Waveguide Flange Gasket for Pressurized Systems: Key Features

In high-power microwave applications, system failures often stem from a seemingly minor component: the waveguide flange gasket. When pressurized systems lose integrity at flange connections, signal degradation accelerates, moisture infiltrates sensitive electronics, and catastrophic arcing can damage expensive equipment. Understanding the key features of waveguide flange gaskets for pressurized systems is essential for engineers who demand reliable performance in satellite communications, aerospace radar, and defense applications where system downtime is not an option.

Understanding Pressurized Waveguide Systems and Sealing Requirements

Pressurization in waveguide assemblies serves two critical purposes that directly impact system performance and longevity. First, maintaining positive internal pressure prevents moisture ingress, which can cause corrosion, signal attenuation, and dielectric breakdown in high-frequency transmission lines. Second, pressurization substantially increases the breakdown voltage threshold within the waveguide, enabling the transmission of significantly higher power levels without the risk of electrical arcing between waveguide walls. For systems operating at hundreds of megawatts or in harsh environmental conditions, pressurization transitions from optional to mandatory. The waveguide flange gasket becomes the critical component ensuring this pressurization remains effective throughout the system's operational lifetime. Every joint in a pressurized waveguide network represents a potential failure point where atmospheric contamination can enter or internal pressure can escape. The gasket must create an airtight seal while simultaneously maintaining optimal electrical continuity across the flange interface to minimize reflection and insertion loss. This dual requirement makes waveguide flange gasket selection far more complex than choosing a standard industrial seal. In pressurized systems operating below high vacuum conditions (approximately 10^-4 Torr), the gasket can be positioned to provide both pressure sealing and RF contact. However, for ultra-high power applications requiring high vacuum environments, the gasket placement must be reconsidered. Narrow gaps and grooves can trap gas molecules, preventing the achievement of necessary vacuum levels. In these scenarios, the rubber O-ring position may be relocated outside the primary RF contact area, though this configuration introduces potential loss factors that must be carefully evaluated against system performance requirements.

Essential Material Properties for High-Performance Gasket Applications

The material composition of waveguide flange gaskets fundamentally determines their suitability for pressurized system applications. Conductive elastomers represent the gold standard for applications requiring both environmental sealing and electromagnetic continuity. These specialized materials combine a flexible elastomeric matrix with conductive fillers such as silver-coated particles, copper particles, or other metallic compounds. The resulting material maintains the compliance necessary for effective sealing while providing the electrical conductivity required to minimize RF signal loss at the flange interface. Temperature stability becomes paramount in aerospace and defense applications where waveguide systems may experience extreme thermal cycling. Advanced waveguide flange gaskets must maintain their sealing effectiveness and electrical properties across temperature ranges typically spanning from -55°C to 125°C or beyond. Silicone-based compounds offer excellent temperature stability and resistance to environmental degradation, while fluorosilicone formulations provide enhanced chemical resistance for applications involving exposure to fuels, hydraulic fluids, or aggressive cleaning solvents. The mechanical properties of gasket materials directly influence installation procedures and long-term reliability. Excessive compression set—the permanent deformation that occurs when a gasket is compressed over time—can lead to seal failure and pressure loss. High-quality waveguide flange gasket materials exhibit minimal compression set even after extended service at elevated temperatures, ensuring consistent sealing performance throughout the system's operational life. Additionally, the material must resist tearing during installation, particularly when flanges are aligned and bolted together in confined spaces or challenging orientations common in complex antenna feed networks.

Critical Design Features for Pressurizable Waveguide Flange Gaskets

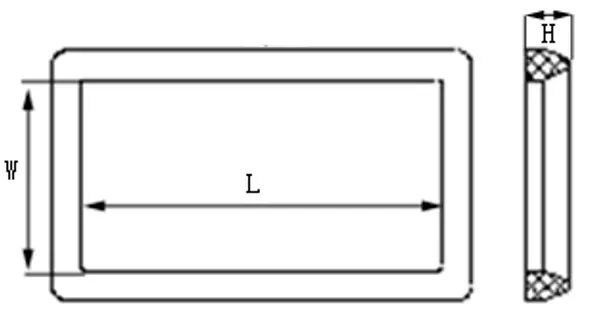

Geometric design variations in waveguide flange gaskets directly correlate to their performance in specific applications and flange configurations. The two primary gasket types—D-type and O-type—serve distinct functional requirements in pressurized systems. O-ring style gaskets typically seat in circular grooves machined into flange faces, providing excellent pressure sealing for grooved flange configurations such as those specified in MIL-DTL-3922 standards for gasket/cover flanges. The O-ring's circular cross-section allows it to compress uniformly under bolt loading, creating a consistent seal around the entire flange perimeter. Die-cut flat gaskets, often resembling the flange face profile, provide an alternative sealing approach particularly suited to flat-face flange connections. These gaskets may incorporate an aluminum carrier plate with a precisely machined elevated sealing surface, ensuring that the conductive elastomer makes optimal contact with both flange faces. The elevated surface design concentrates the sealing force on the critical RF contact region while the surrounding gasket material provides the environmental seal. This integrated approach eliminates the complexity of specifying separate O-rings and RF gaskets, streamlining procurement and installation. For applications involving closely spaced dual waveguides—such as short-slot hybrids or dual transmit-receive configurations—specialized dual contact pressurizable gasket designs become necessary. These configurations must seal two adjacent waveguide openings simultaneously while maintaining independent RF integrity for each transmission path. The gasket design must prevent cross-coupling between adjacent guides while ensuring adequate sealing performance for both pressure retention and environmental protection. Standard flange specifications such as EIA-285 address these specialized requirements for waveguide sizes ranging from WR90 to WR975.

Electromagnetic Performance Optimization in Pressurized Connections

Signal integrity preservation at flange connections represents one of the most demanding requirements for waveguide flange gaskets in high-frequency systems. Electric current in waveguide transmission operates primarily along the interior surface, and any discontinuity at the flange joint creates opportunities for signal reflection, insertion loss, and potential electromagnetic interference leakage. The waveguide flange gasket must facilitate continuous current flow across the joint without introducing impedance mismatches that would degrade return loss performance. The placement of non-conductive sealing elements relative to the RF current path critically affects electromagnetic performance. When rubber O-rings or non-conductive pressure seals are positioned inside the conductive gasket contact area, they can create resonant cavities or capacitive discontinuities that alter the transmission characteristics at specific frequencies. Testing of rectangular cavity resonators has demonstrated that O-ring position affects cavity quality factor and can shift resonant frequencies, particularly in high-power applications where the seal must be positioned to prevent vacuum breakdown in narrow gaps and grooves. Choke flange configurations offer an elegant solution to the conflicting requirements of pressure sealing and RF performance. The choke flange incorporates a precisely machined quarter-wave transformer groove that creates a virtual RF short circuit at the flange interface, eliminating the need for physical metal-to-metal contact to maintain signal continuity. This design allows the pressure seal (O-ring in its groove) to be positioned outside the critical RF path, resolving the potential performance degradation that occurs when sealing elements interrupt current flow. However, choke flanges must always mate with cover or gasket/cover flanges—never with other choke flanges—as the resulting doubled gap creates unacceptable RF discontinuities.

Compliance with Industry Standards and Specifications

Adherence to established military and industry standards ensures interoperability and performance consistency across waveguide systems from different manufacturers. The MIL-DTL-3922 specification provides comprehensive requirements for waveguide flanges and associated gaskets for rectangular waveguides, defining precise dimensions, tolerances, and performance criteria for choke, gasket/cover, and plain cover configurations. Waveguide flange gaskets designed for pressurized systems must conform to specifications such as MIL-G-24211/2, which details requirements for flat-face flange gaskets including material properties, dimensional tolerances, and pressure sealing performance. The Electronics Industries Alliance (EIA) established standardized waveguide sizes designated by WR numbers (Waveguide Rectangular) followed by the broad wall dimension in hundredths of an inch. Corresponding flange designations use CPR (Connector, Pressurizable, Rectangular) or CMR (Connector, Miniature, Rectangular) prefixes followed by the waveguide size number. For example, CPR-112 designates a pressurizable flange for WR112 waveguide. Gaskets designed for these flanges must match the specific dimensional requirements to ensure proper sealing and electromagnetic performance across the wide frequency range each waveguide size supports. International standards such as IEC 60154 provide globally recognized specifications for waveguide flanges across various geometries including ordinary rectangular, medium-flat, square, and circular waveguides. The IEC designation system uses letter codes to identify flange types: U for unpressurizable (plain cover), P for pressurizable (with gasket groove), and C for choke (with both choke and gasket grooves). This international standardization facilitates global procurement and ensures that waveguide components from different sources can be integrated into pressurized systems with confidence in their compatibility and performance.

Installation Best Practices for Leak-Free Pressurized Connections

Proper installation procedures critically influence the long-term reliability and performance of waveguide flange gasket seals in pressurized systems. Surface preparation begins with thorough cleaning of all flange faces to remove dust, metal chips, machining residue, grease, and any oxidation or corrosion that could prevent intimate contact between the gasket and flange surfaces. Even microscopic contamination can create leak paths in pressurized systems or introduce RF discontinuities that degrade signal quality. Appropriate cleaning solvents should be selected based on the flange material and any protective coatings present, ensuring complete removal without residue. Flange alignment before gasket installation ensures uniform compression and prevents seal distortion that could lead to localized stress concentrations or incomplete seating. The flanges should be positioned to mate in a flush, parallel, and uniform manner without angular misalignment or offset. Initial alignment can be verified by inserting two or more flange bolts loosely and checking for even gaps around the perimeter. Any significant misalignment should be corrected through proper waveguide positioning or the use of precision alignment fixtures before the waveguide flange gasket is placed between the flanges. Controlled torque application during bolt tightening ensures consistent gasket compression around the entire flange perimeter without over-compression that could damage the gasket material or under-compression that would allow leakage. A cross-pattern tightening sequence—similar to automotive wheel lug nut patterns—distributes compressive forces evenly and prevents gasket distortion. Torque specifications should follow manufacturer recommendations for the specific gasket type and flange size. For critical applications, torque wrenches provide precise control over bolt loading, while thread lubricants may be specified to ensure consistent friction coefficients and prevent galling on stainless steel or aluminum fasteners.

Waveguide Flange Gasket Selection for Specific Operating Environments

Environmental conditions significantly influence waveguide flange gasket material selection and design requirements. Marine and coastal installations expose waveguide systems to salt spray, high humidity, and temperature variations that accelerate corrosion and degrade many elastomeric materials. Gaskets for these applications require enhanced resistance to water absorption, UV radiation, and salt contamination. Fluorosilicone compounds offer superior resistance to these environmental stressors while maintaining the electrical conductivity necessary for RF performance. Additionally, flange materials should be selected for corrosion resistance, with stainless steel or aluminum alloys providing better longevity than standard steel in corrosive atmospheres. Aerospace applications introduce unique challenges including extreme altitude variations, rapid temperature cycling, vibration loading, and potential exposure to aviation fuels and hydraulic fluids. Waveguide flange gaskets for aircraft-mounted radar systems or satellite communication equipment must maintain seal integrity through thousands of pressure cycles as aircraft climb and descend. The gasket material must resist chemical attack from common aerospace fluids while remaining flexible enough to accommodate the differential thermal expansion between aluminum waveguides and steel mounting structures. Military specifications such as M83528 define performance requirements for EMI shielding gaskets suitable for these demanding aerospace applications.

High-power terrestrial microwave applications including weather radar, air traffic control, and satellite ground stations operate in temperature-controlled environments but must handle significantly higher power levels that can generate substantial heat at flange connections. The waveguide flange gasket must dissipate heat effectively to prevent localized hot spots that could accelerate material degradation or create arcing conditions. Some advanced gasket designs incorporate thermally conductive fillers alongside the electrically conductive particles, optimizing heat transfer from the flange interface to the surrounding structure. Additionally, the gasket must minimize outgassing in partial vacuum conditions that may be used to enhance breakdown voltage thresholds in ultra-high-power systems.

Advanced Gasket Technologies for Next-Generation Systems

Emerging waveguide technologies operating at millimeter-wave frequencies (typically 30 GHz to 110 GHz and beyond) place increasingly stringent demands on flange gasket performance. At these shortened wavelengths, even minor surface irregularities or impedance discontinuities become significant fractions of a wavelength, creating reflection and loss mechanisms that would be negligible at lower frequencies. Waveguide flange gaskets for millimeter-wave applications require exceptionally precise manufacturing tolerances and surface finishes to maintain the smooth electromagnetic transition across the flange interface. Integrated seal designs represent an evolutionary advancement over traditional separate O-ring and RF gasket configurations. These proprietary designs—such as advanced seal systems from leading manufacturers—combine the pressure sealing element with the conductive RF contact surface in a single integrated component. An aluminum carrier plate provides structural support and incorporates a precision-machined elevated contact surface that ensures optimal RF continuity. The compliant elastomeric seal material surrounds this contact region, providing environmental protection while the rigid carrier maintains dimensional stability. This integrated approach simplifies installation, reduces potential assembly errors, and often delivers superior performance compared to multi-component sealing systems.

Customization capabilities enable waveguide flange gasket suppliers to address non-standard requirements including unusual flange sizes, specialized frequency bands, extreme environmental conditions, or unique mounting configurations. Half-height gasket designs accommodate reduced-height waveguide systems used in space-constrained installations. Alternative carrier materials beyond standard aluminum—including copper for enhanced thermal conductivity or stainless steel for corrosion resistance—address specific application requirements. Custom elastomer formulations can be developed to optimize properties such as compression set resistance, temperature stability, chemical compatibility, or electromagnetic shielding effectiveness for applications where standard catalog products prove inadequate.

Conclusion

Waveguide flange gasket selection for pressurized systems demands careful consideration of sealing performance, electromagnetic compatibility, environmental resistance, and standards compliance to ensure reliable long-term operation.

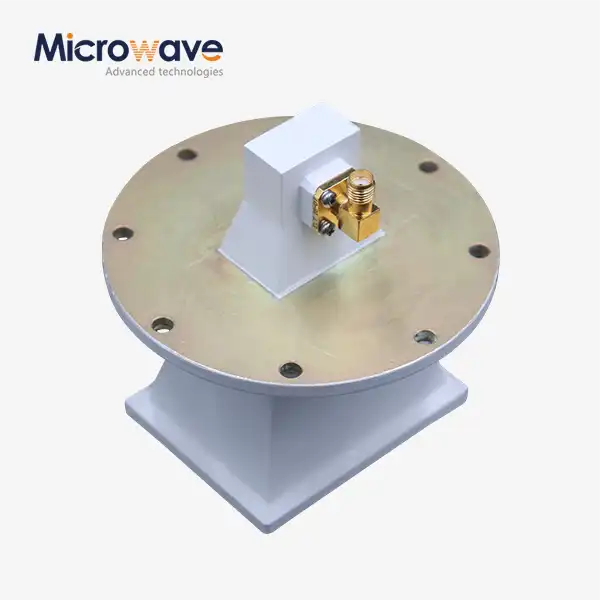

Cooperate with Advanced Microwave Technologies Co., Ltd.

Advanced Microwave Technologies Co., Ltd. stands as your trusted China Waveguide Flange Gasket manufacturer, China Waveguide Flange Gasket supplier, and China Waveguide Flange Gasket factory, delivering High Quality Waveguide Flange Gasket solutions at competitive Waveguide Flange Gasket price points. With over 20 years of specialized experience and ISO 9001:2015 certification, we offer comprehensive China Waveguide Flange Gasket wholesale programs and custom Waveguide Flange Gasket for sale tailored to your exact specifications. Our 24m Microwave Darkroom testing facility ensures every component meets rigorous performance standards across frequencies up to 110 GHz. Whether you require prototyping support for innovative designs or volume production for established systems, our technical team provides expert guidance on material selection, installation optimization, and application-specific customization. Connect with our engineering specialists today at craig@admicrowave.com to discuss how our OEM services can solve your most challenging waveguide sealing requirements and elevate your system reliability.

References

1. Smith, J.R., and Anderson, K.L. "High-Power Waveguide Flange Design and Performance Analysis." IEEE Transactions on Microwave Theory and Techniques, vol. 68, no. 4, 2020.

2. Thompson, M.E. "Electromagnetic Sealing Technologies for Aerospace Applications." Journal of Electromagnetic Compatibility, vol. 45, no. 2, 2019.

3 .Williams, P.D., et al. "Material Selection for Pressurized Waveguide Systems in Extreme Environments." International Journal of RF and Microwave Engineering, vol. 31, no. 3, 2021.

4. Defense Logistics Agency. "Military Specification MIL-DTL-3922: Flanges, Waveguide." United States Department of Defense Standards, 2018.

5. International Electrotechnical Commission. "IEC 60154: Flanges for Waveguides - General Requirements and Specifications." IEC Standards Publication, 2016.

YOU MAY LIKE

VIEW MORELog Periodic Antenna

VIEW MORELog Periodic Antenna VIEW MOREConical Circular Polarization Horn Antenna

VIEW MOREConical Circular Polarization Horn Antenna VIEW MORELadder Membrane Square Dual Circular Polarization Horn Antenna

VIEW MORELadder Membrane Square Dual Circular Polarization Horn Antenna VIEW MOREDual Linear Broadband Circular Polarization Horn Antenna

VIEW MOREDual Linear Broadband Circular Polarization Horn Antenna VIEW MOREPyramidal Linear Polarization Horn Antenna

VIEW MOREPyramidal Linear Polarization Horn Antenna VIEW MORELow Side Lobe Diagonal Linear Polarization Horn Antenna

VIEW MORELow Side Lobe Diagonal Linear Polarization Horn Antenna VIEW MOREQuadrifilar Helix Antenna

VIEW MOREQuadrifilar Helix Antenna VIEW MORECassegrain Antenna

VIEW MORECassegrain Antenna