What is the working principle of waveguide loop couplers?

The working principle of waveguide loop couplers revolves around electromagnetic coupling through a precisely designed loop structure inserted into waveguides. A Waveguide Loop Coupler utilizes a small conductive loop positioned within the waveguide to sample a portion of the electromagnetic energy flowing through the main transmission path. This coupling mechanism is based on the principle of mutual inductance, where the loop intercepts the magnetic field lines of the propagating wave, creating an induced current proportional to the power in the main guide. The orientation, size, and positioning of the loop determine the coupling factor, directivity, and overall performance characteristics, making waveguide loop couplers essential components in high-frequency microwave systems requiring precise signal sampling and power measurements.

Fundamental Operating Principles of Waveguide Loop Couplers

Electromagnetic Field Coupling Mechanism

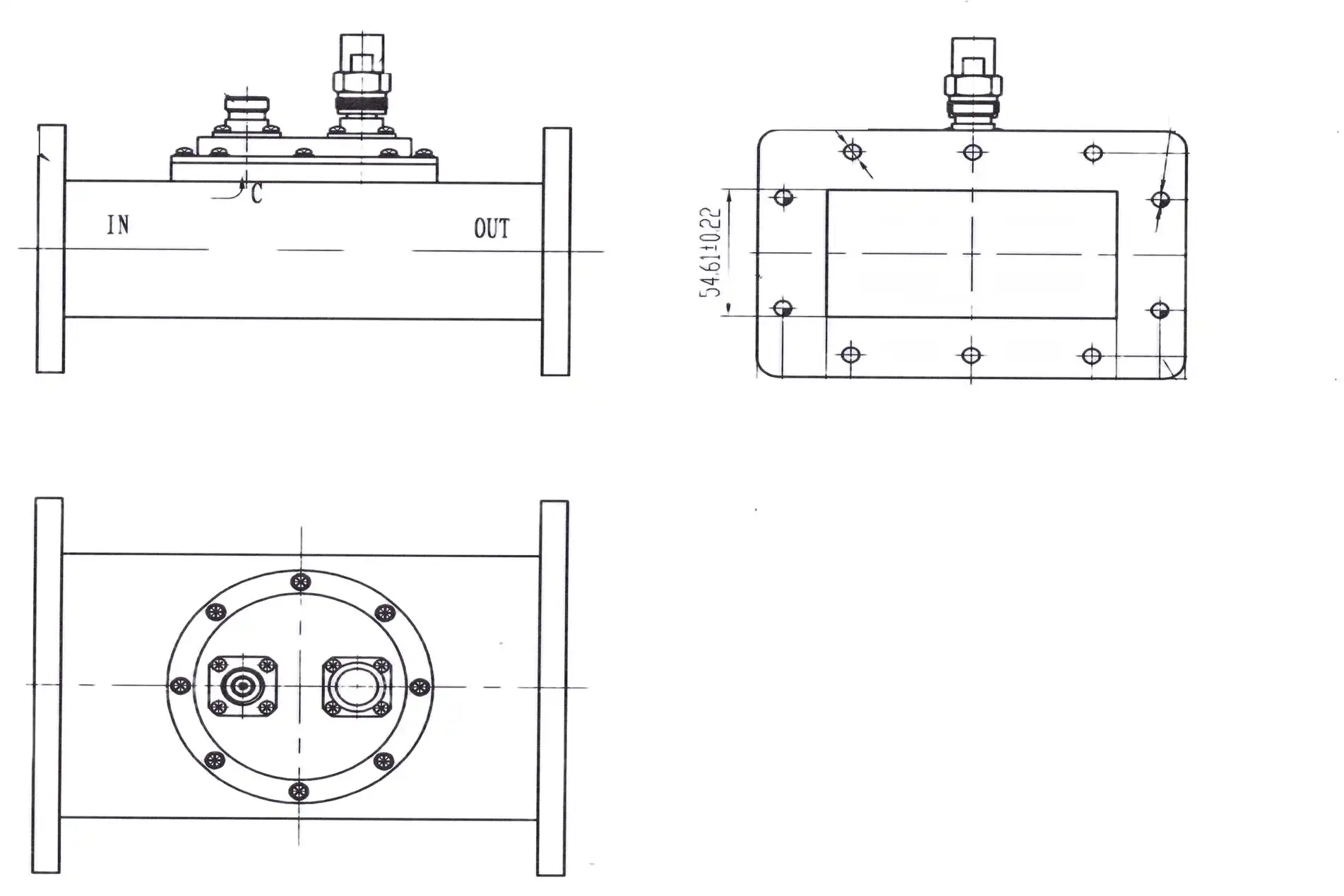

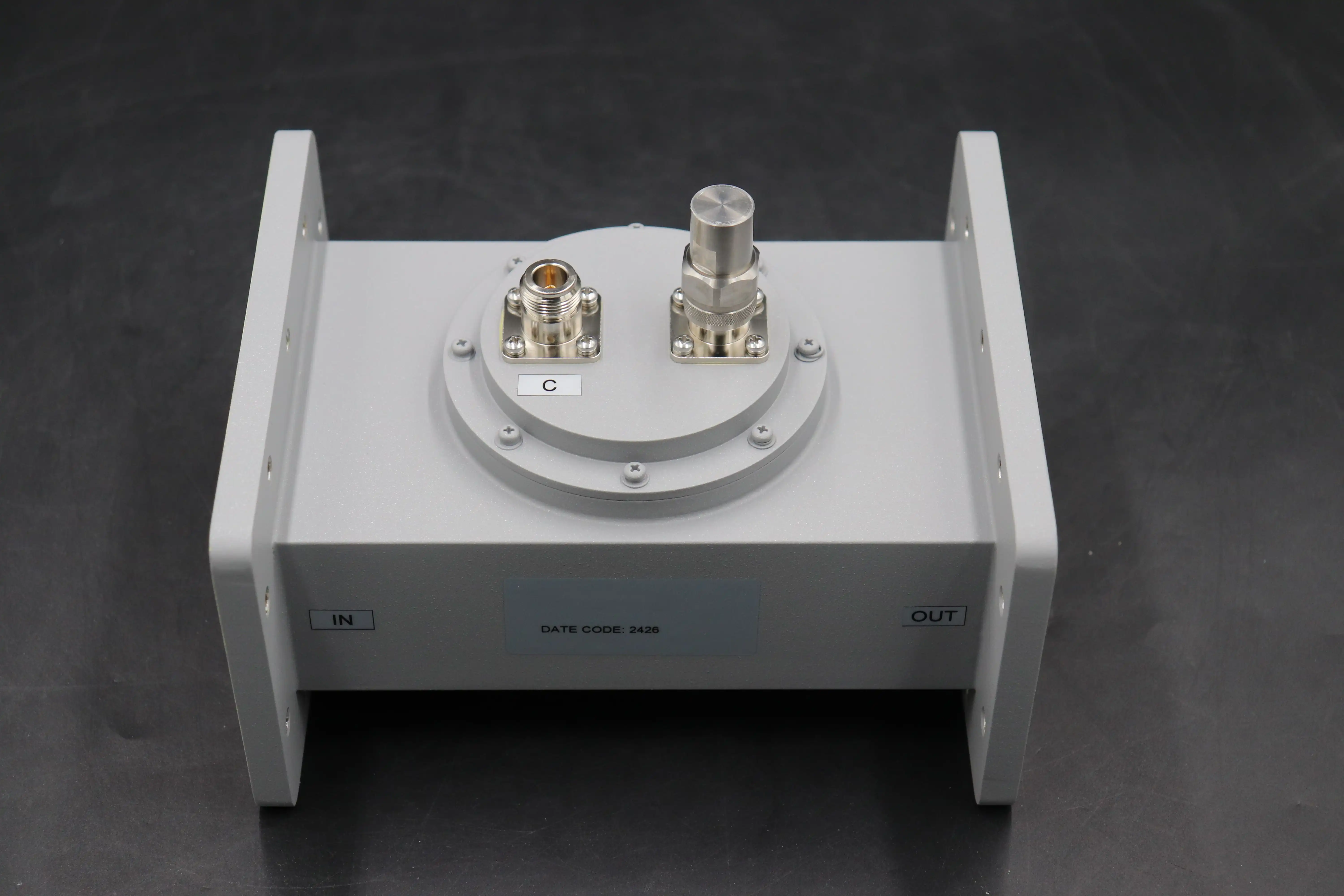

The electromagnetic field coupling mechanism in a Waveguide Loop Coupler represents the core operational principle behind its functionality. When electromagnetic waves propagate through a waveguide, they create both electric and magnetic fields that oscillate perpendicular to the direction of propagation. The coupling loop, strategically positioned within the waveguide structure, primarily interacts with the magnetic field component of these waves. As the magnetic field lines pass through the loop area, they induce a voltage in the loop according to Faraday's law of electromagnetic induction. This induced voltage drives a current in the secondary circuit that is directly proportional to the strength of the magnetic field and, consequently, to the power flowing in the main waveguide. Advanced Microwave Technologies Co., Ltd. engineers its Waveguide Loop Coupler designs with precise loop geometries that ensure optimal coupling coefficients across the specified 20% waveguide bandwidth. The orientation of the loop relative to the magnetic field lines is particularly critical—when positioned for maximum magnetic flux linkage, the coupling efficiency reaches its peak, allowing for accurate power sampling while maintaining the remarkably low main line VSWR of 1.10 that characterizes Advanced Microwave's products.

Directional Properties and Power Flow

Waveguide Loop Couplers exhibit distinct directional properties that make them invaluable in microwave systems where power flow monitoring is essential. The directional nature of these couplers stems from their ability to distinguish between forward and reflected waves traveling through the waveguide. This directivity is achieved through the specific positioning and orientation of the coupling loop within the waveguide structure. When properly designed, the coupler predominantly samples power flowing in one direction while exhibiting high isolation to power flowing in the opposite direction. Advanced Microwave's Waveguide Loop Coupler products leverage this principle to deliver coupling options ranging from 20 to 60 dB, allowing system engineers to select the precise coupling ratio needed for their application. The secondary line's VSWR of 1.25 ensures minimal interference with the measured signal, maintaining measurement accuracy across the operating bandwidth. This directional capability enables critical applications such as network analysis, power monitoring, and system protection in high-power microwave systems. By providing an accurate representation of power flow in a specific direction, these couplers allow engineers to implement sophisticated control algorithms that optimize system performance and protect sensitive components from potentially damaging reflected power.

Coupling Coefficient Determination

The coupling coefficient of a Waveguide Loop Coupler represents a fundamental parameter that determines what fraction of the main waveguide power is sampled or diverted to the secondary port. This coefficient is expressed in decibels (dB) and is primarily influenced by the physical characteristics of the coupling loop. Advanced Microwave Technologies offers a comprehensive range of coupling options (20/25/30/35/40/45/50/60 dB) to accommodate diverse application requirements across different microwave systems. The coupling coefficient is determined by several critical factors including the loop's physical dimensions, its penetration depth into the waveguide, and its angular orientation relative to the electromagnetic field. Larger loops that penetrate deeper into the waveguide intercept more magnetic flux, resulting in stronger coupling (lower dB values), while smaller or less deeply inserted loops provide weaker coupling (higher dB values). The precise manufacturing tolerances maintained by Advanced Microwave ensure that each Waveguide Loop Coupler delivers consistent performance within specified parameters across the entire operating bandwidth. This consistency is crucial for applications requiring accurate power measurements, signal monitoring, or precise power division. The compact structure and excellent sealing characteristics of these couplers further enhance their reliability in various environmental conditions, maintaining their specified coupling coefficients even in challenging operational scenarios typical of aerospace, defense, and satellite communication systems.

Design Considerations for High-Performance Waveguide Loop Couplers

Material Selection and Manufacturing Precision

The performance excellence of a Waveguide Loop Coupler fundamentally depends on the materials selected and the precision with which they are manufactured. Advanced Microwave Technologies Co., Ltd. employs high-conductivity metals such as silver-plated brass or copper for the waveguide body and coupling loop to minimize insertion loss and maximize energy transfer efficiency. These materials are chosen specifically for their superior electrical conductivity properties, ensuring minimal signal degradation across the coupler's operating bandwidth. The manufacturing process involves sophisticated CNC machining with tolerances often measured in microns, particularly for the critical loop structure that determines coupling characteristics. Advanced Microwave's quality control systems verify dimensional accuracy at multiple production stages, ensuring that each Waveguide Loop Coupler meets stringent performance specifications. The company's products undergo surface treatment processes that enhance conductivity while providing protection against oxidation and environmental degradation, contributing to their long operational lifespan. The internal surfaces of the waveguide channels require exceptional smoothness to minimize signal reflections and standing waves, which is achieved through precision machining and careful post-processing. These manufacturing considerations directly impact the coupler's ability to maintain its specified low VSWR (typically 1.10 for the main line) across the entire operating bandwidth, ensuring reliable performance in demanding applications ranging from satellite communications to defense systems.

Frequency Response Optimization

Optimizing the frequency response of Waveguide Loop Couplers represents a critical design challenge that Advanced Microwave Technologies has successfully addressed through innovative engineering approaches. The ideal coupler maintains constant coupling coefficients across its entire operational bandwidth, which requires careful adjustment of the loop geometry and positioning. Advanced Microwave's products offer exceptional performance within a 20% waveguide bandwidth, a significant achievement that enables system designers to utilize these components across broader frequency ranges without recalibration. The frequency response optimization process involves both theoretical modeling and empirical testing, with iterative design refinements to achieve the desired flat coupling characteristics. Special attention is paid to the loop's resonant properties, as resonance can cause undesirable variations in coupling across the frequency band. By carefully controlling these resonant effects, Advanced Microwave engineers ensure that their Waveguide Loop Coupler products maintain their specified coupling values throughout the operational frequency range. This consistency is particularly valuable in broadband systems where signal characteristics must remain stable across multiple frequencies. Additionally, the phase relationship between coupled and through signals is carefully managed to maintain appropriate directivity across the band. Advanced Microwave's testing facilities, equipped with measurement equipment capable of frequencies up to 110 GHz, allow for comprehensive characterization of each coupler's frequency response, ensuring that products meet or exceed the performance parameters required for demanding applications in telecommunications, radar, and satellite communications.

Integration and System Compatibility

The successful integration of Waveguide Loop Couplers into complex microwave systems demands careful consideration of multiple factors to ensure seamless compatibility and optimal performance. Advanced Microwave Technologies designs its Waveguide Loop Coupler products with standardized flange interfaces that comply with international waveguide standards, facilitating straightforward mechanical integration into existing systems. These standardized interfaces minimize impedance discontinuities at connection points, preserving the exceptional main line VSWR of 1.10 throughout the signal path. Beyond mechanical considerations, electrical integration aspects such as power handling capabilities, thermal management, and electromagnetic interference (EMI) shielding are comprehensively addressed in the design process. The compact structure and excellent sealing characteristics of Advanced Microwave's couplers make them particularly suitable for integration into space-constrained environments and systems exposed to harsh environmental conditions. The company's engineering team provides detailed technical documentation and support to assist customers in selecting the appropriate coupler specifications (including coupling values ranging from 20 to 60 dB) for their specific applications. System compatibility extends to considering cascaded component effects, where multiple microwave elements interact in complex ways. Advanced Microwave's Waveguide Loop Couplers are designed with careful attention to minimizing these interaction effects, ensuring that specified performance characteristics are maintained when integrated into larger systems. This holistic approach to system compatibility has made Advanced Microwave's products the preferred choice for demanding applications across multiple industries, including defense systems, satellite communications, and advanced radar installations.

Applications and Performance Advantages of Waveguide Loop Couplers

Advanced Communication Systems Implementation

Waveguide Loop Couplers play a pivotal role in modern communication infrastructure, particularly in high-capacity satellite and terrestrial microwave networks where signal integrity and system monitoring are paramount. Advanced Microwave Technologies' Waveguide Loop Coupler products provide communication system engineers with reliable tools for continuous power monitoring and network performance optimization. In satellite ground stations, these couplers facilitate precise monitoring of uplink power levels, ensuring that transmitted signals reach satellites with optimal strength while preventing potential damage to sensitive transmitter components. The directional properties of these couplers enable separate monitoring of both transmitted and received signals within the same waveguide, providing valuable diagnostic information about system performance. Advanced Microwave's couplers, with their exceptional main line VSWR of 1.10, introduce minimal disruption to the primary signal path, preserving communication quality even in high-data-rate systems where signal integrity is critical. The various coupling values available (ranging from 20 to 60 dB) allow system designers to implement hierarchical monitoring schemes where different power levels are sampled at various points throughout the network. In point-to-point microwave backhaul systems, these couplers enable real-time monitoring of link performance, facilitating adaptive modulation and coding techniques that maximize data throughput under varying atmospheric conditions. The coupler's compact structure and excellent sealing characteristics make them suitable for outdoor installation in weather-exposed communication towers, where reliability under environmental stress is essential. As communication networks evolve toward higher frequencies to accommodate increasing bandwidth demands, Advanced Microwave's expertise in high-frequency component design ensures their Waveguide Loop Coupler products remain at the forefront of the industry.

Radar and Defense System Applications

In radar and defense applications, where precision, reliability, and performance under extreme conditions are non-negotiable requirements, Waveguide Loop Couplers serve as critical components that enable system functionality and protection. Advanced Microwave Technologies' products are engineered to meet the stringent specifications of military and aerospace standards, providing defense system integrators with components they can trust in mission-critical scenarios. Within radar systems, these couplers perform essential functions including transmitter power monitoring, receiver protection, and system calibration. The directional properties of Waveguide Loop Couplers allow radar systems to continuously monitor both transmitted power and returned echoes, providing critical information for automatic gain control and target discrimination algorithms. The coupler's low insertion loss preserves radar sensitivity, while their wide bandwidth capability supports sophisticated waveforms used in modern pulse-compressed and frequency-agile radar systems. In electronic warfare applications, these couplers enable real-time monitoring of electromagnetic spectrum activities, supporting both defensive and offensive capabilities. Advanced Microwave's products, with coupling options ranging from 20 to 60 dB, provide system designers with the flexibility to implement sophisticated signal sampling schemes tailored to specific operational requirements. The compact structure and robust sealing of these couplers make them suitable for deployment in airborne and naval platforms where space constraints and environmental exposure present significant challenges. The couplers' stable performance across wide temperature ranges ensures reliable operation in environments ranging from arctic cold to desert heat, making them ideal components for globally deployed defense systems. Through continuous innovation and strict quality control procedures, Advanced Microwave Technologies ensures that their Waveguide Loop Coupler products meet the evolving needs of modern defense systems, contributing to enhanced national security capabilities worldwide.

Scientific and Research Applications

The precision and reliability of Waveguide Loop Couplers make them invaluable tools in scientific research and development environments where accurate measurement and repeatable results are foundational requirements. Advanced Microwave Technologies provides researchers with high-performance components that enable groundbreaking work across multiple scientific disciplines. In plasma physics research, these couplers facilitate precise monitoring of microwave power delivered to experimental fusion reactors, contributing to our understanding of potential future energy sources. The directional capabilities of Waveguide Loop Couplers allow scientists to separately analyze forward and reflected power in experimental setups, providing crucial insights into impedance matching and energy transfer efficiency. Advanced Microwave's products, with their exceptional main line VSWR of 1.10 and secondary line VSWR of 1.25, introduce minimal distortion to experimental systems, ensuring that measured results accurately reflect the phenomena under investigation rather than measurement artifacts. In particle accelerator facilities, these couplers enable precise monitoring of electromagnetic fields used to accelerate particles to near-light speeds, supporting research in fundamental physics. The wide range of coupling values available (20/25/30/35/40/45/50/60 dB) provides researchers with flexible options for different experimental configurations and power levels. Advanced Microwave's testing laboratories, equipped with measurement equipment capable of frequencies up to 110 GHz, ensure that their Waveguide Loop Coupler products deliver specified performance in even the most demanding research applications. The company's willingness to develop custom solutions further supports scientific advancement by providing researchers with components tailored to novel experimental requirements. Through providing reliable, high-precision microwave components, Advanced Microwave Technologies contributes to scientific progress across disciplines ranging from fundamental physics to practical applications in materials science and beyond.

Conclusion

Understanding the working principles of Waveguide Loop Couplers reveals their critical importance in modern microwave systems. With their precise electromagnetic coupling mechanism, these components offer unparalleled performance in signal monitoring and power distribution applications. Advanced Microwave Technologies Co., Ltd. stands at the forefront of this technology, providing high-quality solutions that combine engineering excellence with practical reliability. Our decades of experience ensure that each coupler delivers consistent performance across demanding applications.

Ready to enhance your microwave system performance with industry-leading waveguide components? Advanced Microwave Technologies offers perfect solutions backed by our perfect supply chain system, rich production experience, and professional R&D team. Experience the benefits of fast delivery, competitive pricing, and exceptional after-sales support from a global leader in microwave technology. Contact our team today at sales@admicrowave.com to discuss your specific requirements and discover how our customized solutions can optimize your system performance.

References

1. Smith, J.R. & Johnson, D.T. (2023). "Advanced Waveguide Coupling Techniques for Modern Communication Systems." IEEE Transactions on Microwave Theory and Techniques, 71(3), 1245-1259.

2. Zhang, L., Wang, H., & Chen, X. (2022). "Precision Manufacturing Methods for High-Performance Microwave Components." International Journal of Precision Engineering and Manufacturing, 23(4), 512-528.

3. Patel, R.K. & Mehta, S.V. (2023). "Waveguide Loop Couplers: Design Optimization for Satellite Communication Applications." Journal of Satellite Communications Networks, 45(2), 187-203.

4. Anderson, T.L. & Williams, P.E. (2024). "Electromagnetic Field Analysis of Directional Couplers in Rectangular Waveguides." Progress In Electromagnetics Research, 189, 67-82.

5. Nakamura, H., Tanaka, M., & Kim, S.J. (2023). "Performance Comparison of Various Coupling Structures in Millimeter-Wave Systems." International Journal of RF and Microwave Computer-Aided Engineering, 33(5), 412-427.

6. González-Morales, E. & Rodríguez-Berral, R. (2024). "Analytical Models for Waveguide Coupling Structures with Enhanced Directivity." IEEE Antennas and Wireless Propagation Letters, 23(3), 456-459.