Why Use a Double‑Ridged Waveguide Loop Coupler in Testing?

In the complex landscape of microwave testing and measurement, engineers frequently encounter a critical challenge: accurately monitoring high-frequency signals without introducing measurement errors, signal degradation, or system instability. When your radar calibration demands precision at millimeter-wave frequencies, or your satellite ground station requires real-time power monitoring across octave-spanning bandwidths, conventional coupling solutions often fall short. The Double-Ridged Waveguide Loop Coupler emerges as the answer to these pain points, offering exceptional wideband performance, minimal insertion loss, and reliable signal sampling in the most demanding test environments where measurement accuracy directly impacts system validation and certification success.

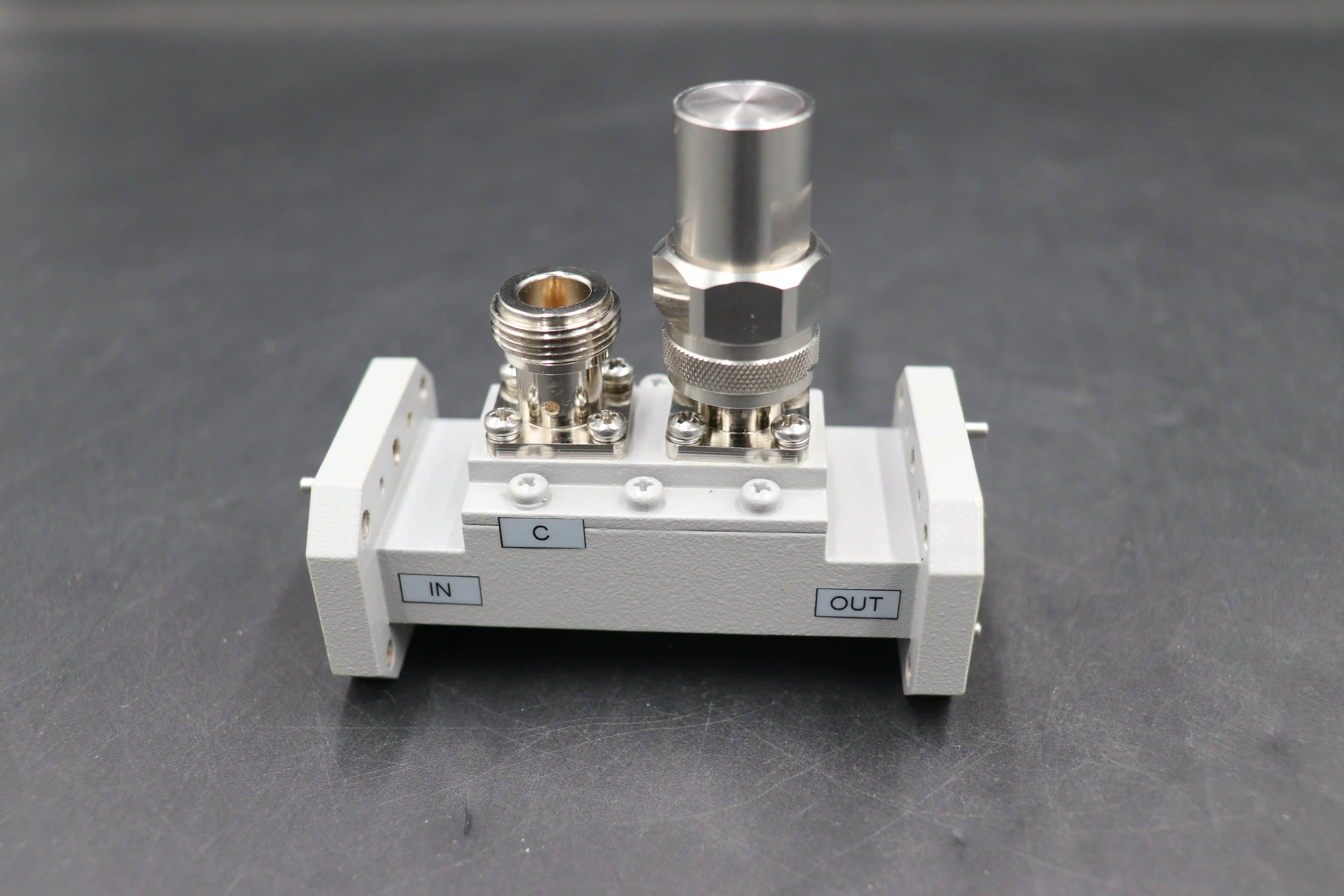

Understanding the Fundamental Architecture of Double-Ridged Waveguide Loop Couplers

The Double-Ridged Waveguide Loop Coupler represents a sophisticated evolution in microwave component design, combining the broadband capabilities of double-ridged waveguide technology with the precise coupling mechanism of loop-based power sampling. At its core, the Double-Ridged Waveguide Loop Coupler consists of two essential structural elements working in harmony to achieve superior performance across wide frequency ranges. The double-ridged waveguide section forms the primary transmission path, featuring two opposing metallic ridges that protrude into the waveguide cavity. These ridge structures fundamentally alter the electromagnetic field distribution within the waveguide, effectively lowering the cutoff frequency and enabling the Double-Ridged Waveguide Loop Coupler to operate across bandwidths that can span from octave to triple-octave ranges, far exceeding the capabilities of standard rectangular waveguides.

The coupling structure integrated into the Double-Ridged Waveguide Loop Coupler typically employs a loop-based design that interacts with the electromagnetic field propagating through the double-ridged waveguide. This loop element, positioned strategically within or adjacent to the waveguide cavity, captures a controlled portion of the electromagnetic energy through magnetic field coupling. The precise geometry, orientation, and placement of this loop structure determine the coupling coefficient, directivity, and frequency response of the Double-Ridged Waveguide Loop Coupler. The interaction between the double-ridged waveguide geometry and the loop coupling mechanism creates a component capable of sampling signal power with remarkable consistency across frequencies ranging from hundreds of megahertz to over one hundred gigahertz, making the Double-Ridged Waveguide Loop Coupler indispensable in modern wideband test systems. Advanced Microwave Technologies Co., Ltd engineers each Double-Ridged Waveguide Loop Coupler with meticulous attention to the dimensional tolerances of both the ridge geometry and coupling loop placement, ensuring that every unit delivers predictable, repeatable performance. The manufacturing precision required for these components becomes particularly critical at higher frequencies, where dimensional variations of just a few micrometers can significantly impact coupling uniformity and directivity performance across the operational bandwidth.

Critical Testing Applications Requiring Double-Ridged Waveguide Loop Coupler Performance

Vector Network Analyzer Calibration and Characterization

In the realm of precision microwave measurements, vector network analyzers serve as the cornerstone instruments for characterizing component performance, but their accuracy depends entirely on proper calibration and signal monitoring. The Double-Ridged Waveguide Loop Coupler plays a vital role in VNA test setups by providing a means to sample the incident and reflected power without disturbing the measurement path. When engineers conduct broadband characterization of antennas, filters, amplifiers, or other microwave components, they require coupling devices that maintain consistent performance across the entire measurement frequency range. The Double-Ridged Waveguide Loop Coupler excels in these applications because its wideband nature eliminates the need for multiple coupler changes during frequency sweeps, dramatically reducing setup time and measurement uncertainty. The low insertion loss characteristic of the Double-Ridged Waveguide Loop Coupler proves particularly valuable when measuring sensitive devices or low-power signals, where every fraction of a decibel matters. Advanced test laboratories utilize these couplers to establish reference power levels, monitor source stability during long measurement runs, and implement sophisticated calibration techniques that account for systematic errors in the measurement system. The superior directivity offered by properly designed Double-Ridged Waveguide Loop Coupler units ensures that forward and reverse signals can be accurately distinguished, enabling precise reflection coefficient measurements and time-domain analysis essential for modern component characterization.

Radar System Testing and Calibration

Radar systems operating across multiple frequency bands demand test equipment capable of handling high power levels while providing accurate power monitoring for transmitter calibration, receiver sensitivity verification, and antenna pattern measurements. The Double-Ridged Waveguide Loop Coupler addresses these requirements through its robust construction, high power handling capability, and broadband performance. During radar transmitter testing, engineers must verify output power levels, spectral purity, and pulse characteristics across the operational bandwidth. The Double-Ridged Waveguide Loop Coupler enables real-time power monitoring without requiring direct connection to high-power measurement equipment, protecting sensitive instruments while ensuring accurate readings. In radar receiver testing scenarios, the Double-Ridged Waveguide Loop Coupler facilitates the injection of calibrated test signals and the monitoring of receiver response across frequency, enabling comprehensive sensitivity measurements and dynamic range characterization. Defense contractors and aerospace manufacturers particularly value the compact design and reliable performance of Double-Ridged Waveguide Loop Coupler components in radar test systems, where space constraints, environmental challenges, and demanding performance specifications create unique engineering challenges. The ability of the Double-Ridged Waveguide Loop Coupler to maintain stable coupling coefficients across temperature variations and mechanical stress ensures consistent test results even in harsh operating environments typical of military and aerospace applications.

Satellite Communication Ground Station Testing

Satellite communication ground stations require continuous monitoring of uplink and downlink signal levels to ensure optimal system performance, meet regulatory requirements, and troubleshoot communication issues. The Double-Ridged Waveguide Loop Coupler serves as a critical component in these monitoring systems, sampling transmitted and received signals without introducing significant loss in the main transmission path. Ground station engineers utilize Double-Ridged Waveguide Loop Coupler assemblies to feed signal samples to spectrum analyzers, power meters, and automated monitoring systems that track link performance, detect interference, and verify compliance with EIRP regulations. The wideband capability of the Double-Ridged Waveguide Loop Coupler proves essential in modern ground stations that support multiple satellite bands and communication protocols. Rather than requiring separate coupling hardware for each frequency band, a single well-designed Double-Ridged Waveguide Loop Coupler can service Ka-band, Ku-band, and even portions of X-band, simplifying system architecture and reducing maintenance complexity. When ground stations undergo acceptance testing or periodic calibration, the stable, predictable performance of the Double-Ridged Waveguide Loop Coupler enables accurate system gain measurements, noise figure verification, and antenna pattern validation essential for certifying station performance against contractual specifications.

Technical Performance Advantages in Laboratory Test Environments

Wideband Operation and Measurement Efficiency

One of the most compelling reasons to use a Double-Ridged Waveguide Loop Coupler in testing applications centers on its exceptional bandwidth capabilities. Traditional rectangular waveguide components typically operate over relatively narrow frequency ranges, often covering less than one octave before cutoff effects and higher-order mode propagation degrade performance. This limitation forces test engineers to maintain inventories of multiple couplers, switches, and adapters to cover their measurement frequency ranges, increasing cost, setup complexity, and potential for errors. The Double-Ridged Waveguide Loop Coupler fundamentally changes this equation by providing consistent coupling performance over bandwidths that can exceed two octaves or more, dramatically simplifying test system architecture.

When conducting swept-frequency measurements or multi-band device characterization, the ability to use a single Double-Ridged Waveguide Loop Coupler eliminates the need for mid-test hardware changes that introduce measurement discontinuities and consume valuable laboratory time. Advanced Microwave Technologies Co., Ltd manufactures Double-Ridged Waveguide Loop Coupler units covering frequency ranges from 500 MHz to 110 GHz, with individual models spanning remarkable bandwidths such as 2-18 GHz, 18-40 GHz, and 40-110 GHz. This wideband performance translates directly to increased measurement throughput, reduced calibration requirements, and improved confidence in measurement continuity across frequency ranges where different coupling devices might introduce systematic variations. The frequency response flatness of the Double-Ridged Waveguide Loop Coupler further enhances its value in precision testing. Engineers can rely on consistent coupling coefficients across the operational band, simplifying power calibration procedures and reducing uncertainty in absolute power measurements. This flatness proves particularly valuable when conducting comparative measurements between devices or tracking subtle performance variations that might be masked by frequency-dependent coupling variations in lesser quality directional couplers.

Low Insertion Loss and Signal Integrity Preservation

In sensitive test applications where signal-to-noise ratio and measurement dynamic range determine the quality of results, the insertion loss characteristics of coupling devices become critical performance parameters. The Double-Ridged Waveguide Loop Coupler achieves remarkably low insertion loss through careful optimization of its waveguide geometry and coupling mechanism design. Typical insertion loss values for high-quality Double-Ridged Waveguide Loop Coupler units range from 0.3 dB to 1.0 dB across their operational bandwidths, representing minimal impact on the main signal path. This low loss proves essential when testing amplifiers with modest gain, measuring receiver noise figures, or characterizing passive components where every tenth of a decibel affects measurement accuracy. The superior signal integrity maintained by the Double-Ridged Waveguide Loop Coupler extends beyond simple insertion loss considerations. The component's excellent voltage standing wave ratio performance minimizes reflections that could disturb device under test behavior or create resonant conditions affecting measurement validity. Engineers testing sensitive oscillators, phase-locked loops, or frequency conversion systems particularly appreciate the minimal perturbation introduced by properly designed Double-Ridged Waveguide Loop Coupler assemblies. The mechanical robustness and thermal stability of these couplers further ensure that insertion loss and VSWR characteristics remain stable across environmental variations, maintaining measurement repeatability during long test sessions or temperature-cycled reliability evaluations. Advanced Microwave Technologies Co., Ltd incorporates precision manufacturing techniques including CNC machining with tolerances to 0.001 inches and advanced surface finishing to ensure that each Double-Ridged Waveguide Loop Coupler delivers optimal insertion loss performance. The use of high-conductivity materials such as aluminum alloy, brass, or specialized copper alloys further minimizes resistive losses, while careful attention to flange design and waveguide interface dimensions ensures low-loss mating with other test system components.

High Directivity for Accurate Bidirectional Measurements

Directivity represents a critical performance parameter for any directional coupler used in test applications, defining the device's ability to distinguish between forward and reverse traveling waves in the transmission line. The Double-Ridged Waveguide Loop Coupler achieves excellent directivity through optimized coupling mechanism design and careful attention to the symmetry and positioning of coupling elements. This high directivity enables accurate measurement of reflected power in the presence of strong incident signals, essential for characterizing antenna return loss, filter rejection performance, and amplifier output match. In sophisticated test setups requiring simultaneous monitoring of incident and reflected power, engineers often employ dual-arm Double-Ridged Waveguide Loop Coupler configurations that provide separate outputs for forward and reverse coupled signals. The directivity performance of the Double-Ridged Waveguide Loop Coupler proves particularly valuable when conducting vector measurements that extract both magnitude and phase information from the device under test. Modern measurement techniques increasingly rely on accurate knowledge of signal direction to implement error correction algorithms, separate incident and scattered waves in antenna measurements, and characterize nonlinear device behavior under large-signal conditions. The Double-Ridged Waveguide Loop Coupler directivity specifications, typically exceeding 20 dB across substantial portions of the operational bandwidth, provide the measurement fidelity required for these advanced characterization methods.

Engineers conducting high-power measurements benefit from the directivity capabilities of the Double-Ridged Waveguide Loop Coupler when monitoring transmitter output while simultaneously detecting reflected power that might indicate antenna mismatch or transmission line faults. The ability to accurately measure small reflected signals in the presence of large forward power flows enables real-time fault detection and system protection, preventing damage to expensive test equipment or devices under test. Advanced Microwave Technologies Co., Ltd tests every Double-Ridged Waveguide Loop Coupler for directivity performance in our 24m Microwave Darkroom facility, employing precision vector network analyzers and calibrated reference standards to verify that each unit meets specified directivity requirements across its full operational bandwidth.

Mechanical Design Considerations for Test System Integration

The physical design and mechanical interface characteristics of the Double-Ridged Waveguide Loop Coupler significantly influence its utility in practical test systems. Advanced Microwave Technologies Co., Ltd engineers these components with standardized flange interfaces compatible with common waveguide sizes and connector types, facilitating straightforward integration into existing test setups. The compact form factor typical of Double-Ridged Waveguide Loop Coupler designs proves advantageous when assembling test systems with limited rack space or when integrating multiple couplers into complex measurement configurations requiring minimal interconnect lengths. The mechanical robustness of precision-manufactured Double-Ridged Waveguide Loop Coupler units ensures reliable performance even under the physical stresses of repeated connection and disconnection common in active test laboratories. Proper attention to flange flatness, alignment pin tolerances, and hardware specifications ensures that measurement uncertainty contributions from mechanical interface variations remain negligible. For applications requiring pressurized waveguide systems or operation in harsh environments, sealed versions of the Double-Ridged Waveguide Loop Coupler incorporate appropriate gaskets and pressure windows while maintaining electrical performance specifications.

Customization and Specialized Testing Requirements

Many sophisticated test applications demand coupling characteristics tailored to specific measurement scenarios that standard catalog components cannot adequately address. The Double-Ridged Waveguide Loop Coupler design lends itself well to customization, allowing engineers to specify coupling coefficients, frequency ranges, power handling capabilities, and interface configurations optimized for particular test requirements. Advanced Microwave Technologies Co., Ltd provides comprehensive OEM services enabling customers to collaborate with our engineering team in developing custom Double-Ridged Waveguide Loop Coupler solutions that precisely match application needs. Common customization parameters include coupling level selection ranging from 10 dB to 60 dB or more, frequency band optimization for specific communication or radar bands, special flange configurations for proprietary test fixtures, and material selections for specialized environmental conditions. The manufacturing flexibility inherent in Double-Ridged Waveguide Loop Coupler production enables relatively rapid prototyping and iteration when developing custom solutions. Engineers can evaluate electromagnetic simulation predictions through fabricated prototypes, conduct performance verification in actual test systems, and refine designs based on measured results. This iterative approach proves particularly valuable when developing test systems for next-generation communication standards, advanced radar concepts, or research applications where optimal coupling characteristics cannot be determined from analytical predictions alone. The extensive measurement capabilities available in our 24m Microwave Darkroom facility support comprehensive characterization of custom Double-Ridged Waveguide Loop Coupler prototypes, providing detailed performance data across parameters including coupling coefficient frequency response, insertion loss, VSWR, directivity, and power handling limits.

Quality Assurance and Performance Validation

Every Double-Ridged Waveguide Loop Coupler manufactured by Advanced Microwave Technologies Co., Ltd undergoes rigorous testing protocols designed to verify compliance with specifications and ensure reliable performance in demanding test environments. Our quality assurance procedures encompass dimensional inspection using precision metrology equipment, electromagnetic performance characterization across the full operational bandwidth, and environmental stress screening to identify potential reliability issues before products reach customers. This comprehensive testing approach reflects our commitment to delivering components that meet or exceed performance specifications while providing the long-term reliability essential for critical test applications. The measurement capabilities available in our ISO-certified facilities enable us to provide detailed performance documentation for each Double-Ridged Waveguide Loop Coupler unit, including calibrated S-parameter data, coupling coefficient measurements, directivity verification, and power handling validation. This documentation serves multiple purposes: enabling customers to incorporate accurate component models into their test system calibration procedures, providing traceability to national standards through our calibration chain, and supporting qualification requirements for aerospace, defense, and telecommunications applications where component performance verification represents a contractual obligation. Our adherence to ISO 9001:2015 quality management standards ensures consistent manufacturing processes, comprehensive documentation, and continuous improvement practices that maintain the highest quality levels across our Double-Ridged Waveguide Loop Coupler product lines.

Conclusion

The Double-Ridged Waveguide Loop Coupler represents an essential component for modern microwave testing applications, delivering wideband performance, low insertion loss, high directivity, and mechanical reliability that enable accurate measurements across demanding frequency ranges and power levels.

Cooperate with Advanced Microwave Technologies Co., Ltd.

Advanced Microwave Technologies Co., Ltd stands ready as your premier China Double-Ridged Waveguide Loop Coupler manufacturer, combining over 20 years of microwave expertise with state-of-the-art manufacturing capabilities to deliver solutions that exceed your testing requirements. As a leading China Double-Ridged Waveguide Loop Coupler supplier, we maintain extensive production capacity and flexible manufacturing processes that support both volume production and rapid prototyping for specialized applications. Our China Double-Ridged Waveguide Loop Coupler factory operates under ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018 certifications, ensuring that every High Quality Double-Ridged Waveguide Loop Coupler leaving our facility meets rigorous quality, environmental, and safety standards.

Whether you require China Double-Ridged Waveguide Loop Coupler wholesale quantities for large-scale test system deployments or custom-engineered solutions for unique measurement challenges, our technical team provides comprehensive support from initial specification development through final product delivery and beyond. Our competitive Double-Ridged Waveguide Loop Coupler price structure reflects efficient manufacturing processes and supply chain optimization, delivering exceptional value without compromising the performance and reliability essential for precision test applications. We offer extensive customization options including tailored frequency ranges, specialized coupling coefficients, custom flange configurations, and material selections optimized for your operating environment.

Our engineering team welcomes collaboration on challenging projects requiring innovative Double-Ridged Waveguide Loop Coupler designs that push the boundaries of current technology. From concept through production, we provide technical expertise in electromagnetic design, precision manufacturing, and comprehensive performance validation within our advanced 24m Microwave Darkroom facility equipped with measurement capabilities spanning 0.5 to 110 GHz. When you partner with Advanced Microwave Technologies Co., Ltd, you gain access to quick turnaround prototyping services, in-depth technical support including installation guidance and troubleshooting assistance, and the confidence that comes from working with a China Double-Ridged Waveguide Loop Coupler supplier committed to your success.

We invite you to discover why leading organizations in satellite communications, defense, aerospace, and telecommunications rely on our Double-Ridged Waveguide Loop Coupler for sale to power their most critical test systems. Our responsive customer service team stands ready to discuss your specific requirements, provide detailed technical specifications, and develop solutions that precisely match your testing needs. For comprehensive information about our High Quality Double-Ridged Waveguide Loop Coupler products, competitive pricing, and customization capabilities, contact our team today at craig@admicrowave.com. Save this resource for future reference whenever your testing challenges demand the superior performance that only precision-engineered Double-Ridged Waveguide Loop Coupler technology can deliver.

References

1. Pozar, David M. "Microwave Engineering, Fourth Edition." John Wiley & Sons, 2012. Chapter 7: Power Dividers and Directional Couplers.

2. Saad, Tamer S. "Microwave Engineers' Handbook, Volume 1." Artech House Publishers, 1971. Section on Waveguide Directional Couplers and Coupling Mechanisms.

3. Montgomery, C. G., Dicke, Robert H., and Purcell, Edward M. "Principles of Microwave Circuits." McGraw-Hill Book Company, MIT Radiation Laboratory Series Volume 8, 1948. Chapter 12: Directional Couplers.

4. Collin, Robert E. "Foundations for Microwave Engineering, Second Edition." IEEE Press, 2001. Chapter 6: Waveguide Components and Applications.

5. Marcuvitz, Nathan. "Waveguide Handbook." McGraw-Hill Book Company, MIT Radiation Laboratory Series Volume 10, 1951. Sections on Ridge Waveguides and Coupling Structures.

YOU MAY LIKE

VIEW MOREBroadwall Directional Coupler

VIEW MOREBroadwall Directional Coupler VIEW MOREWG Circulator

VIEW MOREWG Circulator VIEW MOREHigh Power Waveguide Differential Phase Shift Circulator

VIEW MOREHigh Power Waveguide Differential Phase Shift Circulator VIEW MOREWaveguide Coupling Fixed Attenuator

VIEW MOREWaveguide Coupling Fixed Attenuator VIEW MOREWG Isolator

VIEW MOREWG Isolator VIEW MOREHigh Power Waveguide Differential Phase Shift Isolator

VIEW MOREHigh Power Waveguide Differential Phase Shift Isolator VIEW MOREWG Band Stop Filter

VIEW MOREWG Band Stop Filter VIEW MOREWG Low Pass Filter

VIEW MOREWG Low Pass Filter