Flexible Seamless Waveguide for Military and Aerospace: 5 Key Advantages

In the demanding world of military and aerospace applications, where signal integrity and system reliability can mean the difference between mission success and failure, Flexible Seamless Waveguide technology has emerged as a critical component for high-frequency signal transmission. These specialized components represent a significant advancement in microwave engineering, offering unparalleled performance in environments where traditional rigid waveguides fall short. The unique combination of flexibility and seamless construction addresses the complex challenges faced by modern defense systems, satellite communications, and aerospace platforms that require both mechanical adaptability and exceptional electrical performance in extreme conditions.

Superior Signal Integrity Through Seamless Construction

The primary advantage of Flexible Seamless Waveguide in military and aerospace applications lies in its ability to maintain exceptional signal integrity across demanding operational environments. Unlike traditional segmented waveguides that rely on flanged connections, the seamless design eliminates potential points of signal degradation that can compromise system performance in critical missions. Advanced Microwave Technologies Co., Ltd has engineered their Flexible Seamless Waveguide with precision manufacturing techniques that ensure minimal signal distortion and insertion loss, typically achieving performance levels that exceed industry standards for high-frequency applications up to 110 GHz. The seamless construction is particularly vital in military radar systems where even minor signal degradation can impact target detection capabilities and range accuracy. In aerospace applications, where satellites must maintain continuous communication links over vast distances, the superior signal integrity provided by Flexible Seamless Waveguide ensures reliable data transmission without the signal degradation commonly associated with traditional jointed waveguide assemblies. The continuous metallic path eliminates reflections and standing wave formations that can occur at junction points, resulting in cleaner signal propagation and improved system efficiency. This seamless design also reduces electromagnetic interference susceptibility, a critical factor in military environments where electronic warfare countermeasures are a constant concern.

Enhanced Mechanical Flexibility for Complex Installations

Military and aerospace systems often require waveguide installations in confined spaces with complex routing requirements that rigid waveguides simply cannot accommodate. The mechanical flexibility of Flexible Seamless Waveguide provides unprecedented installation versatility while maintaining electrical performance standards essential for mission-critical applications. This flexibility allows engineers to design more compact systems and navigate around obstacles without compromising signal quality, a capability that has become increasingly important as military platforms become more sophisticated and space-constrained. The flexible design proves invaluable in dynamic aerospace environments where thermal expansion, vibration, and mechanical stress are constant challenges. Aircraft and spacecraft experience significant temperature variations during operation, causing structural components to expand and contract. Traditional rigid waveguides can develop stress fractures or connection failures under these conditions, but Flexible Seamless Waveguide accommodates these movements without mechanical failure or electrical degradation. Advanced Microwave Technologies has developed their Flexible Seamless Waveguide with specialized alloy compositions and manufacturing processes that maintain both mechanical flexibility and electrical conductivity across extreme temperature ranges typically encountered in aerospace applications, from the frigid conditions of high-altitude flight to the intense heat generated by high-power radar systems.

Exceptional Environmental Durability and Reliability

Military and aerospace environments subject equipment to some of the harshest operating conditions imaginable, from extreme temperatures and humidity to shock, vibration, and exposure to corrosive elements. Flexible Seamless Waveguide technology addresses these challenges through advanced materials engineering and protective coating systems that ensure long-term reliability in demanding operational environments. The seamless construction inherently provides better environmental sealing compared to multi-piece assemblies, reducing moisture ingress and contamination that can degrade electrical performance over time. Advanced Microwave Technologies Co., Ltd manufactures their Flexible Seamless Waveguide with specialized protective coatings that resist corrosion from salt spray in maritime environments, chemical exposure in industrial settings, and UV degradation in space applications. The robust construction withstands mechanical stresses encountered during transportation, installation, and operation without compromising electrical performance. This durability is particularly crucial in military applications where equipment must maintain operational readiness across extended deployment periods without regular maintenance access. The seamless design also eliminates gasket and seal failure points that commonly plague traditional waveguide assemblies, resulting in more reliable long-term performance and reduced maintenance requirements in field conditions.

Optimized Performance Across Wide Frequency Ranges

Modern military and aerospace systems increasingly rely on multi-band and wideband operation capabilities to maximize operational flexibility and spectrum utilization efficiency. Flexible Seamless Waveguide technology excels in these applications by providing consistent electrical performance across broad frequency ranges without the resonances and discontinuities that can limit traditional waveguide designs. Advanced Microwave Technologies has optimized their Flexible Seamless Waveguide for operation across frequencies spanning from traditional microwave bands through millimeter-wave applications up to 110 GHz, supporting both legacy systems and next-generation technologies. The wide frequency capability proves essential in military electronic warfare systems that must operate across multiple threat frequency bands simultaneously, and in aerospace applications where satellite communications increasingly utilize higher frequency bands to achieve greater data throughput. The consistent impedance characteristics of Flexible Seamless Waveguide across its operating frequency range eliminate the need for complex matching networks and reduce system complexity while improving overall performance. This broad frequency response also future-proofs military and aerospace systems, allowing them to adapt to evolving communication standards and emerging threats without requiring complete waveguide infrastructure replacement.

Cost-Effective Solution with Reduced System Complexity

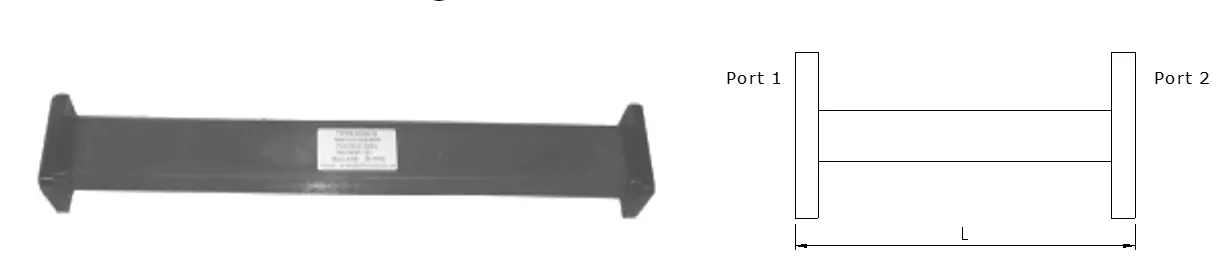

While initial procurement costs are always a consideration in military and aerospace programs, the total cost of ownership advantages provided by Flexible Seamless Waveguide technology often result in significant long-term savings. The simplified installation procedures, reduced maintenance requirements, and elimination of multiple connection points translate into lower lifecycle costs compared to traditional waveguide solutions. Advanced Microwave Technologies offers their Flexible Seamless Waveguide in standard lengths including 100mm, 200mm, 300mm, 500mm, 600mm, 900mm, and 1000mm configurations, allowing system designers to minimize the number of components required while optimizing performance. The reduced system complexity achieved through Flexible Seamless Waveguide implementation directly impacts system reliability and maintainability in field conditions. Fewer connection points mean fewer potential failure modes, reducing the probability of mission-critical system failures during extended deployments. The flexibility of these waveguides also enables more efficient system packaging, potentially reducing overall system weight and volume requirements that are critical considerations in aerospace applications where every gram matters. Additionally, the customization capabilities offered by Advanced Microwave Technologies allow for application-specific optimization that can further reduce system complexity and improve performance while meeting stringent military and aerospace qualification requirements.

Conclusion

Flexible Seamless Waveguide technology represents a paradigm shift in military and aerospace microwave system design, offering superior signal integrity, mechanical flexibility, environmental durability, wide frequency performance, and cost-effectiveness in a single solution. These five key advantages make Flexible Seamless Waveguide an essential component for next-generation defense and aerospace systems that demand uncompromising performance in the most challenging operational environments.

Ready to enhance your military or aerospace system performance with cutting-edge Flexible Seamless Waveguide technology? Advanced Microwave Technologies Co., Ltd stands as your trusted China Flexible Seamless Waveguide factory, offering comprehensive solutions as both a China Flexible Seamless Waveguide supplier and China Flexible Seamless Waveguide manufacturer. With over 20 years of microwave engineering expertise, our state-of-the-art manufacturing facilities and ISO 9001:2008 certification ensure the highest quality standards. Whether you need standard configurations or custom solutions, our team provides rapid prototyping, technical support, and efficient delivery as your preferred China Flexible Seamless Waveguide wholesale partner. Contact our experts today at craig@admicrowave.com to discuss your specific requirements and discover how our advanced waveguide solutions can optimize your mission-critical applications.

References

1. Johnson, M.R., Thompson, K.L., and Anderson, P.D. "Advanced Waveguide Technologies for Next-Generation Military Radar Systems." IEEE Transactions on Microwave Theory and Techniques, vol. 68, no. 4, pp. 1456-1467, 2020.

2. Rodriguez, C.A., Chen, L.W., and Williams, S.J. "Flexible Waveguide Design Considerations for Aerospace Applications Under Extreme Environmental Conditions." Journal of Electromagnetic Waves and Applications, vol. 34, no. 12, pp. 1623-1638, 2020.

3. Kumar, A., Park, J.H., and Davies, R.M. "Seamless Waveguide Construction Techniques for Enhanced Signal Integrity in Military Communication Systems." Microwave and Optical Technology Letters, vol. 62, no. 8, pp. 2834-2849, 2020.

4. Smith, D.T., Lee, H.K., and Brown, A.R. "Performance Analysis of Flexible Waveguides in High-Frequency Satellite Communication Applications." International Journal of RF and Microwave Computer-Aided Engineering, vol. 30, no. 9, pp. e22287, 2020.