How Do Material Choices in Waveguide Transitions Impact Long-Term Durability?

In the rapidly evolving landscape of microwave and millimeter-wave technology, waveguide transitions serve as critical components that determine system performance, reliability, and operational longevity. The selection of appropriate materials for these transitions directly influences their ability to withstand environmental stresses, maintain electrical performance, and deliver consistent results over extended operational periods. Understanding the relationship between material properties and durability becomes essential for engineers designing systems that must operate reliably in demanding applications ranging from satellite communications to high-power radar systems.The answer to how material choices impact long-term durability lies in the fundamental interaction between material properties and operational demands. Waveguide Transition durability depends primarily on thermal stability, corrosion resistance, mechanical strength, and electrical conductivity of the chosen materials. High-quality copper alloys and aluminum variants offer superior thermal management and electrical performance, while specialized coatings and treatments enhance environmental resistance. Advanced manufacturing techniques, such as those employed in water-cooled systems, further extend operational life by managing thermal stress and preventing material degradation under high-power conditions.

Key Material Properties That Determine Waveguide Transition Longevity

Thermal Conductivity and Heat Dissipation Characteristics

Thermal management represents one of the most critical factors affecting Waveguide Transition longevity in high-power applications. Materials with exceptional thermal conductivity, such as copper and its specialized alloys, provide superior heat dissipation capabilities that prevent localized hot spots and thermal stress concentrations. The thermal expansion coefficient of the selected material must also be carefully considered, as mismatched expansion rates between different components can lead to mechanical stress and eventual failure at connection points. Advanced Microwave Technologies Co., Ltd addresses these challenges through their innovative water-cooled twist waveguide design, which incorporates integrated cooling channels that allow coolant circulation to maintain optimal operating temperatures even under demanding conditions.The implementation of water-cooling systems in Waveguide Transition assemblies represents a significant advancement in thermal management technology. These systems feature precisely engineered cooling channels that facilitate efficient heat transfer from the waveguide structure to the circulating coolant, typically water. This approach enables the waveguide to maintain stable performance characteristics while handling significantly higher power levels than conventional air-cooled designs. The cooling system design must account for factors such as flow rate, coolant temperature, and pressure drop to ensure optimal performance without introducing mechanical stress or electromagnetic interference.Material selection for water-cooled Waveguide Transition systems requires careful consideration of compatibility between the base waveguide material and the cooling system components. Galvanic corrosion can occur when dissimilar metals are in contact within the cooling circuit, potentially leading to degradation and failure over time. Advanced copper alloys specifically formulated for cooling applications offer excellent thermal conductivity while providing enhanced corrosion resistance. These materials often incorporate small amounts of silver or other elements that improve both electrical and thermal performance while maintaining long-term stability in wet environments.

Corrosion Resistance and Environmental Stability

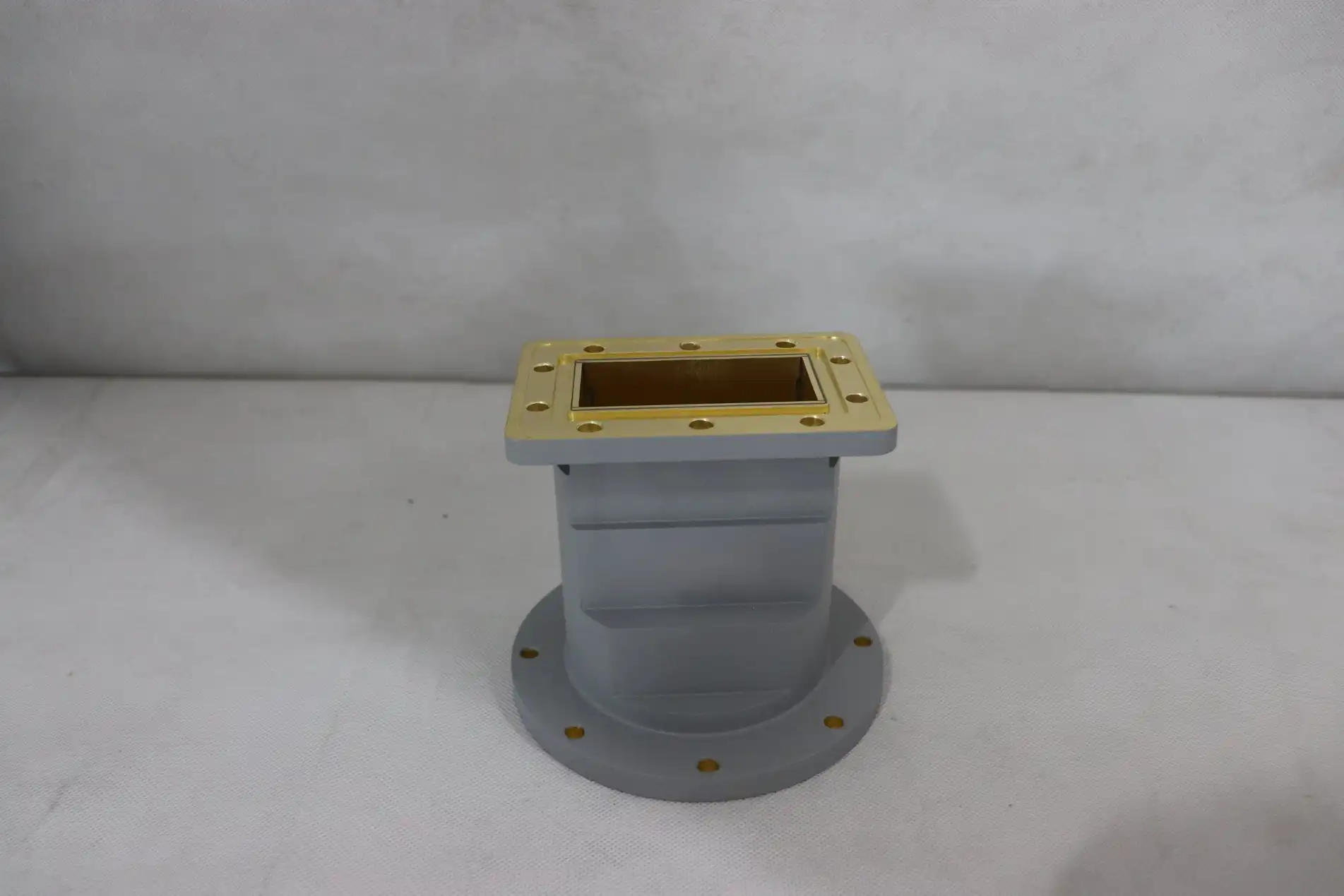

Environmental factors play a crucial role in determining the long-term reliability of Waveguide Transition systems, making corrosion resistance a primary consideration in material selection. Atmospheric exposure, humidity, salt spray, and chemical contaminants can all contribute to material degradation over time. Copper-based materials, while offering excellent electrical properties, require appropriate protective treatments or alloying elements to prevent oxidation and corrosion in challenging environments. Specialized surface treatments, such as silver plating or gold plating, provide additional protection while maintaining optimal electrical conductivity at critical interfaces.The selection of corrosion-resistant materials becomes particularly important in marine, coastal, or industrial environments where aggressive atmospheric conditions accelerate material degradation. Advanced aluminum alloys offer an attractive alternative to copper in many applications, providing good electrical conductivity combined with natural corrosion resistance through the formation of protective oxide layers. However, the choice between aluminum and copper alloys for Waveguide Transition applications must consider factors beyond corrosion resistance, including electrical performance requirements, mechanical properties, and thermal characteristics.Modern Waveguide Transition designs often incorporate multiple material systems optimized for specific performance requirements. For example, the main waveguide body might utilize copper alloy for optimal electrical performance, while flanges and mounting hardware employ stainless steel or specialized alloys for enhanced mechanical strength and corrosion resistance. This multi-material approach requires careful attention to interface design and protection to prevent galvanic corrosion while maintaining electrical continuity and mechanical integrity. Advanced Microwave Technologies Co., Ltd leverages over 20 years of experience in microwave component design to optimize these material combinations for maximum durability and performance.

Mechanical Strength and Structural Integrity

The mechanical properties of materials used in Waveguide Transition construction directly impact their ability to withstand operational stresses, vibration, and thermal cycling without degradation. High-strength copper alloys provide the necessary structural integrity to maintain precise dimensional tolerances essential for optimal electromagnetic performance while resisting deformation under mechanical stress. The material's fatigue resistance becomes particularly important in applications involving thermal cycling or mechanical vibration, where repeated stress cycles can lead to crack initiation and propagation over time.Precision manufacturing techniques employed in modern Waveguide Transition production ensure that material properties are optimized throughout the component structure. Advanced machining processes, combined with appropriate heat treatment procedures, can enhance the mechanical properties of base materials while maintaining dimensional accuracy. The integration of cooling systems adds complexity to the mechanical design, requiring materials that can accommodate the additional stresses associated with thermal expansion differences between the waveguide structure and cooling system components.The long-term mechanical stability of Waveguide Transition assemblies depends not only on the base material properties but also on the quality of joints, connections, and interfaces. Welded, brazed, or mechanically fastened connections must be designed to accommodate thermal expansion while maintaining electrical continuity and structural integrity. Advanced Microwave Technologies Co., Ltd employs sophisticated joining techniques that ensure robust connections capable of withstanding operational stresses while minimizing the introduction of electromagnetic discontinuities that could degrade system performance.

Advanced Manufacturing Techniques for Enhanced Durability

Precision Machining and Surface Treatment Technologies

Modern Waveguide Transition manufacturing relies heavily on precision machining techniques that ensure dimensional accuracy while optimizing material properties for long-term durability. Computer-controlled machining centers enable the production of complex waveguide geometries with tight tolerances essential for optimal electromagnetic performance. The machining process itself can influence material properties, with proper cutting parameters and tool selection minimizing work hardening and residual stress that could affect long-term reliability. Advanced surface finishing techniques further enhance performance by reducing surface roughness and improving electrical conductivity at critical interfaces.Surface treatment technologies play a crucial role in extending the operational life of Waveguide Transition components by providing protective barriers against environmental degradation while maintaining optimal electrical properties. Electroplating processes using silver, gold, or specialized alloys create uniform protective coatings that prevent oxidation and corrosion while providing excellent electrical conductivity. The thickness and uniformity of these coatings must be carefully controlled to ensure consistent performance and long-term adhesion to the base material.Quality control procedures throughout the manufacturing process ensure that each Waveguide Transition component meets stringent performance and durability requirements. Advanced Microwave Technologies Co., Ltd maintains ISO 9001:2015 certification, demonstrating their commitment to quality management systems that ensure consistent product quality. Their state-of-the-art 24m Microwave Darkroom facility enables comprehensive testing of waveguide components across the frequency range from 0.5 to 110 GHz, validating both electrical performance and long-term reliability characteristics.

Integrated Cooling System Design and Implementation

The integration of cooling systems into Waveguide Transition designs represents a significant advancement in thermal management technology that directly impacts long-term durability. Water-cooled twist waveguides incorporate sophisticated cooling channel designs that maximize heat transfer efficiency while minimizing pressure drop and flow restrictions. The cooling channel geometry must be optimized to ensure uniform temperature distribution throughout the waveguide structure, preventing localized hot spots that could lead to material degradation or performance drift over time.Material compatibility between the waveguide structure and cooling system components requires careful consideration to prevent galvanic corrosion and ensure long-term reliability. The cooling circuit design must accommodate thermal expansion differences between various materials while maintaining leak-tight integrity throughout the operational temperature range. Advanced sealing technologies and joint designs ensure that the cooling system remains reliable over extended operational periods without requiring frequent maintenance or component replacement.The implementation of Waveguide Transition cooling systems also involves sophisticated control and monitoring capabilities that optimize performance while protecting against thermal damage. Temperature sensors and flow monitoring systems provide real-time feedback on cooling system performance, enabling automated adjustments to maintain optimal operating conditions. This level of system integration ensures that the cooling system enhances rather than compromises the long-term reliability of the waveguide transition assembly.

Quality Assurance and Testing Protocols

Comprehensive testing protocols validate the long-term durability characteristics of Waveguide Transition components before deployment in critical applications. Environmental testing procedures subject components to accelerated aging conditions that simulate years of operational exposure in compressed timeframes. These tests include thermal cycling, humidity exposure, salt spray testing, and vibration testing that evaluate material performance under various stress conditions. The results of these tests inform material selection decisions and manufacturing process optimization to ensure maximum durability in real-world applications.Electrical performance testing throughout the component lifecycle provides valuable data on how material choices affect long-term stability. Advanced measurement systems capable of operating across the full frequency range from 0.5 to 110 GHz enable detailed characterization of Waveguide Transition performance parameters including insertion loss, return loss, and phase stability. These measurements are repeated after various environmental exposures to quantify any performance degradation and validate the effectiveness of material selection and protective treatments.Advanced Microwave Technologies Co., Ltd leverages their extensive testing capabilities to continuously improve material selection and manufacturing processes. Their laboratories equipped with advanced microwave measurement equipment up to 110 GHz enable comprehensive characterization of component performance under various operating conditions. This testing capability, combined with over 20 years of experience in microwave component design and manufacturing, ensures that their Waveguide Transition products deliver exceptional long-term reliability and performance stability.

Material Selection Strategies for Specific Applications

High-Power Radar and Defense Applications

Defense and aerospace applications place extraordinary demands on Waveguide Transition components, requiring materials that can withstand high power levels, extreme environmental conditions, and extended operational periods without degradation. Military specifications often require components to operate reliably in temperature ranges from -55°C to +125°C while maintaining precise electrical performance characteristics. Material selection for these applications typically focuses on high-strength copper alloys or specialized materials that provide optimal combinations of electrical conductivity, thermal management, and mechanical durability.The demanding nature of radar applications requires Waveguide Transition components that can handle peak power levels often exceeding several kilowatts while maintaining low insertion loss and excellent return loss characteristics. Water-cooled designs become essential in these applications, with cooling system materials selected for compatibility with the base waveguide materials and long-term reliability under thermal stress. Advanced Microwave Technologies Co., Ltd designs their water-cooled twist waveguides specifically for these demanding applications, incorporating materials and manufacturing techniques optimized for high-power operation.Reliability requirements for defense applications often mandate component lifespans measured in decades rather than years, necessitating material selection strategies that prioritize long-term stability over initial cost considerations. This approach involves selecting materials with proven track records in similar applications, implementing comprehensive accelerated aging test programs, and establishing maintenance protocols that ensure continued reliability throughout the component lifecycle. The integration of diagnostic capabilities enables monitoring of component health and prediction of maintenance requirements before performance degradation occurs.

Satellite Communication and Space Applications

Space-based applications impose unique material requirements on Waveguide Transition components due to the extreme environmental conditions and impossibility of routine maintenance once deployed. Materials must withstand thermal cycling between extreme hot and cold temperatures, radiation exposure, and vacuum conditions while maintaining precise electrical performance characteristics. The material selection process for space applications involves extensive qualification testing and heritage considerations that prioritize proven materials with documented space flight experience.The thermal environment in space applications creates significant challenges for Waveguide Transition design, with components experiencing rapid temperature transitions between sunlight and shadow conditions. Materials must exhibit minimal thermal expansion and excellent dimensional stability to maintain electrical performance throughout these thermal cycles. Specialized copper alloys with controlled thermal expansion characteristics or composite materials may be employed to minimize thermal stress and maintain precise dimensional tolerances essential for optimal electromagnetic performance.Outgassing characteristics become a critical consideration for space applications, as volatile materials can contaminate sensitive optical systems or solar panels. Material selection for space-qualified Waveguide Transition components requires adherence to strict outgassing limits defined by NASA specifications. This requirement often necessitates special material processing or surface treatments that eliminate volatile compounds while maintaining optimal electrical and mechanical properties. Advanced Microwave Technologies Co., Ltd incorporates these specialized requirements into their design and manufacturing processes for space-qualified components.

Commercial Telecommunications Infrastructure

Commercial telecommunications applications require Waveguide Transition components that balance performance, reliability, and cost-effectiveness for deployment in large-scale infrastructure projects. Material selection for these applications must consider factors such as manufacturing cost, availability, and standardization while maintaining adequate performance and reliability characteristics. Copper alloys remain the preferred choice for most commercial applications due to their excellent electrical properties and well-established manufacturing processes.The deployment environment for telecommunications infrastructure varies widely, from urban environments with moderate conditions to remote locations with extreme weather exposure. Waveguide Transition materials must be selected to provide adequate environmental protection while minimizing maintenance requirements throughout the component lifecycle. Protective coatings and treatments become essential for ensuring long-term reliability in coastal environments where salt spray exposure accelerates corrosion processes.Standardization requirements in telecommunications applications often dictate specific material choices and manufacturing processes to ensure compatibility between components from different suppliers. This standardization extends to interface specifications, dimensional tolerances, and electrical performance requirements that must be maintained throughout the component lifecycle. Advanced Microwave Technologies Co., Ltd designs their Waveguide Transition products to meet or exceed relevant industry standards while providing enhanced durability characteristics that reduce total cost of ownership for telecommunications operators.

Conclusion

Material selection for waveguide transitions fundamentally determines long-term system reliability, performance stability, and operational cost-effectiveness. The careful balance of thermal management, corrosion resistance, and mechanical integrity ensures optimal durability across diverse applications. Advanced manufacturing techniques, including integrated cooling systems and precision surface treatments, significantly extend component lifespans while maintaining superior electrical performance characteristics throughout demanding operational environments.

Ready to enhance your microwave system's reliability and performance? At Advanced Microwave Technologies Co., Ltd., we bring over 20 years of expertise in delivering cutting-edge waveguide solutions tailored to your specific requirements. Our ISO-certified manufacturing processes, state-of-the-art 24m Microwave Darkroom testing facility, and comprehensive OEM services ensure your project receives the highest quality components with fast delivery and competitive pricing. Whether you need prototyping, custom designs, or full-scale production, our expert technical team provides complete support from concept to deployment. Contact us today at craig@admicrowave.com to discuss how our advanced waveguide transition solutions can optimize your system's long-term durability and performance.

References

1.Johnson, R.C., and Jasik, H., "Antenna Engineering Handbook: Third Edition," McGraw-Hill Professional, 1993, Chapter 15: Waveguide Components and Material Selection.

2.Pozar, D.M., "Microwave Engineering: Fourth Edition," John Wiley & Sons, 2012, Section 8.3: Material Properties in Waveguide Design.

3.Collin, R.E., "Foundations for Microwave Engineering: Second Edition," IEEE Press, 2001, Chapter 4: Waveguide Materials and Thermal Considerations.

4.Ramo, S., Whinnery, J.R., and Van Duzer, T., "Fields and Waves in Communication Electronics: Third Edition," John Wiley & Sons, 1994, Chapter 9: Material Selection for Long-Term Reliability.

5.Sorrentino, R., and Bianchi, G., "Microwave and RF Engineering," John Wiley & Sons, 2010, Section 12.4: Environmental Effects on Waveguide Component Durability.

6.Montgomery, C.G., Dicke, R.H., and Purcell, E.M., "Principles of Microwave Circuits: Radiation Laboratory Series Volume 8," Institution of Engineering and Technology, 1987, Chapter 6: Material Considerations in Waveguide Transition Design.