Top Waveguide Switch Manufacturers and OEM Supply Benefits

In today's demanding RF microwave landscape, system engineers face critical challenges when precise signal routing determines mission success or failure. Whether managing multiple radar channels during target tracking, switching satellite communication paths during signal degradation, or controlling test equipment configurations for complex measurements, unreliable waveguide switches create costly downtime, signal integrity issues, and operational inefficiencies. This comprehensive guide explores how partnering with top Waveguide Switch manufacturers and leveraging OEM supply benefits delivers customized solutions that ensure low-loss transmission, high isolation performance, and long-term reliability across aerospace, defense, telecommunications, and industrial applications.

Understanding Waveguide Switch Technology and Market Leadership

The global waveguide switch market has evolved dramatically with increasing demands for precision RF signal routing in complex microwave systems. Waveguide Switch technology serves as the backbone of modern communication networks, radar installations, and satellite ground stations where signal integrity cannot be compromised. Leading manufacturers distinguish themselves through advanced engineering capabilities, comprehensive frequency coverage, and proven track records in mission-critical applications. Waveguide Switch components function as electromagnetic signal gates that enable flexible path switching while maintaining exceptional electrical performance parameters. These devices control signal flow through waveguide transmission lines using either mechanical actuation mechanisms or solid-state electronic switching elements. The fundamental design principle involves precisely controlling electromagnetic wave propagation through metal waveguide structures, ensuring minimal insertion loss and maximum isolation between switched ports. Modern Waveguide Switch designs accommodate frequency ranges from sub-gigahertz applications up to millimeter-wave bands exceeding 110 GHz. This broad frequency coverage enables deployment across diverse applications including legacy communication systems, contemporary 5G networks, and emerging 6G technologies. The mechanical precision required for manufacturing high-performance waveguide switches demands sophisticated machining capabilities, advanced materials science expertise, and rigorous quality control processes that only established manufacturers can consistently deliver.

Top-tier manufacturers invest heavily in research and development to optimize waveguide switch performance characteristics. Advanced computational electromagnetic simulation tools guide the design of internal geometries that minimize reflection losses and maximize power handling capabilities. Surface treatment technologies including silver plating and gold plating reduce conductor losses while improving environmental resistance. Precision assembly techniques ensure dimensional tolerances remain within micrometers, critical for maintaining proper electromagnetic boundary conditions at waveguide interfaces. The competitive landscape includes manufacturers specializing in different segments of the waveguide switch market. Some focus on space-qualified components for satellite applications requiring extreme reliability and radiation resistance. Others specialize in high-power switches for defense radar systems handling kilowatts of RF energy. Commercial telecommunications manufacturers emphasize cost-effective solutions with rapid delivery schedules for cellular infrastructure deployments. Understanding these specializations helps system integrators select the optimal manufacturing partner for their specific application requirements.

Key Advantages of Partnering with Established Waveguide Switch Manufacturers

Selecting the right Waveguide Switch manufacturer fundamentally impacts project success through multiple dimensions extending far beyond initial component pricing. Established manufacturers bring decades of accumulated engineering experience that translates directly into superior product performance and application support. Their design teams understand subtle electromagnetic phenomena that affect waveguide switch operation in real-world environments, knowledge gained through thousands of fielded systems across diverse operating conditions. Manufacturing expertise represents another critical differentiator among waveguide switch suppliers. Precision machining of waveguide components requires specialized equipment and skilled technicians capable of maintaining extremely tight dimensional tolerances. Advanced manufacturers operate dedicated facilities equipped with computer numerical control machining centers, precision coordinate measuring equipment, and climate-controlled assembly environments. These capabilities ensure consistent dimensional accuracy across production runs, critical for components where micrometer-level variations affect electrical performance. Quality assurance processes employed by leading manufacturers provide confidence in long-term component reliability. Comprehensive testing protocols include network analyzer measurements verifying insertion loss, return loss, and isolation specifications across the full operating frequency range. Environmental stress screening subjects components to temperature cycling, vibration testing, and humidity exposure replicating field conditions. Space-qualified switches undergo additional radiation testing and outgassing analysis meeting stringent aerospace standards. This multilayered validation approach identifies potential failure modes before components ship to customers.

Supply chain stability becomes increasingly important in an era of global disruptions and component shortages. Established Waveguide Switch manufacturers maintain strategic relationships with raw material suppliers, ensuring consistent access to high-quality copper, aluminum, and specialty alloys required for waveguide fabrication. Diversified supplier networks and inventory management strategies protect customers from single-source dependencies. Manufacturers with vertically integrated operations controlling critical manufacturing steps offer additional supply assurance compared to assembly-only competitors. Technical support capabilities distinguish premium manufacturers from commodity suppliers. Expert application engineers provide guidance on waveguide switch selection, helping customers match component specifications to system requirements. Installation support includes detailed mechanical drawings, interface specifications, and mounting recommendations. Troubleshooting assistance helps resolve integration issues during system development and deployment phases. This consultative approach accelerates project timelines while reducing risk of costly design iterations. Customization flexibility represents a significant advantage offered by capable manufacturers. Standard catalog products serve many applications effectively, but demanding requirements often necessitate custom designs. Leading manufacturers maintain engineering teams capable of developing specialized Waveguide Switch configurations addressing unique frequency bands, power levels, environmental conditions, or physical constraints. Custom interface flanges, specialized actuator mechanisms, and modified control circuitry enable seamless integration into existing system architectures. This design flexibility becomes critical for defense programs, satellite missions, and advanced research installations where commercial off-the-shelf solutions prove inadequate.

OEM Supply Benefits: Customization, Cost Efficiency, and Strategic Partnerships

Original Equipment Manufacturer relationships with Waveguide Switch suppliers create substantial value beyond transactional component purchases. OEM partnerships establish collaborative frameworks where manufacturers work closely with system integrators throughout product development lifecycles, from initial concept through production scaling and ongoing field support. This deep engagement model aligns manufacturing capabilities with customer requirements, resulting in optimized solutions impossible to achieve through standard catalog purchasing. Customization represents the cornerstone benefit of OEM waveguide switch supply arrangements. System designers often encounter constraints where standard components cannot meet all requirements simultaneously. Custom waveguide interfaces accommodate non-standard flange types or waveguide cross-sections matching existing system infrastructure. Modified frequency responses optimize performance for specific channel allocations or bandwidth requirements. Specialized power handling requirements necessitate enhanced thermal management features or reinforced mechanical structures. OEM manufacturers work directly with engineering teams to understand these unique needs and develop tailored solutions. Design support services provided through OEM relationships accelerate product development timelines significantly. Waveguide Switch manufacturers assign dedicated application engineers who participate in design reviews, provide electromagnetic simulation support, and offer recommendations on component selection and system architecture. This collaborative approach identifies potential issues early in development cycles when design changes remain inexpensive and straightforward to implement. Prototype fabrication services enable rapid testing of custom configurations before committing to production tooling investments.

Cost efficiency emerges through multiple mechanisms within OEM supply frameworks. Volume commitments enable manufacturers to optimize production scheduling and material procurement, reducing per-unit manufacturing costs passed through to customers as favorable pricing. Standardization of custom designs across multiple product variants leverages common manufacturing processes and tooling investments. Collaborative value engineering identifies opportunities to reduce costs while maintaining or improving performance through alternative materials, simplified manufacturing processes, or design optimization. These savings accumulate substantially over product lifecycles, especially for high-volume programs. Supply chain integration between OEM partners creates operational efficiencies benefiting both parties. Coordinated forecasting improves manufacturing planning and material availability. Consignment inventory programs place components at customer facilities reducing lead times and simplifying logistics. Electronic data interchange automates ordering processes and real-time inventory visibility. These operational improvements reduce working capital requirements, accelerate cash conversion cycles, and minimize stockout risks that could disrupt production schedules. Quality assurance processes strengthen through OEM partnerships as manufacturers gain deeper understanding of how components function within complete systems. This knowledge informs design improvements and enhanced testing protocols targeting application-specific reliability concerns. Failure mode effects analysis conducted jointly between manufacturers and customers identifies critical component characteristics requiring additional process controls. First article inspection procedures verify custom components meet all specifications before production release. Ongoing statistical process control monitors manufacturing consistency ensuring each production lot maintains required performance standards.

Intellectual property protection and confidentiality represent important considerations in OEM relationships. Reputable Waveguide Switch manufacturers maintain robust information security practices protecting customer designs, specifications, and application details from unauthorized disclosure. Non-disclosure agreements formalize confidentiality commitments while defining appropriate information sharing enabling effective collaboration. Manufacturers with diversified customer bases avoid conflicts of interest by maintaining separate business units serving competitive market segments. Long-term strategic partnerships evolving from OEM supply relationships create sustainable competitive advantages. Manufacturers gain detailed understanding of customer roadmaps and future product development plans, enabling proactive capacity planning and technology investments aligned with customer needs. Customers benefit from prioritized access to new capabilities and preferential treatment during supply constraints. Joint development programs share risks and rewards of developing next-generation technologies neither party could economically pursue independently. These enduring relationships transcend individual product programs, creating frameworks for ongoing innovation and mutual success.

Critical Selection Criteria for Waveguide Switch Manufacturers

Evaluating potential Waveguide Switch manufacturing partners requires systematic assessment across multiple performance dimensions to ensure selected suppliers meet both immediate project requirements and long-term strategic needs. Technical capabilities form the foundation of any evaluation, beginning with frequency range coverage and electrical performance specifications. Manufacturers should demonstrate proven expertise across relevant frequency bands with published data confirming low insertion loss, high isolation, and excellent VSWR performance. Portfolio breadth indicates design flexibility and accumulated experience—manufacturers offering diverse switch configurations including SPDT, DPDT, and multi-port variants demonstrate comprehensive engineering capabilities applicable to varied application requirements. Manufacturing infrastructure assessment reveals capacity and quality control capabilities essential for reliable supply. Modern production facilities equipped with advanced CNC machining centers, precision assembly tooling, and comprehensive test equipment indicate serious manufacturing commitment. Climate-controlled environments prevent thermal expansion effects during precision machining and assembly operations. Documented quality management systems certification to ISO 9001 standards demonstrates established procedures for configuration management, process control, and continuous improvement. Environmental certifications including ISO 14001 reflect responsible manufacturing practices increasingly important for corporate procurement policies and regulatory compliance.

Technical support capabilities require careful evaluation as post-sale assistance often proves as valuable as product quality itself. Assess manufacturer responsiveness through initial technical inquiries noting response time, completeness of information provided, and demonstrated understanding of application requirements. Request references from customers operating similar applications to verify manufacturer support performance during challenging integration issues or field problems. Determine availability of application engineers for on-site support during critical project phases. Review documentation quality including detailed product specifications, mechanical interface drawings, and integration guidance—comprehensive documentation indicates customer-focused organization valuing successful component integration. Delivery performance and supply chain reliability directly impact project schedules and production continuity. Request on-time delivery metrics for standard and custom products. Understand lead time expectations for initial orders and production quantities, recognizing custom configurations typically require longer delivery schedules than catalog items. Assess inventory management practices including safety stock policies and buffer capacity for handling demand variations. Manufacturers with geographically diverse production facilities offer supply chain resilience compared to single-location operations vulnerable to regional disruptions. Financial stability indicators including company longevity, ownership structure, and credit ratings provide confidence in long-term business continuity.

Customization capabilities and OEM services distinguish manufacturers capable of true partnership from simple component suppliers. Evaluate engineering staff size and qualifications—experienced design teams with advanced degrees and industry certifications indicate technical depth required for complex custom developments. Review case studies or reference applications demonstrating successful custom waveguide switch programs. Understand design iteration processes, prototype fabrication capabilities, and production transition procedures. Assess flexibility regarding minimum order quantities, production lot sizes, and inventory management arrangements. Progressive manufacturers accommodate varied commercial models from spot purchases through consignment inventory and vendor-managed inventory programs.

Pricing structures and commercial terms merit detailed analysis ensuring cost models align with program economics. Request detailed quotations separating recurring manufacturing costs from non-recurring engineering expenses for custom developments. Understand price sensitivity to order quantities and opportunities for cost reduction through volume commitments or long-term agreements. Compare total cost of ownership including freight expenses, payment terms, and potential inventory carrying costs rather than focusing exclusively on unit prices. Evaluate manufacturers demonstrating value engineering capabilities that identify cost reduction opportunities while maintaining performance requirements—these suppliers partner in program success rather than simply fulfilling purchase orders. Regulatory compliance and export control considerations become critical for defense, aerospace, and certain commercial applications. Verify manufacturer ability to meet relevant specifications including military standards for defense applications or space-qualification requirements for satellite programs. Understand export licensing requirements that may restrict component availability or complicate international shipments. ITAR registration and compliance procedures prove essential for US defense programs. RoHS compliance ensures components meet environmental regulations in major markets. Comprehensive certifications indicate manufacturers prepared to serve regulated industries with proper documentation and traceability systems.

Advanced Microwave Technologies Co., Ltd.: Excellence in Waveguide Switch Manufacturing

In the competitive landscape of Waveguide Switch manufacturers, Advanced Microwave Technologies Co., Ltd. stands out as a China Waveguide Switch manufacturer delivering exceptional technical performance combined with comprehensive customer support. Established in the 2000s with over 20 years of specialized experience in microwave component development, Advanced Microwave Technologies has evolved into a recognized China Waveguide Switch supplier serving global markets across telecommunications, defense, aerospace, and industrial sectors. This extensive industry experience translates directly into refined product designs optimized through thousands of field deployments and continuous improvement based on customer feedback. The company's technical capabilities center around a remarkable 24-meter microwave darkroom facility enabling precise antenna and component characterization from 0.5 GHz through 110 GHz. This state-of-the-art measurement infrastructure provides comprehensive validation of Waveguide Switch electrical performance across extraordinarily wide frequency ranges. The Antenna Plane Near and Far Field Measuring Recombination Chamber enables detailed analysis of electromagnetic field distributions, radiation patterns, and impedance characteristics impossible to assess with standard benchtop equipment. Engineers leverage these advanced measurement capabilities during new product development, validating designs meet stringent specifications before production release. Customers benefit from this comprehensive testing infrastructure through high-confidence performance data and minimized risk of field failures.

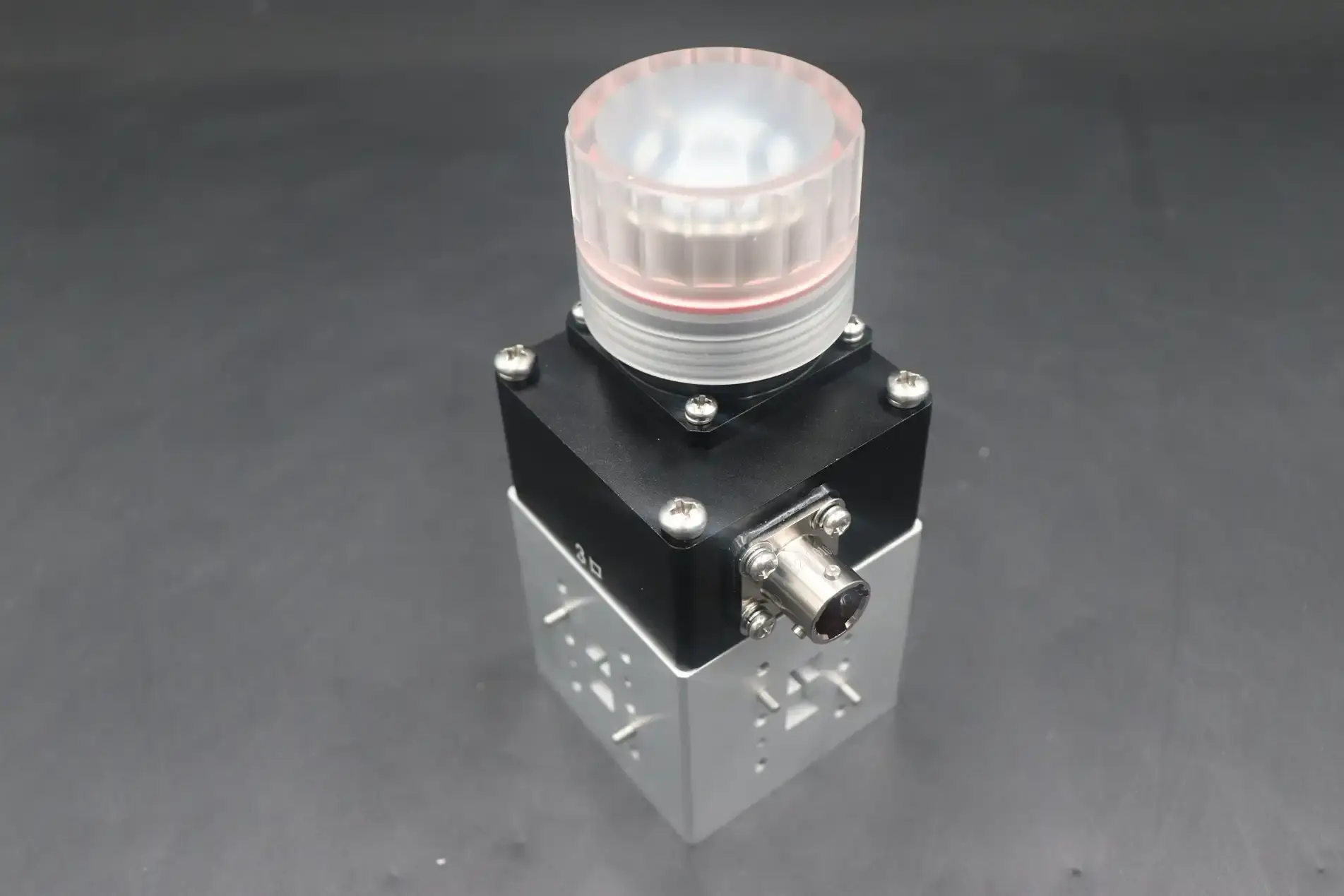

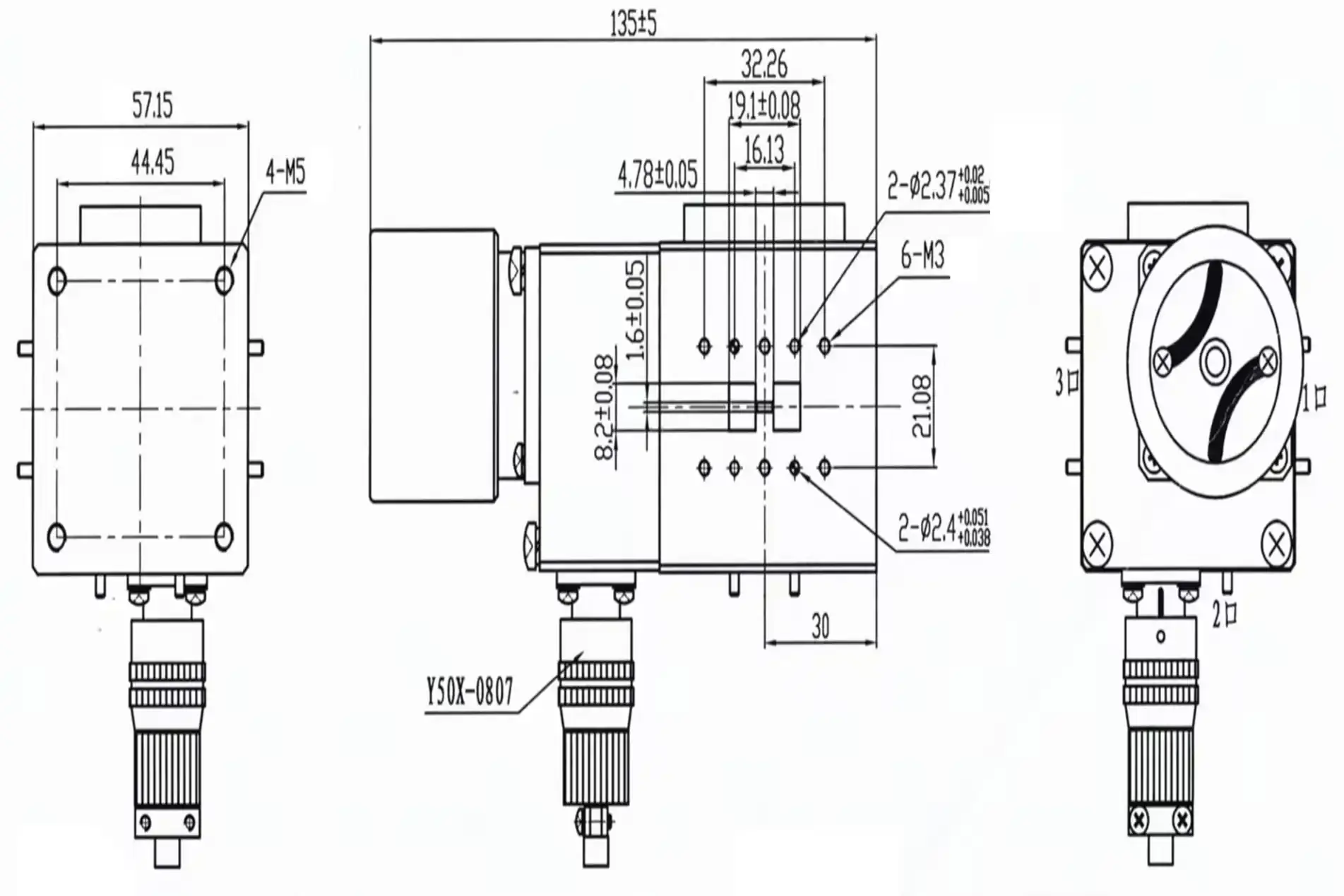

Manufacturing excellence underpins every High Quality Waveguide Switch produced at Advanced Microwave Technologies facilities. Precision CNC machining centers fabricate waveguide bodies and switching elements from premium copper and aluminum alloys selected for optimal electrical conductivity and mechanical stability. Multi-axis machining capabilities enable complex internal geometries optimizing electromagnetic field distributions while minimizing reflection losses. Surface treatment processes including silver plating and gold plating reduce skin effect losses in high-frequency applications while providing excellent environmental resistance. Stringent dimensional inspection procedures using coordinate measuring machines verify critical tolerances remain within specified limits ensuring consistent electrical performance across production quantities. Quality assurance processes implemented throughout manufacturing operations reflect ISO 9001:2015 certification demonstrating commitment to systematic quality management. Incoming material inspection verifies raw materials meet specifications before machining operations commence. In-process checks monitor dimensional accuracy during fabrication preventing waste from out-of-specification components. Final electrical testing validates insertion loss, isolation, VSWR, and power handling specifications for every assembled unit. Environmental stress screening including temperature cycling and vibration testing identifies infant mortality failures before shipment. Comprehensive test data packages document performance for traceability and customer acceptance. These multilayered quality controls ensure only fully compliant components reach customers, minimizing field failures and warranty claims.

Environmental stewardship and occupational safety represent core values at Advanced Microwave Technologies reflected in ISO 14001:2015 and ISO 45001:2018 certifications. Responsible manufacturing practices minimize ecological impact through waste reduction, energy conservation, and emissions control programs. Safe working conditions protect employees through proper training, protective equipment, and established safety protocols. These environmental and safety commitments demonstrate corporate responsibility extending beyond profit motives, creating sustainable operations customers confidently support through their purchasing decisions.

Product portfolio diversity enables Advanced Microwave Technologies to serve varied application requirements with optimized solutions. Standard Waveguide Switch configurations cover C, X, Ku, and Ka frequency bands through 2-port, 4-port, and multi-port architectures. Both mechanical and solid-state switching technologies address different performance priorities including switching speed, power handling, and operational lifetime requirements. Custom designs accommodate specialized needs including non-standard waveguide interfaces, modified frequency responses, enhanced power capabilities, and environmental hardening for aerospace applications. This configuration flexibility combined with responsive engineering support enables efficient matching of components to system requirements. China Waveguide Switch factory capabilities at Advanced Microwave Technologies extend well beyond component manufacturing to encompass comprehensive customer support services. Experienced application engineers provide technical consultation during component selection, system design, and integration phases. Detailed installation guidance includes mechanical interface specifications, mounting recommendations, and control signal requirements. Prototyping services enable evaluation of custom configurations before production commitments. Rapid response to technical inquiries and troubleshooting support accelerate project timelines while reducing integration risks. This consultative approach establishes true partnership relationships rather than transactional supplier interactions.

As a China Waveguide Switch wholesale provider, Advanced Microwave Technologies offers competitive pricing enabled by efficient manufacturing processes and strategic material sourcing. Volume-based pricing structures provide attractive economics for production programs while maintaining accessibility for prototype and low-rate initial production orders. Flexible commercial terms including various Incoterms options, payment schedules, and inventory management programs accommodate diverse customer requirements. Waveguide Switch for sale through direct relationships eliminates distributor markups while ensuring technical support comes directly from design engineers. This commercial flexibility combined with reasonable Waveguide Switch price points makes Advanced Microwave Technologies an attractive partner for cost-sensitive programs without compromising quality or performance. Global logistics capabilities ensure efficient delivery to customers worldwide. Experienced shipping coordinators navigate complex export documentation, customs clearance procedures, and freight forwarding arrangements. Strategic carrier relationships provide reliable transportation options balancing cost and delivery speed. Comprehensive packaging protects sensitive components during international transit preventing damage from shock and vibration. Real-time shipment tracking enables customers to monitor delivery progress and plan receiving operations. This logistics expertise simplifies international procurement for customers lacking specialized import experience.

Conclusion

Selecting the right Waveguide Switch manufacturer and establishing effective OEM supply relationships fundamentally determines project success across telecommunications, defense, aerospace, and industrial applications. Top manufacturers deliver optimized solutions through advanced engineering capabilities, comprehensive testing infrastructure, rigorous quality controls, and responsive customer support. Strategic OEM partnerships unlock customization flexibility, cost efficiencies, and collaborative development frameworks impossible through standard catalog purchasing. Careful evaluation of technical capabilities, manufacturing infrastructure, support services, and commercial terms identifies partners positioned to contribute throughout product lifecycles from initial design through production scaling and ongoing field support.

Cooperate with Advanced Microwave Technologies Co., Ltd.

Ready to elevate your RF microwave system performance with precision-engineered Waveguide Switch solutions? Advanced Microwave Technologies Co., Ltd. combines over 20 years of manufacturing excellence with state-of-the-art 24m darkroom testing capabilities covering 0.5-110 GHz. As a premier China Waveguide Switch factory and trusted China Waveguide Switch supplier, we deliver High Quality Waveguide Switch components optimized for your exact specifications. Our ISO-certified facilities ensure every China Waveguide Switch manufacturer product meets stringent quality standards. Explore our comprehensive China Waveguide Switch wholesale programs offering competitive Waveguide Switch price points with flexible OEM customization. Browse our extensive Waveguide Switch for sale catalog or contact our engineering team for tailored solutions. Email craig@admicrowave.com today to discuss your project requirements and discover how our technical expertise, rapid prototyping, and responsive support transform your signal routing challenges into competitive advantages. Bookmark this page and revisit whenever you need reliable waveguide switching solutions backed by proven performance and global support.

References

1. "Waveguide Components and Systems Design Handbook," authored by George L. Matthaei, Leo Young, and E.M.T. Jones, published by Artech House Publishers

2. "Microwave Engineering: Concepts and Fundamentals," authored by Ahmad Shahid Khan, published by CRC Press

3. "RF and Microwave Switch Design and Applications," authored by Joseph F. White, published by IEEE Press

4. "High-Frequency Techniques: An Introduction to RF and Microwave Engineering," authored by Joseph F. White, published by Wiley-IEEE Press

5. "Foundations for Microwave Engineering," authored by Robert E. Collin, published by Wiley-IEEE Press