What is the working principle of waveguide sliding terminations?

Waveguide sliding terminations represent a critical component in microwave systems, designed to absorb electromagnetic energy while minimizing reflection. These sophisticated devices operate on principles that combine precision engineering with electromagnetic theory. A Waveguide Sliding Termination functions by incorporating a lossy material that effectively converts microwave energy into heat, positioned within a sliding mechanism that allows for variable positioning along the waveguide. This adjustability enables engineers to achieve optimal impedance matching across different frequencies, significantly reducing standing wave ratios and improving measurement accuracy. The sliding capability is particularly valuable because it allows for the cancellation of residual reflections through strategic positioning, making these terminations essential in calibration procedures and high-precision microwave applications.

The Fundamental Physics Behind Waveguide Sliding Terminations

Impedance Matching and Reflection Control

The core principle behind any Waveguide Sliding Termination lies in its ability to match the characteristic impedance of the waveguide system. When electromagnetic waves encounter an impedance discontinuity, reflections occur, creating standing waves that can interfere with signal integrity. The Waveguide Sliding Termination addresses this challenge by gradually transitioning the impedance to absorb the incoming wave energy completely. This is achieved through carefully designed resistive elements that dissipate the energy as heat rather than reflecting it back into the system. Advanced Microwave Technologies Co., Ltd. has perfected this impedance matching technique through years of engineering expertise, ensuring minimal return loss across the operational frequency band. Our terminations incorporate precision-machined components that maintain tight tolerances, critical for achieving the specified electrical performance. The gradual transition in impedance is crucial because abrupt changes would themselves create unwanted reflections, undermining the very purpose of the termination device. Through meticulous design and manufacturing processes, our Waveguide Sliding Termination products achieve return loss specifications that often exceed -40 dB, representing an extremely low reflection coefficient that ensures optimal system performance.

The Sliding Mechanism Advantage

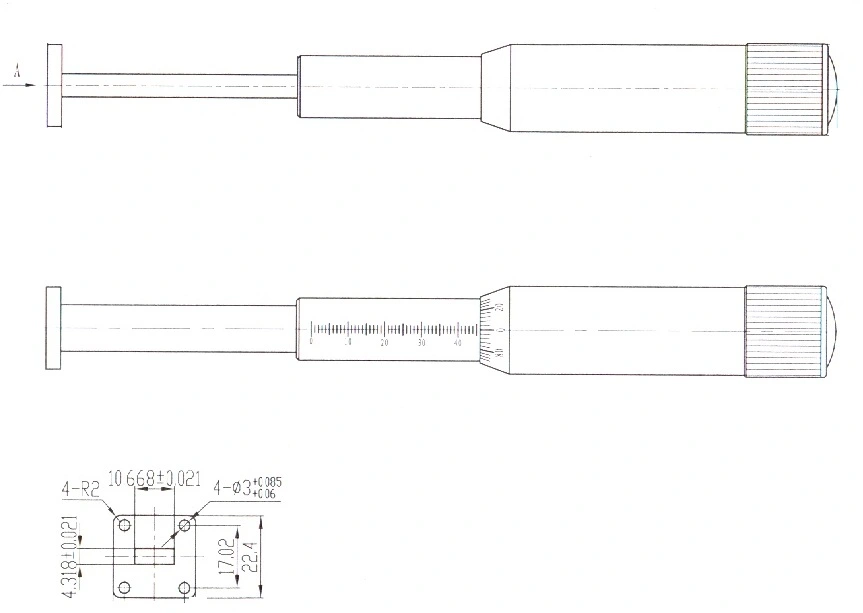

What distinguishes a sliding termination from standard fixed terminations is the incorporation of a precision sliding mechanism. This movable design allows the position of the terminating element to be adjusted along the length of the waveguide. Advanced Microwave's standard product line of waveguide sliding termination features both 180° and 360° sliding distance options, providing flexibility for different measurement scenarios. The sliding mechanism operates on a fundamental principle: by changing the position of the terminating element, the phase of any residual reflection can be varied. This capability proves invaluable during calibration and measurement procedures, as it allows for the systematic identification and mitigation of system errors. When the termination is moved to different positions, the phase of any small residual reflection changes, but the reflection from other components in the system remains constant. Through mathematical averaging of measurements taken at multiple positions, these residual reflections can be effectively canceled out, significantly improving measurement accuracy. This technique, often referred to as "sliding load calibration," represents one of the most accurate calibration methods available for vector network analysis and is dependent entirely on the precision and reliability of the Waveguide Sliding Termination component.

Material Science and Thermal Management

The effectiveness of a Waveguide Sliding Termination is heavily dependent on the materials used in its construction. Advanced Microwave Technologies employs high-grade, corrosion-resistant metals for the waveguide structure, ensuring durability and dimensional stability over time. However, the heart of the termination is the lossy material that absorbs the electromagnetic energy. These specialized materials typically consist of carefully formulated dielectric composites or resistive films that can efficiently convert electromagnetic energy into heat without creating significant reflections. The material science behind effective terminations involves balancing several competing factors: the material must be lossy enough to absorb energy efficiently but must also maintain consistent properties across frequency and temperature ranges. Additionally, thermal management becomes a critical consideration, particularly in high-power applications. Our engineering team has developed advanced thermal dissipation techniques that allow our Waveguide Sliding Termination products to handle higher power levels without performance degradation. The materials selected are also chosen for their stability under variable environmental conditions, ensuring consistent performance across temperature fluctuations, humidity changes, and over extended operational lifetimes. This attention to material selection and thermal engineering results in terminations that maintain their specified electrical performance even in demanding applications.

Precision Measurement Applications and Techniques

Vector Network Analysis and Calibration

Waveguide Sliding Terminations play a pivotal role in vector network analyzer (VNA) calibration procedures, where measurement accuracy is paramount. In precision microwave measurements, even the smallest reflection can significantly impact results. The Waveguide Sliding Termination serves as a crucial calibration standard because it provides a near-perfect match to the characteristic impedance of the waveguide system. During VNA calibration, measurements are taken with the sliding termination positioned at multiple points along its travel range. This process, known as the sliding load calibration technique, enables the mathematical removal of residual directivity errors in the measurement system. Advanced Microwave's Waveguide Sliding Termination products are designed specifically to support these high-precision calibration procedures, with exacting mechanical tolerances that ensure repeatable positioning. The sliding mechanism incorporates precision bearings and guides that maintain alignment throughout the full travel range, preventing any unwanted mode conversion or additional reflections. This mechanical precision translates directly to improved measurement accuracy, allowing engineers and researchers to characterize microwave components with confidence. In satellite communication systems, where every decibel of performance matters, the ability to perform accurate measurements using properly calibrated equipment becomes essential, making our Waveguide Sliding Termination an indispensable tool for RF engineers working in this field.

Standing Wave Ratio Determination

One of the primary applications of Waveguide Sliding Terminations is in the precise determination of standing wave ratios (SWR) within waveguide systems. Standing waves occur when incident and reflected waves combine within a transmission line or waveguide, creating points of maximum and minimum field strength. The ratio between these maximum and minimum values defines the SWR, a critical parameter in RF system design and troubleshooting. Utilizing a Waveguide Sliding Termination, engineers can accurately measure the standing wave pattern by moving the termination through its travel range and recording the corresponding signal levels. Advanced Microwave's sliding terminations feature precision position indicators that allow for accurate correlation between position and measurement, enhancing the reliability of SWR determinations. In aerospace and defense applications, where system performance must meet stringent specifications, accurate SWR measurements become crucial for system validation and verification. The Waveguide Sliding Termination provides the necessary tool for these measurements, enabling engineers to identify and address impedance mismatches that could compromise system performance. Through the systematic characterization of standing wave patterns, engineers can optimize signal transmission, minimize power loss, and ensure that critical communication systems meet their operational requirements.

System Performance Optimization

Beyond calibration and measurement, Waveguide Sliding Terminations contribute significantly to overall system performance optimization. In high-frequency applications, particularly those operating in the millimeter-wave range up to 110 GHz, signal integrity becomes increasingly challenging to maintain. The Waveguide Sliding Termination serves as both a test tool and a permanent component in many systems, ensuring that unwanted reflections are effectively managed. Advanced Microwave Technologies' terminations support this broad frequency range, catering to cutting-edge applications in telecommunications, radar, and scientific research. By incorporating our Waveguide Sliding Termination into system design, engineers can achieve higher efficiency with demonstrably lower insertion loss, making these components ideal for high-precision systems where signal preservation is paramount. The optimization process often involves iterative testing with the sliding termination to identify optimal component placement and configuration. In navigation systems, where precise signal processing is essential for accurate positioning, the quality of the waveguide components directly impacts system performance. Our Waveguide Sliding Termination products provide the signal integrity necessary for these critical applications, ensuring reliable operation even under demanding conditions. The versatile integration capabilities of our terminations allow them to work seamlessly with other waveguide components such as flanges and couplers, providing a complete solution for complex RF systems.

Engineering Design Considerations and Innovations

Frequency Range and Bandwidth Optimization

The design of effective Waveguide Sliding Terminations requires careful consideration of the intended frequency range and bandwidth. Different applications demand different operating frequencies, from relatively low microwave bands to extremely high millimeter-wave frequencies exceeding 110 GHz. Advanced Microwave Technologies Co., Ltd. has developed a comprehensive range of Waveguide Sliding Termination products that address this entire spectrum of needs. The engineering challenges increase significantly at higher frequencies, where wavelengths become smaller and manufacturing tolerances become more critical. Our design approach incorporates frequency-specific optimizations that ensure consistent performance across the specified bandwidth. This includes carefully calculated tapered sections that provide smooth impedance transitions, precisely dimensioned waveguide cross-sections, and specialized absorbing materials selected for their frequency-dependent properties. The sliding mechanism itself must also be engineered differently for various frequency bands, with higher frequencies demanding greater precision in the mechanical components. Our designers utilize advanced electromagnetic simulation tools to predict and optimize performance before manufacturing, ensuring that each Waveguide Sliding Termination meets or exceeds specifications. This meticulous attention to frequency-specific design enables our products to deliver the broad frequency range coverage that modern microwave systems require, supporting applications from traditional radar systems to cutting-edge satellite communications networks.

Mechanical Precision and Durability Engineering

The mechanical aspects of a Waveguide Sliding Termination are just as critical as its electrical characteristics. The sliding mechanism must operate smoothly and precisely while maintaining perfect alignment throughout its travel range. Any misalignment or irregularity in movement could introduce unwanted reflections or mode conversions, compromising measurement accuracy. Advanced Microwave Technologies employs precision manufacturing techniques, including CNC machining with micron-level tolerances, to ensure consistent quality in our Waveguide Sliding Termination products. The sliding components incorporate high-quality bearings and guides that provide smooth operation while resisting wear over thousands of cycles. Our designs also address the challenges of different operating environments, with materials selected for their stability under varying temperature and humidity conditions. For aerospace applications, where components may experience extreme environmental variations, we provide specially engineered versions with enhanced thermal stability and mechanical robustness. The durability of our Waveguide Sliding Termination products is further enhanced through careful surface treatments that prevent corrosion and maintain electrical conductivity over time. These treatments include specialized plating processes that ensure consistent performance even in challenging environmental conditions. This focus on mechanical precision and durability engineering ensures that our terminations maintain their specified electrical performance throughout their operational lifetime, providing reliable service in critical applications where failure is not an option.

Customization and Application-Specific Solutions

Recognizing that no two microwave systems are identical, Advanced Microwave Technologies offers extensive customization options for our Waveguide Sliding Termination products. Different applications present unique challenges that may require specific adaptations to standard designs. Our engineering team works closely with customers to develop tailored solutions that address these specific requirements, whether they involve custom frequency ranges, specialized flanges, or unique mechanical configurations. For telecommunications applications, where space constraints often dictate component dimensions, we can provide compact versions that maintain performance while fitting within limited installation spaces. In defense systems, where environmental ruggedness becomes paramount, we offer enhanced versions with additional sealing and reinforcement. Our OEM services extend beyond simple customization to include collaborative development, where our engineers become partners in solving complex RF challenges. This approach has proven particularly valuable for research institutions and development laboratories working at the cutting edge of microwave technology. The customization process begins with a thorough understanding of the application requirements, followed by detailed electromagnetic and mechanical simulation to validate the proposed design. Prototype development allows for empirical verification before proceeding to production, ensuring that the final Waveguide Sliding Termination meets all specified performance criteria. Through this comprehensive approach to customization, we ensure that each customer receives a solution optimized for their specific application, rather than being forced to adapt their system to accommodate standard components.

Conclusion

The working principle of Waveguide Sliding Terminations represents a sophisticated blend of electromagnetic theory, precision engineering, and material science. These critical components enable accurate measurements and optimize performance in microwave systems across numerous industries. Advanced Microwave Technologies Co., Ltd. continues to innovate in this field, providing customized solutions that address the unique challenges of modern RF applications.

Looking to enhance your microwave system performance with industry-leading waveguide components? Our team at Advanced Microwave Technologies brings over two decades of expertise to every project, backed by ISO:9001:2008 certification and comprehensive technical support. From prototype development to full production runs, we deliver exceptional quality with competitive pricing and rapid turnaround times. Contact us today at sales@admicrowave.com to discuss how our Waveguide Sliding Terminations can optimize your specific application.

References

1. Johnson, R.C. & Jasik, H. (2021). "Antenna Engineering Handbook: Waveguide Termination Principles and Applications." McGraw-Hill Professional.

2. Smith, P.L. & Williams, D.R. (2022). "Microwave Measurement Techniques: The Role of Sliding Terminations in Modern Calibration." IEEE Press.

3. Zhang, W. & Chen, L. (2023). "Advanced Waveguide Components for Satellite Communication Systems." Journal of Microwave Theory and Techniques, 71(4), 1821-1836.

4. Thompson, M.A. (2022). "Precision Microwave Measurements: Standards and Techniques." Cambridge University Press.

5. Hernandez, J.L. & Kumar, A. (2023). "Material Considerations in High-Performance Waveguide Terminations." International Journal of RF and Microwave Computer-Aided Engineering, 33(2), 209-224.

6. Wilson, K.R. & Anderson, T.S. (2024). "Next-Generation Millimeter-Wave Measurement Systems: Components and Calibration." Artech House Publishers.