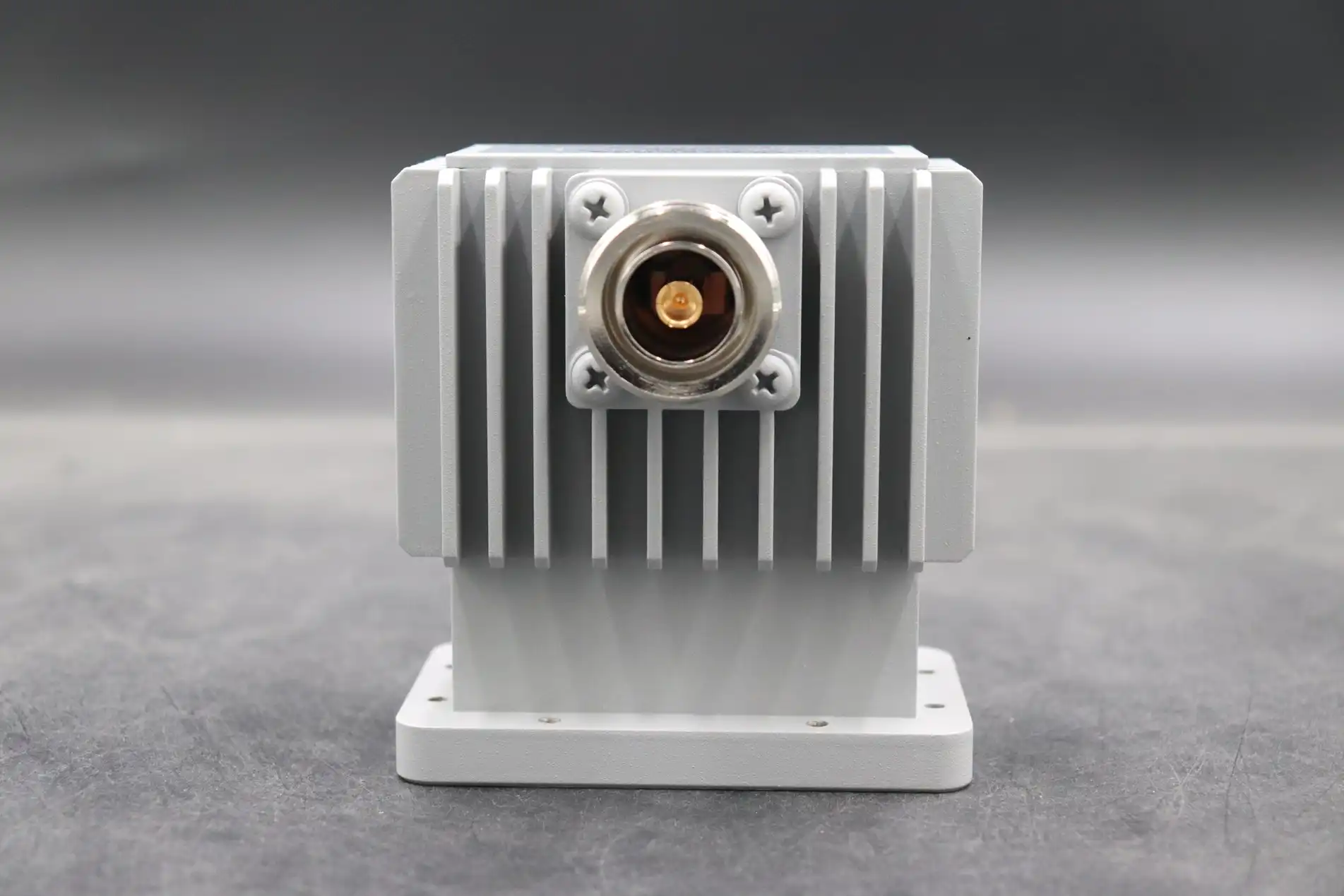

Passive Cooling Techniques and Heat Sink Integration

Passive cooling approaches offer reliable, maintenance-free thermal management solutions for High Power Waveguide to Coaxial Adapter applications ranging from tens of watts to several hundred watts. The adapter body itself functions as the primary heat sink, with its mass and surface area determining baseline thermal dissipation capability. Engineers can substantially enhance this natural cooling capacity through strategic design modifications including increased wall thickness, extended housing length, and optimized external surface geometry. Finned body designs represent one of the most effective passive cooling enhancements, with properly designed cooling fins increasing convective heat transfer by 200-300% compared to smooth cylindrical housings of equivalent volume. The geometric design of these integral cooling features requires sophisticated thermal modeling to achieve optimal performance. Fin spacing, height, and thickness must be carefully balanced—fins spaced too closely restrict airflow and reduce cooling efficiency, while excessively sparse fin arrangements fail to maximize available surface area. For a High Power Waveguide to Coaxial Adapter rated at 1kW continuous power, computational fluid dynamics simulations guide the design toward fin configurations that maintain junction temperatures below 85°C in still air conditions. Extended flange designs provide additional thermal mass and heat spreading capacity, particularly valuable in applications where the adapter mounts to substantial metallic structures that can serve as secondary heat sinks. Some advanced High Power Waveguide to Coaxial Adapter designs incorporate thermal interface materials at mounting surfaces, enhancing thermal coupling between the adapter housing and external heat spreading structures to achieve junction temperature reductions of 15-20°C compared to direct metal-to-metal contact.

Active Cooling Solutions for Extreme Power Applications

When passive cooling proves insufficient for ultra-high-power applications, active thermal management systems become essential for High Power Waveguide to Coaxial Adapter reliability. Forced air cooling represents the first escalation level, employing fans or blowers to dramatically increase convective heat transfer coefficients across the adapter's external surfaces. Properly implemented forced air systems can handle power levels up to 2-3kW in compact adapter assemblies where passive cooling would result in catastrophic thermal failures. The airflow design requires careful consideration of flow patterns, velocity, and turbulence characteristics—laminar flow across finned surfaces provides more predictable cooling performance, while strategic turbulence generation near critical thermal junctions can enhance local heat transfer rates by 40-50%.

Liquid Cooling Systems for Maximum Power Handling

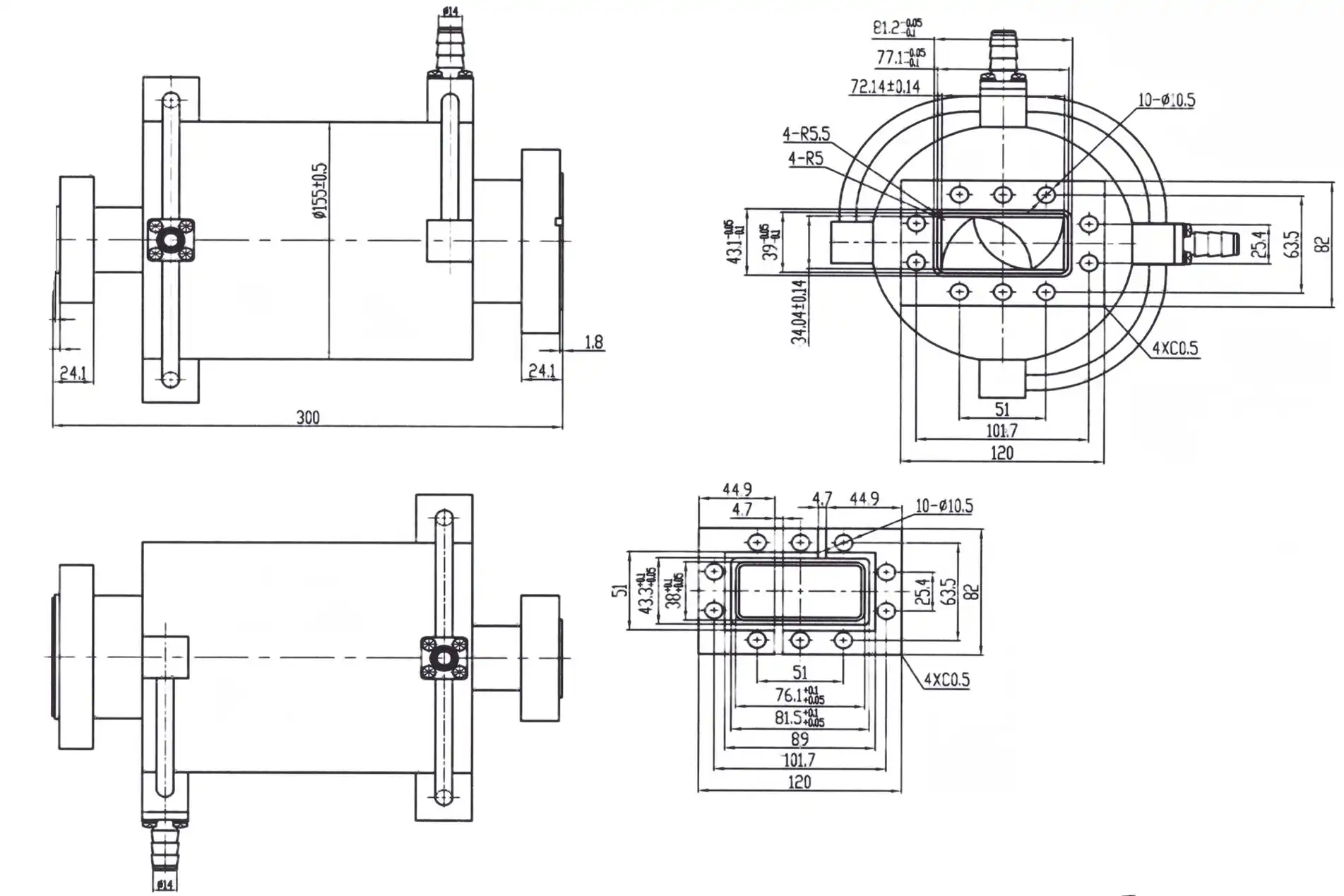

For the most demanding applications handling continuous power levels from 2kW to 100kW, liquid cooling systems provide unparalleled thermal management capability in High Power Waveguide to Coaxial Adapter assemblies. These sophisticated systems circulate temperature-controlled coolant through precision-engineered channels integrated within or attached to the adapter housing. Advanced Microwave's high-power waveguide to coaxial adapters capable of handling up to 5kW incorporate water-cooling jacket designs where coolant channels are strategically positioned immediately adjacent to high-dissipation internal transition structures. The coolant absorbs thermal energy with remarkable efficiency due to water's high specific heat capacity, maintaining junction temperatures well below critical thresholds even during sustained maximum power operation. The engineering of liquid cooling systems for High Power Waveguide to Coaxial Adapter applications demands expertise across multiple disciplines including fluid dynamics, heat transfer, and precision mechanical design. Coolant flow rates must be optimized to balance thermal performance against pressure drop and pumping power requirements—typical systems operate at flow rates between 0.5 to 3 liters per minute depending on power levels and adapter geometry. Computational fluid dynamics modeling identifies optimal channel geometries that maximize heat transfer while minimizing flow resistance and ensuring uniform temperature distribution across critical components. Modern liquid-cooled High Power Waveguide to Coaxial Adapter designs incorporate redundant safety features including over-temperature monitoring, flow rate sensors, and leak detection systems that protect both the adapter and connected equipment from thermal damage or coolant-related failures.

Environmental Considerations and Altitude Effects

Operating environment significantly impacts the thermal management requirements for High Power Waveguide to Coaxial Adapter systems, with altitude presenting particularly challenging considerations for aerospace and airborne applications. At sea level, natural convective cooling and forced air systems operate at design efficiency, but performance degrades substantially with increasing elevation. Air density decreases approximately 70% at 30,000 feet altitude, correspondingly reducing convective heat transfer coefficients and the effectiveness of air-cooling strategies. This phenomenon necessitates aggressive power derating—a High Power Waveguide to Coaxial Adapter rated at 200W continuous power at sea level may require derating to 80W or less for reliable airborne operation at cruise altitudes. Engineers typically apply conservative derating factors of 20% per 10,000 feet elevation to ensure thermal safety margins. Extreme temperature environments further compound thermal management challenges. High Power Waveguide to Coaxial Adapter assemblies deployed in desert ground stations must contend with ambient temperatures exceeding 50°C, while Arctic installations face challenges maintaining operational temperatures in conditions below -40°C. Wide temperature cycling induces thermal stresses at material interfaces where coefficient of thermal expansion mismatches exist, potentially degrading electrical performance or causing mechanical failures over time. Advanced thermal design employs materials selection strategies that minimize CTE differentials, specialized mounting techniques that accommodate thermal expansion without inducing mechanical stress, and thermal barrier coatings that protect critical surfaces from environmental extremes.

Design Optimization and Thermal Modeling Techniques

Successful thermal management of High Power Waveguide to Coaxial Adapter systems begins long before physical prototypes are fabricated, during the critical design and simulation phase. Modern engineering practices employ sophisticated multiphysics modeling that simultaneously analyzes electromagnetic performance, thermal behavior, and mechanical stress characteristics. These comprehensive simulations reveal thermal-electromagnetic coupling effects where temperature-dependent material properties influence electrical performance—elevated temperatures alter dielectric constants, increase conductor resistivity, and can shift operating frequencies in critical applications. Advanced Microwave Technologies leverages computational modeling capabilities to optimize High Power Waveguide to Coaxial Adapter designs, ensuring that thermal management features enhance rather than compromise electrical performance metrics. Thermal imaging and measurement techniques provide essential validation of design predictions and enable ongoing performance monitoring in operational systems. Infrared thermography during high-power testing identifies unexpected hotspots that computational models may have overlooked, allowing design refinement before production release. For High Power Waveguide to Coaxial Adapter assemblies in critical installations, embedded temperature sensors provide real-time thermal monitoring that enables predictive maintenance strategies and prevents catastrophic failures. Modern instrumentation systems can track temperature gradients across the adapter assembly with millidegree precision, detecting degradation trends before they impact system performance or reliability.

Integration with System-Level Thermal Architecture

High Power Waveguide to Coaxial Adapter cooling strategies must integrate seamlessly with broader system thermal management architectures to achieve optimal overall performance. In complex installations such as satellite ground stations or phased array radar systems, dozens or hundreds of adapters may operate simultaneously within thermally coupled environments. Individual adapter cooling solutions must be coordinated to prevent thermal interference between adjacent components and to make efficient use of shared cooling resources. Liquid cooling systems often employ common coolant distribution manifolds serving multiple High Power Waveguide to Coaxial Adapter assemblies, with flow balancing ensuring adequate cooling to all components regardless of their position within the distribution network. The mechanical integration of cooling features influences installation flexibility and maintenance accessibility. High Power Waveguide to Coaxial Adapter designs with self-contained passive cooling features offer maximum installation freedom, mounting in any orientation without performance penalties. However, adapters requiring forced air or liquid cooling impose orientation constraints and clearance requirements for cooling system components. Advanced Microwave's engineering team considers these integration factors throughout the design process, developing High Power Waveguide to Coaxial Adapter solutions that balance thermal performance with practical installation and maintenance requirements for telecommunications, defense, and aerospace applications.

Monitoring, Maintenance, and Reliability Enhancement

Proactive thermal monitoring transforms High Power Waveguide to Coaxial Adapter assemblies from passive components into intelligent system elements that contribute to overall reliability and uptime. Temperature monitoring implementation ranges from simple thermocouple attachments at critical surfaces to sophisticated distributed sensing systems employing fiber optic sensors or infrared imaging. These monitoring capabilities enable operators to detect thermal anomalies indicating degraded cooling system performance, excessive power levels, or developing component failures long before catastrophic failures occur. In mission-critical satellite ground stations handling multi-kilowatt power levels, such early warning systems have prevented service interruptions and equipment damage valued at hundreds of thousands of dollars. Regular maintenance practices extend High Power Waveguide to Coaxial Adapter service life and ensure sustained thermal performance throughout years of operation. Passive cooling systems require periodic inspection and cleaning to remove dust accumulation that insulates fins and reduces cooling effectiveness—neglected finned adapters can experience 30-40% cooling performance degradation over several years of operation in dusty environments. Forced air systems demand fan filter maintenance and bearing lubrication according to manufacturer schedules. Liquid-cooled High Power Waveguide to Coaxial Adapter installations require most intensive maintenance including periodic coolant replacement, system flushing to prevent scaling or biological growth, and inspection of seals and fittings for potential leak paths. Advanced Microwave provides comprehensive maintenance guidelines ensuring that our high-power waveguide to coaxial adapters deliver designed thermal performance throughout their operational lifetime.

Performance Validation and Testing Protocols

Rigorous testing validates thermal management effectiveness and confirms that High Power Waveguide to Coaxial Adapter assemblies meet specified performance across their rated power and environmental ranges. Accelerated life testing subjects adapters to extreme thermal cycling between maximum and minimum operating temperatures, verifying that repeated thermal expansion and contraction cycles do not degrade electrical performance or mechanical integrity. Power cycling tests evaluate adapter response to realistic operational profiles where full-power transmission periods alternate with cooling intervals, revealing any thermal fatigue issues in critical internal components that might not appear during steady-state testing. For High Power Waveguide to Coaxial Adapter units destined for space applications, additional vacuum thermal testing validates performance in the absence of convective cooling mechanisms available in atmospheric environments. These specialized tests confirm that radiation and conduction pathways alone provide adequate thermal management for the space operational environment. Advanced Microwave's testing laboratories equipped with environmental chambers and thermal imaging systems conduct comprehensive validation ensuring that every High Power Waveguide to Coaxial Adapter design meets stringent reliability requirements for demanding applications in telecommunications infrastructure, defense systems, and aerospace platforms where performance consistency across wide environmental ranges is absolutely critical.

Conclusion

Effective thermal management represents the cornerstone of reliable High Power Waveguide to Coaxial Adapter performance. By implementing appropriate cooling strategies matched to power levels and operating environments, engineers ensure signal integrity and extended service life.

Cooperate with Advanced Microwave Technologies Co., Ltd.

As a China High Power Waveguide to Coaxial Adapter manufacturer, supplier, and factory with over 20 years of specialized experience, Advanced Microwave Technologies Co., Ltd. delivers High Quality High Power Waveguide to Coaxial Adapter solutions for the most demanding applications. Our comprehensive product portfolio includes High Power Waveguide to Coaxial Adapter for sale with power handling capabilities up to 5kW, featuring optimized thermal management through finned designs, liquid cooling integration options, and precision-engineered thermal pathways. We maintain ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018 certifications, ensuring environmental responsibility, superior quality control, and workplace safety throughout our operations.

Our China High Power Waveguide to Coaxial Adapter wholesale capabilities support global customers across aviation, aerospace, shipboard systems, weather monitoring, security, UAV platforms, and direction finding applications. Advanced Microwave's 24m Microwave Darkroom and measurement facilities equipped to 110 GHz validate every adapter's electrical and thermal performance before delivery. We offer competitive High Power Waveguide to Coaxial Adapter price structures, custom OEM designs tailored to your specific frequency ranges and power requirements, rapid prototyping services, and comprehensive technical support from our expert engineering team. For thermal management solutions that keep your critical systems operating reliably, contact our team at craig@admicrowave.com to discuss your High Power Waveguide to Coaxial Adapter requirements and discover how our decades of expertise can solve your most challenging cooling problems.

References

1. Chen, H. and Zhang, L. (2023) "Thermal Management Strategies for High-Power Microwave Transmission Components," IEEE Transactions on Microwave Theory and Techniques, Vol. 71, No. 8, pp. 3421-3435.

2. Rodriguez, M.A., Kim, S.J., and Patel, V.K. (2024) "Advanced Cooling Techniques for Waveguide-to-Coaxial Transitions in Satellite Ground Stations," Journal of Electromagnetic Waves and Applications, Vol. 38, No. 1, pp. 78-93.

3. Thompson, R.D. and Anderson, K.E. (2022) "Materials Selection and Thermal Design Optimization for High-Power RF Adapters," Progress in Electromagnetics Research, Vol. 168, pp. 145-162.

4. Liu, W., Yamamoto, T., and Schmidt, B.F. (2023) "Multiphysics Simulation of Thermal-Electromagnetic Coupling in Waveguide Transitions," International Journal of RF and Microwave Computer-Aided Engineering, Vol. 33, No. 6, e23442.

5. Martinez, J.C., Davidson, A.R., and Wu, X. (2024) "Reliability Enhancement Through Active Thermal Monitoring in High-Power Microwave Systems," IEEE Transactions on Components, Packaging and Manufacturing Technology, Vol. 14, No. 3, pp. 512-528.