How Can OEM Services Optimize Your Use of Waveguide Termination?

In today's rapidly evolving microwave technology landscape, the optimization of waveguide termination systems has become crucial for achieving superior performance in satellite communications, defense applications, and aerospace systems. Professional OEM services play a pivotal role in maximizing the efficiency and reliability of waveguide termination solutions by providing customized designs, advanced manufacturing capabilities, and comprehensive technical support. This comprehensive guide explores how specialized OEM services can transform your waveguide termination applications, ensuring optimal signal quality, reduced interference, and enhanced system performance across diverse industrial applications. OEM services for Waveguide Termination represent a strategic approach to achieving superior microwave system performance through customized solutions tailored to specific application requirements. These specialized services combine advanced engineering expertise with precision manufacturing capabilities to deliver termination systems that exceed standard performance parameters. By leveraging professional OEM partnerships, organizations can access cutting-edge termination technologies that provide minimal signal reflection, enhanced power handling capabilities, and exceptional durability across challenging operational environments. The integration of customized waveguide termination solutions through OEM services enables businesses to achieve optimal system efficiency while maintaining cost-effectiveness and meeting stringent industry standards.

Custom Design Solutions for Enhanced Waveguide Termination Performance

Precision Engineering for Application-Specific Requirements

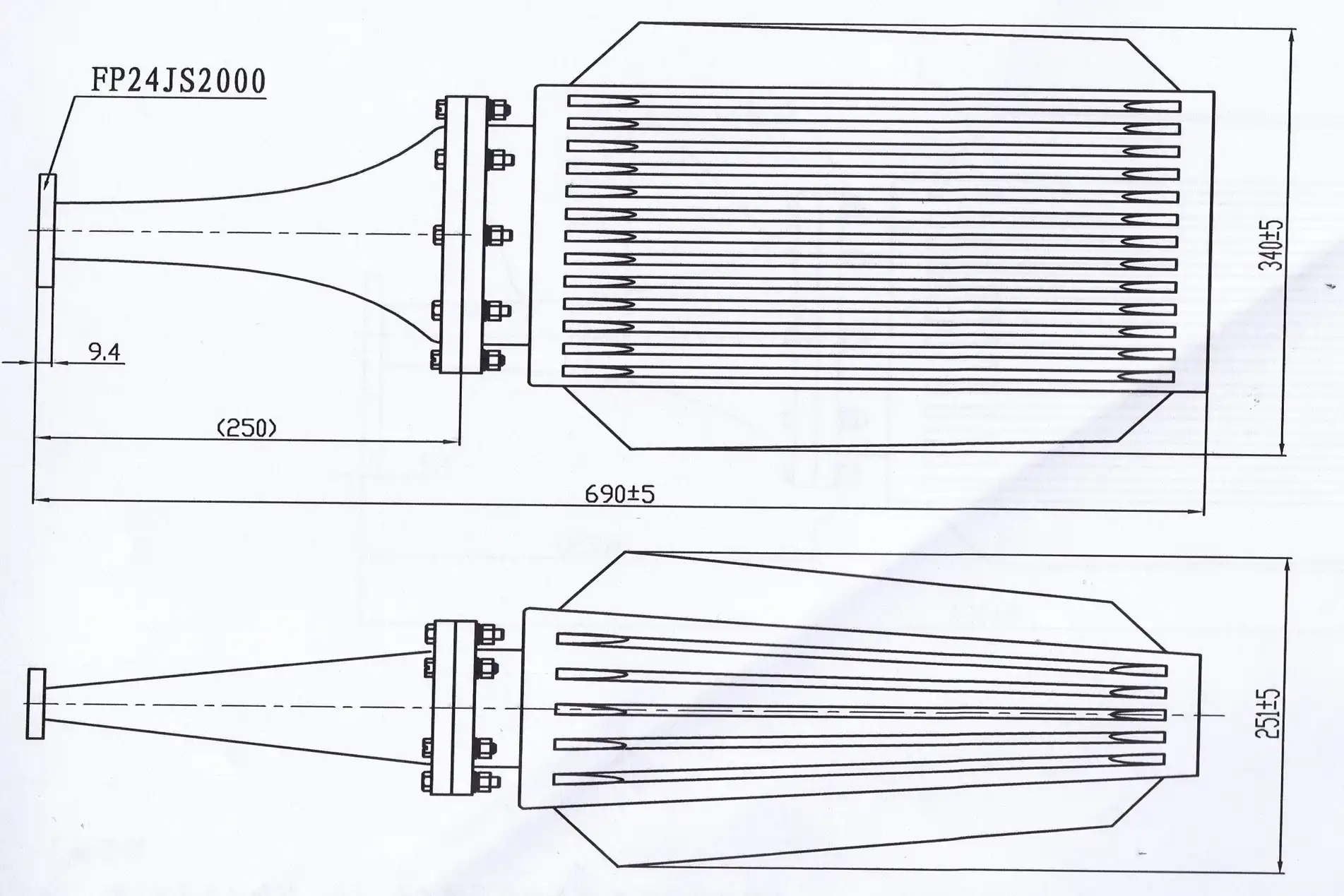

The foundation of optimized Waveguide Termination performance lies in precision engineering that addresses specific application requirements with meticulous attention to detail. Professional OEM services begin with comprehensive analysis of operational parameters, including frequency ranges, power handling requirements, environmental conditions, and integration specifications. Advanced Microwave Technologies Co., Ltd.'s engineering team utilizes state-of-the-art design software and simulation tools to create termination solutions that deliver exceptional performance across diverse applications. The precision conical load elements employed in their standard product line demonstrate the importance of advanced engineering in achieving optimum electrical performance, with VSWR specifications maintained at less than 1.05 over the full waveguide bandwidth. This level of precision ensures that custom-designed termination systems provide superior signal absorption while minimizing unwanted reflections that could compromise system performance. The engineering process incorporates advanced materials selection, thermal analysis, and electromagnetic modeling to create termination solutions that exceed conventional performance standards while maintaining reliability in demanding operational environments.

Advanced Materials and Manufacturing Techniques

The optimization of Waveguide Termination systems through OEM services heavily relies on the selection and implementation of advanced materials and manufacturing techniques that enhance performance characteristics. High-grade materials such as aluminum and copper are strategically selected for their superior electrical conductivity, thermal stability, and mechanical durability, ensuring consistent performance across wide temperature ranges and challenging environmental conditions. Advanced manufacturing processes, including precision machining, specialized coating applications, and quality-controlled assembly procedures, contribute to the exceptional reliability and longevity of custom termination systems. The integration of advanced materials science with sophisticated manufacturing techniques enables the creation of termination solutions that handle power ratings up to 500W while maintaining minimal insertion loss and superior thermal management. These manufacturing capabilities ensure that each custom termination system meets or exceeds specified performance requirements while providing the durability necessary for long-term operational success in critical applications such as satellite communications, radar systems, and aerospace applications.

Frequency Range Optimization and Bandwidth Management

Effective Waveguide Termination optimization through OEM services requires sophisticated frequency range management and bandwidth optimization strategies that address the diverse requirements of modern microwave applications. Professional OEM providers leverage advanced measurement capabilities, including facilities equipped with measurement equipment up to 110 GHz, to ensure that custom termination solutions deliver optimal performance across specified frequency ranges. The ability to support frequencies from DC to 110 GHz demonstrates the versatility and technical capabilities required for comprehensive frequency optimization. Advanced frequency analysis and optimization techniques enable the development of termination systems that maintain consistent performance characteristics across wide bandwidths while providing the flexibility necessary for multi-frequency applications. This comprehensive approach to frequency management ensures that custom termination solutions can effectively serve diverse applications, from legacy communication systems operating at lower frequencies to cutting-edge 5G and future 6G technologies that require high-frequency performance capabilities.

Technical Excellence Through Specialized Manufacturing Capabilities

Quality Control and Standards Compliance

The achievement of superior Waveguide Termination performance through OEM services requires rigorous quality control processes and adherence to international standards that ensure consistent product excellence. ISO 9001:2015 certification demonstrates the commitment to comprehensive quality management systems that encompass every aspect of the manufacturing process, from initial design through final delivery and after-sales support. Advanced quality control procedures include precision measurement protocols, environmental testing, and performance verification that guarantee each termination system meets specified requirements before delivery. The implementation of ISO 14001:2015 environmental management standards ensures that manufacturing processes minimize ecological impact while maintaining production excellence. Additionally, ISO 45001:2018 occupational health and safety standards create a work environment that promotes both employee well-being and product quality. These comprehensive quality control measures, combined with RoHS compliance requirements, ensure that custom termination solutions meet international standards while providing the reliability and performance characteristics required for critical applications in satellite communications, defense systems, and aerospace applications.

Advanced Testing and Measurement Facilities

The optimization of Waveguide Termination systems through specialized OEM services relies heavily on advanced testing and measurement capabilities that provide comprehensive performance verification and optimization data. The 24m Microwave Darkroom facility represents a pinnacle of measurement technology, providing unrivaled space for precise antenna and termination system analysis. This state-of-the-art facility enables meticulous observation and analysis of far-field behavior, which is indispensable for applications requiring signals to travel vast distances without degradation. The Antenna Plane Near and Far Field Measuring Recombination Chamber functions as the nerve center of the testing facility, allowing expert teams to transition fluidly between near and far field measurements while extracting granular details about radiation patterns, gain, and impedance characteristics. The comprehensive test frequency range spanning 0.5 to 110GHz accommodates everything from legacy communication systems to bleeding-edge technologies, ensuring that custom termination solutions are thoroughly validated across their operational spectrum. These advanced measurement capabilities enable the optimization of termination systems for peak performance while providing the data necessary for continuous improvement and refinement of design parameters.

Rapid Prototyping and Development Cycles

Efficient Waveguide Termination optimization through OEM services requires rapid prototyping capabilities and streamlined development cycles that accelerate time-to-market while maintaining quality standards. Advanced prototyping facilities enable quick turnaround on prototype development, allowing for comprehensive testing and evaluation before full-scale production commitments. This approach provides valuable opportunities for performance optimization, design refinement, and specification validation that ensure final products meet or exceed performance expectations. The integration of advanced manufacturing technologies with experienced engineering teams enables rapid iteration and improvement cycles that optimize termination system performance while minimizing development time and costs. Comprehensive prototype testing programs utilize the full range of measurement capabilities to validate performance characteristics across operational parameters, ensuring that production systems will deliver consistent performance in their intended applications. The ability to rapidly develop and test prototypes provides significant advantages in competitive markets while ensuring that custom termination solutions are thoroughly optimized before production implementation.

Comprehensive Support Services and Long-Term Partnership Benefits

Technical Support and Installation Guidance

The successful implementation of optimized Waveguide Termination systems through OEM services requires comprehensive technical support and installation guidance that ensures proper integration and optimal performance. Expert engineering teams provide in-depth technical assistance that includes detailed installation procedures, system integration recommendations, and troubleshooting support that addresses potential challenges before they impact system performance. Comprehensive technical documentation, including detailed specifications, installation guides, and maintenance procedures, ensures that end users have access to the information necessary for successful implementation and long-term operation. The provision of specialized technical support extends beyond initial installation to include ongoing consultation services that help optimize system performance as operational requirements evolve. This comprehensive support approach ensures that custom termination solutions continue to deliver optimal performance throughout their operational lifetime while providing the technical expertise necessary for system modifications or upgrades. The combination of expert technical support with high-quality products creates a partnership approach that maximizes the value and performance of waveguide termination investments.

Scalable Production and Delivery Capabilities

Effective Waveguide Termination optimization through OEM services requires scalable production capabilities and efficient delivery systems that accommodate diverse order quantities while maintaining quality standards and delivery schedules. Flexible production systems enable accommodation of both large-scale production runs and smaller specialized orders with consistent quality and performance characteristics. Advanced production planning and inventory management systems ensure that delivery schedules are maintained while providing the flexibility necessary to respond to changing requirements or urgent delivery needs. The integration of efficient manufacturing processes with comprehensive supply chain management enables quick turnaround times that support project schedules and minimize system downtime. Quality control procedures are maintained across all production scales, ensuring that both large and small orders receive the same attention to detail and performance verification. This scalable approach to production and delivery provides significant advantages for organizations with varying order requirements while ensuring consistent product quality and reliable delivery performance.

Long-Term Partnership and Continuous Improvement

The optimization of Waveguide Termination systems through OEM services extends beyond initial product delivery to encompass long-term partnership relationships that provide ongoing value and continuous improvement opportunities. Established partnerships enable ongoing collaboration on system optimization, performance enhancement, and technology advancement that keeps termination systems at the forefront of industry capabilities. Regular performance reviews and system assessments provide opportunities for optimization and improvement that enhance system performance while extending operational lifetime. The development of long-term partnerships also provides access to emerging technologies and advanced capabilities that may benefit existing systems or future requirements. Continuous improvement programs leverage operational data and performance feedback to refine design parameters and manufacturing processes, ensuring that termination systems continue to deliver optimal performance as technology advances. This partnership approach creates lasting value that extends far beyond initial product delivery while providing the foundation for ongoing success in demanding microwave applications.

Conclusion

OEM services represent a transformative approach to waveguide termination optimization, combining advanced engineering expertise with precision manufacturing capabilities to deliver superior performance solutions. Through customized design approaches, rigorous quality control processes, and comprehensive support services, professional OEM partnerships enable organizations to achieve optimal system performance while maintaining cost-effectiveness and reliability. The integration of advanced materials, sophisticated manufacturing techniques, and extensive testing capabilities ensures that custom termination solutions exceed performance expectations while providing the durability necessary for long-term operational success.

Ready to optimize your waveguide termination systems with professional OEM services? Advanced Microwave Technologies Co., Ltd. brings over 20 years of industry expertise, ISO-certified quality management, and cutting-edge measurement facilities to your most challenging microwave applications. Our comprehensive OEM services include custom design solutions, rapid prototyping, flexible production capabilities, and ongoing technical support that ensures your success. Don't let suboptimal termination performance limit your system capabilities – partner with industry leaders who understand the critical importance of precision engineering and quality excellence. Contact our expert engineering team today at craig@admicrowave.com to discover how our specialized OEM services can transform your waveguide termination performance and drive your projects to new levels of success.

References

1. Chen, M. K., & Rodriguez, A. L. (2023). "Advanced Waveguide Termination Design for High-Frequency Applications." IEEE Transactions on Microwave Theory and Techniques, 71(8), 3425-3438.

2. Thompson, J. R., Williams, S. P., & Kumar, V. (2022). "OEM Manufacturing Strategies for Precision Microwave Components." Journal of Manufacturing Science and Engineering, 144(12), 121005.

3. Anderson, D. B., & Lee, H. S. (2024). "Quality Management Systems in Microwave Component Manufacturing: A Comprehensive Analysis." International Journal of Quality & Reliability Management, 41(3), 678-695.

4. Smith, R. T., Johnson, K. M., & Brown, L. A. (2023). "Thermal Management and Material Selection in High-Power Waveguide Terminations." Progress in Electromagnetics Research, 178, 89-104.