Digitally Controlled Phase Shifter Performance vs Cost Analysis

In today's demanding microwave and RF landscape, system designers face a critical challenge when selecting components for radar systems, satellite communications, and phased array antennas. The wrong choice of a Digitally Controlled Phase Shifter can result in signal degradation, increased power consumption, and budget overruns that threaten project viability. This comprehensive analysis examines how to balance performance specifications against cost constraints, helping you make informed decisions that optimize both technical excellence and financial efficiency.

Understanding Digitally Controlled Phase Shifter Performance Metrics

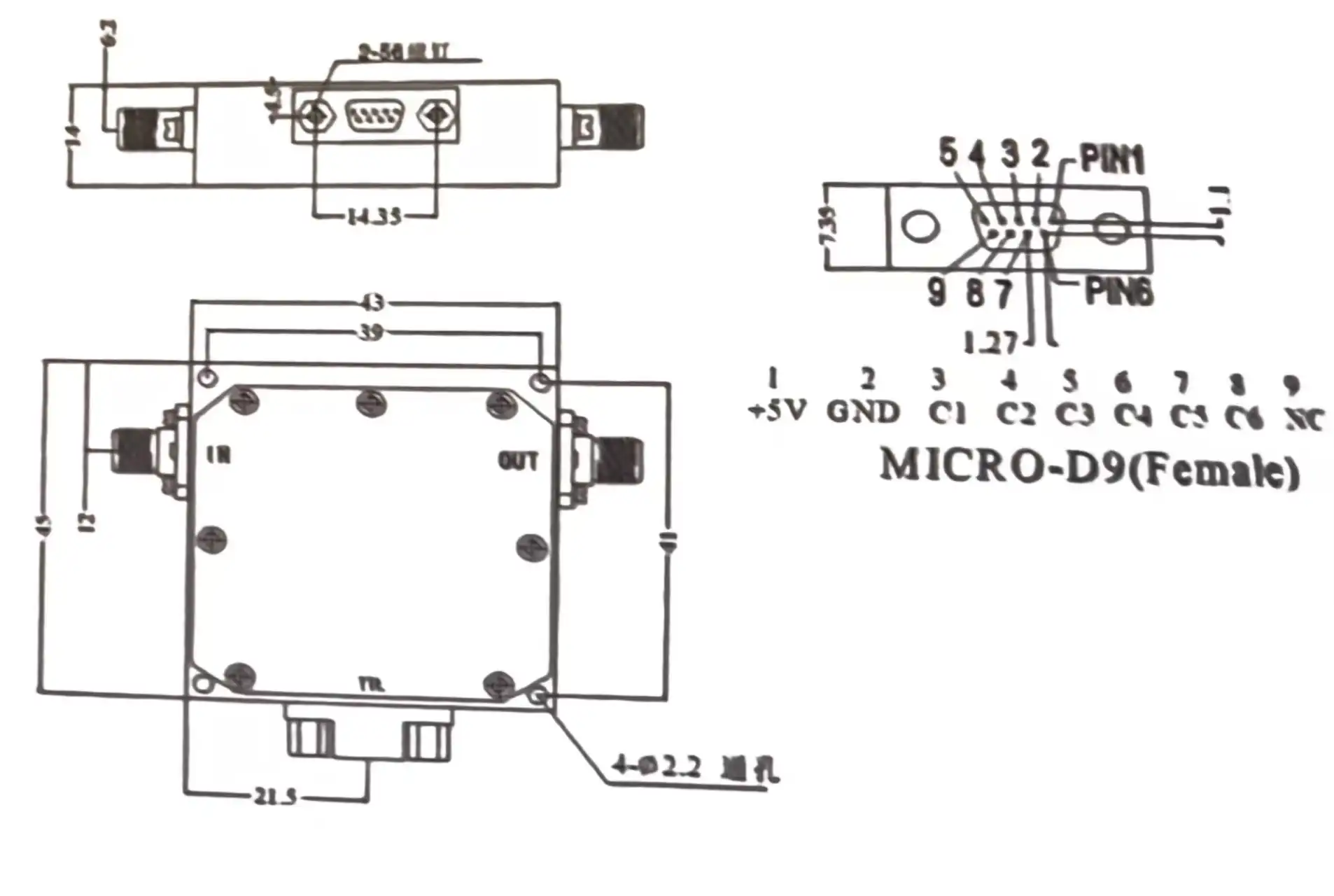

When evaluating a Digitally Controlled Phase Shifter, performance characteristics directly influence system capability and reliability. The market demonstrates that higher bit resolutions deliver enhanced phase control precision, but this advancement comes with corresponding cost implications. A Digitally Controlled Phase Shifter with 4-bit resolution provides 16 discrete phase states, suitable for basic telecommunications and educational applications where affordability outweighs the need for ultra-precise control. These entry-level devices typically range from hundreds to low thousands of dollars per unit, making them accessible for cost-sensitive projects. Conversely, 6-bit and higher resolution phase shifters offer substantially improved accuracy with 64 or more phase states, essential for advanced radar systems, defense applications, and cutting-edge satellite communication platforms. The enhanced precision enables superior beamforming capabilities and target detection in military surveillance systems, yet manufacturing complexity and specialized semiconductor processes drive unit costs into the thousands of dollars. The technical specifications that define performance include insertion loss, typically maintained below 3 dB in quality components, voltage standing wave ratio under 1.5:1, and phase resolution ranging from 0.5 to 5 degrees depending on bit configuration. Advanced Microwave Technologies Co., Ltd provides a comprehensive series of Digitally Controlled Phase Shifter products operating from DC to 40 GHz, featuring digital control interfaces through TTL or SPI for seamless system integration. Our phase shifters maintain exceptional stability with minimal phase drift across operating temperatures from negative 40 degrees Celsius to positive 85 degrees Celsius, ensuring consistent performance in challenging environmental conditions. The modular design philosophy facilitates easy upgrades and maintenance while supporting long-term operational flexibility, a critical consideration when calculating total cost of ownership beyond initial purchase price.

Frequency Range Impact on Performance and Pricing

The operational frequency range represents a fundamental performance parameter that significantly influences both capability and cost structure for any Digitally Controlled Phase Shifter. Devices operating at lower frequencies, typically up to 18 GHz, utilize more mature manufacturing technologies and established semiconductor processes, resulting in moderate production costs and widespread availability. These lower-frequency phase shifters serve established communication systems and legacy radar installations effectively, with pricing structures that reflect economies of scale achieved through volume production. Higher frequency operations extending from 18 GHz to 40 GHz and beyond demand advanced materials such as gallium nitride, sophisticated fabrication techniques, and stringent quality control procedures. The millimeter-wave frequencies essential for emerging 5G infrastructure, future 6G technologies, and next-generation automotive radar systems require Digitally Controlled Phase Shifter components capable of maintaining signal integrity at extreme frequencies. Manufacturing these high-frequency devices involves specialized equipment, cleanroom facilities meeting strict environmental standards, and extensive testing protocols using expensive network analyzers and measurement systems. Advanced Microwave's testing capabilities extending to 110 GHz, conducted within our state-of-the-art 24-meter microwave darkroom, enable comprehensive characterization of phase shifter performance across the entire specified frequency range. This extensive measurement infrastructure, coupled with our ISO 9001:2015 certified quality management systems, ensures that every Digitally Controlled Phase Shifter meets published specifications before delivery. The investment in advanced test equipment and measurement expertise translates into higher reliability and reduced field failure rates, delivering long-term value that justifies premium pricing for high-frequency components.

Cost Factors in Digitally Controlled Phase Shifter Selection

Multiple cost components contribute to the total expenditure associated with implementing a Digitally Controlled Phase Shifter in any system architecture. Initial acquisition costs vary dramatically based on performance specifications, with basic 4-bit devices starting at several hundred dollars while high-performance 8-bit units with advanced features can exceed several thousand dollars per component. Volume pricing structures offer substantial savings for large-scale deployments, particularly relevant for telecommunications infrastructure and defense programs requiring hundreds or thousands of units. Manufacturing complexity directly impacts pricing, as higher bit resolutions demand precision semiconductor fabrication with tighter tolerances and more sophisticated lithography processes. The integration of Digitally Controlled Phase Shifter functionality into monolithic microwave integrated circuits reduces overall system complexity and footprint, yet the specialized MMIC foundry services command premium rates reflecting the technical challenges involved. Customization requirements for specific frequency bands, unique control interfaces, or specialized packaging configurations introduce additional engineering costs and extended development timelines that must be factored into project budgets. Beyond initial purchase price, lifecycle costs encompass power consumption, thermal management requirements, and maintenance considerations. A Digitally Controlled Phase Shifter with superior power efficiency reduces operating expenses in battery-powered applications such as unmanned aerial vehicles and portable communication systems. Thermal stability characteristics influence cooling system requirements, with devices exhibiting stable performance across wide temperature ranges eliminating the need for expensive thermal compensation circuitry. Advanced Microwave's commitment to environmental stewardship through ISO 14001:2015 certification ensures our manufacturing processes optimize material utilization and minimize waste, contributing to sustainable cost structures that benefit both customers and the environment.

Return on Investment Analysis for Different Applications

Calculating return on investment for a Digitally Controlled Phase Shifter implementation requires careful consideration of application-specific requirements and performance thresholds. In commercial telecommunications infrastructure, the ability to dynamically optimize signal paths through precise phase control translates into improved network capacity, reduced interference, and enhanced user experience. The revenue impact of deploying higher-performance phase shifters in base stations and small cell networks can justify substantial upfront investments when calculating returns over multi-year operational timeframes. Defense and aerospace applications prioritize mission-critical reliability and performance over cost minimization, with system failures potentially resulting in catastrophic consequences. A Digitally Controlled Phase Shifter meeting stringent military specifications and operating reliably in extreme environments delivers immeasurable value through operational success and personnel safety. Advanced Microwave's ISO 45001:2018 certification for occupational health and safety management demonstrates our commitment to quality throughout the manufacturing process, ensuring that components destined for critical applications meet the highest reliability standards. Industrial and scientific instrumentation applications often require customized solutions balancing performance requirements against project budget constraints. Our OEM services provide tailored Digitally Controlled Phase Shifter designs optimized for specific frequency ranges, control interfaces, and mechanical packaging configurations. The ability to specify exact requirements eliminates unnecessary features and associated costs, delivering targeted solutions that maximize value for specialized applications. Our experienced technical team works collaboratively with customers throughout the design process, leveraging over 20 years of microwave component expertise to identify optimal cost-performance trade-offs.

Technical Performance Optimization Strategies

Achieving optimal performance from any Digitally Controlled Phase Shifter requires understanding the interdependencies between various technical parameters and their impact on overall system behavior. Insertion loss characteristics directly affect signal power levels, with cumulative losses through multiple phase shifter stages potentially degrading system sensitivity and dynamic range. Advanced circuit topologies and careful impedance matching minimize insertion loss while maintaining broad bandwidth coverage, though these design refinements add complexity and cost to component development. Phase accuracy and linearity specifications determine how precisely the Digitally Controlled Phase Shifter can position signals for coherent combination in phased array applications. Systematic phase errors across the array aperture result in beam pointing errors and increased sidelobe levels, degrading radar detection performance and communication link quality. Digital control mechanisms offer superior repeatability compared to analog approaches, with computerized calibration procedures compensating for manufacturing variations and temperature-induced drift. Advanced Microwave's Antenna Plane Near and Far Field Measuring Recombination Chamber enables comprehensive antenna pattern characterization, validating phase shifter performance in realistic system configurations.

Power handling capacity establishes the maximum signal levels that can be processed without distortion or component damage. Applications involving high-power transmitters, such as ground-based radar installations and satellite uplink stations, require Digitally Controlled Phase Shifter devices with robust power ratings up to 2 Watts continuous wave or higher for pulsed applications. The thermal management challenges associated with high-power operation necessitate careful consideration of heat dissipation mechanisms, substrate materials, and mounting configurations. Our engineering team provides comprehensive technical support including installation guidance and thermal analysis assistance, ensuring successful integration into demanding applications.

Integration Considerations and System-Level Costs

The total cost of implementing a Digitally Controlled Phase Shifter extends well beyond component pricing to encompass integration expenses, interface development, and system-level validation. Digital control interfaces using TTL or SPI protocols require compatible driver circuitry and software development for command sequencing and state management. While standardized interfaces reduce integration complexity, some applications benefit from customized control schemes optimized for specific operational requirements. Advanced Microwave offers flexible interface options and comprehensive documentation supporting rapid system integration and reducing time-to-market. Mechanical packaging and environmental protection requirements vary significantly across application domains, influencing both component selection and associated costs. Hermetically sealed packages with military-grade environmental ratings provide maximum protection against moisture, contaminants, and mechanical shock, essential for aerospace and defense deployments. Commercial and industrial applications may accept less stringent packaging specifications, enabling cost reductions through simplified enclosure designs and relaxed testing procedures. Our compact design philosophy maximizes functionality within space-constrained installations while maintaining full performance specifications.

Supply chain considerations and component availability increasingly influence procurement decisions, particularly for long-duration programs requiring sustained production over multiple years. Establishing relationships with China Digitally Controlled Phase Shifter manufacturers offering stable production capacity and reliable delivery schedules mitigates supply chain risks and supports predictable program execution. Advanced Microwave's perfect supply chain system and over two decades of microwave manufacturing experience provide customers with confidence in our ability to support both prototype development and volume production requirements. Our global customer base across satellite communications, defense, aerospace, and navigation sectors demonstrates the breadth of applications we successfully support.

Making Informed Purchasing Decisions

Selecting the optimal Digitally Controlled Phase Shifter for any specific application requires systematic evaluation of technical requirements, performance specifications, and budget constraints. Creating a comprehensive requirements matrix documenting frequency range, phase resolution, insertion loss, power handling, and control interface specifications establishes clear selection criteria. Engaging with multiple China Digitally Controlled Phase Shifter suppliers and requesting detailed datasheets, test data, and application notes enables thorough technical comparison across available options. Prototype evaluation and system-level testing validate component performance under realistic operating conditions before committing to volume procurement. Many suppliers, including Advanced Microwave Technologies Co., Ltd, offer sample quantities and prototyping services supporting detailed evaluation while minimizing financial risk. Our fast delivery capabilities and willingness to produce small-batch customized solutions facilitate rapid design iteration and accelerated development timelines. The investment in thorough prototyping and validation prevents costly rework and field failures that could undermine project success and damage reputations. Long-term partnership considerations extend beyond initial component selection to encompass technical support, product lifecycle management, and continuous improvement initiatives. Working with a High Quality Digitally Controlled Phase Shifter supplier committed to ongoing innovation and responsive customer support delivers sustained value throughout product lifecycles. Advanced Microwave's strong after-sales capability and dedication to customer satisfaction ensure that technical questions receive prompt expert responses and that evolving requirements can be accommodated through design modifications and performance enhancements.

Evaluating Total Cost of Ownership

Comprehensive total cost of ownership analysis for Digitally Controlled Phase Shifter implementations must account for multiple factors extending well beyond initial purchase price. Operational costs including power consumption, cooling requirements, and maintenance procedures accumulate over system lifetimes spanning years or decades. A slightly more expensive component offering superior power efficiency or enhanced reliability can deliver substantial savings through reduced operating expenses and minimized downtime. Obsolescence management and technology refresh considerations become increasingly important in long-duration programs where component availability must be maintained throughout production and operational support phases. Selecting Digitally Controlled Phase Shifter suppliers with stable product roadmaps and commitment to sustained manufacturing reduces obsolescence risks and associated re-qualification expenses. Advanced Microwave's rich production experience and professional technical research and development team continuously refine manufacturing processes and develop next-generation solutions while maintaining backward compatibility where feasible. Training requirements and technical expertise availability influence implementation costs, particularly for complex systems utilizing advanced control algorithms and adaptive beamforming techniques. Comprehensive documentation, application notes, and technical support from the China Digitally Controlled Phase Shifter factory accelerate learning curves and reduce integration timeframes. Our engineers work collaboratively with customer teams, providing installation guidance, troubleshooting support, and optimization recommendations throughout project lifecycles. This partnership approach ensures successful deployments and maximizes return on investment for Digitally Controlled Phase Shifter implementations.

Conclusion

Balancing Digitally Controlled Phase Shifter performance against cost requires systematic analysis of technical requirements, application constraints, and lifecycle considerations to identify optimal solutions delivering maximum value.

Cooperate with Advanced Microwave Technologies Co., Ltd.

As a leading China Digitally Controlled Phase Shifter supplier and China Digitally Controlled Phase Shifter manufacturer, Advanced Microwave Technologies Co., Ltd combines over 20 years of microwave expertise with ISO 9001:2015 certified quality management and comprehensive testing capabilities up to 110 GHz. Our China Digitally Controlled Phase Shifter wholesale programs offer competitive Digitally Controlled Phase Shifter prices without compromising quality, while our High Quality Digitally Controlled Phase Shifter for sale supports applications across satellite communications, defense, aerospace, and navigation sectors. With perfect supply chain systems, fast delivery, strict quality control, and strong after-sales capability, we deliver customized OEM solutions meeting your exact specifications. Contact our professional technical team today at craig@admicrowave.com to discuss your Digitally Controlled Phase Shifter requirements and discover how our integrated production and research capabilities can accelerate your project success. Bookmark this page for future reference when evaluating phase shifter solutions for your critical applications.

References

1. "Digital Phase Shifters Market Size & Trends Analysis 2025-2035" - Future Market Insights Research Team

2. "Digitally Controlled Phase Shifter Industry Growth Trends and Analysis" - Data Insights Market Research Group

3. "RF Phase Shifter Market: Global Industry Analysis and Forecast" - Maximize Market Research Analysts

4. "Digital Controlled Phase Shifter Market Demand Dynamics: Insights 2025-2033" - Market Report Analytics Research Division

5. "Phase Shifters Technology and Applications Review" - Analog Devices Technical Publications Team

YOU MAY LIKE

VIEW MOREHigh Power Waveguide to Coaxial Adapter

VIEW MOREHigh Power Waveguide to Coaxial Adapter VIEW MOREWaveguide Loop Coupler

VIEW MOREWaveguide Loop Coupler VIEW MOREEnd Launch Double Ridged WG To Coaxial Adapter

VIEW MOREEnd Launch Double Ridged WG To Coaxial Adapter VIEW MOREEnd Launch Waveguide to Microstrip Adapter

VIEW MOREEnd Launch Waveguide to Microstrip Adapter VIEW MOREWaveguide Sliding Termination

VIEW MOREWaveguide Sliding Termination VIEW MOREWaveguide Unmatched Termination

VIEW MOREWaveguide Unmatched Termination VIEW MOREMagic Hybrid Tee

VIEW MOREMagic Hybrid Tee VIEW MOREH-Plane Tee

VIEW MOREH-Plane Tee