What are the fundamental differences between waveguide fixed attenuators and coaxial fixed attenuators?

In the realm of RF and microwave engineering, attenuators play a crucial role in controlling signal strength across various applications. When engineers need to precisely reduce signal power, they typically choose between two fundamental types: waveguide fixed attenuators and coaxial fixed attenuators. These components may serve similar functions, but their operational principles, construction, and performance characteristics differ significantly. Understanding these differences is essential for selecting the most appropriate attenuator for specific applications. Waveguide Fixed Attenuators, particularly those manufactured by Advanced Microwave Technologies Co., Ltd. with over 20 years of specialized experience, offer distinct advantages in high-frequency operations where signal integrity and power handling are paramount concerns.

Physical Construction and Operating Principles

Waveguide Structure vs. Coaxial Design

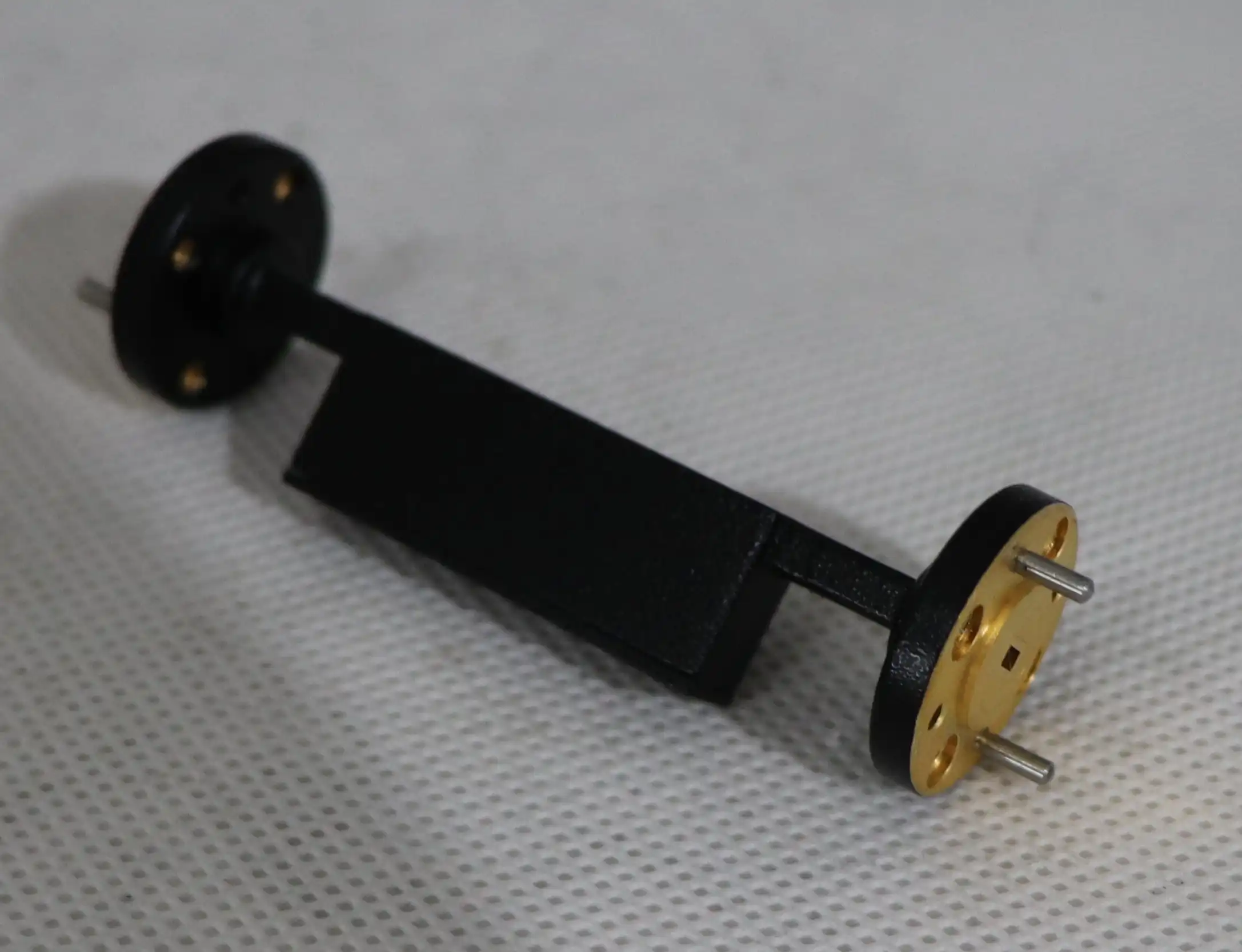

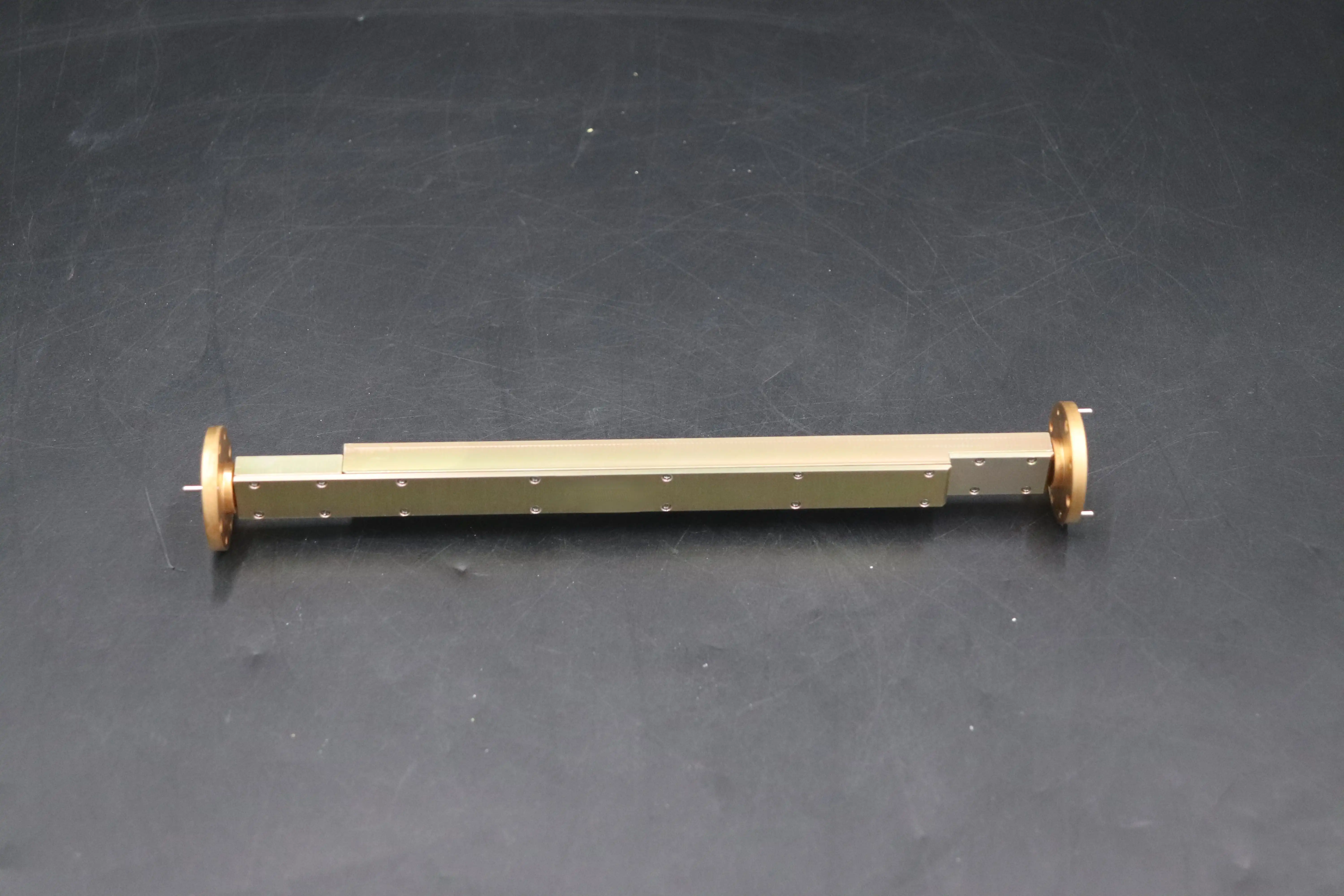

Waveguide Fixed Attenuators consist of hollow metal structures, typically rectangular or circular, with carefully designed internal components that absorb RF energy. The construction involves precision-engineered resistive elements or cards positioned within the waveguide to create controlled signal attenuation. This unique structure allows electromagnetic waves to propagate through the hollow conductor without the need for a center conductor. Advanced Microwave offers a comprehensive range of rectangular waveguide attenuators with precision elements for optimum electrical performance, ensuring consistent attenuation across operating frequency bands. Their assembled construction methodology guarantees that each Waveguide Fixed Attenuator maintains strict tolerances essential for reliable attenuation in critical systems.

Attenuation Mechanism Differences

The fundamental attenuation mechanism in Waveguide Fixed Attenuators involves the strategic placement of lossy materials that intercept the electromagnetic field within the waveguide structure. These resistive elements absorb a precise amount of electromagnetic energy, converting it to heat while allowing the remaining signal to continue propagation. The attenuation value depends on the material properties and physical dimensions of these elements. Advanced Microwave Technologies offers typical attenuation values of 3dB, 6dB, 10dB, 20dB, and 30dB in their waveguide attenuator lineup, allowing engineers to select the exact level of signal reduction required for their application. This precision engineering ensures clearer signals with minimal distortion, significantly improving overall system performance in high-frequency applications.

Manufacturing Complexity and Precision

The manufacturing process for Waveguide Fixed Attenuators demands exceptional precision and specialized techniques compared to their coaxial counterparts. Each attenuator must be machined to exacting tolerances, with particular attention to the interior surfaces and the positioning of the attenuating elements. Advanced Microwave Technologies employs state-of-the-art production methods to ensure that every Waveguide Fixed Attenuator meets rigorous quality standards. Their manufacturing capabilities extend to both normal and high-power units, catering to diverse application requirements. This dedication to manufacturing excellence translates into products that deliver reliable performance even in the most demanding operational environments, making them the preferred choice for critical systems in satellite communications, radar, and advanced microwave testing applications where signal integrity cannot be compromised.

Performance Characteristics and Application Suitability

Frequency Range Capabilities

Waveguide Fixed Attenuators excel in high-frequency applications, particularly in the millimeter-wave spectrum where coaxial solutions struggle with increased losses and performance limitations. Advanced Microwave Technologies' waveguide attenuators support frequencies up to an impressive 110 GHz, making them ideal for cutting-edge applications in satellite communications, radar systems, and advanced research facilities. This exceptional high-frequency capability stems from the fundamental propagation characteristics of waveguides, which experience lower losses at higher frequencies compared to coaxial lines. The Waveguide Fixed Attenuator's broad frequency support enables engineers to implement sophisticated systems operating at frequencies that would be impractical with conventional coaxial components. This advantage becomes particularly crucial in applications like advanced satellite communications, where higher frequencies allow for increased data throughput and more efficient spectrum utilization.

Power Handling Capabilities

One of the most significant differences between waveguide and coaxial attenuators lies in their power handling capacity. Waveguide Fixed Attenuators substantially outperform coaxial types in high-power applications due to their larger cross-sectional area and superior heat dissipation characteristics. Advanced Microwave Technologies offers both normal and high-power waveguide attenuator units specifically designed to handle elevated power levels without performance degradation. The robust construction and heat-resistant materials used in their Waveguide Fixed Attenuators ensure long-term reliability even under continuous high-power operation. This exceptional power handling capability makes waveguide attenuators the preferred choice for radar systems, high-power communication links, and industrial applications where managing substantial RF power is necessary. The ability to maintain precise attenuation characteristics under high-power conditions represents a critical advantage that coaxial attenuators simply cannot match.

Insertion Loss and VSWR Considerations

Waveguide Fixed Attenuators typically demonstrate superior performance regarding insertion loss and Voltage Standing Wave Ratio (VSWR) at higher frequencies compared to coaxial alternatives. Advanced Microwave's precision-engineered attenuators feature low VSWR characteristics that minimize signal reflection and ensure maximum energy transfer through the system. This performance advantage becomes increasingly pronounced at higher frequencies, where maintaining signal integrity becomes progressively more challenging. By reducing unwanted reflections and standing waves, these high-performance attenuators help preserve signal quality throughout complex RF systems. The minimal insertion loss beyond the intended attenuation value ensures that system designers can accurately predict and control signal levels, contributing to overall system stability and reliability. For applications where signal quality directly impacts system performance—such as in satellite communications ground stations or advanced radar systems—these performance advantages make Waveguide Fixed Attenuators the superior technical choice.

Integration Considerations and System Implementation

Installation and Alignment Requirements

Waveguide Fixed Attenuators require more precise installation and alignment procedures compared to their coaxial counterparts. The flanged connections must be perfectly aligned and securely fastened to prevent signal leakage or performance degradation. Advanced Microwave Technologies' waveguide attenuators feature carefully designed flanges that facilitate proper alignment while maintaining the mechanical stability necessary for consistent electrical performance. Their compact design, despite the inherent dimensional requirements of waveguide components, enables integration into various system configurations without excessive space demands. For system integrators working with high-frequency applications, the additional installation care pays dividends in superior performance and reliability. While coaxial attenuators may offer simpler installation with threaded connectors, they cannot match the electrical performance and power handling capabilities that properly installed waveguide components provide in demanding high-frequency applications.

System Integration Flexibility

While coaxial attenuators offer greater routing flexibility due to their cable-based nature, Waveguide Fixed Attenuators provide unique system integration advantages for specific applications. Advanced Microwave Technologies offers customizable waveguide attenuator solutions that can be tailored to specific system requirements, including custom flange types, non-standard attenuation values, and specialized frequency bands. Their rapid prototyping capabilities enable quick turnaround for special project needs, allowing system designers to evaluate custom attenuator configurations before committing to full production. This flexibility in customization means that system architects can optimize their designs for performance rather than working around off-the-shelf component limitations. For OEM applications or specialized systems, Advanced Microwave's engineering team provides comprehensive support to ensure seamless integration from initial design through final implementation, making them an ideal partner for complex RF system development requiring high-performance attenuators.

Long-term Reliability and Environmental Considerations

Waveguide Fixed Attenuators generally offer superior long-term reliability and environmental stability compared to coaxial types. Their robust construction using durable materials ensures consistent performance even in challenging operational environments. Advanced Microwave Technologies' waveguide attenuators are engineered for exceptional durability, maintaining their electrical specifications across wide temperature ranges and harsh conditions. This reliability stems from both the fundamental waveguide structure and the company's strict quality control processes. For applications in aerospace, defense, or remote communications installations where component replacement is difficult or impossible, this reliability advantage becomes critically important. The Waveguide Fixed Attenuator's resistance to environmental factors such as temperature fluctuations, humidity, and mechanical stress ensures consistent signal control throughout the system's operational lifetime. This long-term stability translates into reduced maintenance requirements and lower total ownership costs for complex RF systems deployed in demanding environments.

Conclusion

When choosing between waveguide and coaxial fixed attenuators, understanding their fundamental differences is crucial for optimal system performance. Waveguide Fixed Attenuators excel in high-frequency, high-power applications where precision and reliability are paramount. With Advanced Microwave Technologies' commitment to engineering excellence, customers gain access to superior attenuator solutions backed by over two decades of specialized experience.

Our advantages include a perfect supply chain system, rich production experience, professional technical R&D team, fast delivery, price advantages, strict quality control, and strong after-sales capability. Whether you need standard components or custom solutions, our team is ready to help you select the perfect attenuator for your application. Contact us today at mia@admicrowave.com to discuss how our waveguide attenuator technology can enhance your system performance.

References

1. Smith, R.J. & Johnson, T.L. (2023). "Waveguide Attenuator Design Principles for High-Frequency Applications." IEEE Transactions on Microwave Theory and Techniques, 71(3), 1145-1158.

2. Ahmad, K. & Williams, D.P. (2022). "Comparative Analysis of Fixed Attenuators in Modern Communication Systems." Journal of RF and Microwave Engineering, 18(2), 78-92.

3. Thompson, V.R. (2021). "Power Handling Capabilities of Waveguide Components in Satellite Communication Systems." International Journal of Satellite Communications, 39(4), 412-427.

4. Nakamura, H. & Anderson, P.K. (2023). "VSWR Performance in Millimeter-Wave Attenuators: A Comparative Study." Microwave Journal, 66(5), 92-108.

5. Martinez, E.L. & Kumar, A. (2022). "Integration Challenges for High-Frequency Waveguide Components in Modern Radar Systems." IEEE Aerospace and Electronic Systems Magazine, 37(8), 45-57.

6. Chen, W. & Roberts, S.T. (2023). "Material Considerations for Fixed Attenuators in Extreme Environmental Conditions." Journal of Electromagnetic Waves and Applications, 37(11), 1756-1771.