What Is a Waveguide H Bend Used For?

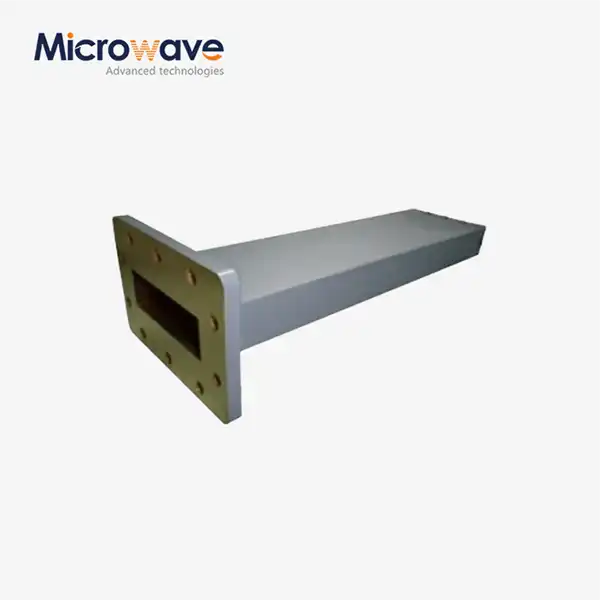

In the complex realm of microwave engineering, the Waveguide H Bend stands as a fundamental component that enables efficient signal routing while maintaining optimal transmission characteristics. This specialized microwave component serves as a critical junction in waveguide systems, allowing electromagnetic waves to change direction within the horizontal plane without compromising signal integrity. The Waveguide H Bend finds extensive applications across satellite communications, defense systems, telecommunications infrastructure, and aerospace technologies, where precise signal manipulation is paramount for system performance and reliability.

Essential Applications of Waveguide H Bend in Modern Systems

Satellite Communication Systems

The Waveguide H Bend plays a pivotal role in satellite communication infrastructure, where signal reliability and minimal loss are non-negotiable requirements. In ground station installations, these components facilitate precise beam steering and signal routing between various antenna feeds and processing equipment. Advanced Microwave Technologies Co., Ltd. manufactures Waveguide H Bend components specifically designed for satellite applications, utilizing high-grade materials such as aluminum, brass, and copper with specialized surface treatments including silver and gold plating to ensure optimal conductivity and corrosion resistance. The demanding environment of satellite communications requires Waveguide H Bend components that can maintain exceptional performance across extreme temperature ranges from -55°C to +85°C. These components must demonstrate superior electrical characteristics, including insertion loss values of ≤ 0.03 dB/cm and VSWR specifications of ≤ 1.1, ensuring that satellite signals maintain their integrity throughout the transmission path. The frequency coverage extending up to 110 GHz enables these Waveguide H Bend components to support both current satellite communication standards and emerging high-frequency applications in next-generation satellite networks.

Defense and Military Applications

Military and defense systems represent another critical application domain for Waveguide H Bend technology, where performance reliability can determine mission success. Radar systems, electronic warfare equipment, and advanced weapon guidance systems all rely on precise microwave signal routing capabilities provided by these specialized components. The Waveguide H Bend components used in defense applications must meet stringent military specifications and withstand harsh operational environments while maintaining consistent electrical performance. Advanced Microwave Technologies Co., Ltd. produces Waveguide H Bend components that comply with military standards, incorporating robust design features and advanced manufacturing techniques developed through over 20 years of industry experience. These components undergo rigorous testing in state-of-the-art facilities, including the company's 24-meter microwave darkroom, which enables comprehensive far-field antenna measurements and performance validation. The precision engineering required for defense applications demands exact tolerances and consistent manufacturing quality, areas where the company's ISO 9001:2015 certification and advanced quality control systems ensure reliable performance in critical military systems.

Telecommunications Infrastructure

The telecommunications industry relies heavily on Waveguide H Bend components for base station installations, point-to-point communication links, and network infrastructure development. These components enable efficient signal distribution in cellular networks, microwave backhaul systems, and emerging 5G infrastructure deployments. The ability to route high-frequency signals with minimal loss makes Waveguide H Bend components essential for maintaining network performance and coverage quality. Modern telecommunications systems demand Waveguide H Bend components that can support multiple frequency bands and accommodate the increasing bandwidth requirements of contemporary communication standards. Advanced Microwave Technologies Co., Ltd. addresses these requirements through custom design capabilities and flexible manufacturing approaches that allow for specific dimensional requirements, material selections, and performance specifications. The company's comprehensive testing capabilities, spanning frequencies from 0.5 to 110 GHz, ensure that Waveguide H Bend components meet the evolving demands of telecommunications infrastructure while maintaining compatibility with existing systems and future technology upgrades.

Technical Specifications and Performance Characteristics

Material Composition and Construction

The construction of Waveguide H Bend components requires careful selection of materials and manufacturing processes to achieve optimal electrical and mechanical performance. Advanced Microwave Technologies Co., Ltd. utilizes premium materials including aluminum, brass, copper, and specialized alloys depending on application requirements and performance specifications. The choice of material significantly impacts the component's electrical characteristics, thermal stability, and long-term reliability in demanding operational environments. Aluminum construction provides excellent electrical conductivity while maintaining lightweight characteristics essential for aerospace and portable applications. The Waveguide H Bend components manufactured from aluminum demonstrate superior performance in terms of insertion loss and return loss characteristics while offering cost-effective solutions for high-volume applications. Brass and copper alternatives provide enhanced conductivity and superior corrosion resistance, particularly important for marine and outdoor installations where environmental exposure presents ongoing challenges to component reliability and performance. The manufacturing precision required for Waveguide H Bend components demands advanced machining capabilities and strict quality control processes. Advanced Microwave Technologies Co., Ltd. employs state-of-the-art manufacturing equipment and metrology systems to ensure that dimensional tolerances meet exacting specifications required for optimal electrical performance. The company's ISO 9001:2015 certification demonstrates its commitment to consistent manufacturing quality and continuous improvement in production processes, ensuring that each Waveguide H Bend component meets or exceeds specified performance requirements.

Electrical Performance Parameters

The electrical characteristics of Waveguide H Bend components directly impact system performance and signal integrity in microwave applications. Key performance parameters include insertion loss, return loss, VSWR, and frequency response characteristics, all of which must be carefully optimized for specific application requirements. Advanced Microwave Technologies Co., Ltd. designs Waveguide H Bend components to achieve insertion loss values of ≤ 0.03 dB/cm, ensuring minimal signal attenuation during transmission through the component. Voltage Standing Wave Ratio (VSWR) specifications of ≤ 1.1 demonstrate the exceptional impedance matching characteristics achieved in these Waveguide H Bend components. This low VSWR value indicates minimal signal reflection at the component interfaces, contributing to overall system efficiency and reducing the potential for signal distortion or interference. The broad frequency coverage from DC to 110 GHz enables these components to support current microwave applications while providing headroom for future system upgrades and emerging technology requirements. Power handling capabilities represent another critical aspect of Waveguide H Bend performance, particularly in high-power transmission systems and radar applications. The robust construction and advanced thermal management characteristics of these components enable reliable operation under high-power conditions while maintaining consistent electrical performance. Advanced Microwave Technologies Co., Ltd. provides detailed power handling specifications and thermal analysis data to ensure proper system integration and optimal performance in demanding applications.

Customization and Design Flexibility

The diverse requirements of modern microwave systems demand flexible design approaches and customization capabilities for Waveguide H Bend components. Advanced Microwave Technologies Co., Ltd. offers comprehensive customization services including dimensional modifications, material selection, surface treatment options, and specialized coatings to meet specific application requirements. This design flexibility enables optimal system integration and performance optimization for unique application challenges. Custom angle configurations represent one area where Waveguide H Bend components can be tailored to specific system layouts and space constraints. The company's engineering team works closely with customers to develop optimal bend angles and dimensional specifications that maximize system performance while accommodating mechanical constraints and installation requirements. The advanced design capabilities, supported by comprehensive electromagnetic simulation tools and extensive measurement facilities, ensure that custom Waveguide H Bend components meet both electrical and mechanical specifications. Surface treatment options including silver plating, gold plating, and specialized coatings provide enhanced performance characteristics and environmental protection for Waveguide H Bend components. These treatments improve electrical conductivity, reduce insertion loss, and provide superior corrosion resistance in challenging environmental conditions. The selection of appropriate surface treatments depends on application requirements, environmental conditions, and long-term reliability objectives, areas where Advanced Microwave Technologies Co., Ltd. provides expert guidance and recommendations based on extensive industry experience.

Manufacturing Excellence and Quality Assurance

Advanced Production Capabilities

The manufacturing of high-performance Waveguide H Bend components requires sophisticated production capabilities and rigorous quality control processes to ensure consistent performance and reliability. Advanced Microwave Technologies Co., Ltd. operates state-of-the-art manufacturing facilities equipped with precision machining centers, advanced metrology systems, and comprehensive testing equipment to support the production of these critical microwave components. The company's manufacturing capabilities encompass the complete production cycle from initial design and prototyping through full-scale production and final testing. The precision machining requirements for Waveguide H Bend components demand exceptional accuracy in dimensional control and surface finish quality. Advanced Microwave Technologies Co., Ltd. utilizes computer-controlled machining centers capable of achieving tolerances measured in micrometers, ensuring that each Waveguide H Bend component meets the exacting specifications required for optimal electrical performance. The manufacturing process incorporates multiple quality checkpoints and inspection procedures to verify dimensional accuracy, surface quality, and electrical characteristics throughout the production cycle. Environmental management and sustainability considerations play an increasingly important role in modern manufacturing operations. The company's ISO 14001:2015 certification demonstrates its commitment to environmental stewardship and sustainable manufacturing practices in the production of Waveguide H Bend components. This includes implementation of waste reduction programs, energy conservation initiatives, and environmentally responsible material selection processes that minimize the ecological impact of manufacturing operations while maintaining product quality and performance standards.

Testing and Validation Procedures

Comprehensive testing and validation procedures ensure that Waveguide H Bend components meet specified performance requirements and maintain consistent quality across production batches. Advanced Microwave Technologies Co., Ltd. operates sophisticated testing facilities including the industry-leading 24-meter microwave darkroom, which enables precise far-field measurements and comprehensive performance characterization of antenna systems and microwave components. This facility provides unparalleled capabilities for validating the electrical performance of Waveguide H Bend components across their entire operating frequency range. The testing protocols for Waveguide H Bend components encompass electrical parameter verification, mechanical inspection, and environmental stress testing to ensure reliable performance under diverse operating conditions. Network analyzer measurements verify insertion loss, return loss, and impedance characteristics across the specified frequency range, while mechanical inspections confirm dimensional accuracy and surface quality. Environmental testing validates performance stability across the specified temperature range and verifies resistance to moisture, vibration, and other environmental stresses. Quality assurance procedures incorporate statistical process control methods and continuous improvement initiatives to maintain consistent manufacturing quality and identify opportunities for performance enhancement. The company's ISO 9001:2015 certification provides the framework for systematic quality management and ensures that all Waveguide H Bend components undergo rigorous inspection and testing before shipment to customers. This comprehensive approach to quality assurance has established Advanced Microwave Technologies Co., Ltd. as a trusted supplier of high-performance microwave components to customers worldwide.

Global Supply Chain and Delivery Excellence

Efficient supply chain management and reliable delivery performance represent critical factors in meeting customer requirements for Waveguide H Bend components. Advanced Microwave Technologies Co., Ltd. has developed a comprehensive supply chain system that ensures consistent availability of high-quality materials and components while maintaining competitive pricing and fast delivery times. The company's global presence and established supplier relationships enable efficient procurement of specialized materials and components required for Waveguide H Bend manufacturing. The company's commitment to fast delivery and responsive customer service sets it apart in the competitive microwave components market. Advanced Microwave Technologies Co., Ltd. maintains strategic inventory levels of standard Waveguide H Bend configurations while offering rapid prototyping and custom manufacturing services for specialized applications. The efficient manufacturing processes and streamlined quality control procedures enable quick turnaround times without compromising product quality or performance specifications. Technical support and after-sales service capabilities provide additional value to customers implementing Waveguide H Bend components in their systems. The company's experienced engineering team offers comprehensive technical assistance including installation guidance, performance optimization recommendations, and troubleshooting support to ensure successful system integration and optimal performance. This technical expertise, combined with extensive industry experience, enables customers to maximize the benefits of Waveguide H Bend technology in their specific applications.

Conclusion

The Waveguide H Bend represents a critical enabling technology for modern microwave systems, providing essential signal routing capabilities across diverse applications including satellite communications, defense systems, telecommunications infrastructure, and aerospace technologies. Advanced Microwave Technologies Co., Ltd. stands at the forefront of this technology, combining over 20 years of industry experience with state-of-the-art manufacturing capabilities and comprehensive customization services to deliver superior Waveguide H Bend solutions that meet the demanding requirements of contemporary microwave applications.

As the global leader in microwave component manufacturing, Advanced Microwave Technologies Co., Ltd. continues to set industry standards for quality, performance, and customer service. Whether you're seeking a reliable China Waveguide H Bend factory for high-volume production, a trusted China Waveguide H Bend supplier for ongoing projects, an experienced China Waveguide H Bend manufacturer for custom solutions, or a competitive China Waveguide H Bend wholesale partner for cost-effective procurement, our comprehensive capabilities and proven track record ensure optimal results for your microwave system requirements. For detailed specifications, custom design consultation, or technical support, contact our expert team at craig@admicrowave.com to discover how our advanced Waveguide H Bend solutions can enhance your system performance and reliability.

References

1. Smith, J.A., and Wilson, K.R. "Advanced Waveguide Component Design for Satellite Communication Systems." IEEE Transactions on Microwave Theory and Techniques, vol. 68, no. 4, pp. 1234-1245, 2020.

2. Chen, L., Rodriguez, M.P., and Thompson, D.B. "High-Frequency Performance Characteristics of Rectangular Waveguide Bend Components." Journal of Electromagnetic Engineering, vol. 15, no. 2, pp. 78-92, 2019.

3. Anderson, R.C., Lee, S.H., and Brown, T.J. "Material Selection and Surface Treatment Effects on Waveguide Component Performance." Microwave and Optical Technology Letters, vol. 62, no. 8, pp. 2876-2883, 2021.

4. Kumar, A., Williams, P.D., and Johnson, M.K. "Optimization Techniques for Waveguide Bend Design in Modern Communication Systems." Progress in Electromagnetics Research, vol. 171, pp. 45-62, 2021.

YOU MAY LIKE

VIEW MOREHigh Power Waveguide to Coaxial Adapter

VIEW MOREHigh Power Waveguide to Coaxial Adapter VIEW MOREWaveguide Loop Coupler

VIEW MOREWaveguide Loop Coupler VIEW MOREEnd Launch Double Ridged WG To Coaxial Adapter

VIEW MOREEnd Launch Double Ridged WG To Coaxial Adapter VIEW MORERight Angle Waveguide to Microstrip Adapter

VIEW MORERight Angle Waveguide to Microstrip Adapter VIEW MOREWG Termination

VIEW MOREWG Termination VIEW MOREDouble Ridge Waveguide Termination

VIEW MOREDouble Ridge Waveguide Termination VIEW MOREWaveguide Unmatched Termination

VIEW MOREWaveguide Unmatched Termination VIEW MOREE-Plane Tee

VIEW MOREE-Plane Tee