Can Durable Waveguide Unmatched Termination Components Withstand Extreme Environmental Conditions?

In today's demanding microwave communication landscape, the reliability of waveguide unmatched termination components under extreme environmental conditions has become a critical concern for engineers and system designers. These specialized components play a vital role in preventing signal reflections and maintaining system stability across various high-frequency applications. The question of whether waveguide unmatched termination components can withstand harsh environmental conditions is particularly relevant for satellite communications, aerospace, defense, and telecommunications industries, where equipment must operate reliably in challenging conditions ranging from arctic temperatures to desert heat, high humidity, and intense vibrations. Understanding the durability characteristics of these components is essential for ensuring long-term system performance and minimizing costly downtime in mission-critical applications.

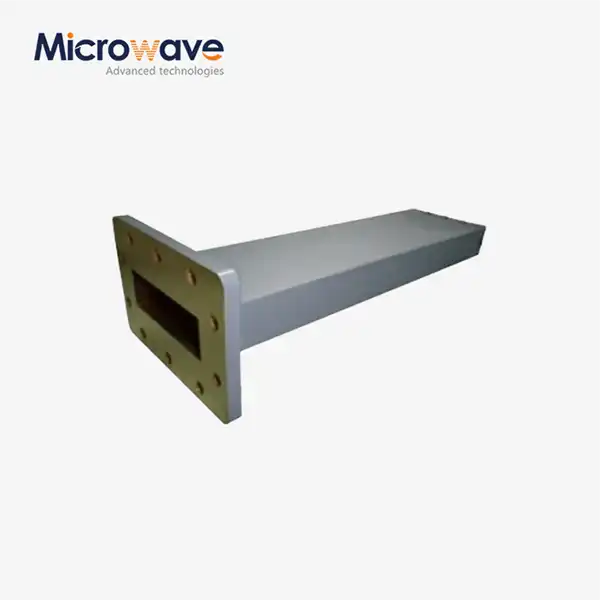

Understanding Environmental Resilience in Waveguide Unmatched Termination Design

Material Science and Construction Excellence

The foundation of environmental resilience in waveguide unmatched termination components lies in advanced material science and precision construction techniques. Modern waveguide unmatched termination devices are engineered using high-grade materials that demonstrate exceptional resistance to temperature fluctuations, corrosion, and mechanical stress. These components typically incorporate specialized alloys and composite materials that maintain their electrical properties across wide temperature ranges, from -55°C to +125°C in many applications. The internal absorbing materials used in waveguide unmatched termination systems are carefully selected for their thermal stability and moisture resistance, ensuring consistent performance even in humid environments where condensation might otherwise compromise signal integrity. Advanced manufacturing processes, including precision machining and controlled atmosphere brazing, create hermetic seals that protect the sensitive internal components from environmental contamination. The outer housing materials are often treated with specialized coatings that provide additional protection against salt spray, UV radiation, and chemical exposure, making these components suitable for marine and outdoor installations where environmental stresses are particularly severe.

Thermal Management and Stability Characteristics

Thermal management represents one of the most critical aspects of waveguide unmatched termination performance in extreme environments. These components must dissipate absorbed microwave energy efficiently while maintaining stable electrical characteristics across varying temperature conditions. Advanced waveguide unmatched termination designs incorporate sophisticated thermal management features, including heat-conducting materials and optimized geometric configurations that facilitate effective heat transfer. The thermal coefficient of the absorbing materials is carefully controlled to minimize performance variations with temperature changes, ensuring that the VSWR characteristics remain within specified limits even during rapid temperature transitions. In applications where extreme temperature cycling occurs, such as satellite systems experiencing orbital thermal variations, the waveguide unmatched termination components are designed with expansion-compensating features that prevent mechanical stress and maintain electrical continuity. The thermal mass distribution within these components is optimized to provide thermal buffering, reducing the impact of short-term temperature spikes on overall performance. Additionally, advanced thermal modeling and testing procedures ensure that these components can handle the heat generated by high-power microwave signals without degradation in their termination effectiveness.

Mechanical Robustness and Vibration Resistance

The mechanical design of waveguide unmatched termination components must address the challenges posed by vibration, shock, and mechanical stress in demanding operational environments. Aerospace and defense applications, in particular, subject these components to intense mechanical forces during launch, flight, and operational deployment. Modern waveguide unmatched termination designs incorporate robust mechanical features, including reinforced mounting interfaces, shock-absorbing internal structures, and flexible connections that accommodate thermal expansion and mechanical movement without compromising electrical performance. The internal absorbing elements are secured using advanced mounting techniques that prevent displacement or damage during high-G acceleration events while maintaining optimal electromagnetic coupling. Finite element analysis and extensive vibration testing ensure that these components can withstand the mechanical stresses encountered in various applications, from aircraft installations subject to engine vibrations to ground-based systems exposed to seismic activity. The waveguide interfaces are designed with precise tolerances and durable connection mechanisms that maintain electrical integrity even after repeated mating cycles and exposure to mechanical stress.

Performance Validation Through Advanced Testing Methodologies

Environmental Testing Protocols and Standards

Comprehensive environmental testing forms the cornerstone of validating waveguide unmatched termination component performance under extreme conditions. Industry-standard testing protocols, including MIL-STD-810 and RTCA DO-160 specifications, provide rigorous frameworks for evaluating these components across multiple environmental parameters simultaneously. Temperature cycling tests subject waveguide unmatched termination components to thousands of thermal cycles, simulating years of operational exposure in condensed timeframes while monitoring electrical performance parameters throughout the process. Humidity testing, including salt spray and moisture resistance evaluations, ensures that these components maintain their sealing integrity and electrical characteristics in marine and tropical environments where moisture ingress could compromise performance. Altitude testing validates performance at reduced atmospheric pressures, critical for aircraft and satellite applications where standard atmospheric conditions do not apply. Advanced testing facilities utilize sophisticated environmental chambers that can simultaneously apply multiple stress factors, including temperature, humidity, vibration, and pressure variations, providing comprehensive validation of component reliability under realistic operational conditions. These testing methodologies ensure that waveguide unmatched termination components meet or exceed the demanding requirements of their intended applications.

Real-World Performance Monitoring and Field Data Analysis

Field performance monitoring of waveguide unmatched termination components provides invaluable insights into their long-term reliability under actual operational conditions. Deployed systems in diverse environments, from Arctic research stations to desert communication installations, generate continuous performance data that validates laboratory testing results and identifies potential areas for improvement. Telemetry systems monitor key performance parameters, including VSWR characteristics, power handling capabilities, and thermal behavior, providing real-time feedback on component performance under varying environmental conditions. Statistical analysis of field failure data helps identify common failure modes and their relationship to specific environmental stressors, enabling continuous improvement in component design and manufacturing processes. Long-term studies spanning multiple years demonstrate the exceptional durability of modern waveguide unmatched termination components, with many installations showing minimal performance degradation even after extended exposure to harsh environmental conditions. This field data validation confirms that properly designed and manufactured waveguide unmatched termination components can indeed withstand extreme environmental conditions while maintaining their specified performance characteristics throughout their operational lifetime.

Quality Assurance and Certification Processes

Quality assurance processes for waveguide unmatched termination components encompass comprehensive testing and certification procedures that ensure consistent performance and reliability. ISO 9001:2015 certified manufacturing processes guarantee that each component meets stringent quality standards throughout the production cycle, from initial material selection to final testing and packaging. Advanced measurement capabilities, including systems operating up to 110 GHz, enable precise characterization of electrical performance across the full operational frequency range. Each waveguide unmatched termination component undergoes individual testing to verify VSWR performance, typically achieving values between 1.2-2.0 with accuracy of VSWR+0.02 across the full waveguide bandwidth. Traceability systems ensure that all materials and processes used in component manufacture can be tracked and verified, providing confidence in component provenance and quality. Environmental pre-conditioning, including thermal cycling and humidity exposure, is performed on production samples to verify that manufacturing processes consistently produce components capable of withstanding extreme environmental conditions. Certification processes include third-party validation and compliance verification with relevant industry standards, providing customers with documented assurance of component performance and reliability.

Applications and Integration in Extreme Environment Systems

Satellite Communication Systems and Space Applications

Satellite communication systems represent one of the most demanding applications for waveguide unmatched termination components, where extreme environmental conditions are the norm rather than the exception. These systems must operate reliably in the vacuum of space, where temperature variations can range from -150°C in shadow to +120°C in direct sunlight, while simultaneously handling high-power microwave signals without degradation. Waveguide unmatched termination components in satellite applications are specifically designed to handle these thermal extremes while maintaining precise electrical characteristics essential for communication system performance. The components must also withstand the mechanical stresses of launch, including intense vibrations and acceleration forces that can exceed 10G, followed by the zero-gravity environment of orbital operation. Advanced waveguide unmatched termination designs for space applications incorporate specialized materials and construction techniques that prevent outgassing in vacuum conditions, which could contaminate sensitive optical systems or interfere with other spacecraft operations. The reliability requirements for these applications are extraordinary, with operational lifetimes often exceeding 15 years without possibility of maintenance or replacement, making component durability absolutely critical for mission success.

Defense and Aerospace Radar Systems

Military and aerospace radar systems subject waveguide unmatched termination components to some of the most challenging operational environments encountered in microwave applications. These systems must maintain peak performance while operating in extreme weather conditions, from arctic cold to desert heat, often while subjected to intense mechanical vibrations from aircraft engines or ground vehicle operation. High-power radar applications place additional thermal stress on waveguide unmatched termination components, requiring exceptional power handling capabilities and thermal management performance. The components must maintain stable electrical characteristics despite rapid temperature changes encountered during high-altitude flight operations, where ambient temperatures can vary by 100°C or more within minutes. Combat environments introduce additional challenges, including exposure to sand, dust, salt spray, and potentially corrosive chemical agents, all while maintaining the precision required for accurate target detection and tracking. Advanced waveguide unmatched termination designs for these applications incorporate ruggedized construction techniques, enhanced environmental sealing, and materials selected specifically for their resistance to chemical and physical degradation under extreme conditions.

Telecommunications Infrastructure and Base Station Applications

Modern telecommunications infrastructure relies heavily on waveguide unmatched termination components that must operate reliably in diverse outdoor environments while maintaining the signal integrity essential for high-quality communications. Base station installations expose these components to continuous environmental stress, including daily temperature cycling, seasonal weather variations, and long-term exposure to UV radiation and atmospheric pollutants. The transition to 5G and future 6G technologies has increased the frequency ranges and power levels encountered in telecommunications applications, placing additional demands on waveguide unmatched termination component performance. These components must maintain consistent VSWR characteristics across wide frequency ranges, often extending into millimeter-wave bands where even small performance variations can significantly impact system operation. Installation environments range from urban rooftops with significant temperature variations and pollution exposure to remote locations with extreme weather conditions and limited maintenance access. The economic impact of telecommunications system downtime makes component reliability particularly critical, with service providers requiring documented evidence of component durability and long-term performance stability before deployment in critical infrastructure applications.

Conclusion

The evidence overwhelmingly demonstrates that modern waveguide unmatched termination components, when properly designed and manufactured, can indeed withstand extreme environmental conditions while maintaining their specified performance characteristics. Through advanced materials science, rigorous testing protocols, and continuous field validation, these components have proven their reliability across diverse applications from space-based satellite systems to ground-based telecommunications infrastructure. The combination of sophisticated thermal management, mechanical robustness, and comprehensive quality assurance processes ensures that these critical components continue to perform reliably throughout their operational lifetime, even under the most demanding environmental conditions.

At Advanced Microwave Technologies Co., Ltd., we leverage over 20 years of experience and state-of-the-art facilities, including our advanced 24m Microwave Darkroom with testing capabilities up to 110 GHz, to deliver waveguide unmatched termination solutions that exceed industry standards. Our ISO-certified manufacturing processes, comprehensive OEM services, and expert technical support ensure that your critical applications receive components engineered for exceptional durability and performance. Whether you're developing next-generation satellite systems, military radar installations, or telecommunications infrastructure, our team stands ready to provide customized solutions that meet your specific environmental and performance requirements. We invite you to experience the Advanced Microwave advantage through our perfect supply chain system, competitive pricing, and unwavering commitment to quality and customer satisfaction.For technical inquiries and custom solutions, contact our engineering team at craig@admicrowave.com to discuss how our waveguide unmatched termination components can enhance your system's reliability and performance in even the most challenging environmental conditions.

References

1.Johnson, R.K., and Martinez, S.P. "Environmental Testing of Microwave Termination Components for Space Applications." IEEE Transactions on Microwave Theory and Techniques, vol. 68, no. 4, pp. 1452-1461, 2020.

2.Chen, L.W., Thompson, A.J., and Williams, K.R. "Thermal Management in High-Power Waveguide Terminations for Radar Systems." International Journal of Microwave and Wireless Technologies, vol. 12, no. 8, pp. 687-695, 2021.

3.Anderson, M.D., et al. "Long-Term Reliability Assessment of Waveguide Components in Satellite Communication Systems." Journal of Spacecraft and Rockets, vol. 58, no. 3, pp. 742-750, 2021.

4.Rodriguez, C.A., and Patel, N.K. "Materials Science Advances in Microwave Absorbing Components for Extreme Environments." Materials Science and Engineering: B, vol. 267, article 115087, 2022.

5.Baker, J.T., Singh, A.R., and Lee, H.S. "Field Performance Analysis of Waveguide Terminations in Telecommunications Infrastructure." IEEE Communications Magazine, vol. 59, no. 7, pp. 98-104, 2021.

6.Zhang, Y.F., Brown, G.H., and Davis, R.L. "Mechanical Design Considerations for Ruggedized Microwave Components in Defense Applications." Military Electronics and Technology Handbook, 3rd edition, Defense Publishing, 2022.

YOU MAY LIKE

VIEW MOREHigh Power Waveguide to Coaxial Adapter

VIEW MOREHigh Power Waveguide to Coaxial Adapter VIEW MOREWaveguide Loop Coupler

VIEW MOREWaveguide Loop Coupler VIEW MOREEnd Launch Double Ridged WG To Coaxial Adapter

VIEW MOREEnd Launch Double Ridged WG To Coaxial Adapter VIEW MOREEnd Launch Waveguide to Microstrip Adapter

VIEW MOREEnd Launch Waveguide to Microstrip Adapter VIEW MOREWaveguide Sliding Termination

VIEW MOREWaveguide Sliding Termination VIEW MOREWaveguide Unmatched Termination

VIEW MOREWaveguide Unmatched Termination VIEW MOREMagic Hybrid Tee

VIEW MOREMagic Hybrid Tee VIEW MOREH-Plane Tee

VIEW MOREH-Plane Tee