Why Use a Waveguide Variable Attenuator?

In high-frequency microwave systems where signal integrity is paramount, engineers face a critical challenge: how to precisely control signal amplitude without introducing distortion, phase shifts, or excessive losses. When your satellite communication system demands exact power levels to prevent transponder overload, when your radar installation requires fine-tuned signal strength for optimal target detection, or when your laboratory testing setup needs repeatable attenuation adjustments across multiple frequency bands, the solution lies in implementing a Waveguide Variable Attenuator. These sophisticated components provide the dynamic control necessary to optimize system performance, protect sensitive equipment from power surges, and enable accurate measurements in demanding applications where fixed attenuation simply cannot deliver the flexibility required for mission-critical operations.

Understanding Waveguide Variable Attenuator Technology

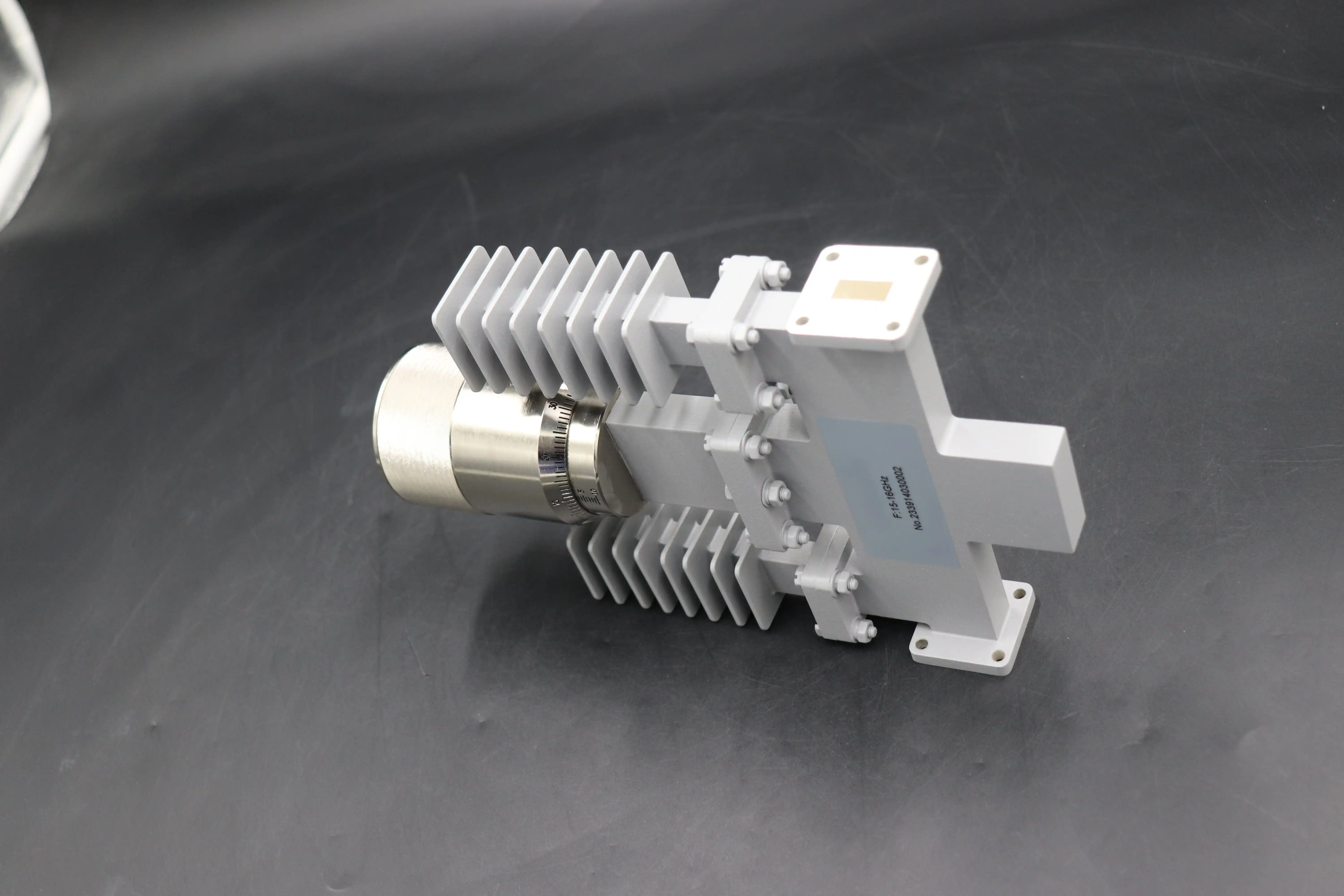

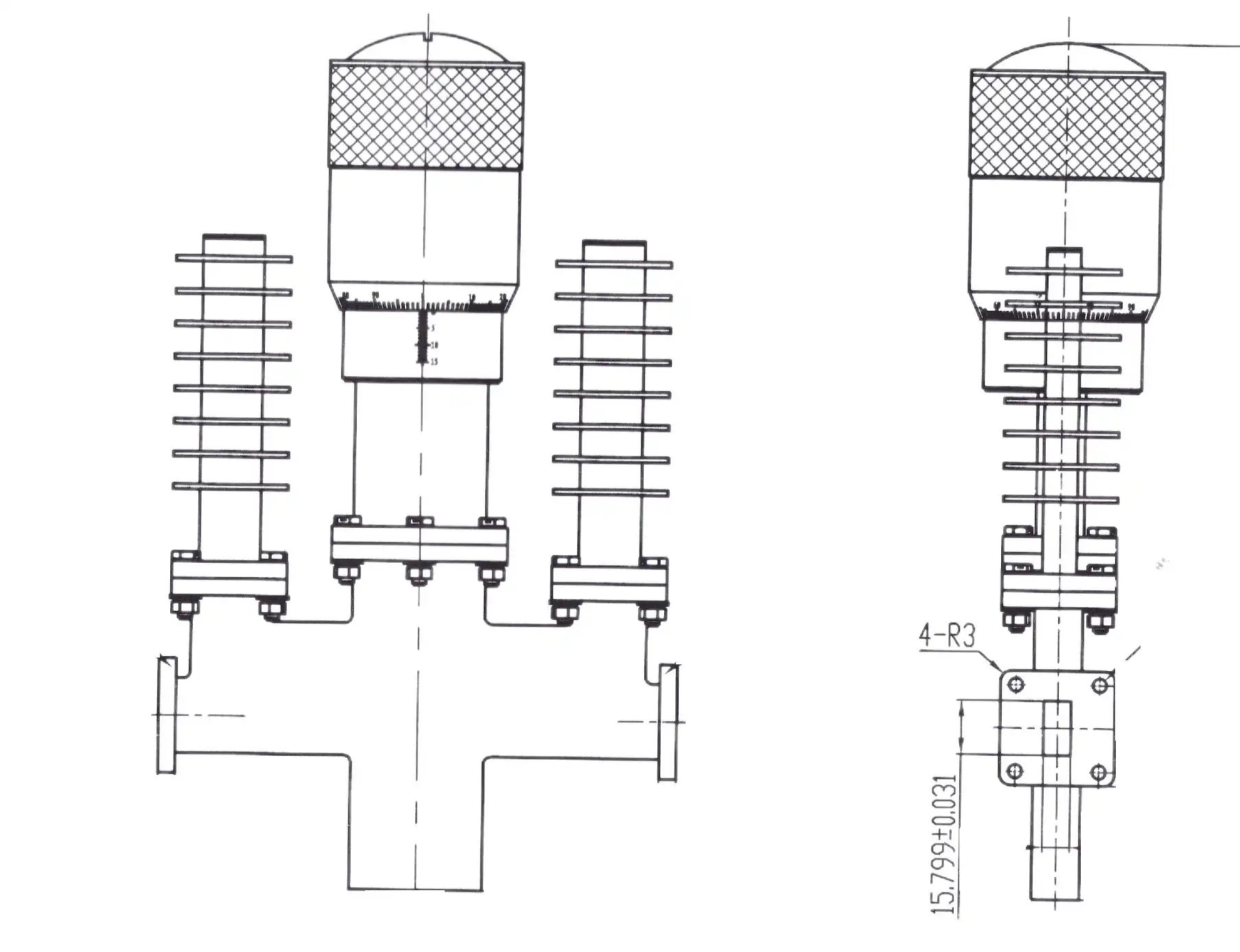

Waveguide variable attenuators represent a fundamental advancement in microwave signal control technology, offering engineers unprecedented precision in managing electromagnetic wave propagation through waveguide structures. Unlike fixed attenuators that provide only a single attenuation value, variable attenuators deliver adjustable control across a specified range, typically from zero to thirty decibels or more, depending on the design architecture. This adjustability stems from the sophisticated mechanical systems that position resistive or absorptive materials within the waveguide cavity, allowing controlled interaction with the electromagnetic field propagating through the structure. The continuously variable waveguide attenuators series from Advanced Microwave covers a broad frequency range of thirty-three gigahertz to one hundred ten gigahertz in five distinct bands, demonstrating the technological capability to serve applications spanning from traditional microwave systems to cutting-edge millimeter-wave implementations. The operational principle of a Waveguide Variable Attenuator centers on controlled energy absorption through precisely positioned resistive elements. When electromagnetic waves propagate through the waveguide structure, they encounter these strategically placed materials—typically fabricated from carbon-loaded epoxy, specialized ferrites, or metalized films—which convert a portion of the electromagnetic energy into thermal energy through resistive losses. The brilliance of this design lies in its mechanical precision: by adjusting the position of the absorptive element using calibrated micrometer mechanisms, operators can vary the amount of material intersecting the wave path, thereby changing attenuation levels with remarkable accuracy. Advanced Microwave Technologies Co., Ltd. has perfected this principle in their product line, enabling attenuation adjustments that can be dialed in from zero to thirty decibels over specified bands, with the attenuation level controlled through micrometer adjustment for repeatable and rapid re-setting to different values. This mechanical interface converts macro-scale operator adjustments into precisely controlled micro-movements, achieving attenuation changes as fine as zero-point-one decibel, providing engineers with the granular control necessary for optimizing complex microwave systems.

Precision Control Through Micrometer Adjustment

The micrometer control mechanism represents the technological heart of modern Waveguide Variable Attenuator systems, transforming these components from simple passive devices into precision instruments capable of delivering repeatable, accurate attenuation adjustments. This sophisticated mechanical interface features calibrated dials with clear markings corresponding to specific attenuation values, enabling operators to rapidly set and reset to exact levels with minimal effort and maximum confidence. The micrometer system's precision stems from its ability to convert rotational motion into linear displacement with exceptional accuracy, typically achieving positioning resolution within micrometers. When engineers adjust the micrometer dial, they're directly controlling the depth of penetration of the resistive element into the waveguide cavity, which in turn determines how much electromagnetic energy encounters the absorptive material. Advanced Microwave Technologies Co., Ltd. incorporates high-quality micrometer mechanisms in their Waveguide Variable Attenuator designs, ensuring that each adjustment produces consistent, predictable changes in attenuation across the operating frequency range. This repeatability is crucial for applications requiring multiple measurement cycles or frequent reconfiguration, as it eliminates the uncertainty associated with less sophisticated adjustment mechanisms. The flat performance characteristic of these attenuators across wide frequency bands, combined with low insertion loss, makes them particularly valuable for broadband applications where consistent attenuation behavior is essential. Engineers often utilize this type of variable attenuator when designing systems and testing design concepts in laboratory environments, as the ultra-high frequency capabilities allow designers to observe system performance at various signal strengths and determine optimum signal parameters for their specific applications. The mechanical stability of the micrometer adjustment system ensures that once an attenuation value is set, it remains stable throughout extended testing sessions, eliminating drift that could compromise measurement accuracy or introduce variables into experimental protocols.

Key Applications Driving Waveguide Variable Attenuator Adoption

Satellite Communication Systems Optimization

Satellite communication systems represent one of the most demanding application environments for Waveguide Variable Attenuator technology, where precise signal level control directly impacts both regulatory compliance and operational efficiency. In satellite ground stations, these attenuators play a critical role in optimizing signal strength for both uplink and downlink paths, ensuring that transmitted power levels fall within specified ranges mandated by international regulatory bodies while maximizing throughput for high-definition video, data transmission, and voice communications. The ability to adjust attenuation dynamically allows operators to compensate for atmospheric conditions, satellite position changes, and varying link budgets without requiring system shutdown or hardware replacement. Advanced Microwave Technologies Co., Ltd. provides Waveguide Variable Attenuator solutions specifically engineered for satellite communication applications, offering the frequency coverage, power handling capability, and environmental stability necessary for reliable operation in demanding ground station installations where equipment must function continuously across temperature extremes and varying atmospheric conditions. The continuously variable nature of these attenuators proves particularly valuable during satellite commissioning phases and link optimization procedures, where engineers must methodically test system performance across a range of power levels to identify optimal operating parameters. By enabling precise, repeatable adjustments, these components facilitate systematic characterization of satellite transponder response, allowing operators to maximize available bandwidth while avoiding transponder saturation that could degrade signal quality or cause service interruptions. Furthermore, the low insertion loss characteristics of premium Waveguide Variable Attenuator designs ensure that signal degradation introduced by the attenuator itself remains minimal, preserving the overall link budget and maintaining system efficiency even when significant attenuation is applied.

Radar System Performance Enhancement

Radar systems across aviation, maritime, meteorological, and defense applications rely heavily on Waveguide Variable Attenuator technology to achieve optimal detection performance and measurement accuracy. In air traffic control radar installations, these attenuators enable ultra-sharp beamforming capabilities essential for accurate aircraft tracking, even under challenging weather conditions that introduce atmospheric attenuation or ground clutter interference. By allowing dynamic adjustment of transmitted and received signal levels, variable attenuators help radar operators maintain optimal receiver sensitivity while preventing saturation from strong return signals, thereby maximizing detection range and improving target discrimination capabilities. Military surveillance radars particularly benefit from this technology, utilizing Waveguide Variable Attenuator networks to detect potential threats and distinguish between multiple targets in complex operational environments where signal processing demands precise control over received power levels to extract meaningful intelligence from noisy backgrounds. The ability to rapidly adjust attenuation levels without system interruption proves invaluable for radar testing and calibration procedures, where engineers must verify system performance across the full dynamic range of expected signal conditions. Advanced Microwave Technologies Co., Ltd. offers Waveguide Variable Attenuator solutions covering frequency ranges specifically tailored for common radar bands, including X-band systems widely deployed for weather monitoring, navigation, and security applications. These attenuators provide the frequency stability, power handling capacity, and mechanical reliability necessary for integration into radar systems that must operate continuously in outdoor installations subjected to temperature cycling, humidity exposure, and mechanical vibration. The precision adjustment capabilities enable radar system designers to fine-tune receiver sensitivity during development phases, systematically testing detection algorithms against signals of varying strength to optimize processing parameters before field deployment.

Laboratory Testing and Research Applications

Research laboratories and development facilities represent perhaps the most demanding application environment for Waveguide Variable Attenuator technology, where measurement accuracy, repeatability, and flexibility are absolutely critical for producing reliable experimental data. Engineers designing microwave systems utilize these attenuators extensively during prototype evaluation phases, where the ability to systematically vary signal levels while holding other parameters constant enables isolation of specific performance characteristics and identification of optimal operating points. The ultra-high frequency variable waveguide attenuators from Advanced Microwave Technologies Co., Ltd., covering frequencies from thirty-three gigahertz to one hundred ten gigahertz, allow designers to observe system behavior at various signal strengths across millimeter-wave bands increasingly important for next-generation wireless technologies, including fifth-generation cellular systems and emerging sixth-generation concepts. This comprehensive frequency coverage ensures that researchers can maintain consistent testing methodologies across different bands, simplifying experimental design and facilitating comparative analysis of results obtained at different frequencies. The long-term stability and durability of precision Waveguide Variable Attenuator designs ensure consistent test conditions throughout production runs that may span months or years, eliminating measurement drift that could compromise data validity or require time-consuming recalibration procedures. For research applications exploring cutting-edge millimeter-wave technologies, these precision attenuators enable controlled experiments where signal strength must be systematically varied while all other parameters remain constant, isolating specific effects being studied and leading to more definitive research conclusions. The micrometer-controlled adjustment mechanism provides the repeatability necessary for rigorous scientific methodology, allowing researchers to return to specific attenuation settings with confidence that measured performance differences reflect actual system behavior rather than measurement variability introduced by the test equipment itself.

Technical Advantages of Advanced Microwave Variable Attenuators

Broad Frequency Coverage and Flexibility

One of the most compelling advantages of modern Waveguide Variable Attenuator technology lies in its ability to deliver consistent performance across extraordinarily broad frequency ranges, accommodating both legacy communication systems operating at lower microwave frequencies and bleeding-edge technologies pushing into millimeter-wave spectrum allocations. Advanced Microwave Technologies Co., Ltd. has developed attenuator designs covering frequency ranges from thirty-three gigahertz extending to one hundred ten gigahertz, segmented into five distinct waveguide bands that provide optimal performance characteristics for each frequency regime. This comprehensive frequency coverage eliminates the need for multiple specialized attenuators when working across different bands, simplifying inventory management, reducing procurement costs, and streamlining test procedures that require measurements at multiple frequencies. The ability to support numerous frequencies ranging from traditional microwave bands through millimeter-wave allocations makes these Waveguide Variable Attenuator products invaluable for organizations developing multi-band systems or conducting research spanning broad frequency ranges where equipment commonality improves operational efficiency. The flat frequency response characteristic achieved by premium attenuator designs ensures that attenuation values remain consistent across the specified operating band, eliminating frequency-dependent variations that could introduce measurement errors or complicate system characterization procedures. This flatness stems from careful attention to the geometry of resistive elements, optimization of waveguide transitions, and selection of absorptive materials exhibiting stable performance across wide frequency ranges. Engineers can therefore confidently apply these attenuators in broadband applications, knowing that the specified attenuation value will be maintained regardless of the operating frequency within the design range. Furthermore, the low insertion loss characteristics minimize signal degradation when the attenuator is set to minimum attenuation positions, preserving system sensitivity and maintaining link budgets in applications where every decibel of available signal power contributes to overall performance.

High Power Handling and Reliability

The ability to handle significant power levels without performance degradation or reliability concerns distinguishes high-quality Waveguide Variable Attenuator designs from inferior alternatives that may exhibit thermal drift, mechanical instability, or premature failure under demanding operating conditions. Advanced Microwave Technologies Co., Ltd. engineers their attenuators with power handling capabilities extending up to one kilowatt for certain models, enabling deployment in high-performance systems where substantial signal power must be controlled without introducing non-linear effects or thermal management challenges. This high power capacity stems from careful thermal design considerations, including selection of materials with appropriate thermal conductivity, optimization of heat dissipation paths, and incorporation of sufficient thermal mass to absorb transient power surges without exceeding safe operating temperatures for critical components. The mechanical robustness of these designs ensures reliable operation throughout thousands of adjustment cycles, with precision-machined components and high-quality bearings maintaining smooth, consistent operation without developing backlash or hysteresis that could compromise adjustment accuracy. The longevity and durability of these Waveguide Variable Attenuator products reflect construction from premium materials selected to resist harsh environmental conditions commonly encountered in outdoor installations, aboard mobile platforms, or within equipment racks subjected to temperature cycling and mechanical vibration. Waveguide structures fabricated from high-conductivity aluminum alloys or copper provide excellent electrical performance while maintaining structural integrity across wide temperature ranges. Plating processes applied to waveguide flanges and internal surfaces minimize oxidation and ensure long-term electrical stability, while precision manufacturing tolerances guarantee proper electromagnetic performance and mechanical fit with mating components. This attention to quality extends to resistive elements themselves, which employ specialized materials exhibiting stable electrical properties throughout the operating temperature range and across extended service life, ensuring that calibration remains valid and performance specifications continue to be met years after initial installation.

Customization and OEM Integration Support

Advanced Microwave Technologies Co., Ltd. recognizes that modern microwave systems increasingly demand customized solutions tailored to specific operational requirements that may not be fully addressed by standard catalog products. The company's extensive OEM services enable customers to specify modifications to size, material composition, frequency range, and mechanical interface characteristics, creating Waveguide Variable Attenuator designs perfectly matched to unique application needs. This customization capability proves particularly valuable for system integrators developing proprietary platforms where standard components may not fit available space envelopes, interface properly with existing waveguide infrastructure, or provide the exact frequency coverage required for specialized applications. Engineering consultation services connect customers directly with experienced design engineers who can evaluate requirements, recommend optimal approaches, and collaborate throughout the development process to ensure that final products meet all performance, mechanical, and environmental specifications. Modifications to waveguide dimensions and materials allow adaptation to non-standard waveguide sizes or specialized applications requiring particular material properties such as enhanced corrosion resistance, reduced weight, or specific thermal characteristics. Frequency range expansion capabilities enable customers to obtain attenuators covering bands not available in standard product lines, supporting emerging applications in newly allocated spectrum or specialized systems operating at unusual frequencies. The company's prototyping services provide quick turnaround on initial units for testing and evaluation before full-scale production commitments, reducing development risk and allowing iterative refinement of designs based on actual performance data obtained from prototype testing. Technical support extends beyond initial product delivery, with expert engineers providing installation guidance, troubleshooting assistance, and application advice throughout the product lifecycle, ensuring that customers achieve optimal results from their Waveguide Variable Attenuator investments.

Quality Assurance and International Standards Compliance

Advanced Microwave Technologies Co., Ltd. has established comprehensive quality management systems reflecting the company's commitment to delivering products that meet or exceed the most stringent industry requirements. The attainment of ISO nine thousand one certification, specifically the twenty-fifteen revision, demonstrates adherence to internationally recognized quality control procedures throughout all aspects of business operations, from initial design and development activities through manufacturing processes, final testing, and after-sales service. This certification provides customers with confidence that each Waveguide Variable Attenuator produced undergoes rigorous inspection and testing protocols designed to verify compliance with published specifications and identify potential defects before products ship to customers. Quality control procedures encompass incoming material inspection to ensure raw materials meet required standards, in-process monitoring to verify manufacturing processes remain within specification limits, and final testing that confirms electrical performance, mechanical operation, and environmental resistance of completed assemblies. Environmental responsibility represents another cornerstone of the company's operational philosophy, as evidenced by ISO fourteen thousand one:twenty-fifteen certification demonstrating commitment to minimizing ecological footprint throughout operations. This dedication to environmental stewardship extends from manufacturing processes and facility operations through product design decisions that consider material selection, energy efficiency, and end-of-life disposal implications. The ISO forty-five thousand one:twenty-eighteen standard certification showcases concern for employee well-being through implementation of comprehensive occupational health and safety management systems that create workplace environments prioritizing personnel safety. These international standard certifications are not mere accolades but integral parts of corporate culture, empowering the company to continue leading the microwave technology sector while providing cutting-edge Waveguide Variable Attenuator solutions that uphold environmental responsibility, quality excellence, and safety values customers expect from industry-leading suppliers.

The company's state-of-the-art measurement capabilities further reinforce quality assurance processes, with laboratories equipped with advanced microwave measurement equipment operating up to one hundred ten gigahertz. This comprehensive test capability enables full characterization of Waveguide Variable Attenuator performance across entire specified frequency ranges, verifying critical parameters including insertion loss, return loss, attenuation range, adjustment linearity, and frequency response flatness. The remarkable twenty-four-meter microwave darkroom facility provides unrivaled space for precise antenna measurements and system-level testing, incorporating an Antenna Plane Near and Far Field Measuring Recombination Chamber that allows fluid transition between measurement modes and extraction of granular performance details. This investment in measurement infrastructure demonstrates the company's commitment to delivering thoroughly verified products and supporting customers with accurate characterization data necessary for confident system integration.

Conclusion

Waveguide Variable Attenuator technology delivers the precise, flexible signal control essential for modern microwave systems across satellite communications, radar applications, telecommunications infrastructure, and research environments. The continuously variable adjustment capability, broad frequency coverage, high power handling, and exceptional reliability of these components make them indispensable tools for engineers optimizing system performance and conducting accurate measurements in demanding applications.

Cooperate with Advanced Microwave Technologies Co., Ltd.

As a leading China Waveguide Variable Attenuator factory, China Waveguide Variable Attenuator supplier, and China Waveguide Variable Attenuator manufacturer, Advanced Microwave Technologies Co., Ltd. brings over twenty years of microwave manufacturing excellence to every project. Our China Waveguide Variable Attenuator wholesale programs deliver competitive Waveguide Variable Attenuator price points without compromising quality, with High Quality Waveguide Variable Attenuator for sale backed by comprehensive technical support. Our ISO-certified facilities, equipped with measurement capabilities to one hundred ten gigahertz and featuring our renowned twenty-four-meter microwave darkroom, ensure every product meets exacting standards. From prototyping through production, our experienced engineers provide customized solutions perfectly matched to your requirements. Contact craig@admicrowave.com today to discuss how our waveguide components, coaxial assemblies, microwave antennas, and specialized feed networks can enhance your next project. Save this resource for future reference when technical challenges arise.

References

1. "Waveguide Variable Attenuators in Microwave Systems" by Johnson, R.C. and Henderson, P.T., IEEE Transactions on Microwave Theory and Techniques

2. "Precision Attenuation Control for Satellite Ground Stations" by Williams, M.K., International Journal of Satellite Communications and Networking

3. "Mechanical Design Considerations for Variable Waveguide Components" by Zhang, L. and Kumar, S., Microwave Engineering Handbook

4. "Performance Characterization of Millimeter-Wave Attenuators" by Anderson, D.F., Journal of Electromagnetic Waves and Applications

YOU MAY LIKE

VIEW MOREAc Power Amplifier

VIEW MOREAc Power Amplifier VIEW MOREVoltage Controlled Phase Shifter

VIEW MOREVoltage Controlled Phase Shifter VIEW MOREStandard Horn Antenna

VIEW MOREStandard Horn Antenna VIEW MOREMMDS Transmitting Antenna

VIEW MOREMMDS Transmitting Antenna VIEW MOREConical Horn Lens Antenna

VIEW MOREConical Horn Lens Antenna VIEW MOREPoint Focusing Horn Lens Antenna

VIEW MOREPoint Focusing Horn Lens Antenna VIEW MORECorrugated Horn and Multimode Horn Antenna

VIEW MORECorrugated Horn and Multimode Horn Antenna VIEW MOREMini Wideband Double-ridged Horn Antenna

VIEW MOREMini Wideband Double-ridged Horn Antenna