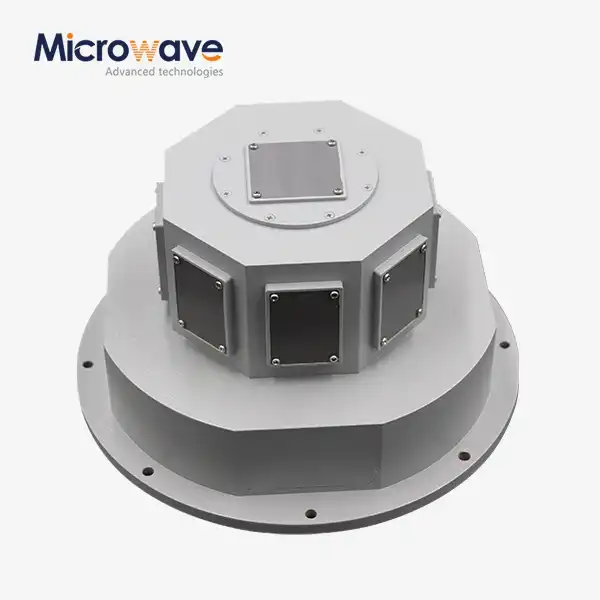

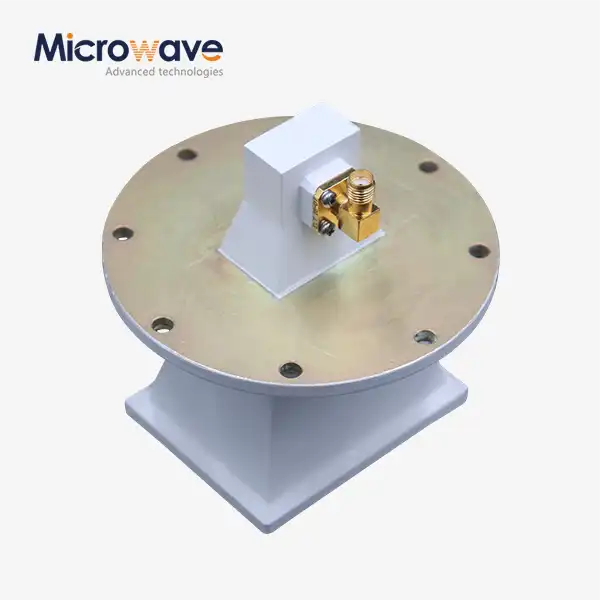

Coaxial Verification Kits

Product Introduction

As a core integrated test solution for coaxial system quality assurance, Coaxial Verification Kits primarily address the problem of efficient, accurate, and standardized performance verification of coaxial transmission lines, connectors, and RF subsystems. Each kit typically includes calibrated coaxial test cables , impedance standard loads, insertion loss reference modules, connector inspection gauges, a digital VSWR meter, and a detailed operation & calibration manual. According to application scenarios, common Coaxial Verification Kits are categorized into laboratory precision type, production line rapid type, and field maintenance type; according to frequency range, they cover DC to 110GHz, meeting the verification needs of low-frequency communication to high-frequency millimeter-wave systems.

Product Specifications

Parameters | Details |

|---|---|

Frequency Range | DC to 50 GHz |

Connector Types | SMA, N-Type, 3.5mm, 2.92mm |

Impedance | 50 Ohms |

Calibration Standards | Open, Short, Load, Through |

Operating Temperature | -45°C to +85°C |

Customization Options | Available for specific requirements |

Product Benefits

- Standardized test processes: Integrates pre-calibrated tools and unified operation guidelines, eliminating test result deviations caused by fragmented tools or non-uniform procedures, ensuring consistency across laboratories, production lines, and field teams.

- Comprehensive parameter coverage: Covers core verification indicators of coaxial systems, avoiding missing key performance risks that single test tools may cause.

- High verification accuracy: Adopts traceable calibrated components and high-precision test instruments, ensuring test data reliability for R&D validation and quality certification.

- Efficient operation: All tools are organized in a custom foam-lined case for quick access; the integrated design eliminates the need for time-consuming tool assembly and compatibility checks, reducing verification time by 40% compared to fragmented tools.

- Strong environmental adaptability: Field-oriented kits use rugged, anti-drop casings and dustproof/waterproof components; high-temperature-resistant materials for internal modules ensure stable operation in harsh environments such as outdoor construction sites or industrial workshops.

- Cost-effective: Reduces the cost of purchasing individual test tools and repeated calibration; the kit’s modular design allows partial component replacement instead of full kit replacement, lowering long-term maintenance costs.

Technical Features

- Traceable calibration components: All standard loads, test cables, and reference modules in the kit undergo third-party metrology calibration, with a calibration certificate provided to ensure test data traceability and compliance with international standards.

- High-stability test cables: Uses silver-plated copper inner conductors and low-loss PTFE dielectrics; the cable jacket is made of wear-resistant TPE material, ensuring low insertion loss and stable performance even after 1000+ bending cycles.

- Intelligent test assistance: High-end kits are equipped with a built-in touchscreen controller that automatically records test data, generates verification reports, and sends calibration reminders, avoiding manual data entry errors.

- Anti-interference design: The digital VSWR meter in the kit adopts shielded circuit boards and differential signal sampling technology, reducing electromagnetic interference (EMI) from the surrounding environment, ensuring accurate measurement in complex industrial or field settings.

- Modular compatibility: The kit's test instruments support interface compatibility with mainstream RF test equipment, allowing integration into existing test systems without additional hardware replacement.

Product Applications

- Communication infrastructure deployment: Used in 5G/6G base station construction, microwave backhaul link installation, and fiber-optic-RF hybrid network deployment to verify the performance of coaxial cables, jumpers, and antenna feed systems, ensuring stable signal transmission.

- RF device manufacturing: Applied in the production of coaxial connectors, attenuators, filters, and RF amplifiers to conduct batch performance screening and final quality inspection, improving product pass rates.

- Test & measurement laboratories: Essential for R&D of coaxial transmission systems, millimeter-wave components, and satellite communication modules; provides accurate reference standards for validating prototype performance and optimizing circuit designs.

- Field maintenance & troubleshooting: Used by telecom operators and system integrators for on-site maintenance of communication towers, indoor distributed systems, and radar stations to quickly locate issues such as coaxial cable damage, connector loosening, or impedance mismatch.

- Aerospace & defense systems: Adopted in the testing of aircraft communication systems, missile guidance RF links, and satellite ground station feed networks; the high-precision and anti-vibration design ensures reliable performance verification in harsh aerospace environments.

- Industrial & medical RF equipment: Applied in the maintenance of microwave heating equipment, RF plasma generators, and medical RF ablation devices to verify the integrity of coaxial transmission paths, preventing equipment failure caused by transmission line defects.

OEM

Advanced Microwave provides professional OEM services for Coaxial Verification Kits to meet the personalized needs of different customer projects:

- Customized parameter configuration: Tailor the kit’s frequency range, impedance accuracy, and measurement indicators according to customer-specific application scenarios.

- Tool & accessory customization: Design kits with non-standard coaxial connector gauges, custom-length test cables, or integrated power supplies for field use, adapting to unique test requirements.

- Software & report customization: Develop dedicated test data management software for the kit, supporting custom report templates and integration with customer's MES for production line data tracking.

- Structural & packaging customization: Design compact, portable cases for field-use kits or bench-top storage racks for laboratory kits; support custom color casings and logo printing to enhance brand recognition.

- Technical collaboration & training: Offer pre-sales technical consultation and post-sales on-site training for customer teams, ensuring proficient use of the Coaxial Verification Kits and accurate interpretation of test results.

FAQ

Q: What is the difference between Coaxial Verification Kits and individual coaxial test tools?

A: Coaxial Verification Kits integrate pre-calibrated, matched test components and standardized procedures, avoiding compatibility issues and result deviations between individual tools. Individual tools require separate calibration and assembly, which is time-consuming and prone to errors—especially unsuitable for scenarios requiring consistent, efficient verification .

Q: How often do Coaxial Verification Kits need to be recalibrated?

A: The calibration interval depends on the kit type and usage frequency: Laboratory Precision Kits (used for high-accuracy testing) require recalibration every 6 months; Production Line Rapid Kits and Field Maintenance Kits can be recalibrated every 12 months. If the kit is exposed to severe impact, high temperature, or humid environments, it is recommended to shorten the calibration interval and conduct a pre-use verification.

Q: Are Coaxial Verification Kits suitable for non-professional operators in the field?

A: Yes. The Field Maintenance Type Coaxial Verification Kits are designed with user-friendly features: simplified operation interfaces, clear LED status indicators, and a detailed troubleshooting guide. Additionally, we provide pre-sales training to ensure non-professional operators can quickly master basic verification operations and identify common issues.

Q: Can the components of Coaxial Verification Kits be replaced individually if damaged?

A: Yes. The kit adopts a modular design—all components are replaceable independently. When a component is worn or damaged, customers only need to purchase the corresponding replacement part instead of replacing the entire kit, significantly reducing maintenance costs.

Contact Us

If you need a high-performance Coaxial Verification Kit to solve the problems of inefficient, inaccurate, or non-standard verification of coaxial systems, contact us now to get customized solutions tailored to your project!

📧 Email: [sales@admicrowave.com]

YOU MAY LIKE

VIEW MORESlotted Waveguide Array Antenna

VIEW MORESlotted Waveguide Array Antenna VIEW MOREOpen Boundary Dual Linear Polarization Four Ridged Horn Antenna

VIEW MOREOpen Boundary Dual Linear Polarization Four Ridged Horn Antenna VIEW MOREDual Linear Broadband Circular Polarization Horn Antenna

VIEW MOREDual Linear Broadband Circular Polarization Horn Antenna VIEW MOREPyramidal Linear Polarization Horn Antenna

VIEW MOREPyramidal Linear Polarization Horn Antenna VIEW MOREConical Linear Polarization Horn Antenna

VIEW MOREConical Linear Polarization Horn Antenna VIEW MORELow Side Lobe Diagonal Linear Polarization Horn Antenna

VIEW MORELow Side Lobe Diagonal Linear Polarization Horn Antenna VIEW MOREQuadrifilar Helix Antenna

VIEW MOREQuadrifilar Helix Antenna VIEW MORECassegrain Antenna

VIEW MORECassegrain Antenna