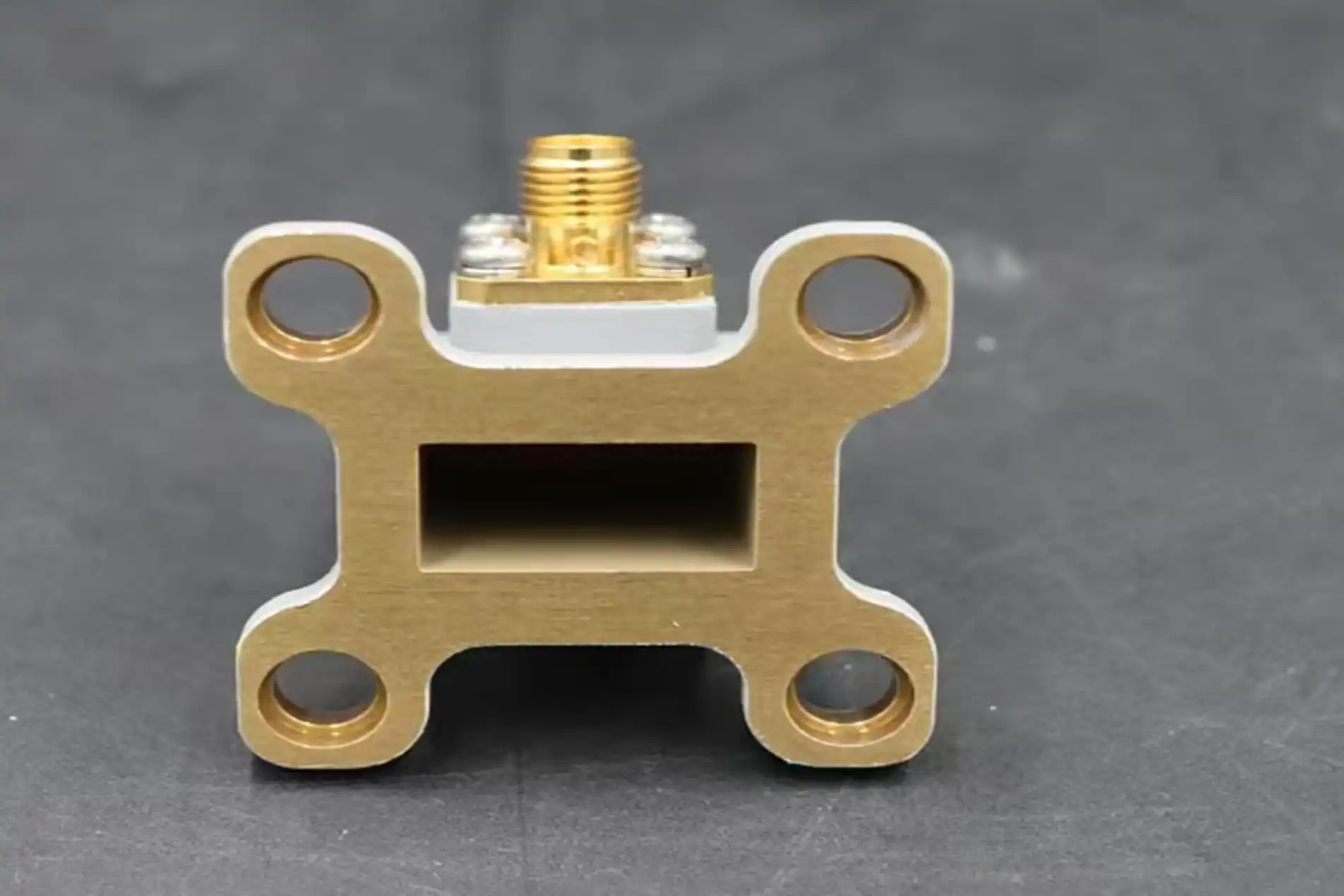

China Customized OEM Bulk Custom Waveguide to Coaxial Adapter

When your satellite communication system experiences signal degradation or your radar installation faces impedance mismatches between waveguide and coaxial transmission lines, the solution lies in precision-engineered Custom Waveguide to Coaxial Adapters. These critical components bridge the gap between different transmission media, ensuring seamless signal transition in microwave and RF systems where every decibel of insertion loss matters and every VSWR point impacts system performance.

Understanding Custom Waveguide to Coaxial Adapter Technology

Custom Waveguide to Coaxial Adapters represent sophisticated interface solutions designed to connect rectangular or circular waveguide transmission lines to coaxial cable systems. In modern microwave engineering, these adapters serve as the crucial link that enables signal transfer between high-power waveguide systems and flexible coaxial assemblies. The Custom Waveguide to Coaxial Adapter operates by transforming the electromagnetic field pattern from the waveguide's propagation mode to the TEM mode characteristic of coaxial lines, maintaining signal integrity throughout the transition. This transformation requires precise impedance matching, typically achieving VSWR values below 1.2 across specified frequency bands, while minimizing insertion loss to preserve signal strength in critical applications ranging from satellite ground stations to military radar systems.

Engineering Principles Behind Waveguide to Coaxial Transitions

The fundamental challenge in designing a Custom Waveguide to Coaxial Adapter involves managing the dramatic change in field structure between waveguide and coaxial propagation modes. Waveguides support TE and TM modes with field patterns distributed across their cross-sectional area, while coaxial lines propagate TEM modes with fields confined between inner and outer conductors. Advanced Microwave Technologies Co., Ltd. addresses this challenge through precision-machined probe assemblies that couple electromagnetic energy from the waveguide's dominant mode into the coaxial line's characteristic impedance environment. The probe depth, diameter, and positioning are calculated using electromagnetic simulation tools to optimize power transfer across the operating frequency range, whether that spans X-band frequencies from 8.2 to 12.4 GHz or extends into millimeter-wave bands approaching 110 GHz. Material selection plays an equally critical role, with oxygen-free copper providing excellent conductivity while silver plating reduces surface resistance and oxidation that could degrade performance over time.

Frequency Range Considerations for Custom Waveguide Adapters

Operating frequency directly dictates the physical dimensions and design approach for Custom Waveguide to Coaxial Adapters. Lower frequency applications in L-band and S-band utilize larger waveguide apertures, resulting in adapters with substantial physical dimensions and robust mechanical construction suitable for high-power transmission applications. As frequency increases into Ku-band and Ka-band territory, waveguide dimensions shrink dramatically, requiring micromachining precision to maintain the tight tolerances necessary for optimal electrical performance. Advanced Microwave Technologies Co., Ltd.'s Custom WG to Coaxial Adapter product line spans frequencies from 500 MHz to 110 GHz, accommodating everything from legacy UHF communication systems to cutting-edge millimeter-wave 5G infrastructure and next-generation 6G research platforms. The wide frequency coverage capability stems from the company's advanced measurement facilities, including their 24m Microwave Darkroom equipped with Antenna Plane Near and Far Field Measuring Recombination Chamber, enabling precise characterization across this expansive spectrum.

Custom OEM Solutions for Specialized Applications

Original Equipment Manufacturer services for Custom Waveguide to Coaxial Adapters have become increasingly critical as industries demand tailored solutions that address unique system requirements. Off-the-shelf adapters rarely meet the exacting specifications of advanced radar systems, satellite communication payloads, or precision test instrumentation where every parameter must align perfectly with system architecture. Custom Waveguide to Coaxial Adapter OEM development begins with comprehensive requirements analysis, examining factors including operating frequency bands, power handling capabilities, environmental conditions, mounting configurations, and interface specifications for both waveguide flanges and coaxial connectors. Advanced Microwave Technologies Co., Ltd.'s engineering team collaborates directly with clients during the specification phase, leveraging over two decades of microwave component expertise to recommend optimal design approaches that balance electrical performance, mechanical reliability, manufacturing feasibility, and cost-effectiveness for bulk production quantities.

Material Selection and Mechanical Design Optimization

The choice of materials for Custom Waveguide to Coaxial Adapters significantly impacts both electrical performance and long-term reliability in demanding operational environments. Aluminum alloys offer excellent strength-to-weight ratios and thermal conductivity, making them ideal for aerospace applications where weight constraints are paramount, while copper and brass provide superior electrical conductivity for applications prioritizing lowest insertion loss. Advanced Microwave Technologies Co., Ltd. typically constructs adapter bodies from aerospace-grade aluminum with precision CNC machining, then applies silver plating to interior surfaces for enhanced conductivity and corrosion resistance. The exterior receives anticorrosion grey paint as standard, though custom finishes including chromate conversion coatings, hard anodizing, or nickel plating can be specified for extreme environmental conditions. Mechanical design encompasses not only the RF transition itself but also the mounting interface, with options including standard UG flange patterns, custom bolt-hole arrangements, or integrated brackets for specific installation geometries. The robust construction ensures the Custom Waveguide to Coaxial Adapter maintains performance specifications even when subjected to vibration, thermal cycling, and mechanical shock common in mobile radar platforms, shipboard systems, and airborne communication equipment.

Electrical Performance Parameters and Testing Protocols

Quantifying the electrical performance of Custom Waveguide to Coaxial Adapters requires comprehensive testing across multiple parameters that collectively determine system-level impact. Insertion loss measurements reveal the signal attenuation introduced by the adapter, with high-quality designs achieving values below 0.15 dB across the specified bandwidth as demonstrated by Advanced Microwave Technologies Co., Ltd.'s ADM-100WCAST21 model operating from 9.32 to 9.42 GHz. Voltage Standing Wave Ratio testing characterizes impedance matching quality, with maximum VSWR specifications of 1.1 indicating exceptional match that minimizes reflected power and maximizes forward transmission efficiency. Return loss measurements provide complementary information, with values exceeding 26 dB confirming that less than 0.25% of incident power reflects back toward the source. Power handling capability varies with frequency and physical size, ranging from several watts for millimeter-wave adapters to hundreds of kilowatts for lower-frequency high-power applications. Advanced Microwave Technologies Co., Ltd. conducts all electrical validation in their ISO-certified laboratories using calibrated network analyzers and the sophisticated measurement capabilities of their 24m Microwave Darkroom, ensuring every Custom Waveguide to Coaxial Adapter meets or exceeds specified performance before shipment.

Bulk Manufacturing and Quality Assurance Processes

Producing Custom Waveguide to Coaxial Adapters in bulk quantities while maintaining consistent quality demands sophisticated manufacturing infrastructure and rigorous process controls. Advanced Microwave Technologies Co., Ltd. has developed streamlined production workflows that leverage CNC machining centers, precision assembly fixtures, and automated testing equipment to achieve high throughput without compromising the tight tolerances essential for microwave components. The manufacturing process begins with precision machining of waveguide bodies and coaxial probe assemblies using CAD/CAM programming derived from electromagnetic simulation models. Component cleaning removes machining oils and contaminants that could interfere with plating adhesion, followed by electroplating processes that deposit silver or gold layers to specified thicknesses with uniform coverage across all RF surfaces. Assembly operations integrate coaxial connectors, positioning probes at precisely calculated depths and orientations, then secure all elements with locking mechanisms designed to maintain alignment through environmental extremes. Each assembled Custom Waveguide to Coaxial Adapter undergoes individual electrical testing using automated network analyzers that verify insertion loss, VSWR, and return loss across the operating band, with measurement data recorded for quality documentation and traceability.

ISO Certification and Compliance Standards

Quality management systems certified to ISO 9001:2015 provide the foundation for consistent manufacturing of Custom Waveguide to Coaxial Adapters that meet customer specifications batch after batch. Advanced Microwave Technologies Co., Ltd.'s ISO certification encompasses design control procedures that validate new Custom Waveguide to Coaxial Adapter variants through prototype testing before production release, process control mechanisms that monitor critical manufacturing parameters, and inspection protocols that verify dimensional accuracy and surface finish quality at defined checkpoints throughout fabrication. Environmental management under ISO 14001:2015 ensures manufacturing operations minimize ecological impact through responsible waste management, energy conservation, and emissions control, while ISO 45001:2018 certification demonstrates commitment to occupational health and safety for technicians and engineers working with precision machining equipment and electroplating systems. RoHS compliance guarantees Custom Waveguide to Coaxial Adapters contain no prohibited hazardous substances, making them suitable for European markets and environmentally conscious customers worldwide. This comprehensive certification framework provides customers with confidence that bulk orders will deliver consistent performance characteristics and regulatory compliance across all units.

Application-Specific Custom Waveguide to Coaxial Adapter Solutions

Different application domains impose distinct requirements on Custom Waveguide to Coaxial Adapter designs, necessitating tailored approaches that optimize performance for specific operational contexts. Satellite communication ground stations require adapters with exceptional phase stability across temperature variations, low passive intermodulation for minimal interference generation, and power handling sufficient for transmit chains potentially exceeding hundreds of watts. Radar systems demand Custom Waveguide to Coaxial Adapters with extremely low insertion loss to preserve precious transmit power and receiver sensitivity, wide instantaneous bandwidth to support advanced waveforms, and rugged construction withstanding the mechanical stresses of rotating antenna platforms. Test and measurement applications prioritize measurement repeatability, with adapters designed to minimize uncertainty contributions through superior impedance matching and phase linearity across sweeping frequency ranges. Advanced Microwave Technologies Co., Ltd. addresses these diverse requirements through customization capabilities spanning frequency optimization, power scaling, impedance tailoring, material selection, and environmental hardening, ensuring each Custom Waveguide to Coaxial Adapter precisely matches its intended application.

Defense and Aerospace Applications

Military and aerospace systems subject Custom Waveguide to Coaxial Adapters to extreme environmental conditions while demanding unfailing reliability. Airborne radar installations experience temperature swings from minus 55 degrees Celsius at altitude to plus 85 degrees Celsius on desert airfields, vibration spectra spanning dozens of hertz to several kilohertz, and humidity variations from arid to saturated. Naval shipboard systems face salt spray corrosion, shock loads from weapons fire and rough seas, and the additional challenge of maintaining performance despite constant motion. Advanced Microwave Technologies Co., Ltd. qualifies Custom Waveguide to Coaxial Adapters for these harsh environments through accelerated life testing, thermal cycling between temperature extremes, vibration table validation at multiple frequencies and amplitudes, and corrosion chamber exposure to salt fog atmospheres. The resulting designs incorporate features like hermetically sealed coaxial interfaces, conformal coating application, and mechanical stress relief to ensure reliable signal transition even when deployed on aircraft carriers, fighter jets, unmanned aerial vehicles, and satellite platforms operating beyond Earth's atmosphere.

Commercial Communication Infrastructure

The explosive growth of wireless communication infrastructure creates substantial demand for high-performance Custom Waveguide to Coaxial Adapters that enable efficient signal distribution in base stations and network equipment. Fifth-generation cellular networks operating in millimeter-wave frequency bands above 24 GHz require precise impedance matching and minimal insertion loss to maximize cell coverage from expensive spectrum allocations. Massive MIMO antenna arrays incorporate dozens or hundreds of radiating elements, each requiring a transition from waveguide distribution networks to coaxial feed lines with consistent amplitude and phase characteristics across all channels. Advanced Microwave Technologies Co., Ltd. supports telecom infrastructure deployment through Custom Waveguide to Coaxial Adapter designs optimized for 5G frequency bands including n257, n258, n260, and n261, with low VSWR ensuring efficient power transfer and phase-matched sets maintaining beamforming accuracy. The company's bulk manufacturing capabilities enable network operators to source adapter quantities sufficient for large-scale deployments while custom OEM services accommodate proprietary antenna designs requiring specialized interface configurations.

China Manufacturing Advantages for Custom Waveguide Components

China has emerged as a global manufacturing powerhouse for microwave components, combining advanced technical capabilities with efficient production infrastructure and competitive pricing structures. Advanced Microwave Technologies Co., Ltd. exemplifies these advantages through state-of-the-art facilities located in China that house precision CNC machining centers, modern electroplating lines, sophisticated assembly stations, and comprehensive testing laboratories equipped with instrumentation up to 110 GHz. The company's supply chain integration provides access to high-quality raw materials including oxygen-free copper, aerospace aluminum alloys, and precious metal plating solutions at advantageous costs, while skilled engineering teams deliver design expertise honed through thousands of Custom Waveguide to Coaxial Adapter projects spanning military, aerospace, telecom, and scientific research applications. Customers partnering with this China Custom Waveguide to Coaxial Adapter manufacturer benefit from rapid prototyping capabilities that accelerate product development cycles, scalable production capacity supporting orders from single prototype units to thousands of pieces for bulk deployment, and responsive technical support that facilitates specification optimization and application troubleshooting throughout project lifecycles.

Global Export Capabilities and Customer Support

As a China Custom Waveguide to Coaxial Adapter supplier serving international markets, Advanced Microwave Technologies Co., Ltd. has developed comprehensive export operations that simplify procurement for customers worldwide. The company handles all export documentation, customs clearance procedures, and shipping logistics, delivering Custom Waveguide to Coaxial Adapters to destinations across North America, Europe, Asia, and beyond through established relationships with international freight carriers. Technical support extends globally through multilingual engineering staff available to discuss specifications, recommend design approaches, and assist with system integration challenges regardless of customer location or time zone. Quality documentation accompanies every shipment, including calibration certificates traceable to national standards, material certifications verifying composition and plating specifications, and test data confirming electrical performance parameters. This comprehensive support infrastructure makes Advanced Microwave Technologies Co., Ltd. a reliable China Custom Waveguide to Coaxial Adapter factory for organizations seeking high-performance components backed by responsive service and technical expertise.

Conclusion

Custom Waveguide to Coaxial Adapters represent critical enabling technology for modern microwave systems, with China-based manufacturing offering compelling advantages in quality, capability, and value for bulk procurement needs.

Cooperate with Advanced Microwave Technologies Co., Ltd.

Advanced Microwave Technologies Co., Ltd. stands ready as your trusted China Custom Waveguide to Coaxial Adapter manufacturer, offering over 20 years of microwave expertise backed by ISO certifications and cutting-edge facilities including our 24m Microwave Darkroom testing capability. Whether you need High Quality Custom Waveguide to Coaxial Adapter prototypes or bulk wholesale quantities, our China Custom Waveguide to Coaxial Adapter factory delivers precision-engineered solutions with competitive Custom Waveguide to Coaxial Adapter price points. As a leading China Custom Waveguide to Coaxial Adapter supplier with Custom Waveguide to Coaxial Adapter for sale across global markets, we provide comprehensive OEM services, fast delivery, and expert technical support. Contact our team at craig@admicrowave.com to discuss your specific requirements and discover how our custom solutions can optimize your RF system performance. Bookmark this resource for future reference when waveguide interface challenges arise.

References

1. Pozar, David M. "Microwave Engineering: Fourth Edition." John Wiley & Sons, 2012. Chapter 5: Impedance Matching and Tuning.

2. Saad, Theodore S. "Microwave Engineers' Handbook: Volume Two." Artech House, 1971. Section on Waveguide-to-Coaxial Transitions.

3. Ramo, Simon, John R. Whinnery, and Theodore Van Duzer. "Fields and Waves in Communication Electronics: Third Edition." John Wiley & Sons, 1994. Chapter 9: Guided Electromagnetic Waves.

4. Collin, Robert E. "Foundations for Microwave Engineering: Second Edition." IEEE Press, 2001. Chapter 4: Microwave Network Analysis and Waveguide Discontinuities.