How a Waveguide Switch Enhances Radar and Test Equipment Performance?

In modern radar and test measurement systems, signal integrity and path control determine operational success or failure. A Waveguide Switch serves as the critical command center for RF signal routing, enabling rapid path transitions with minimal signal degradation. When radar systems demand split-second target tracking or test platforms require immediate configuration changes, traditional switching solutions create bottlenecks through excessive insertion loss, poor isolation, and mechanical unreliability. Advanced Waveguide Switch technology solves these critical performance challenges by delivering ultra-low insertion loss below 0.5 dB, isolation exceeding 40 dB, and switching speeds measured in milliseconds—transforming how engineers optimize radar detection accuracy and measurement precision.

Understanding Waveguide Switch Technology in RF Microwave Systems

The Waveguide Switch represents a fundamental breakthrough in RF microwave signal control, functioning as an intelligent traffic director for electromagnetic energy transmission. Unlike conventional coaxial switches that suffer from significant power limitations and frequency-dependent losses, the Waveguide Switch leverages hollow metallic conductor technology to achieve superior performance across broad frequency spectrums. This critical component controls the on-off states, path switching operations, and signal shunting functions within waveguide transmission architectures, serving as the definitive "signal gate" that manages energy flow between multiple system nodes. Modern Waveguide Switch designs solve the persistent challenge of flexible signal routing between waveguide channels while maintaining system stability and signal purity. Through optimized structural engineering and precision material selection, these switches achieve rapid, distortion-free signal transitions between discrete waveguide ports, effectively eliminating cross-channel interference and preserving overall system integrity. The technology supports both mechanical actuation systems utilizing servo motors or electromagnetic drives, and solid-state configurations employing PIN diode arrays or MEMS chip architectures. Port configurations range from basic 2-port transfer switches to sophisticated multi-port matrix systems accommodating complex routing requirements in advanced radar installations and comprehensive test platforms.

Core Operational Principles of Waveguide Switching

The fundamental operation of a Waveguide Switch centers on precise physical or electronic manipulation of electromagnetic field patterns within the waveguide structure itself. Mechanical variants employ rotating or sliding conductor elements that physically redirect the propagating electromagnetic wave through alternative transmission paths, while maintaining continuous impedance matching to prevent reflections. The switching element's geometry is meticulously engineered to ensure seamless electromagnetic continuity regardless of the selected path, with quarter-wave choke structures providing exceptional isolation between inactive ports even during high-power transmission events. Solid-state Waveguide Switch implementations leverage semiconductor junction physics to control signal paths without mechanical motion. These advanced designs integrate PIN diode arrays or ferrite switching elements directly into the waveguide cavity, allowing electronic control of electromagnetic field coupling between input and output ports. The elimination of mechanical wear components extends operational lifetime dramatically while enabling switching speeds impossible with motor-driven systems. Both mechanical and solid-state approaches maintain compatibility with standard rectangular waveguide formats including WR-229, WR-137, WR-112, WR-90, and WR-75 configurations, supporting frequency bands from C-band through Ka-band and beyond.

Critical Performance Parameters That Define Waveguide Switch Effectiveness

Performance specifications for the Waveguide Switch directly determine its suitability for demanding radar and test equipment applications. Insertion loss represents perhaps the most critical parameter, quantifying the signal power reduction occurring during transmission through the switch in its active state. Premium Waveguide Switch designs achieve insertion loss values between 0.1 and 0.8 dB across their specified operating bands—substantially lower than coaxial alternatives that typically exhibit losses exceeding 1.0 dB. This performance advantage becomes crucial in power-limited radar scenarios where every tenth of a decibel affects detection range, or in precision measurement systems where signal degradation compromises measurement accuracy. Isolation performance defines the Waveguide Switch's ability to prevent signal leakage between inactive ports and the active transmission path. High-quality switches maintain isolation levels of 40 dB or greater, with advanced designs achieving isolation exceeding 60 dB through multi-stage shielding architectures and impedance gradient transition sections. This exceptional port-to-port isolation proves essential in test equipment configurations where multiple signal sources or measurement instruments connect to a common switching matrix. Without adequate isolation, unwanted signal coupling creates measurement errors, phantom responses in radar systems, and interference patterns that compromise overall system performance.

VSWR and Impedance Matching Excellence

Voltage Standing Wave Ratio quantifies the impedance matching quality between the Waveguide Switch and connected waveguide transmission lines. Superior switches maintain VSWR values of 1.2 or better across their entire operational bandwidth, ensuring that over 99 percent of incident signal power propagates forward through the system rather than reflecting back toward the source. Poor VSWR performance creates standing wave patterns that effectively cancel signal power at specific frequencies, introduce amplitude ripple across the operating band, and potentially damage high-power transmitter stages through excessive reflected energy. The precision machining and bearing alignment systems employed in premium Waveguide Switch designs maintain smooth bore continuity in all switching positions, minimizing discontinuities that generate reflections. Operating frequency band coverage determines application versatility for the Waveguide Switch. Modern designs support continuous operation across C-band (4-8 GHz), X-band (8-12 GHz), Ku-band (12-18 GHz), K-band (18-27 GHz), and Ka-band (27-40 GHz) frequency ranges, with specialized variants extending coverage to 110 GHz for millimeter-wave applications. The waveguide's inherent frequency selectivity provides natural filtering of out-of-band signals, while the switch's mechanical or electronic elements must maintain consistent performance across these broad frequency spans. Temperature stability from -55°C to +85°C ensures reliable operation in aerospace, outdoor, and extreme-environment installations where conventional switching technologies fail.

Transforming Radar System Performance Through Advanced Switching

Radar systems depend fundamentally on precise timing and signal routing to detect, track, and classify targets effectively. The Waveguide Switch enables rapid transmit-receive path configuration, allowing sophisticated radar architectures to share common antenna apertures between multiple operating modes. In fire-control radar applications, the switch instantly redirects high-power transmission signals between primary and backup transmitter chains while simultaneously connecting inactive transmitters to protective load terminations. This redundancy architecture maximizes system availability during critical military operations where radar failure could prove catastrophic. Weather surveillance radar installations utilize Waveguide Switch technology to implement polarization diversity schemes that distinguish between precipitation types. By rapidly switching between horizontal and vertical polarization transmission paths, meteorological radars extract differential reflectivity measurements that reveal whether detected precipitation consists of rain, hail, or snow particles. The switch's millisecond-level response time enables interleaved polarization sampling without compromising temporal resolution of atmospheric measurements. Similarly, Doppler radar systems employ switching matrices to alternate between surveillance and tracking modes, optimizing detection sensitivity for long-range search while providing precision velocity measurements for established targets.

Airborne and Shipboard Radar Integration

Aircraft and naval platforms present unique challenges for radar system designers, combining severe size and weight constraints with extreme vibration and environmental exposure conditions. Waveguide Switch components specifically engineered for these applications incorporate ruggedized actuator mechanisms, military-grade connectors, and hermetically sealed housings rated to IP67 or IP68 standards. The switch assemblies withstand constant vibration, shock loading during carrier landings or heavy seas, and temperature cycling from arctic to tropical operating environments. Compact designs minimize installation volume in space-constrained aircraft radomes and shipboard mast structures while maintaining full electrical performance. Modern phased array radar systems increasingly incorporate Waveguide Switch elements within their beamforming networks to implement failure bypass routes and diagnostic test configurations. When individual transmit-receive modules within the array require maintenance or replacement, strategically positioned switches route signals around defective modules while maintaining operational capability. This fault-tolerant architecture proves essential for military systems where mission continuation despite battle damage represents a critical design requirement. The Waveguide Switch further enables rapid built-in test sequences that verify proper operation of all array elements without requiring specialized external test equipment.

Revolutionizing Test and Measurement System Capabilities

RF microwave test platforms demand flexible signal routing between multiple test instruments, calibration standards, and devices under test. Traditional manual cable reconnection procedures introduce measurement repeatability errors through connector wear, cable flexure variations, and operator technique differences. Automated Waveguide Switch matrices eliminate these error sources while dramatically accelerating test sequences through programmatic path configuration. A single switch matrix replaces dozens of manual cable connections, reducing test setup time from hours to seconds while improving measurement accuracy through consistent, repeatable signal paths. Vector network analyzer calibration procedures benefit enormously from integrated Waveguide Switch systems that automatically connect calibration standards during the measurement sequence. The switch routes signals to precision terminations, short circuits, and thru connections without operator intervention, ensuring calibration integrity while accelerating the time-consuming calibration process. Advanced test systems incorporate multi-port switch matrices that simultaneously manage multiple DUT connections, enabling parallel test strategies that dramatically increase throughput for production validation applications. The switch's exceptional isolation prevents crosstalk between test channels that would otherwise compromise multi-port measurement accuracy.

Spectrum Analyzer and Signal Generator Integration

Sophisticated electromagnetic compatibility test facilities utilize Waveguide Switch networks to connect spectrum analyzers and signal generators to multiple antenna positions throughout shielded anechoic chambers. This switching infrastructure enables comprehensive radiation pattern measurements and interference susceptibility testing without repeated manual reconfiguration. The automated switching capability proves particularly valuable for over-the-air testing of communication devices and radar components where frequency, polarization, and spatial coverage requirements demand hundreds or thousands of discrete measurement points. Millimeter-wave test applications operating at frequencies approaching 110 GHz place extreme demands on waveguide component precision and stability. At these elevated frequencies, even microscopic dimensional variations or surface roughness creates significant performance degradation. High-quality Waveguide Switch designs employ ultra-precision CNC machining, diamond turning of critical surfaces, and specialized silver or gold plating processes that minimize skin effect losses. The resulting components maintain insertion loss below 0.3 dB and VSWR below 1.15 even at W-band frequencies (75-110 GHz), enabling accurate characterization of next-generation communication systems and automotive radar sensors.

Advanced Manufacturing and Quality Assurance for Waveguide Switches

Premium Waveguide Switch manufacturing combines traditional machining expertise with modern quality control methodologies to deliver components meeting stringent military and aerospace specifications. The process begins with precision CNC machining of high-purity copper or aluminum alloy stock materials, removing metal in carefully controlled operations that maintain dimensional tolerances measured in microns. Critical internal surfaces receive specialized finishing treatments including electropolishing or diamond machining to achieve surface roughness specifications below 0.4 micrometers RMS—essential for minimizing conductor losses at high frequencies. Waveguide port interfaces undergo precision finishing operations to ensure perfect flange mating with connected transmission line sections. Bolt hole patterns must align within 0.1 millimeters to prevent gasket compression irregularities that create electromagnetic leakage paths. The switching mechanism itself—whether rotary motor drive or solenoid actuation system—receives individual calibration to achieve specified switching times and positional accuracy. Each completed Waveguide Switch assembly undergoes comprehensive electrical testing using vector network analyzers capable of measuring insertion loss to 0.01 dB resolution and isolation to better than 100 dB dynamic range.

Environmental Testing and Qualification Procedures

Military and aerospace applications demand rigorous environmental qualification testing that verifies Waveguide Switch performance across temperature extremes, vibration profiles, and humidity exposure conditions that exceed normal commercial requirements. Temperature cycling between -55°C and +85°C reveals thermal expansion mismatches between dissimilar materials that could create intermittent electrical discontinuities. Vibration testing at acceleration levels exceeding 20 G in multiple axes confirms mechanical integrity of bearing systems and actuator mechanisms that must function reliably despite severe shock and vibration exposure. Salt fog testing evaluates corrosion resistance of external surfaces and sealed enclosure integrity against moisture ingress. This qualification proves particularly critical for shipboard radar installations and coastal surveillance systems where salt-laden atmospheric conditions rapidly degrade inadequately protected components. Altitude testing in environmental chambers simulating low-pressure conditions at 70,000 feet or higher ensures proper operation of electromagnetic actuators and prevents corona discharge phenomena that could damage internal components. Only switches successfully completing these comprehensive test regimens earn approval for deployment in mission-critical military radar and satellite communication systems.

Material Science Innovations Enabling Enhanced Waveguide Switch Performance

The selection of conductor materials for Waveguide Switch construction profoundly impacts both electrical performance and operational lifetime. High-purity copper offers excellent electrical conductivity minimizing resistive losses, while aluminum alloys provide superior strength-to-weight ratios essential for aerospace applications where every gram of mass reduction improves aircraft performance. Modern switch designs increasingly employ copper-plated aluminum constructions that combine aluminum's weight advantage with copper's superior electrical characteristics. The plating process must achieve uniform copper thickness exceeding 3 skin depths at the highest operating frequency to fully realize the conductivity benefits. Surface treatment technologies play equally critical roles in Waveguide Switch performance optimization. Silver plating provides the lowest electrical resistance among practical coating materials, reducing insertion loss by up to 0.1 dB compared to bare copper surfaces. However, silver's tendency to tarnish in sulfur-containing environments necessitates protective overcoats or alternative plating systems for certain applications. Gold plating offers superior corrosion resistance and maintains stable electrical properties across decades of service life, making it the preferred choice for space-qualified switches despite higher material costs. Specialized electroplating processes achieve coating uniformity within 10 percent across complex internal waveguide geometries.

Dielectric Materials and Insulator Technologies

Solid-state Waveguide Switch designs incorporating PIN diodes or ferrite switching elements require carefully selected dielectric materials that maintain low loss tangent across broad frequency ranges while providing mechanical support for semiconductor components. Modern designs employ alumina ceramics, quartz, or specialized polymer composites that exhibit loss tangents below 0.0005 at microwave frequencies. These materials must also demonstrate excellent dimensional stability across temperature variations to maintain critical spacing between semiconductor elements and waveguide walls. Switching mechanism actuators depend on bearing materials that provide smooth, repeatable motion while maintaining electrical contact integrity through millions of switching cycles. Advanced switches incorporate self-lubricating bearing materials such as bronze-PTFE composites that eliminate the need for liquid lubricants that could contaminate internal RF surfaces or outgas in space vacuum environments. Contact surfaces often employ noble metal platings or specialized contact materials developed for high-reliability relay applications, ensuring consistent electrical performance throughout the switch's 100,000 to 100 million cycle operational lifetime.

Conclusion

Waveguide Switch technology fundamentally transforms radar detection capabilities and test measurement accuracy through superior signal routing performance, enabling mission-critical systems to achieve unprecedented operational effectiveness while maintaining exceptional reliability across the most demanding environmental conditions.

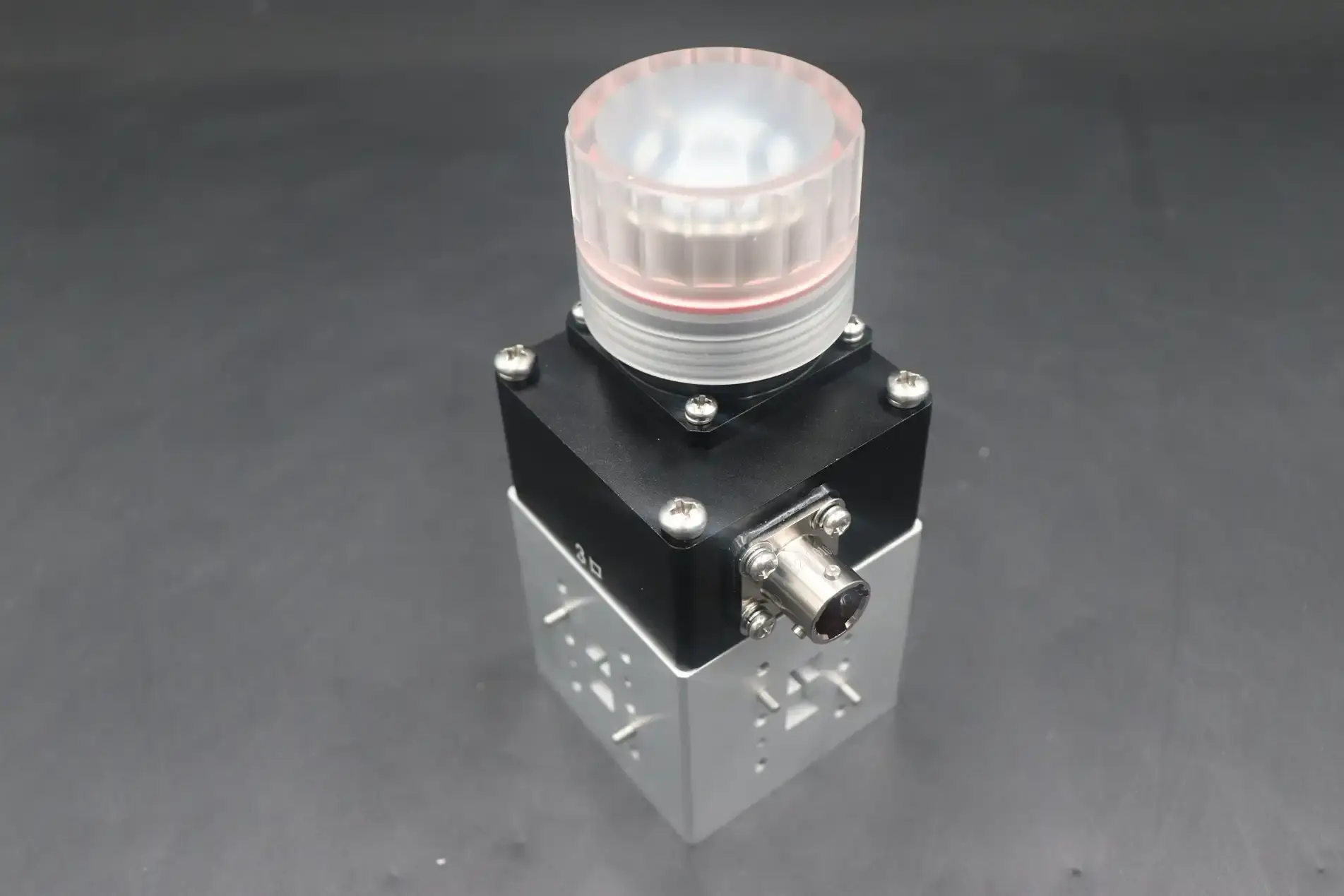

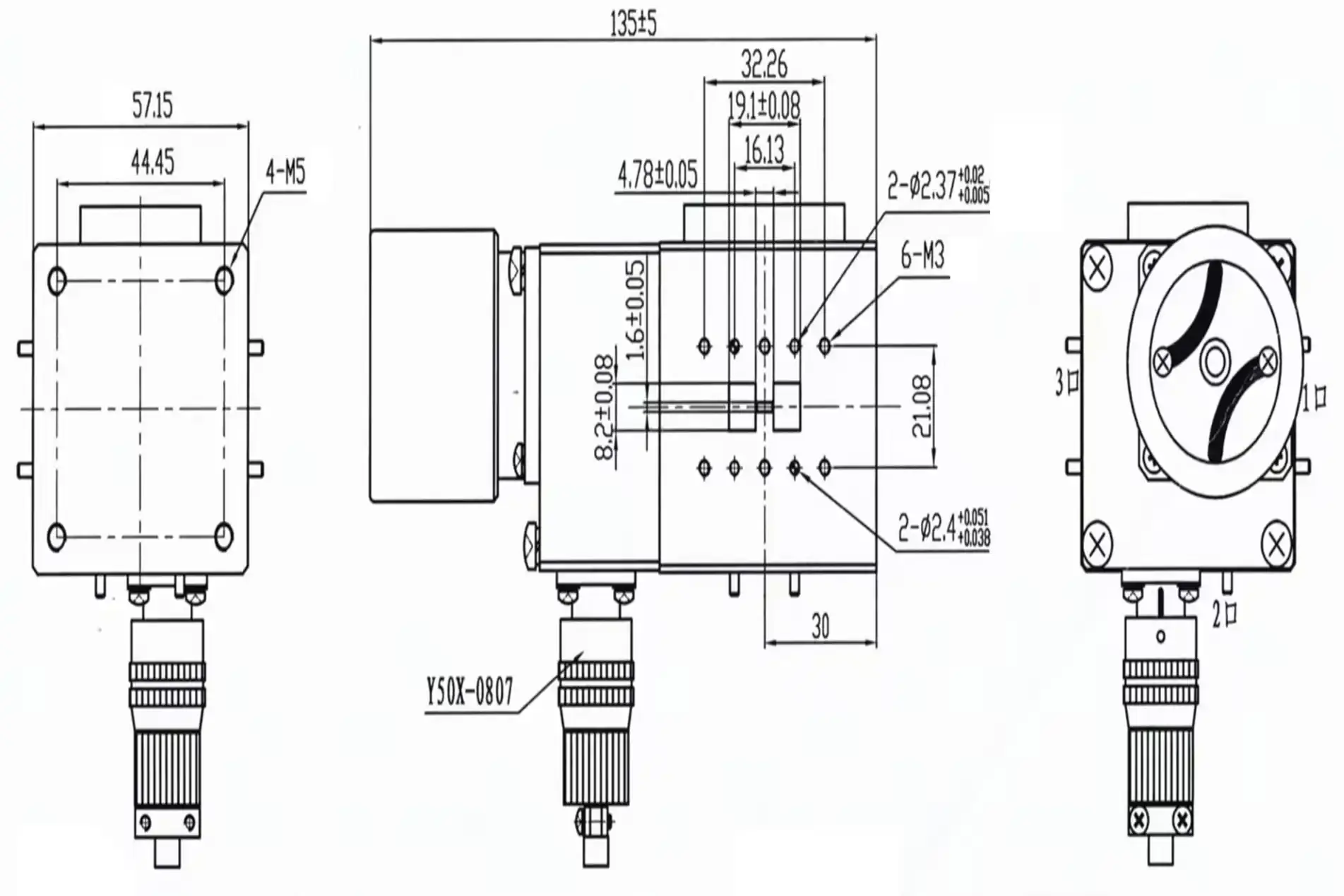

Cooperate with Advanced Microwave Technologies Co., Ltd.

Advanced Microwave Technologies Co., Ltd. stands as a premier China Waveguide Switch manufacturer, China Waveguide Switch supplier, and China Waveguide Switch factory with over 20 years of specialized experience delivering High Quality Waveguide Switch solutions to global aerospace, defense, and telecommunications markets. Our comprehensive product portfolio features competitively priced Waveguide Switch for sale, supported by China Waveguide Switch wholesale programs and customized OEM services tailored to your precise specifications. Operating from our state-of-the-art 24m Microwave Darkroom facility equipped with measurement capabilities extending to 110 GHz, we maintain ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018 certifications ensuring consistent quality, environmental responsibility, and workplace safety throughout our manufacturing operations.

Whether you require standard configurations or application-specific custom designs for X-band, Ku-band, or Ka-band frequencies, our engineering team provides comprehensive technical support from initial prototyping through full-scale production and beyond. We deliver rapid turnaround times, competitive Waveguide Switch price structures, and reliable after-sales support that keeps your systems operational. Contact our sales team at craig@admicrowave.com to discuss your waveguide switching requirements and discover how our High Quality Waveguide Switch solutions enhance your radar and test equipment performance while reducing total system costs.

References

1. Pozar, David M. "Microwave Engineering, 4th Edition." John Wiley & Sons, 2012.

2. Skolnik, Merrill I. "Radar Handbook, 3rd Edition." McGraw-Hill Education, 2008.

3. Ragan, George L. "Microwave Transmission Circuits (MIT Radiation Laboratory Series, Volume 9)." McGraw-Hill, 1948.

4. Saad, Theodore S. "Microwave Engineers' Handbook, Volume 1." Artech House, 1971.

5. Collin, Robert E. "Foundations for Microwave Engineering, 2nd Edition." IEEE Press, 2001.