Lightweight Signal Transmission: The 2025 Guide to Inflatable Twist Waveguides

Are you struggling with bulky, rigid waveguides that fail in space-constrained environments or dynamic installations? The revolutionary inflatable twist waveguide technology addresses these critical challenges by combining unprecedented flexibility with reliable microwave signal transmission. This comprehensive guide explores how this innovative solution transforms signal routing in aerospace, telecommunications, and defense applications, providing engineers with the lightweight, adaptable technology they need for 2025's most demanding projects.

Understanding Inflatable Twist Waveguide Technology

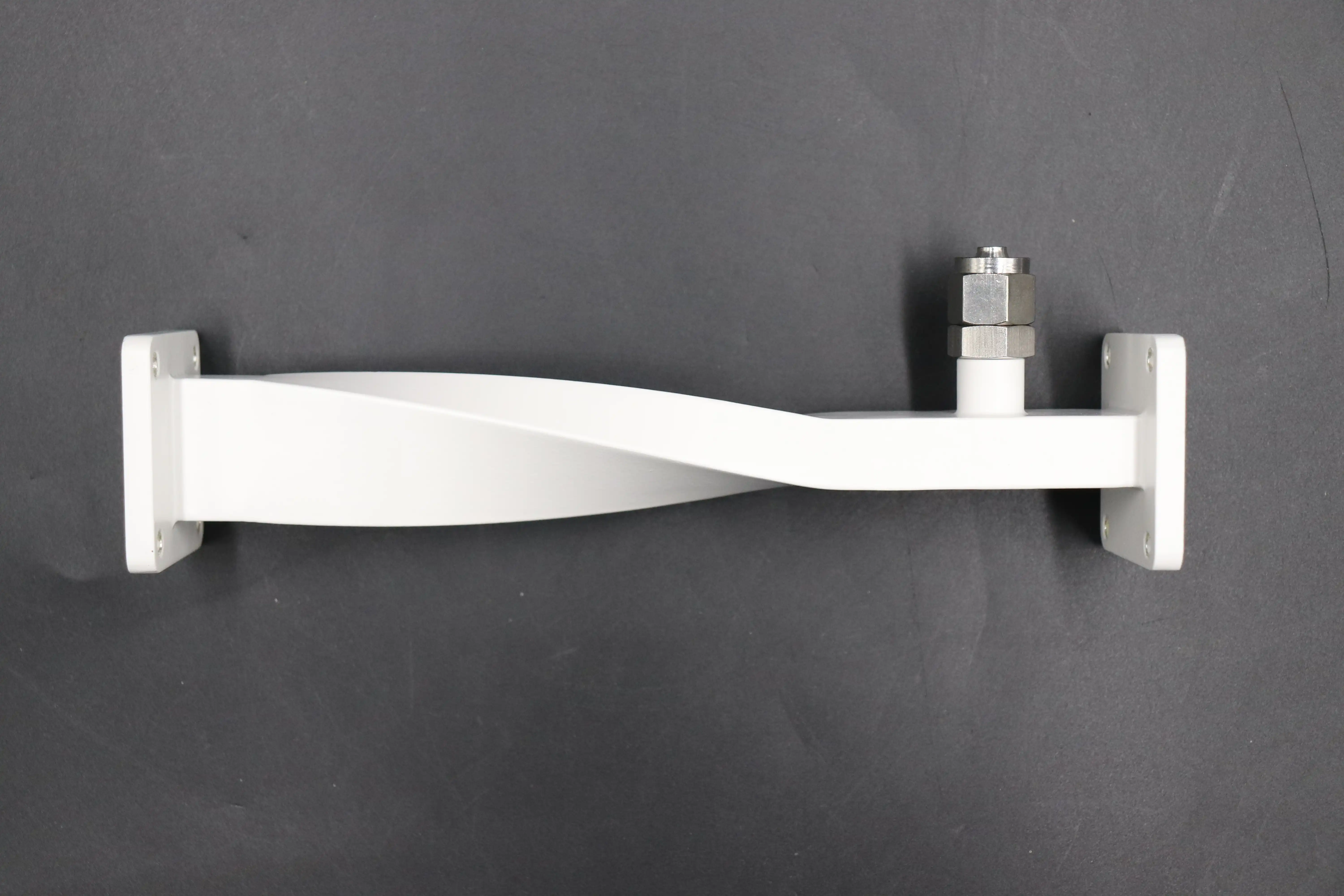

The inflatable twist waveguide represents a paradigm shift in microwave signal transmission technology. Unlike traditional rigid waveguides that occupy significant space and lack adaptability, this innovative solution combines inflatable and twistable structures to guide electromagnetic waves with remarkable flexibility. The technology utilizes a sophisticated dual-layer construction featuring a flexible outer layer and an inflation-resistant inner layer structure, designed to transmit microwave signals through total reflection principles. Advanced Microwave Technologies Co., Ltd. has pioneered this technology, creating waveguides that can dynamically adjust their wave propagation path through inflation or twisting mechanisms. The inflatable twist waveguide consists of flexible materials that expand after inflation while allowing controlled twisting or bending, providing enhanced flexibility and adaptability that traditional waveguides simply cannot match. This breakthrough addresses the growing demand for lightweight, space-efficient components in modern communication systems.

Core Construction and Operating Principles

The inflatable twist waveguide operates on fundamental electromagnetic principles while incorporating innovative mechanical design elements. The waveguide structure maintains proper impedance matching throughout its flexible range, ensuring minimal signal loss even during dynamic shape changes. The inner surface features specialized coatings, such as silver plating in Advanced Microwave Technologies' ADM-100QWTA180PMA model, which optimizes signal reflection and minimizes insertion loss to just 0.1dB maximum. The twistable feature enables the waveguide to adapt to complex installation environments without affecting signal transmission quality. This capability proves particularly valuable in applications where traditional rigid waveguides would require multiple joints, fittings, and transitions that introduce signal degradation and increase system complexity. The inflatable mechanism allows for compact storage and rapid deployment, making it ideal for temporary installations, emergency communications, and space-limited applications.

Material Science and Manufacturing Excellence

Modern inflatable twist waveguides utilize advanced materials engineering to achieve optimal performance characteristics. The aluminum construction provides excellent conductivity while maintaining lightweight properties essential for aerospace and mobile applications. The manufacturing process involves precision engineering to ensure consistent wall thickness and surface finish, critical factors in maintaining signal integrity across the waveguide's operating frequency range. Quality control measures during production include rigorous testing for VSWR performance, with specifications typically achieving 1.05 maximum VSWR ratings. This exceptional performance stems from careful attention to material selection, manufacturing tolerances, and surface treatments. The result is a product that meets stringent aerospace and defense standards while offering the flexibility advantages that traditional waveguides cannot provide.

Key Performance Advantages and Features

The inflatable twist waveguide offers eight critical advantages that distinguish it from conventional waveguide solutions. Flexibility stands as the primary benefit, enabling twisting and inflation capabilities that suit scenarios where rigid waveguides fail completely. This flexibility proves invaluable in dynamic environments, rotating antenna systems, and installations where mechanical movement is required. Space efficiency represents another crucial advantage, as these waveguides occupy minimal space when deflated or compacted. This characteristic proves especially useful in space-constrained settings such as aircraft, satellites, and mobile communication systems where every cubic inch matters. The ability to store the waveguide in a compact form and deploy it quickly makes it ideal for emergency response situations and temporary installations.

Adaptability and Performance Optimization

Real-time shape adjustment enables precise wave propagation control across various frequencies, allowing system designers to optimize performance for specific applications. The inflatable twist waveguide can be fine-tuned during installation to achieve optimal signal paths, something impossible with rigid alternatives. This adaptability extends to frequency response characteristics, where the waveguide maintains consistent performance across its entire operating range. The lightweight construction, achieved through flexible materials, makes these waveguides significantly lighter than traditional alternatives. This weight reduction proves crucial for aerospace applications where every gram affects fuel consumption and payload capacity. In mobile communications, reduced weight translates to easier installation and lower structural requirements for mounting systems.

Cost-Effectiveness and Deployment Advantages

The simpler inflatable design reduces manufacturing costs, especially in mass production scenarios. Traditional waveguides require complex machining, welding, and finishing processes, while inflatable twist waveguides can be manufactured using more efficient production methods. This cost advantage becomes particularly significant in large-scale deployments or when budget constraints are primary concerns. Ease of deployment represents a practical advantage that cannot be overlooked. The waveguides inflate quickly and fit temporary or dynamic installations perfectly. Installation time reduces dramatically compared to rigid waveguide systems that require careful alignment, multiple fittings, and complex routing solutions. This rapid deployment capability makes inflatable twist waveguides ideal for military applications, emergency communications, and field research operations.

Critical Applications and Industry Implementation

Telecommunications applications showcase the versatility of inflatable twist waveguides in mobile and satellite communications. These systems often face challenging installation environments where traditional waveguides cannot accommodate the required routing paths. The inflatable twist waveguide adapts to tough installation requirements while significantly reducing payload weight in satellite applications, directly impacting launch costs and system efficiency. Space applications particularly benefit from the lightweight characteristics and compact storage capabilities. Spacecraft designers face extreme weight and space constraints, making every component selection critical. Inflatable twist waveguides enable connections to deployable antennas and communication systems while maintaining the flexibility needed for orbital mechanical systems and deployable structures.

Medical and Defense Applications

Medical applications leverage the low-loss signal transfer capabilities for imaging systems and endoscopic equipment. The flexibility allows routing through complex medical equipment configurations while maintaining signal integrity essential for diagnostic accuracy. The biocompatible materials and reliable performance make these waveguides suitable for critical medical applications where signal quality directly impacts patient care. Military applications power portable communications and radar systems with the easy deployment characteristics that field operations demand. Defense contractors require rapid setup capabilities for temporary installations, mobile command centers, and deployable radar systems. The inflatable twist waveguide provides the reliability needed for mission-critical communications while offering the flexibility required for military mobility requirements.

Broadcasting and Research Applications

Broadcasting applications utilize inflatable twist waveguides for signal transmission in remote and temporary setups. Television production, emergency broadcasting, and event coverage often require rapid deployment of communication systems in challenging environments. The waveguides provide reliable signal transmission while accommodating the dynamic requirements of broadcast operations. Research applications facilitate signal transfer in field research and wave propagation studies. Scientists conducting atmospheric research, radio astronomy, and electromagnetic compatibility testing benefit from the adaptability and precision offered by these advanced waveguide systems. The ability to modify the waveguide configuration during experiments provides unprecedented flexibility for research applications.

Technical Specifications and Performance Parameters

Advanced Microwave Technologies Co., Ltd. produces inflatable twist waveguides with precise technical specifications that meet demanding application requirements. The ADM-100QWTA180PMA model operates in the 9.3-9.5GHz frequency range, providing optimal performance for X-band applications including air traffic control radar, satellite communications, and defense systems. The maximum VSWR specification of 1.05 demonstrates exceptional impedance matching throughout the waveguide structure. This low VSWR indicates minimal signal reflection, ensuring maximum power transfer and system efficiency. The insertion loss specification of 0.1dB maximum represents industry-leading performance, minimizing signal degradation even in complex routing configurations.

Material Properties and Durability

The aluminum construction with silver plating inner finish provides optimal electrical properties while ensuring long-term reliability. Silver plating offers superior conductivity compared to other plating materials, reducing resistive losses and maintaining signal integrity across the operating frequency range. The aluminum base material provides structural strength while maintaining lightweight characteristics essential for mobile applications. Durability testing demonstrates the waveguide's ability to withstand diverse environmental conditions, though continuous monitoring of wear patterns remains important for maintenance planning. Environmental testing includes temperature cycling, vibration resistance, and humidity exposure to ensure reliable operation across expected operating conditions. The robust construction enables operation in challenging environments while maintaining performance specifications.

Customization and OEM Services

Advanced Microwave Technologies Co., Ltd. specializes in customizing inflatable twist waveguides to meet specific application requirements. The company's engineering team works closely with customers to develop tailored solutions that address unique waveguide challenges across multiple sectors. This customization capability includes frequency band optimization, mechanical interface design, and environmental protection requirements. OEM services extend beyond basic customization to include complete system integration support. The company provides design assistance, prototyping services, and manufacturing scale-up to help customers bring their products to market efficiently. This comprehensive approach ensures that customers receive not just components, but complete solutions that integrate seamlessly into their systems.

Conclusion

Inflatable twist waveguides represent the future of lightweight signal transmission, offering unparalleled flexibility, space efficiency, and deployment advantages over traditional solutions. These innovative components address critical challenges in modern communication systems while providing the reliability and performance that demanding applications require.

Cooperate with Advanced Microwave Technologies Co., Ltd.

Advanced Microwave Technologies Co., Ltd stands as a global leader in microwave technology, bringing over 20 years of expertise to the inflatable twist waveguide market. Our comprehensive product portfolio, including waveguide assemblies, coaxial and cable assemblies, microwave antennas, and measurement systems, positions us uniquely to serve diverse industry needs from our state-of-the-art facilities equipped with measurement capabilities up to 110 GHz.

Our ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018 certifications demonstrate our commitment to quality, environmental responsibility, and workplace safety. The remarkable 24m Microwave Darkroom facility enables precise antenna measurements and optimizations that drive innovation across the microwave industry. Whether you need prototyping services, technical support, or full-scale production, our expert engineering team delivers solutions tailored to your specifications.

As a leading China Inflatable twist waveguide manufacturer, China Inflatable twist waveguide supplier, and China Inflatable twist waveguide factory, we offer competitive pricing on High Quality Inflatable twist waveguide products. Our China Inflatable twist waveguide wholesale capabilities ensure Inflatable twist waveguide for sale at competitive Inflatable twist waveguide prices. Contact craig@admicrowave.com today to discuss your specific requirements and discover how our expertise can advance your projects. Click to bookmark this guide for future reference when planning your next microwave system design.

FAQ

Q: What frequency range do inflatable twist waveguides typically support?

A: Most inflatable twist waveguides operate across specific bands, with Advanced Microwave Technologies' models covering ranges like 9.3-9.5GHz for X-band applications.

Q: How does insertion loss compare between inflatable and rigid waveguides?

A: High-quality inflatable twist waveguides achieve insertion losses as low as 0.1dB maximum, comparable to or better than many rigid waveguide systems.

Q: What are the primary weight savings compared to traditional waveguides?

A: Inflatable twist waveguides typically offer 30-50% weight reduction compared to rigid alternatives, depending on the specific application and configuration.

Q: How quickly can these waveguides be deployed in field applications?

A: Deployment time is significantly reduced, often taking minutes rather than hours required for rigid waveguide installation and alignment procedures.

References

1. "Microwave Engineering: Passive Circuits" by Peter A. Rizzi - Comprehensive coverage of waveguide theory and applications in modern microwave systems.

2. "Waveguide Handbook" by Nathan Marcuvitz - Classic reference covering fundamental principles of waveguide design and electromagnetic wave propagation.

3. "RF and Microwave Engineering: Fundamentals of Wireless Communications" by Frank Gustrau - Modern approach to microwave component design including flexible waveguide technologies.

4. "Microwave and RF Design: A Systems Approach" by Michael Steer - Systems-level perspective on microwave component integration and performance optimization.