Conical Circular Polarization Horn Antenna Applications Guide

When satellite communication networks experience signal degradation during critical operations, or when defense systems struggle with polarization mismatch in adverse atmospheric conditions, the root cause often traces back to inadequate antenna technology. The Conical Circular Polarization Horn Antenna emerges as the definitive solution for professionals facing these challenges, delivering exceptional performance across diverse microwave applications where signal integrity cannot be compromised under any circumstances.

Understanding Conical Circular Polarization Horn Antenna Technology

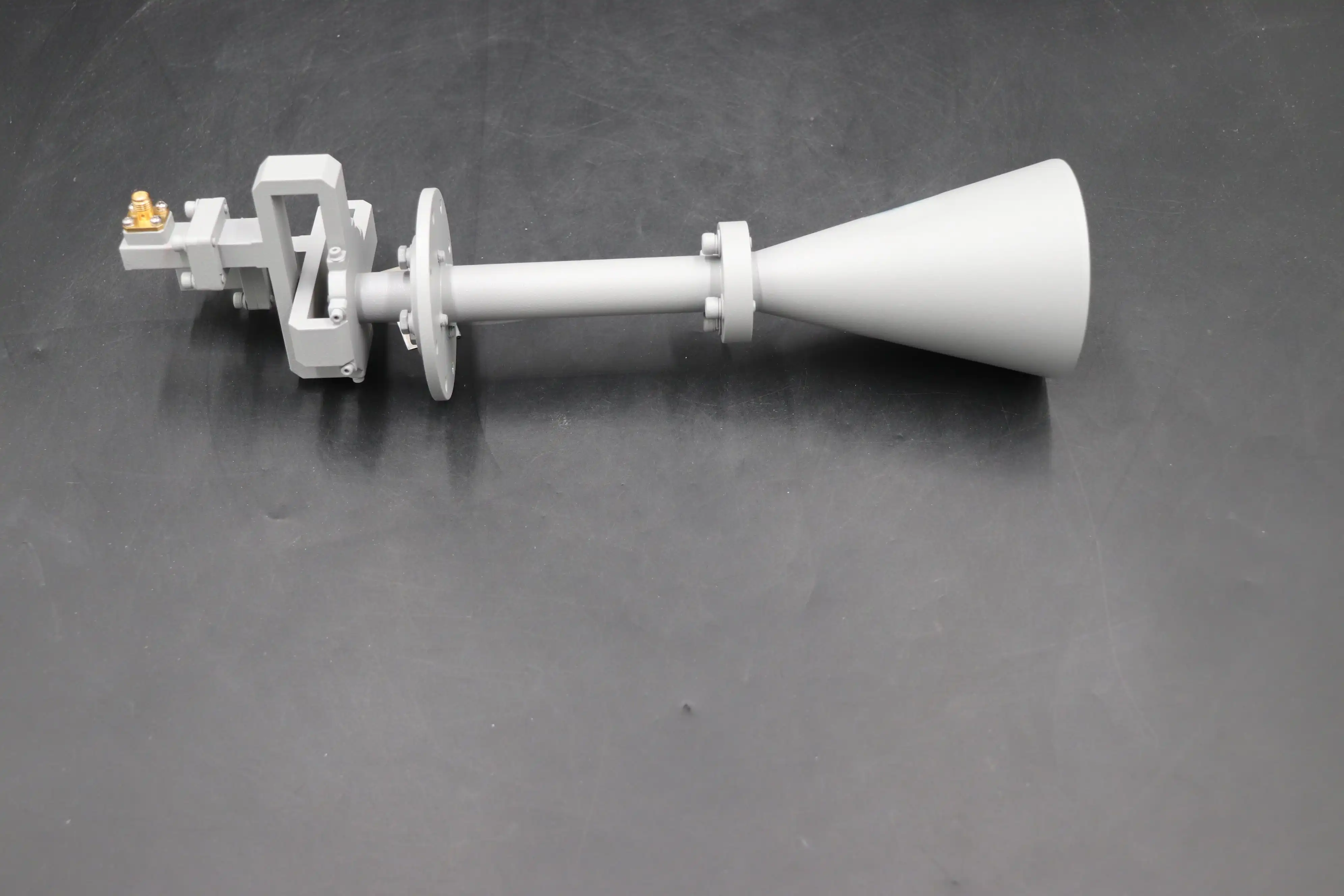

The Conical Circular Polarization Horn Antenna represents a sophisticated evolution in microwave antenna design, combining conical geometry with circular polarization capabilities to address fundamental challenges in modern communication systems. Unlike conventional linearly polarized antennas that suffer from orientation sensitivity and atmospheric interference, these specialized components maintain signal integrity regardless of receiver orientation or environmental conditions. The technology leverages electromagnetic wave propagation principles where electric field vectors rotate in a circular pattern perpendicular to the direction of propagation, effectively eliminating polarization mismatch losses that plague traditional antenna systems. Advanced Microwave manufactures a comprehensive line of circular polarization horn antennae designed to assist users in implementing solutions across different frequencies, bandwidths, and gain requirements. The electromagnetic vibrator configurations include various circular polarization antenna types such as spiral antennas, circular polarization horn antennas, aperture circular polarization antennas, microstrip circularly polarized antennas, reflector circular polarization antennas, and variable polarization antennas. Each configuration serves specific application requirements while maintaining the core advantage of circular polarization technology.

The fundamental operating principle behind Conical Circular Polarization Horn Antenna systems involves generating orthogonal electric field components with precise ninety-degree phase differences. This phase relationship creates the characteristic rotating electric field pattern essential for circular polarization performance. The conical horn structure provides natural impedance transformation between the feeding waveguide and free space, while simultaneously supporting the propagation modes necessary for maintaining polarization purity across extended frequency ranges. Modern designs typically incorporate specialized feed structures or polarizer elements that generate the required phase differential, ensuring consistent axial ratio performance throughout the operational bandwidth.

Critical Applications of Conical Circular Polarization Horn Antenna Systems

Satellite Communication Infrastructure

Satellite communication networks represent the primary application domain where Conical Circular Polarization Horn Antenna technology demonstrates indispensable value. Ground station terminals operating with these antennas achieve remarkable immunity against Faraday rotation effects that occur when electromagnetic waves traverse the ionosphere, a phenomenon that severely degrades linearly polarized signals during periods of high solar activity or geomagnetic disturbances. The circular polarization characteristic ensures that transmitted and received signals maintain consistent quality regardless of atmospheric conditions, making these antennas essential for mission-critical satellite links supporting telecommunications, broadcasting, and data relay services. The versatility of Conical Circular Polarization Horn Antenna systems extends across multiple satellite frequency bands, from L-band applications at lower frequencies through Ku-band and Ka-band services operating at higher microwave frequencies. Advanced Microwave's product line spans frequency ranges from one gigahertz to forty gigahertz, providing comprehensive coverage for legacy systems and next-generation satellite constellations. The antennas deliver antenna gain ranging from ten to twenty decibels isotropic circular, ensuring sufficient link margins for reliable communication over vast distances between ground stations and orbiting satellites positioned in geostationary or low Earth orbits.

Aerospace and Defense Applications

Military and aerospace platforms demand antenna systems capable of delivering unwavering performance under the most challenging operational scenarios. Conical Circular Polarization Horn Antenna technology fulfills these stringent requirements through robust construction, consistent radiation patterns, and excellent environmental resilience. Radar systems mounted on aircraft, unmanned aerial vehicles, and naval vessels utilize these antennas for target detection, tracking, and identification missions where polarization diversity provides crucial advantages in distinguishing between genuine threats and environmental clutter or deliberate countermeasures. The compact and lightweight design characteristics of modern Conical Circular Polarization Horn Antenna implementations make them particularly suitable for airborne applications where size, weight, and power constraints impose severe design limitations. Despite maintaining structural efficiency, these antennas achieve high aperture efficiency exceeding seventy percent across their operational bandwidths, maximizing effective radiated power for transmission functions and enhancing sensitivity for reception operations. Defense contractors integrating these components into surveillance systems benefit from low sidelobe levels that minimize vulnerability to electronic warfare threats while reducing interference with adjacent communication channels operating in crowded electromagnetic spectrum environments.

Navigation and Positioning Systems

Precision navigation systems including global positioning satellite receivers and differential GPS applications rely fundamentally on circular polarization technology to maintain signal acquisition and tracking performance. The Conical Circular Polarization Horn Antenna serves as the critical interface element that captures weak signals transmitted from navigation satellites orbiting approximately twenty thousand kilometers above Earth's surface. Circular polarization proves essential in these applications because reflected signals from buildings, terrain, and other structures typically undergo polarization reversal, allowing navigation receivers to discriminate between direct line-of-sight signals and potentially corrupting multipath reflections. Advanced applications in aviation navigation, maritime positioning, and land surveying demand extremely stable antenna performance with consistent gain patterns and minimal axial ratio degradation across the reception bandwidth. The Conical Circular Polarization Horn Antenna meets these requirements through careful design optimization that maintains three-decibel axial ratio performance over substantial fractional bandwidths. This consistent polarization purity translates directly into improved positioning accuracy and reliability, particularly in challenging urban canyon environments or dense forest canopies where signal strength margins prove marginal and multipath interference becomes problematic for conventional antenna technologies.

Wireless Communication Networks

Modern wireless communication infrastructure increasingly adopts Conical Circular Polarization Horn Antenna technology for base station and point-to-point link applications where polarization diversity provides measurable performance advantages. The circular polarization characteristic reduces sensitivity to device orientation, a particularly valuable attribute for mobile communication scenarios where terminal antenna alignment cannot be guaranteed or controlled. Network operators deploying these antennas in rural coverage extension projects or industrial Internet of Things implementations achieve improved link reliability and extended coverage ranges compared to conventional linearly polarized alternatives. The frequency range capabilities spanning from one gigahertz through forty gigahertz position Conical Circular Polarization Horn Antenna systems advantageously for emerging fifth-generation wireless networks and anticipated sixth-generation technology development. Higher frequency millimeter-wave bands allocated for next-generation cellular services experience more severe atmospheric attenuation and precipitation effects, conditions where circular polarization provides enhanced resilience compared to linear polarization schemes. Base station designers leveraging these antenna technologies can optimize network coverage patterns while minimizing interference between adjacent cells through careful control of radiation pattern characteristics and polarization orientation.

Technical Specifications and Performance Parameters

Electrical Performance Characteristics

The Conical Circular Polarization Horn Antenna manufactured by Advanced Microwave Technologies delivers exceptional electrical performance across comprehensive frequency coverage from one gigahertz to forty gigahertz. This broad operational bandwidth accommodates diverse application requirements spanning traditional microwave communication bands through emerging millimeter-wave frequency allocations. The antenna achieves typical gain values ranging between ten and twenty decibels isotropic circular, providing sufficient directivity for long-distance communication links while maintaining reasonable beamwidth characteristics that facilitate pointing and tracking operations. Input power handling capability reaches fifty watts continuous power, adequate for most terrestrial and airborne transmission applications while maintaining conservative operation well below physical damage thresholds. The standard fifty-ohm impedance matches conventional microwave system architectures, simplifying integration with existing transmitters, receivers, and signal processing equipment without requiring additional impedance transformation networks. Connector options including SMA and N-type interfaces provide flexibility for various installation scenarios, with custom connector configurations available through Advanced Microwave's comprehensive OEM services program.

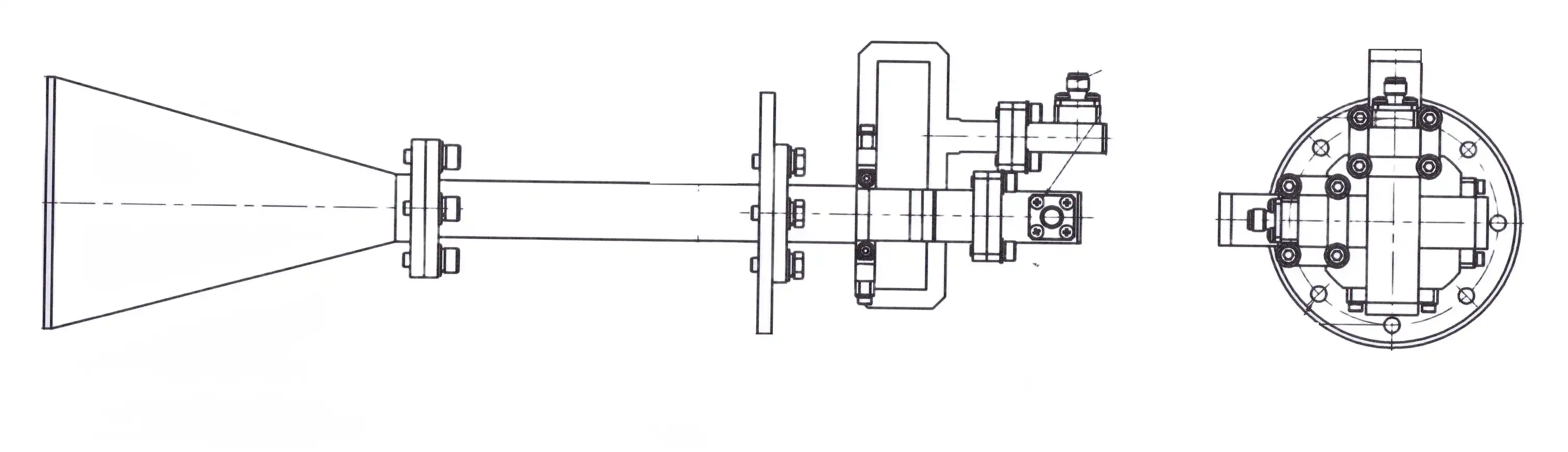

Mechanical Design and Construction

Physical construction of the Conical Circular Polarization Horn Antenna emphasizes durability and environmental resilience through selection of high-quality aluminum materials or customizable alternatives matched to specific application requirements. The weight range spanning from half a kilogram to two and a half kilograms varies according to frequency band and aperture size, with dimensional parameters fully customizable to accommodate space-constrained installations or specific radiation pattern requirements. The robust mechanical design ensures reliable operation under challenging environmental conditions including temperature extremes, precipitation, salt spray, and vibration exposure typical in aerospace and maritime deployment scenarios. Manufacturing precision proves critical for maintaining the tight tolerances necessary to achieve specified electrical performance, particularly regarding axial ratio and polarization purity across the operational frequency range. Advanced Microwave employs state-of-the-art fabrication techniques including computer numerical control machining processes that ensure consistent reproduction of critical geometric features including flare angles, aperture dimensions, and polarizer element positioning. Quality assurance testing conducted in the company's twenty-four meter microwave darkroom validates antenna performance against specified parameters, with comprehensive near-field and far-field radiation pattern measurements confirming conformance to design objectives before product delivery.

Optimizing Conical Circular Polarization Horn Antenna Implementation

Selection and Specification Process

Successful implementation of Conical Circular Polarization Horn Antenna systems begins with careful analysis of application-specific requirements including operational frequency bands, required gain levels, polarization sense selection between right-hand and left-hand circular polarization, and environmental exposure conditions anticipated during the antenna's operational lifetime. System designers must evaluate link budget calculations to determine minimum antenna gain necessary for achieving required signal-to-noise ratios at receiving terminals, accounting for path loss, atmospheric attenuation, and system noise contributions from receiving equipment and environmental sources. The selection process benefits significantly from consultation with experienced antenna engineers who understand the nuanced trade-offs between competing performance parameters. Advanced Microwave's technical support team provides comprehensive guidance throughout the specification process, leveraging decades of collective experience in microwave antenna design and application engineering. Engineers assist customers in determining optimal antenna configurations that balance electrical performance requirements against mechanical constraints, environmental exposure factors, and budgetary considerations while ensuring full compliance with relevant industry standards and regulatory requirements.

Integration and Installation Considerations

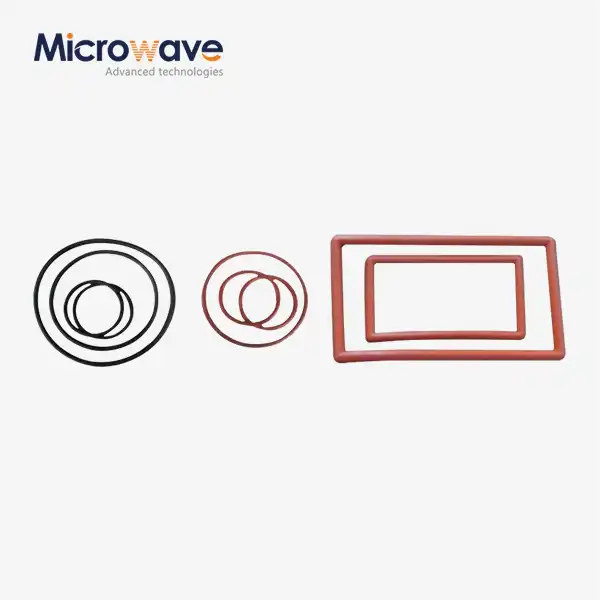

Physical installation of Conical Circular Polarization Horn Antenna systems requires attention to mounting stability, feed line routing, weatherproofing provisions, and electromagnetic interference mitigation measures. The antenna must be securely mounted to prevent physical movement during wind loading or vibration exposure that could degrade pointing accuracy or induce mechanical fatigue failures over extended operational periods. Feed line connections require proper torquing and weatherproofing to prevent moisture ingress that might compromise electrical performance through corrosion or dielectric degradation. Electromagnetic compatibility considerations demand careful attention to prevent unwanted coupling between the antenna and nearby metallic structures that could distort radiation patterns or create additional reflection paths degrading axial ratio performance. Installation locations should provide clear line-of-sight paths to intended coverage areas while minimizing nearby obstacles that might cause blockage, reflection, or diffraction effects compromising signal quality. Ground-based installations may require lightning protection measures including properly bonded grounding systems and surge suppression devices protecting sensitive receiver front-end electronics from transient overvoltages induced during electrical storm activity.

Advanced Manufacturing Capabilities and Quality Assurance

Advanced Microwave Technologies operates comprehensive manufacturing facilities equipped with precision machining centers, specialized assembly stations, and extensive testing capabilities that ensure consistent production of high-quality Conical Circular Polarization Horn Antenna products. The company's twenty-four meter microwave darkroom represents a significant competitive advantage, providing unmatched capabilities for precise antenna measurement across frequency ranges extending from half a gigahertz through one hundred ten gigahertz. This state-of-the-art facility features an Antenna Plane Near and Far Field Measuring Recombination Chamber that enables engineers to conduct comprehensive radiation pattern analysis, gain measurements, and polarization characterization essential for validating antenna performance. Quality management systems certified to ISO nine thousand one:two thousand fifteen standards govern all aspects of product development, manufacturing, and delivery processes. Every Conical Circular Polarization Horn Antenna undergoes rigorous testing protocols including reflection coefficient measurements confirming proper impedance matching, radiation pattern verification ensuring conformance to specified beamwidth and sidelobe parameters, and axial ratio characterization validating polarization purity across the operational frequency range. Environmental qualification testing validates mechanical integrity and electrical stability under temperature cycling, humidity exposure, and vibration conditions representative of field deployment scenarios.

The company's commitment to environmental stewardship reflected in ISO fourteen thousand one:two thousand fifteen certification ensures manufacturing operations minimize ecological impact through responsible waste management, energy conservation, and emissions reduction initiatives. Occupational health and safety programs meeting ISO forty-five thousand one:two thousand eighteen requirements protect employees while maintaining the high productivity levels necessary for competitive manufacturing operations. These comprehensive quality and environmental management systems provide customers with confidence that Conical Circular Polarization Horn Antenna products will deliver reliable performance throughout their intended operational lifetimes.

Conclusion

The Conical Circular Polarization Horn Antenna stands as an indispensable component enabling reliable microwave communication across satellite, aerospace, defense, and wireless infrastructure applications.

Cooperate with Advanced Microwave Technologies Co., Ltd.

Advanced Microwave Technologies Co., Ltd. brings over twenty years of specialized experience manufacturing precision microwave components for global customers across satellite communications, defense, aerospace, and navigation industries. Our comprehensive product portfolio includes waveguide assemblies, coaxial and cable assemblies, microwave antennas with advanced feed systems and servo controls, antenna measurement systems, and microwave measurement equipment supporting frequencies up to one hundred ten gigahertz. Our state-of-the-art laboratories feature the remarkable twenty-four meter microwave darkroom with Antenna Plane Near and Far Field Measuring Recombination Chamber, providing unparalleled testing capabilities from half a gigahertz through one hundred ten gigahertz for ensuring optimal antenna performance.

As a leading China Conical Circular Polarization Horn Antenna manufacturer, China Conical Circular Polarization Horn Antenna supplier, and China Conical Circular Polarization Horn Antenna factory, we offer comprehensive OEM services tailored to your unique specifications. Whether you require frequency range adjustments, custom materials, specialized connector types, or modified dimensional parameters, our expert engineering team provides complete technical support from initial concept through installation assistance and troubleshooting. We maintain competitive Conical Circular Polarization Horn Antenna price structures through efficient manufacturing processes while never compromising on quality, with every High Quality Conical Circular Polarization Horn Antenna for sale meeting ISO certification standards. Our China Conical Circular Polarization Horn Antenna wholesale programs deliver rapid prototyping, quick turnaround times, and comprehensive technical documentation supporting your integration efforts. Contact craig@admicrowave.com today to discuss your specific requirements and discover how our cutting-edge antenna solutions can elevate your system performance.

References

1. Balanis, Constantine A. "Antenna Theory: Analysis and Design." Fourth Edition. John Wiley & Sons.

2. Rappaport, Theodore S., Xing, Yunchou, Kanhere, Ojas, Ju, Shihao, Madanayake, Arjuna, Mandal, Soumyajit, Alkhateeb, Ahmed, and Trichopoulos, George C. "Wireless Communications and Applications Above 100 GHz: Opportunities and Challenges for 6G and Beyond." IEEE Access, Volume 7.

3. Milligan, Thomas A. "Modern Antenna Design." Second Edition. John Wiley & Sons.

4. Stutzman, Warren L. and Thiele, Gary A. "Antenna Theory and Design." Third Edition. John Wiley & Sons.

5. Rao, B. L. J. "Circular Polarization Techniques for Satellite Communications." Proceedings of the IEEE International Symposium on Antennas and Propagation.

YOU MAY LIKE

VIEW MOREDouble Ridge Straight Waveguide

VIEW MOREDouble Ridge Straight Waveguide VIEW MOREDouble Ridge Waveguide Transition

VIEW MOREDouble Ridge Waveguide Transition VIEW MOREDouble Ridged Flexible Waveguide

VIEW MOREDouble Ridged Flexible Waveguide VIEW MOREDouble Ridge Waveguide Load

VIEW MOREDouble Ridge Waveguide Load VIEW MOREDouble Ridge Waveguide Rotary Joint

VIEW MOREDouble Ridge Waveguide Rotary Joint VIEW MOREDouble-Ridged Waveguide Broadwall Directional Coupler

VIEW MOREDouble-Ridged Waveguide Broadwall Directional Coupler VIEW MOREWaveguide Flange Gasket

VIEW MOREWaveguide Flange Gasket VIEW MOREWaveguide Adjustable Support

VIEW MOREWaveguide Adjustable Support