Boost Your Radar System's Efficiency with Our WR-90 & WR-75 Waveguide Circulators

Are your radar systems experiencing signal degradation, poor isolation, or unreliable performance in critical applications? Many radar engineers face the frustrating challenge of maintaining optimal signal paths while minimizing interference and maximizing power efficiency. The solution lies in selecting the right Waveguide Circulator technology that can handle high-power applications while delivering consistent, reliable performance across demanding frequency ranges.

Understanding WR-90 & WR-75 Waveguide Circulator Technology

Core Functionality and Operating Principles

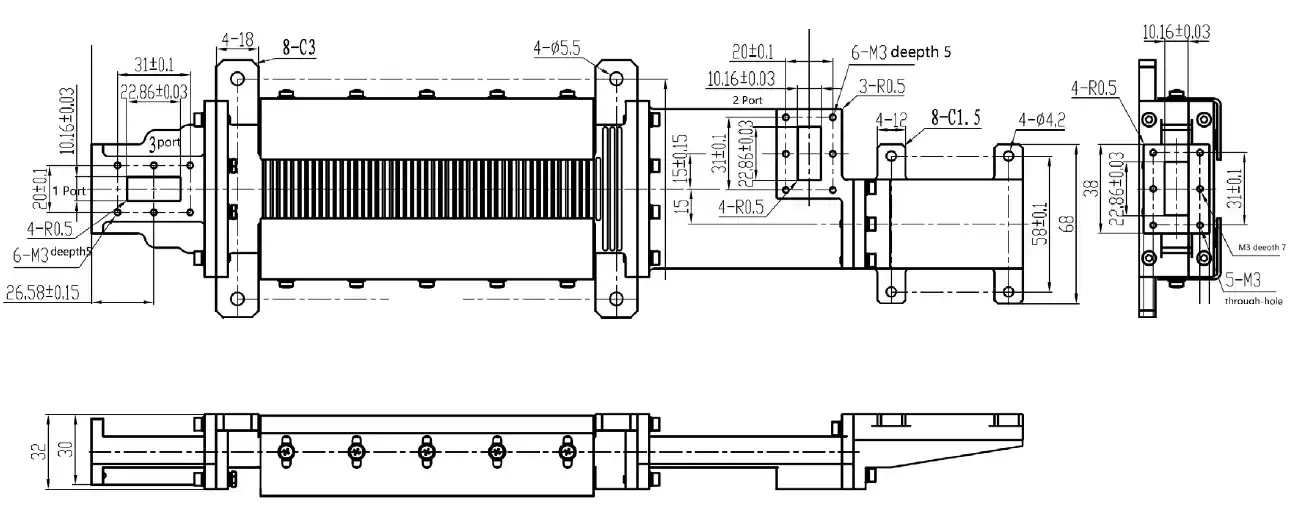

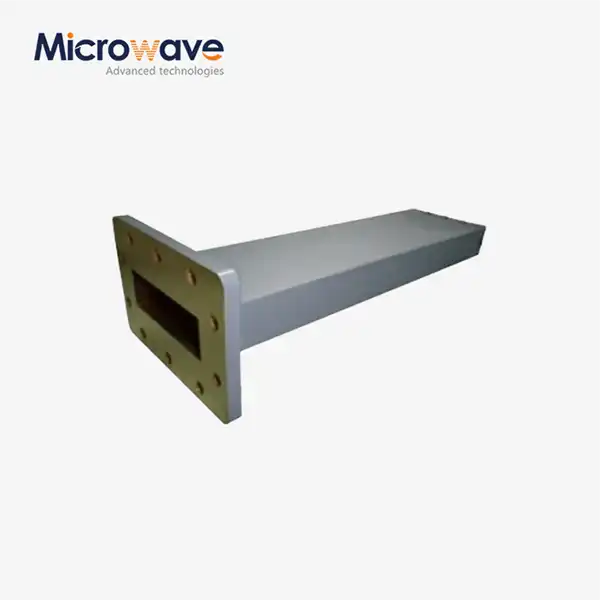

The WR-90 and WR-75 Waveguide Circulator represents a critical component in modern radar systems, designed to provide unidirectional signal flow while maintaining exceptional isolation between ports. These specialized ferrite devices operate within the X-band frequency range, with WR-90 covering 8.2 to 12.4 GHz and WR-75 spanning 10.0 to 15.0 GHz, making them ideal for high-performance radar applications. The Waveguide Circulator utilizes a magnetic field to create non-reciprocal behavior, allowing signals to flow in only one direction through the device while providing excellent isolation to prevent unwanted reflections from affecting system performance. dvanced Microwave Technologies Co., Ltd. has perfected the design and manufacturing of these essential components, incorporating decades of engineering expertise into each Waveguide Circulator. Our manufacturing process ensures that every device meets stringent performance specifications, including minimum isolation levels of 20 dB and insertion loss characteristics that preserve signal integrity throughout the transmission path. The precision engineering involved in creating these devices requires careful attention to ferrite material properties, magnetic biasing techniques, and mechanical construction methods that guarantee reliable operation under extreme environmental conditions.

Technical Specifications and Performance Characteristics

The technical excellence of our WR-90 and WR-75 Waveguide Circulator solutions stems from rigorous design optimization and advanced manufacturing techniques. Each Waveguide Circulator undergoes comprehensive testing in our state-of-the-art 24-meter microwave darkroom facility, where far-field antenna measurements and precise signal analysis ensure optimal performance across the entire operating frequency range. The WR-90 configuration provides exceptional performance in applications requiring broad bandwidth coverage, while the WR-75 variant offers enhanced performance characteristics for higher frequency operations typical in modern radar systems. Our Waveguide Circulator designs incorporate high-quality ferrite materials that maintain stable magnetic properties across wide temperature ranges, ensuring consistent performance in both commercial and military applications. The robust construction methodology employed in manufacturing these devices includes precision machining of waveguide interfaces, careful assembly of ferrite components, and comprehensive quality control procedures that verify electrical performance, mechanical integrity, and environmental durability. Each Waveguide Circulator is designed to handle high power levels while maintaining low insertion loss characteristics that preserve signal strength throughout the transmission system.

Applications in Modern Radar Systems

Air Traffic Control and Aviation Radar Enhancement

Air traffic control radar systems demand the highest levels of reliability and performance, making the selection of appropriate Waveguide Circulator technology critical for safe aviation operations. Our WR-90 and WR-75 Waveguide Circulator solutions provide the exceptional isolation and signal integrity required for accurate aircraft detection and tracking, even in challenging weather conditions and high-traffic environments. The superior performance characteristics of these devices enable radar systems to distinguish between legitimate aircraft targets and unwanted clutter, improving overall system accuracy and reducing false alarm rates that can compromise air traffic control efficiency. The implementation of Advanced Microwave Technologies Co., Ltd. Waveguide Circulator components in aviation radar systems provides significant advantages in terms of signal path optimization and interference reduction. These devices effectively isolate the transmitter from receiver circuits, preventing high-power transmission signals from damaging sensitive receiver components while maintaining the signal integrity necessary for accurate range and bearing measurements. The robust construction of our Waveguide Circulator products ensures reliable operation in demanding aviation environments, where temperature variations, vibration, and electromagnetic interference present ongoing challenges to system performance.

Military and Defense Radar Applications

Modern military radar systems require Waveguide Circulator technology that can deliver exceptional performance under the most demanding operational conditions. Our WR-90 and WR-75 Waveguide Circulator solutions provide the reliability and performance characteristics essential for military surveillance, threat detection, and missile guidance applications. The high isolation levels achieved by these devices ensure that sensitive receiver circuits remain protected from high-power transmission signals, while the low insertion loss characteristics preserve signal strength for maximum detection range and accuracy. Defense contractors worldwide rely on Advanced Microwave Technologies Co., Ltd. Waveguide Circulator products for their critical radar system applications, recognizing the superior quality and performance that comes from our decades of experience in microwave component manufacturing. Our Waveguide Circulator designs undergo extensive testing and qualification procedures to ensure they meet or exceed the stringent requirements of military specifications, including environmental testing, vibration resistance, and electromagnetic compatibility verification. The rugged construction and proven reliability of these components make them ideal for deployment in harsh battlefield environments where equipment failure is not an option.

Performance Advantages and Technical Benefits

Superior Isolation and Signal Integrity

The exceptional isolation performance of our WR-90 and WR-75 Waveguide Circulator products represents a significant advantage for radar system designers seeking to optimize signal path architecture. Each Waveguide Circulator is engineered to provide minimum isolation levels of 20 dB between adjacent ports, effectively preventing unwanted signal coupling that can degrade system performance and introduce measurement errors. This high level of isolation is particularly critical in radar applications where powerful transmission signals must be completely separated from sensitive receiver circuits to prevent damage and maintain accurate target detection capabilities. Advanced Microwave Technologies Co., Ltd. achieves superior isolation performance through precise control of ferrite material properties, magnetic biasing techniques, and mechanical construction methods that minimize unwanted coupling between waveguide ports. Our Waveguide Circulator designs incorporate advanced modeling techniques and electromagnetic simulation tools that optimize device geometry for maximum isolation while maintaining low insertion loss characteristics. The result is a high-performance component that enables radar system designers to achieve exceptional signal integrity throughout their transmission and reception paths, improving overall system sensitivity and accuracy.

High-Power Handling and Durability

The ability to handle high power levels while maintaining consistent performance represents a critical requirement for modern radar systems, making the power handling capabilities of our Waveguide Circulator products essential for demanding applications. Our WR-90 and WR-75 designs are engineered to handle significant power levels without degradation, incorporating robust ferrite materials and advanced thermal management techniques that ensure reliable operation even under continuous high-power conditions. This exceptional power handling capability allows radar system designers to maximize transmission power for extended range performance while maintaining system reliability and component longevity. The durability and reliability of Advanced Microwave Technologies Co., Ltd. Waveguide Circulator products stem from our commitment to using only the highest quality materials and manufacturing processes. Each device undergoes comprehensive environmental testing to verify performance under extreme temperature conditions, humidity variations, and mechanical stress that may be encountered in real-world radar system deployments. Our Waveguide Circulator designs incorporate materials and construction techniques that have been proven through decades of successful operation in demanding military and commercial applications, providing customers with confidence in long-term system reliability.

Customization and Engineering Solutions

OEM Services and Custom Design Capabilities

Advanced Microwave Technologies Co., Ltd. recognizes that modern radar system requirements often demand specialized Waveguide Circulator solutions that go beyond standard catalog products. Our comprehensive OEM services and custom design capabilities enable us to work closely with system integrators and radar manufacturers to develop tailored solutions that meet specific performance requirements, mechanical constraints, and operational parameters. Whether you need modifications to standard frequency ranges, specialized power handling requirements, or unique mechanical interfaces, our experienced engineering team can develop custom Waveguide Circulator solutions that optimize your system performance. Our custom design process begins with detailed consultation to understand your specific application requirements and performance objectives. Our engineers utilize advanced electromagnetic modeling tools and extensive manufacturing experience to develop optimized Waveguide Circulator designs that meet your exact specifications while maintaining the reliability and performance characteristics that Advanced Microwave Technologies Co., Ltd. products are known for. From initial concept through prototype development and full-scale production, we provide comprehensive support to ensure your custom Waveguide Circulator solution meets all technical and schedule requirements.

Technical Support and Application Engineering

The complexity of modern radar systems requires comprehensive technical support and application engineering expertise to ensure optimal Waveguide Circulator integration and performance. Advanced Microwave Technologies Co., Ltd. provides extensive technical support services to help customers select the appropriate Waveguide Circulator configuration for their specific application, optimize system integration, and troubleshoot any performance issues that may arise during system development or deployment. Our experienced application engineers work closely with customers to understand their system architecture and provide recommendations for optimal component selection and implementation. Our technical support capabilities extend throughout the entire product lifecycle, from initial design consultation through manufacturing support and field service assistance. Whether you need guidance on impedance matching, power handling considerations, or environmental qualification requirements, our team of experienced engineers provides the expertise necessary to ensure successful Waveguide Circulator integration into your radar system. We also provide comprehensive documentation, installation guidelines, and troubleshooting support to help customers achieve optimal system performance and reliability.

Industry Standards and Quality Assurance

ISO Certification and Manufacturing Excellence

Advanced Microwave Technologies Co., Ltd. maintains the highest standards of quality and manufacturing excellence through comprehensive ISO certification programs that ensure consistent product quality and customer satisfaction. Our ISO 9001:2015 certification demonstrates our commitment to quality management systems that encompass every aspect of Waveguide Circulator design, manufacturing, and delivery. From initial material procurement through final product testing and customer delivery, our quality management systems ensure that every Waveguide Circulator meets or exceeds customer specifications and industry standards. The environmental responsibility demonstrated through our ISO 14001:2015 certification reflects our commitment to sustainable manufacturing practices throughout the Waveguide Circulator production process. We have implemented comprehensive environmental management systems that minimize waste generation, reduce energy consumption, and eliminate the use of hazardous materials wherever possible. Our ISO 45001:2018 certification for occupational health and safety demonstrates our commitment to providing a safe working environment for our employees while maintaining the highest standards of product quality and reliability.

Testing and Validation Procedures

The reliability and performance of our WR-90 and WR-75 Waveguide Circulator products is ensured through comprehensive testing and validation procedures that verify all critical performance parameters before customer delivery. Our state-of-the-art measurement facilities, including our 24-meter microwave darkroom, enable precise characterization of Waveguide Circulator performance across the entire operating frequency range. Each device undergoes rigorous electrical testing to verify insertion loss, isolation, VSWR, and power handling characteristics, ensuring that every product meets specified performance requirements. Environmental testing procedures validate the long-term reliability and durability of our Waveguide Circulator products under conditions that simulate real-world operating environments. Temperature cycling, humidity testing, vibration analysis, and thermal shock testing verify that each device will maintain consistent performance throughout its operational lifetime. Our comprehensive test data documentation provides customers with detailed performance verification and traceability information that supports their own system qualification and acceptance procedures.

Conclusion

The superior performance, reliability, and customization capabilities of our WR-90 and WR-75 Waveguide Circulator solutions make them the ideal choice for demanding radar system applications. With over two decades of experience in microwave technology and comprehensive ISO certification, Advanced Microwave Technologies Co., Ltd. delivers the quality and performance that modern radar systems require for optimal efficiency and reliability.

Cooperate with Advanced Microwave Technologies Co., Ltd.

As a China Waveguide Circulator factory and leading China Waveguide Circulator supplier, Advanced Microwave Technologies Co., Ltd. offers comprehensive solutions for your radar system needs. Our China Waveguide Circulator manufacturer capabilities ensure reliable China Waveguide Circulator wholesale options with competitive Waveguide Circulator price structures. We provide High Quality Waveguide Circulator solutions with Waveguide Circulator for sale globally. Contact our expert team at craig@admicrowave.com for technical consultations, custom designs, and immediate quotes. Save this resource for future reference and experience the difference that professional microwave engineering makes in your radar system performance.

FAQ

Q: What frequency ranges do WR-90 and WR-75 Waveguide Circulators support?

A: WR-90 operates from 8.2 to 12.4 GHz, while WR-75 covers 10.0 to 15.0 GHz, both optimized for X-band radar applications.

Q: What isolation performance can I expect from these Waveguide Circulators?

A: Our WR-90 and WR-75 Waveguide Circulators provide minimum 20 dB isolation with typical performance exceeding 23 dB across the operating bandwidth.

Q: Are custom power handling requirements available for these products?

A: Yes, we offer custom designs with power handling capabilities ranging from standard levels to high-power applications exceeding 100 watts average power.

Q: What delivery timeframes are typical for standard and custom Waveguide Circulators?

A: Standard products ship within 2-4 weeks, while custom designs typically require 6-12 weeks depending on complexity and specifications.

References

1. "Microwave Engineering Fundamentals and Applications" by David M. Pozar, focusing on waveguide component design and ferrite device theory for radar applications.

2. "Radar Systems Analysis and Design Using MATLAB" by Bassem R. Mahafza, covering radar system architecture and microwave component integration techniques.

3. "Microwave Ferrite Devices" by Robert J. Trew and Peter B. Kenington, detailing circulator design principles and high-power applications in military systems.

4. "Modern Radar Systems" by Hamish Meikle, examining contemporary radar technologies and the role of waveguide components in system performance optimization.

YOU MAY LIKE

VIEW MOREHigh Power Waveguide to Coaxial Adapter

VIEW MOREHigh Power Waveguide to Coaxial Adapter VIEW MOREWaveguide Loop Coupler

VIEW MOREWaveguide Loop Coupler VIEW MOREEnd Launch Double Ridged WG To Coaxial Adapter

VIEW MOREEnd Launch Double Ridged WG To Coaxial Adapter VIEW MOREEnd Launch Waveguide to Microstrip Adapter

VIEW MOREEnd Launch Waveguide to Microstrip Adapter VIEW MOREWaveguide Sliding Termination

VIEW MOREWaveguide Sliding Termination VIEW MOREWaveguide Unmatched Termination

VIEW MOREWaveguide Unmatched Termination VIEW MOREMagic Hybrid Tee

VIEW MOREMagic Hybrid Tee VIEW MOREH-Plane Tee

VIEW MOREH-Plane Tee