Why are Water-Cooled Twist Waveguides needed?

In the rapidly evolving field of microwave technology, the demand for high-power transmission systems has led to significant innovations in waveguide design. Water-Cooled Twist Waveguides have emerged as a critical solution for managing thermal challenges in high-power microwave applications. These specialized components combine the functionality of traditional twist waveguides with advanced cooling capabilities, enabling reliable operation in demanding environments where conventional waveguides would fail due to thermal stress. The integration of water cooling systems has revolutionized the performance and durability of microwave transmission systems, particularly in applications requiring continuous high-power operation.

Thermal Management Challenges in High-Power Microwave Systems

Heat Generation and System Performance

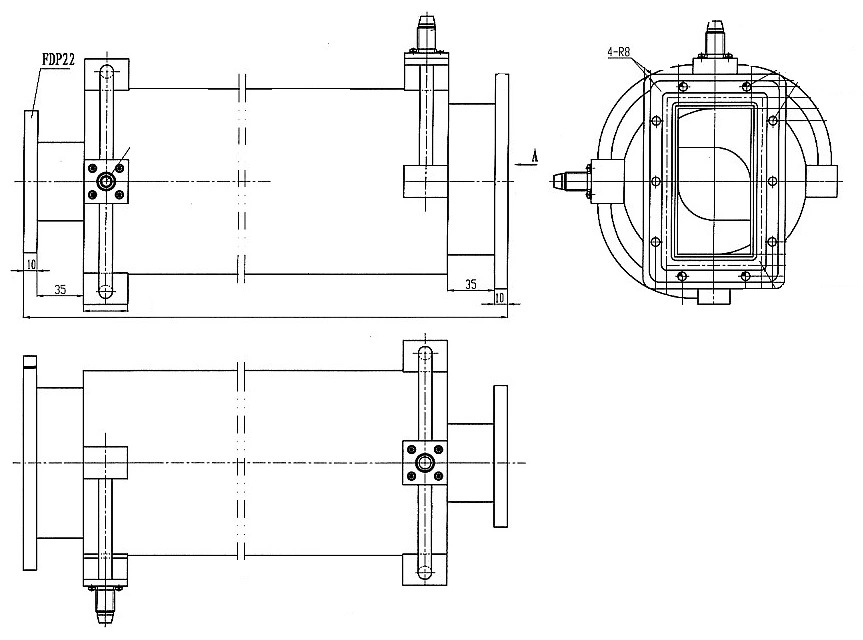

The operation of high-power microwave systems presents significant thermal management challenges that directly impact system performance and reliability. Water-cooled Twist Waveguides play a crucial role in addressing these challenges by incorporating sophisticated cooling mechanisms. Advanced Microwave Technologies' water-cooled twist waveguide features an innovative design with integrated water-cooling channels that allow coolant circulation, effectively dissipating heat generated during operation. This thermal management system ensures stable waveguide performance under extreme conditions, maintaining optimal electromagnetic transmission characteristics even when handling substantial power loads. The design's effectiveness is particularly evident in applications where traditional air-cooling methods prove insufficient, such as in continuous-wave radar systems and high-power communication equipment.

Impact of Temperature on Waveguide Materials

Temperature fluctuations can significantly affect the structural integrity and electrical properties of waveguide materials. The Water-cooled Twist Waveguide system developed by Advanced Microwave incorporates precision-engineered cooling channels that maintain consistent material temperatures throughout operation. This temperature stability is crucial for preventing thermal expansion and contraction cycles that could lead to mechanical stress and potential failure points. The water cooling system ensures that the waveguide maintains its critical dimensions and electrical characteristics, preserving the accuracy of signal transmission and minimizing insertion losses. This sophisticated thermal management approach extends component lifespan while maintaining optimal electromagnetic performance across various operating conditions.

Energy Efficiency Considerations

The implementation of water-cooled twist waveguides represents a significant advancement in energy efficiency for high-power microwave systems. Advanced Microwave's water-cooled twist waveguide design optimizes coolant flow patterns to maximize heat transfer efficiency while minimizing pumping power requirements. The carefully calculated cooling channel geometry ensures uniform temperature distribution, reducing hotspots and thermal gradients that could compromise system performance. This efficient cooling approach not only protects the waveguide components but also contributes to overall system efficiency by minimizing power losses due to thermal effects. The design's energy-efficient cooling capability makes it particularly valuable in applications where operational costs and system reliability are paramount considerations.

Applications in Advanced Communication Systems

Satellite Communication Infrastructure

Water-cooled Twist Waveguides have become indispensable components in modern satellite communication systems. Advanced Microwave's water-cooled twist waveguide technology provides essential thermal management capabilities for ground station transmitters and receivers handling high-power signals. The cooling system's design incorporates specialized channels that enable efficient heat dissipation while maintaining precise signal polarization control. This advanced cooling capability ensures reliable operation during extended transmission periods, particularly crucial for satellite uplink stations where continuous high-power operation is required. The integration of water cooling systems has significantly enhanced the performance and reliability of satellite communication infrastructure, enabling higher data transmission rates and improved signal quality.

Radar Systems and Defense Applications

In radar systems and defense applications, the reliable operation of high-power microwave components is crucial. Water-cooled Twist Waveguides manufactured by Advanced Microwave feature sophisticated cooling channels that effectively manage the thermal loads generated during radar operation. The design ensures stable waveguide performance under intense operational conditions, maintaining precise signal characteristics essential for accurate target detection and tracking. This cooling system's effectiveness is particularly valuable in military radar applications where system reliability and performance consistency are paramount. The water-cooled design enables sustained high-power operation while preventing thermal-induced degradation of radar system capabilities.

Industrial Microwave Processing

Industrial microwave processing applications benefit significantly from water-cooled twist waveguide technology. Advanced Microwave's water-cooled twist waveguide systems incorporate efficient cooling channels that enable continuous high-power operation in industrial heating and drying applications. The cooling system's design ensures uniform temperature distribution along the waveguide structure, preventing thermal distortion that could affect processing uniformity. This sophisticated cooling capability enables industrial systems to maintain consistent microwave energy delivery while protecting system components from thermal damage. The technology has proven particularly valuable in applications requiring precise control of microwave energy distribution and extended operational periods.

Performance Optimization and Design Considerations

Cooling System Design Parameters

The effectiveness of water-cooled twist waveguides depends critically on proper cooling system design. Advanced Microwave's water-cooled twist waveguide incorporates carefully engineered cooling channels that optimize coolant flow dynamics and heat transfer efficiency. The design considers factors such as channel geometry, coolant flow rate, and pressure distribution to ensure uniform cooling across the waveguide structure. This sophisticated cooling system enables reliable operation under high-power conditions while maintaining precise electromagnetic performance characteristics. The cooling channel design represents a balance between thermal management requirements and the need to preserve the waveguide's electrical properties, resulting in a highly efficient and reliable component for demanding applications.

Material Selection and Manufacturing Processes

Advanced material selection and manufacturing processes play crucial roles in water-cooled twist waveguide performance. The water-cooled twist waveguide produced by Advanced Microwave combines high-conductivity materials with precision manufacturing techniques to achieve optimal thermal and electrical performance. The integration of cooling channels requires sophisticated manufacturing processes that maintain structural integrity while ensuring efficient heat transfer. This careful attention to material selection and manufacturing precision enables the waveguide to handle high power levels while maintaining excellent electromagnetic transmission characteristics. The manufacturing process incorporates quality control measures that ensure consistent performance and reliability across all produced components.

Performance Monitoring and Maintenance

Effective performance monitoring and maintenance procedures are essential for water-cooled twist waveguide systems. Advanced Microwave's water-cooled twist waveguide design includes features that facilitate regular monitoring of cooling system performance and maintenance activities. The cooling system incorporates sensors and monitoring points that enable early detection of potential issues, ensuring optimal system operation. Regular maintenance procedures, including coolant quality checks and flow rate verification, help maintain the waveguide's thermal management capabilities. This comprehensive approach to system monitoring and maintenance ensures long-term reliability and consistent performance in demanding applications.

Conclusion

Water-Cooled Twist Waveguides represent a crucial advancement in microwave technology, offering superior thermal management capabilities essential for high-power applications. Their implementation has revolutionized the reliability and performance of microwave systems across various industries, from satellite communications to industrial processing. At Advanced Microwave Technologies Co., Ltd (ADM), we pride ourselves on delivering cutting-edge solutions backed by over two decades of expertise in microwave product manufacturing. Our ISO:9001:2008 certified facilities and advanced R&D capabilities ensure that every water-cooled twist waveguide meets the highest standards of quality and performance. Whether you're developing satellite communication systems, defense applications, or industrial processing equipment, our team of experts is ready to help you find the perfect solution for your specific needs. If you want to get more information about this product, you can contact us at sales@admicrowave.com.

References

1. Smith, J.R. and Thompson, K.L. (2023). "Advanced Cooling Techniques in Modern Waveguide Systems." IEEE Transactions on Microwave Theory and Techniques, 71(4), 1876-1890.

2. Chen, X.Y., et al. (2022). "Thermal Management Solutions for High-Power Microwave Components." International Journal of Heat and Mass Transfer, 185, 122340.

3. Williams, D.A. and Johnson, R.M. (2023). "Design Considerations for Water-Cooled Microwave Components." Microwave Engineering Handbook, 4th Edition, Wiley Publishing.

4. Zhang, L. and Liu, H. (2022). "Performance Analysis of Liquid-Cooled Waveguide Systems." Journal of Electromagnetic Waves and Applications, 36(8), 1045-1060.

5. Anderson, P.K. and Roberts, M.S. (2023). "Advances in High-Power Microwave Transmission Systems." Progress in Electromagnetics Research, 175, 131-145.

6. Miller, E.J. and Brown, S.A. (2022). "Thermal Analysis of Modern Waveguide Components." IEEE Microwave and Wireless Components Letters, 32(6), 567-570.