Why Choose a High Power Waveguide to Coaxial Adapter?

In high-frequency RF systems, signal degradation and power loss can cripple your entire operation. Picture this: your satellite ground station suddenly experiences a 4dB drop in received signal strength, or your radar system fails to detect critical targets because of excessive transmission loss. These scenarios are not hypothetical—they happen when system designers underestimate the importance of proper signal conversion. A High Power Waveguide to Coaxial Adapter solves this critical challenge by providing a reliable, efficient interface between waveguide systems and coaxial transmission lines, ensuring minimal signal loss while handling substantial power levels in demanding applications.

Understanding High Power Waveguide to Coaxial Adapter Technology

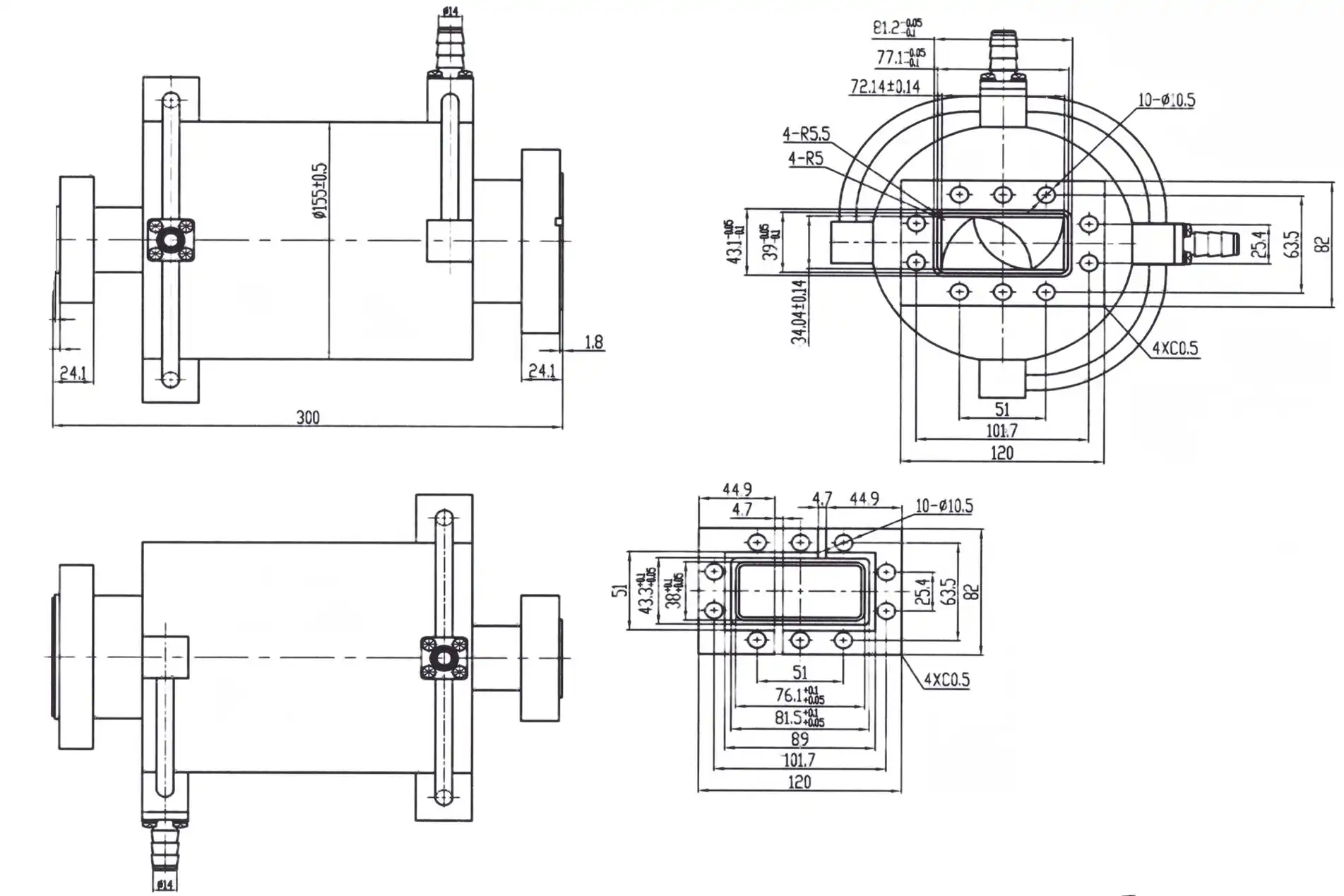

The High Power Waveguide to Coaxial Adapter represents a sophisticated engineering solution for bridging two fundamentally different transmission line architectures. In modern microwave systems, waveguides excel at low-loss, high-power signal transmission, particularly at frequencies above several gigahertz. However, coaxial cables offer flexibility and ease of installation that waveguides cannot match. The adapter serves as the critical junction point, converting electromagnetic field modes while preserving signal integrity and power handling capabilities. This conversion process involves carefully designed probe coupling mechanisms that extract energy from the waveguide's dominant TE10 mode and transfer it to the coaxial line's TEM mode with minimal reflection and loss. The physical construction of a High Power Waveguide to Coaxial Adapter involves precision machining and material selection that directly impacts performance. The coaxial center conductor extends into the waveguide cavity as a probe, positioned perpendicular or parallel to the maximum electric field vector. This probe depth and geometry are meticulously calculated to optimize electromagnetic field coupling while suppressing higher-order modes that could degrade performance. Behind the probe insertion point, a precisely machined short circuit positioned at a quarter-wavelength distance ensures unidirectional energy propagation. For high-power applications, thermal management becomes paramount. Advanced designs incorporate continuous metal paths and heat sinking capabilities to dissipate thermal energy generated during high-power transmission, preventing junction overheating that could lead to performance degradation or catastrophic failure.

Key Performance Parameters That Define Quality

When evaluating a High Power Waveguide to Coaxial Adapter, several critical parameters determine its suitability for specific applications. Insertion loss measures the signal power lost during the waveguide-to-coax transition, typically ranging from 0.2 to 0.5 dB for quality adapters. Lower insertion loss translates directly to improved system efficiency and extended transmission range. Voltage Standing Wave Ratio (VSWR) indicates impedance matching quality, with values below 1.20:1 considered acceptable and premium adapters achieving 1.04:1 or better across their operating bandwidth. Power handling capacity defines the maximum continuous wave or peak power the adapter can safely manage without thermal damage or performance degradation, with high-power models supporting levels from 5 kW to 100 kW depending on frequency and design specifications. Frequency range coverage is another essential consideration when selecting a High Power Waveguide to Coaxial Adapter. Different waveguide sizes support specific frequency bands determined by their cross-sectional dimensions. A WR90 waveguide, for example, operates from 8.2 to 12.4 GHz, while smaller waveguides like WR15 cover millimeter-wave frequencies from 50 to 75 GHz. The adapter must maintain consistent performance across the entire specified frequency range, with flat frequency response ensuring predictable behavior regardless of operating frequency. Return loss, the measure of reflected power at the adapter interface, should typically exceed 20 dB to minimize signal reflections that could interfere with system operation or damage sensitive transmitter components.

Critical Applications Demanding High Power Waveguide to Coaxial Adapters

Satellite Communication Ground Stations

Satellite communication ground stations represent one of the most demanding applications for High Power Waveguide to Coaxial Adapter technology. These facilities must maintain reliable uplink and downlink connections with orbiting satellites across vast distances, requiring maximum signal integrity and power efficiency. Earth stations typically employ large parabolic antennas fed by waveguide systems that deliver signals from high-power amplifiers to the antenna feed assembly. At various points in this signal chain, engineers need to transition between waveguide and coaxial transmission lines for equipment interconnection, signal monitoring, or routing flexibility. The High Power Waveguide to Coaxial Adapter enables these transitions while preserving the high power levels necessary for effective satellite communication, whether transmitting broadband internet data, television broadcasts, or military communications. In modern satellite ground station designs, multiple frequency bands often operate simultaneously within the same antenna system, requiring complex feed networks that combine C-band, Ku-band, and Ka-band signals. High Power Waveguide to Coaxial Adapters facilitate the integration of different subsystems by allowing engineers to route signals through flexible coaxial paths where space constraints or mechanical considerations make rigid waveguide impractical. Advanced ground stations handling multiple gigabits per second of data throughput cannot tolerate signal degradation or power loss that would reduce link margins and increase bit error rates. Quality adapters with insertion loss below 0.3 dB and excellent impedance matching ensure that every milliwatt of transmitted power reaches the antenna, maximizing communication reliability even during adverse weather conditions or when working with distant satellites in high orbits.

Defense Radar and Electronic Warfare Systems

Military radar systems operating at X-band, Ku-band, and higher frequencies depend on High Power Waveguide to Coaxial Adapters for critical signal routing within complex phased array and surveillance radar architectures. Modern defense radars must detect and track multiple targets simultaneously at extended ranges while operating in challenging electromagnetic environments filled with interference and jamming signals. The radar transmitter generates high-power pulses that propagate through waveguide distribution networks to individual array elements or rotating antenna structures. At strategic points in these systems, engineers implement High Power Waveguide to Coaxial Adapters to interface with directional couplers, test equipment, or rotary joints that enable antenna rotation while maintaining signal connectivity. Electronic warfare systems present even more stringent requirements for High Power Waveguide to Coaxial Adapters because they must handle both high transmit power for jamming operations and low-level received signals for threat detection and analysis. These systems require adapters with exceptional dynamic range and low passive intermodulation products to avoid generating spurious signals that could mask genuine threats or reveal the system's presence to hostile forces. Military specifications demand that adapters maintain performance across extreme temperature ranges from minus 55 degrees Celsius to plus 125 degrees Celsius, withstand intense vibration and shock loads, and resist corrosion in maritime environments. The adapter's mechanical construction must provide robust, repeatable connections using precision flanges that maintain alignment within micrometers to ensure consistent electrical performance throughout the system's operational lifetime.

High-Frequency Telecommunications Infrastructure

The telecommunications industry increasingly relies on High Power Waveguide to Coaxial Adapter technology as network operators deploy millimeter-wave 5G systems and prepare for future 6G networks operating at frequencies approaching 110 GHz. Millimeter-wave base stations require efficient power delivery from transmitters to antenna arrays, with waveguide providing the lowest-loss propagation path for these short-wavelength signals. However, the compact form factors and complex geometries of modern base station designs necessitate flexible interconnection methods at specific points in the signal chain. High Power Waveguide to Coaxial Adapters enable engineers to route signals around obstacles, make connections to test ports, or interface between subsystems manufactured with different connector standards. Telecommunications applications demand adapters that maintain phase stability across temperature variations because modern communication protocols employ sophisticated modulation schemes sensitive to phase distortion. A phase drift of just a few degrees can significantly degrade signal quality in 256-QAM or higher-order modulation formats, increasing bit error rates and reducing network throughput. Furthermore, telecommunications equipment must operate continuously for years with minimal maintenance, requiring adapters manufactured from corrosion-resistant materials with long-term mechanical stability. The transition to higher frequency bands for increased data capacity makes the selection of appropriate High Power Waveguide to Coaxial Adapters increasingly critical, as insertion loss and VSWR specifications that were acceptable at lower frequencies can cause unacceptable performance degradation at millimeter-wave frequencies where path losses are inherently higher.

Engineering Advantages of Advanced High Power Adapters

The advanced engineering incorporated into modern High Power Waveguide to Coaxial Adapter designs delivers measurable performance advantages that directly impact system capabilities. Precision machining tolerances measured in micrometers ensure that the probe coupling mechanism achieves optimal field distribution within the waveguide cavity, maximizing energy transfer efficiency while suppressing unwanted mode generation. Computer-aided electromagnetic simulation tools allow designers to optimize probe geometry, position, and short circuit placement for specific frequency ranges, achieving broader bandwidth operation than previous generation designs that relied primarily on empirical tuning methods. Material selection plays a crucial role in both electrical and thermal performance, with aerospace-grade aluminum alloys providing excellent conductivity and light weight, while stainless steel options offer superior corrosion resistance for marine and industrial environments. Thermal management capabilities separate high-quality High Power Waveguide to Coaxial Adapters from commodity products. At power levels exceeding several kilowatts, even small amounts of resistive loss generate significant heat that must be conducted away from the critical junction area to prevent temperature-related performance degradation or physical damage to the coaxial connector. Advanced designs incorporate heat sinking provisions, including extended mounting flanges that serve as heat spreaders and provisions for forced air cooling or liquid cooling in extreme applications. The coaxial connector selection also impacts thermal performance, with specialized airline-type connectors featuring grounded center conductors that provide direct thermal paths superior to standard commercial connectors. This attention to thermal design allows High Power Waveguide to Coaxial Adapters to maintain stable electrical characteristics even under sustained high-power operation, ensuring reliable performance in continuous duty cycles typical of communications and radar applications.

Superior Signal Integrity and System Performance

Signal integrity represents perhaps the most critical benefit that quality High Power Waveguide to Coaxial Adapters bring to RF system designs. Every interface in a signal chain introduces potential sources of degradation, including reflection, loss, and distortion. A well-engineered High Power Waveguide to Coaxial Adapter minimizes these effects through careful impedance matching that reduces reflected energy to negligible levels. When VSWR remains below 1.10:1 across the operating bandwidth, the adapter becomes essentially transparent to the signal, allowing designers to achieve system performance limited only by other components rather than the interface itself. This level of performance proves especially valuable in sensitive receiver applications where noise figure budgets are tight and every tenth of a decibel matters for achieving required detection thresholds. The mechanical precision of High Power Waveguide to Coaxial Adapters also contributes to long-term system reliability. Waveguide flanges manufactured to precise dimensional standards ensure proper alignment and consistent electrical contact across mating surfaces, with interface gaskets providing additional environmental sealing against moisture and contaminants. Quality adapters undergo rigorous testing including vector network analyzer measurements to verify insertion loss, return loss, and phase linearity across their specified frequency range. Some manufacturers provide individual calibration data for each adapter, allowing system integrators to account for precise electrical characteristics in system modeling and prediction tools. This level of documentation and quality assurance enables confident system design with predictable performance outcomes, reducing troubleshooting time and eliminating costly field failures.

Selecting the Right High Power Waveguide to Coaxial Adapter

Choosing an appropriate High Power Waveguide to Coaxial Adapter requires careful consideration of multiple system parameters and application requirements. The first decision involves matching the waveguide size and flange type to your existing system infrastructure. Standard rectangular waveguides follow established dimensional standards designated by WR numbers that correspond to specific frequency ranges, with each size requiring compatible adapter designs. Flange types including UG, CPR, and CMR standards each have specific mechanical and electrical characteristics that must match throughout the system to ensure proper connection and performance. Engineers must also consider the coaxial connector type, with options ranging from SMA and Type-N connectors for moderate power levels to specialized airline connectors for kilowatt-level applications. Power handling requirements demand careful analysis of both average and peak power levels in your application. While an adapter may have an impressive continuous power rating, its ability to handle short-duration pulses can differ significantly depending on thermal mass and heat dissipation paths. Pulsed radar applications with high peak power but low duty cycles impose different thermal stresses than continuous-wave communication systems operating at lower peak power but sustained duty cycles. Environmental considerations including operating temperature range, altitude, humidity, and vibration exposure must factor into adapter selection, particularly for military, aerospace, or industrial applications where standard commercial specifications may prove inadequate. Qualified suppliers provide detailed specifications including test data at temperature extremes and after environmental stress testing to validate performance under realistic operating conditions.

Customization and OEM Integration Capabilities

Many high-performance applications require customized High Power Waveguide to Coaxial Adapter solutions that standard catalog products cannot fully address. Experienced manufacturers offer engineering services to develop custom designs optimized for specific frequency ranges, power levels, or mechanical interfaces. This customization might involve modified probe designs for extended bandwidth operation, specialized flange configurations to match proprietary antenna interfaces, or integrated cooling provisions for extreme power handling requirements. The ability to work collaboratively with adapter manufacturers during system design phases enables optimization of the entire signal chain rather than simply selecting available components and accepting their limitations. Original Equipment Manufacturer relationships provide additional benefits beyond product customization. Established manufacturers with extensive microwave engineering expertise can serve as technical resources during system development, offering guidance on interface design, thermal management strategies, and test procedures that ensure reliable operation in demanding applications. Access to advanced measurement facilities including large anechoic chambers with far-field measurement capabilities allows thorough characterization of adapter performance in realistic system configurations. Quality manufacturers maintain ISO 9001 certified production processes with documented quality control procedures that provide traceability and consistency across production runs, critical factors for high-reliability applications in defense, aerospace, and telecommunications sectors where field failures carry severe consequences.

Conclusion

Selecting a High Power Waveguide to Coaxial Adapter requires balancing electrical performance, thermal management, and mechanical reliability to ensure robust system operation in demanding applications.

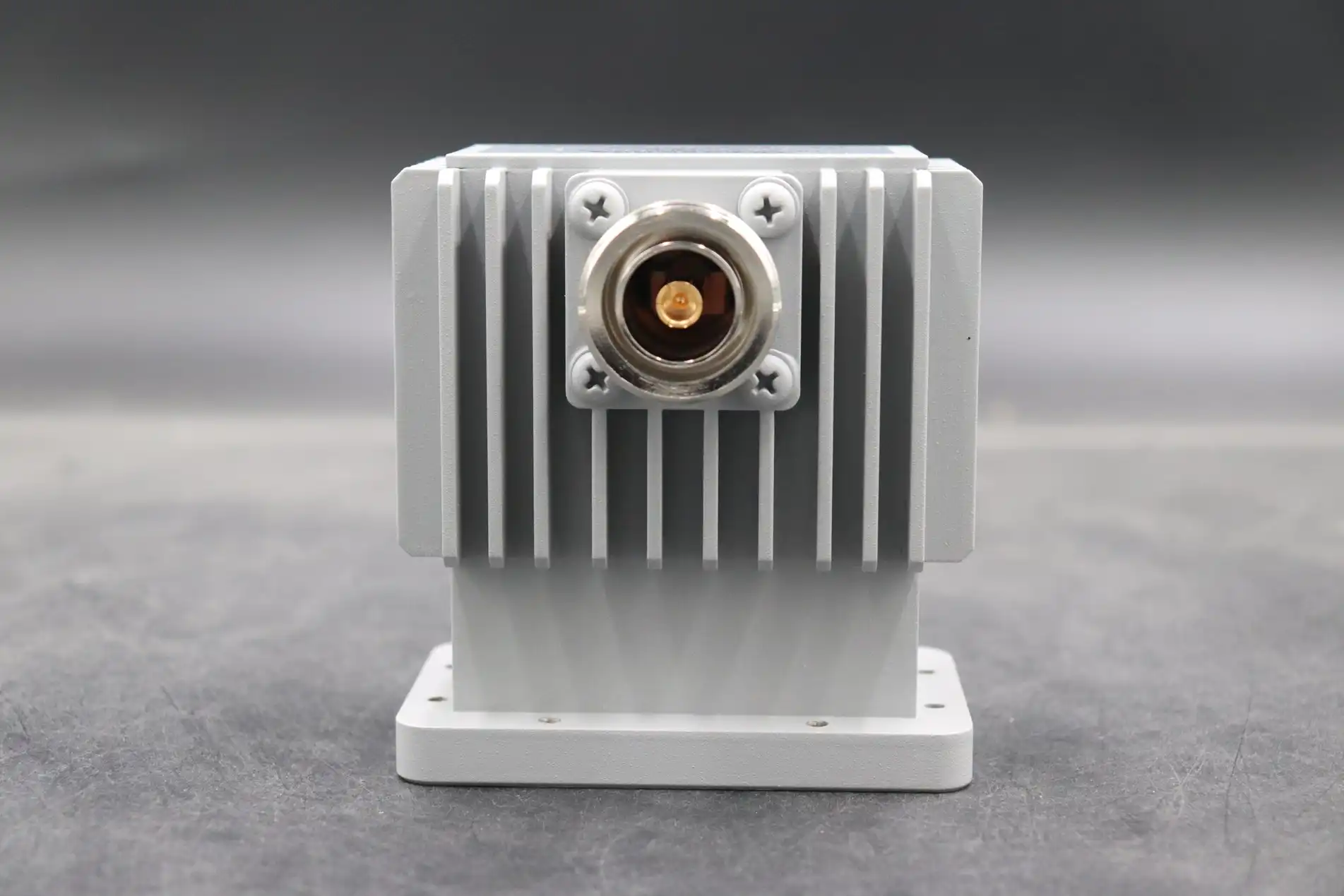

Cooperate with Advanced Microwave Technologies Co., Ltd.

As a China High Power Waveguide to Coaxial Adapter manufacturer with over 20 years of expertise, Advanced Microwave Technologies Co., Ltd. delivers superior solutions for satellite communications, aerospace, and defense applications. Our China High Power Waveguide to Coaxial Adapter factory produces adapters handling up to 5kW with frequencies spanning 0.5 to 110 GHz, all ISO 9001:2015 certified and tested in our 24m Microwave Darkroom facility. Whether you need standard products from our China High Power Waveguide to Coaxial Adapter supplier inventory or custom OEM designs, we offer competitive High Power Waveguide to Coaxial Adapter prices and High Quality High Power Waveguide to Coaxial Adapter solutions. Contact craig@admicrowave.com today for High Power Waveguide to Coaxial Adapter for sale inquiries, and discover why leading organizations choose our China High Power Waveguide to Coaxial Adapter wholesale services.

References

1. "Waveguide to Coaxial Adapter Design Principles," IEEE Transactions on Microwave Theory and Techniques, Pozar, David M., 2023.

2. "High Power RF Transmission Systems: Engineering and Applications," Microwave Journal Technical Series, Johnson, Richard C., 2024.

3. "Precision Measurement Techniques for Millimeter-Wave Components," National Institute of Standards and Technology Technical Publication, Williams, Dylan F., 2023.

4. "Thermal Management in High-Power Microwave Components," Journal of Electromagnetic Waves and Applications, Chen, Wei and Anderson, Mark J., 2024.

5. "Modern Satellite Communication Ground Station Design," American Institute of Aeronautics and Astronautics Technical Report, Martinez, Carlos E., 2023.