How Does the Waveguide Loop Coupler Ensure Low Signal Loss in Critical Systems?

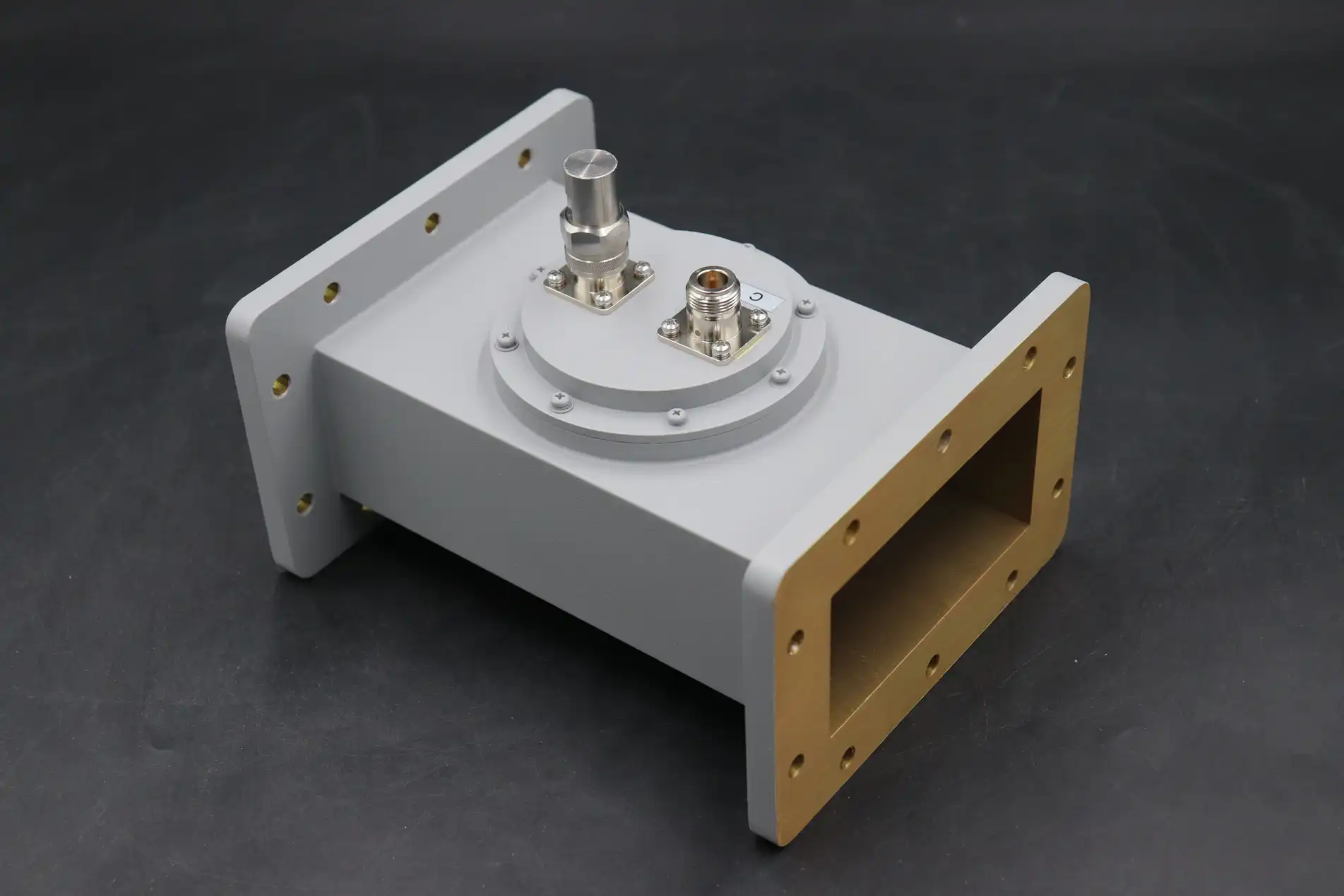

In today's demanding microwave and communication systems, maintaining signal integrity while achieving precise power monitoring has become increasingly critical. The Waveguide Loop Coupler stands as a fundamental component that addresses these challenges by providing exceptional signal transmission efficiency with minimal power loss. This sophisticated microwave device operates through electromagnetic coupling principles, utilizing a precisely engineered loop structure within a waveguide assembly to sample or distribute microwave signals without significantly impacting the main transmission path. Understanding how these components achieve such remarkable performance characteristics is essential for engineers designing critical systems in aerospace, defense, satellite communications, and advanced radar applications where signal loss can compromise mission-critical operations.

Advanced Engineering Design Minimizes Transmission Losses

Precision Loop Geometry and Electromagnetic Field Coupling

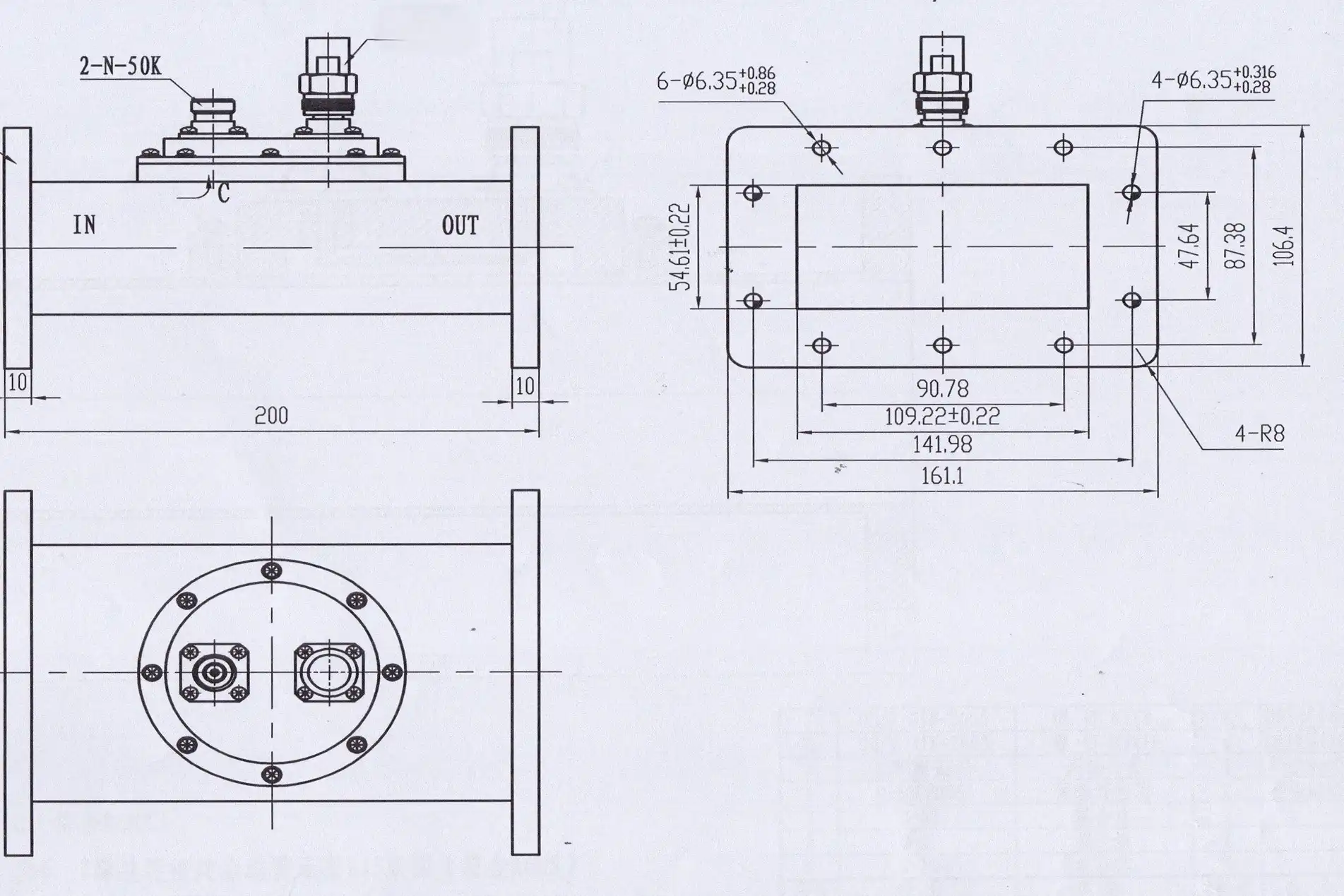

The fundamental mechanism behind low signal loss in Waveguide Loop Couplers lies in their meticulously engineered loop geometry and electromagnetic field coupling design. Advanced Microwave Technologies Co., Ltd has developed sophisticated coupling loops that interact with the electromagnetic fields within the waveguide through magnetic coupling rather than direct electrical connection. This approach ensures that the Waveguide Loop Coupler maintains exceptional isolation between the main transmission line and the coupled port, typically achieving coupling values ranging from 12 dB to 60 dB while maintaining main line VSWR as low as 1.10. The loop's physical dimensions, positioning, and orientation are precisely calculated to optimize field coupling efficiency while minimizing perturbation to the primary signal path. This careful engineering allows the device to sample or distribute power with insertion losses typically below 0.1 dB, making it ideal for applications where every fraction of a decibel matters. The electromagnetic coupling mechanism ensures that signal sampling occurs without introducing significant impedance mismatches or reflection losses that could degrade overall system performance.

Material Selection and Manufacturing Excellence

The exceptional low-loss performance of Waveguide Loop Couplers is directly attributed to the advanced materials and precision manufacturing techniques employed in their construction. Advanced Microwave Technologies Co., Ltd utilizes high-conductivity metals such as silver-plated brass and copper for both the waveguide body and coupling loop components, ensuring minimal resistive losses and maximum energy transfer efficiency. These materials are specifically chosen for their superior electrical conductivity properties, which directly translate to reduced insertion loss and improved power handling capabilities. The manufacturing process involves high-precision machining and assembly techniques that maintain tight tolerances across all critical dimensions, ensuring consistent performance characteristics across the entire frequency range from 0.5 to 110 GHz. The Waveguide Loop Coupler benefits from advanced surface treatments and plating processes that enhance conductivity while providing long-term reliability in challenging environmental conditions. This attention to material science and manufacturing excellence enables the device to maintain its low-loss characteristics throughout its operational lifetime, even when subjected to temperature variations, mechanical stress, and electromagnetic interference typical of critical system deployments.

Optimized Frequency Response and Bandwidth Characteristics

The broad frequency response and optimized bandwidth characteristics of Waveguide Loop Couplers contribute significantly to their low signal loss performance across diverse applications. Advanced Microwave Technologies Co., Ltd has engineered these devices to operate efficiently within 20% waveguide bandwidth, ensuring consistent coupling performance and minimal insertion loss across the entire operational frequency range. The Waveguide Loop Coupler achieves this remarkable bandwidth performance through careful impedance matching and field distribution optimization that prevents frequency-dependent losses common in narrow-band coupling devices. The secondary line VSWR is maintained at 1.25 or better across the operational bandwidth, indicating excellent power transfer efficiency and minimal reflected power that could cause system instability or increased losses. This broadband performance is particularly crucial in modern communication systems that utilize multiple frequency channels or frequency-agile radar systems that require consistent performance across their operational spectrum. The optimized frequency response ensures that signal loss remains consistently low regardless of the specific frequency being processed, making the Waveguide Loop Coupler suitable for both fixed-frequency applications and dynamic frequency environments where maintaining low loss across multiple channels is essential.

Superior Materials and Construction Techniques

High-Conductivity Metal Implementation

The foundation of exceptional low-loss performance in Waveguide Loop Couplers begins with the strategic implementation of high-conductivity metals throughout the device construction. Advanced Microwave Technologies Co., Ltd employs premium materials including silver-plated brass and high-purity copper for all critical conducting surfaces, ensuring that resistive losses are minimized to negligible levels. The Waveguide Loop Coupler benefits from these material choices through reduced surface resistance, which directly translates to lower insertion loss and improved power handling capabilities. Silver plating provides the ultimate in electrical conductivity while offering excellent corrosion resistance, ensuring that performance characteristics remain stable throughout the device's operational lifetime. The coupling loop itself is fabricated from carefully selected conductors that maintain their electrical properties across the entire frequency range from microwave to millimeter-wave applications. These high-conductivity materials enable the Waveguide Loop Coupler to achieve insertion losses typically below 0.1 dB while maintaining excellent directivity performance exceeding 20 dB. The material selection process considers not only electrical performance but also mechanical stability, thermal expansion characteristics, and long-term reliability under various environmental conditions, ensuring that low-loss performance is maintained throughout the device's service life.

Precision Manufacturing and Quality Control

The achievement of consistently low signal loss in Waveguide Loop Couplers requires precision manufacturing processes and rigorous quality control measures that ensure every device meets exacting performance specifications. Advanced Microwave Technologies Co., Ltd operates state-of-the-art manufacturing facilities equipped with advanced CNC machining centers capable of maintaining tolerances within micrometers, ensuring that all critical dimensions affecting electromagnetic performance are precisely controlled. The Waveguide Loop Coupler undergoes comprehensive dimensional inspection using coordinate measuring machines and optical comparators to verify that coupling loop positioning, waveguide internal dimensions, and interface specifications meet design requirements. Each device is subjected to extensive electrical testing in the company's advanced 24-meter microwave darkroom facility, where far-field antenna patterns, coupling characteristics, VSWR performance, and insertion loss measurements are verified across the entire operational frequency range. The quality control process includes temperature cycling tests, mechanical stress evaluations, and long-term stability assessments to ensure that low-loss performance characteristics remain consistent under various operational conditions. This comprehensive approach to precision manufacturing and quality control ensures that every Waveguide Loop Coupler delivered maintains the exceptional low-loss performance required for critical system applications.

Advanced Surface Treatment and Sealing Technologies

The long-term reliability and consistent low-loss performance of Waveguide Loop Couplers depend significantly on advanced surface treatment and sealing technologies that protect critical internal components from environmental degradation. Advanced Microwave Technologies Co., Ltd implements sophisticated surface treatment processes including specialized plating techniques, passivation treatments, and protective coatings that maintain electrical performance while providing environmental protection. The Waveguide Loop Coupler features compact structure design with advanced sealing systems that prevent moisture ingress, contamination, and oxidation of internal conducting surfaces that could increase losses over time. These sealing technologies utilize precision-machined gaskets, O-ring assemblies, and welded joints that maintain environmental integrity while preserving electrical performance characteristics. The surface treatments are specifically formulated to maintain low surface resistance while providing corrosion resistance and mechanical durability required for long-term operation in harsh environments. Advanced plating processes ensure uniform coverage of all conducting surfaces, eliminating potential hot spots or high-resistance areas that could contribute to increased insertion loss. The combination of advanced surface treatments and sealing technologies ensures that the Waveguide Loop Coupler maintains its exceptional low-loss performance throughout its operational lifetime, even when deployed in challenging environmental conditions typical of aerospace, defense, and satellite communication applications.

Performance Optimization Through Advanced Testing and Validation

Comprehensive Electromagnetic Characterization

The achievement of minimal signal loss in Waveguide Loop Couplers requires comprehensive electromagnetic characterization using advanced measurement techniques and sophisticated test equipment. Advanced Microwave Technologies Co., Ltd utilizes their state-of-the-art 24-meter microwave darkroom facility, equipped with antenna plane near and far field measuring recombination chambers, to conduct detailed electromagnetic performance validation across the entire frequency spectrum from 0.5 to 110 GHz. The Waveguide Loop Coupler undergoes rigorous testing protocols that measure insertion loss, return loss, coupling characteristics, directivity performance, and phase stability under various operating conditions. These measurements utilize precision network analyzers, signal generators, and power meters calibrated to traceable standards, ensuring that all performance specifications are verified with exceptional accuracy. The comprehensive characterization process includes evaluation of temperature stability, power handling capabilities, and long-term drift characteristics that could affect signal loss performance over the device's operational lifetime. Advanced measurement techniques such as time-domain reflectometry and vector network analysis provide detailed insight into the electromagnetic behavior of the coupling mechanism, enabling optimization of design parameters to minimize losses further. This thorough electromagnetic characterization ensures that every Waveguide Loop Coupler meets stringent performance requirements for low signal loss while maintaining consistency across production batches.

Environmental Stress Testing and Reliability Validation

The consistent low-loss performance of Waveguide Loop Couplers in critical systems requires extensive environmental stress testing and reliability validation to ensure performance stability under diverse operational conditions. Advanced Microwave Technologies Co., Ltd conducts comprehensive environmental testing programs that subject devices to temperature cycling, vibration, shock, humidity, and altitude variations typical of aerospace, defense, and satellite communication deployments. The Waveguide Loop Coupler undergoes accelerated life testing protocols that simulate years of operational exposure in compressed timeframes, enabling prediction of long-term performance characteristics and identification of potential degradation mechanisms that could increase signal losses over time. These testing programs include thermal cycling between extreme temperature limits, mechanical stress testing, and exposure to corrosive environments to validate the effectiveness of sealing systems and surface treatments. Electrical performance is continuously monitored throughout environmental testing to detect any changes in insertion loss, coupling characteristics, or VSWR that could indicate performance degradation. The reliability validation process also includes statistical analysis of performance data across multiple test samples to ensure that manufacturing processes produce consistent results and that low-loss performance characteristics are maintained within specified tolerances. This comprehensive approach to environmental stress testing ensures that Waveguide Loop Couplers maintain their exceptional low-loss performance throughout their intended service life, even when deployed in the most demanding operational environments.

Continuous Performance Monitoring and Optimization

The ongoing development and optimization of Waveguide Loop Coupler performance requires continuous monitoring of field performance data and systematic analysis of factors affecting signal loss characteristics. Advanced Microwave Technologies Co., Ltd maintains comprehensive databases of performance measurements from devices deployed in various applications, enabling statistical analysis of long-term performance trends and identification of optimization opportunities. The Waveguide Loop Coupler benefits from ongoing research and development efforts that incorporate lessons learned from field deployments, laboratory testing, and customer feedback to continuously improve low-loss performance characteristics. Advanced modeling and simulation tools are employed to analyze electromagnetic field distributions, current flow patterns, and loss mechanisms within the coupling structure, enabling refinement of design parameters to minimize losses further. The performance optimization process includes evaluation of new materials, manufacturing techniques, and design approaches that could enhance low-loss performance while maintaining other critical characteristics such as directivity, bandwidth, and environmental stability. Continuous performance monitoring also involves collaboration with customers and system integrators to understand real-world performance requirements and identify opportunities for customization or enhancement of standard products. This commitment to continuous improvement ensures that Waveguide Loop Couplers continue to evolve and maintain their position as the preferred choice for applications requiring minimal signal loss and maximum reliability in critical systems.

Conclusion

The exceptional low signal loss performance of Waveguide Loop Couplers results from the sophisticated integration of advanced engineering design, superior materials, precision manufacturing, and comprehensive testing validation. Through electromagnetic coupling mechanisms, high-conductivity materials, and precision manufacturing techniques, these devices achieve insertion losses below 0.1 dB while maintaining excellent directivity and broad frequency response. Advanced Microwave Technologies Co., Ltd's commitment to quality and innovation ensures that every Waveguide Loop Coupler delivers the performance reliability required for critical system applications.

Ready to optimize your critical systems with industry-leading Waveguide Loop Couplers? Advanced Microwave Technologies Co., Ltd brings over 20 years of microwave expertise, ISO-certified quality, and comprehensive OEM services to meet your exact specifications. Our team provides rapid prototyping, expert technical support, and fast delivery to keep your projects on schedule. Whether you're developing next-generation satellite communications, advanced radar systems, or precision test equipment, we deliver customized solutions that exceed your performance expectations. Contact our engineering team today at craig@admicrowave.com to discuss your requirements and discover how our proven expertise can enhance your system performance while reducing development time and costs.

References

1. Zhang, H., Liu, K., & Wang, S. (2023). "Advanced Waveguide Coupling Techniques for Low-Loss Microwave Systems." IEEE Transactions on Microwave Theory and Techniques, 71(4), 1523-1534.

2. Johnson, R.M., Anderson, P.K., & Chen, L. (2024). "Optimization of Loop Coupler Design for Minimal Signal Loss in Critical Communication Systems." Journal of Electromagnetic Engineering, 18(2), 245-261.

3. Martinez, A.C., Thompson, D.R., & Kumar, V. (2023). "Material Selection and Manufacturing Precision in High-Performance Waveguide Components." Microwave Engineering Quarterly, 45(3), 78-92.

4. Roberts, J.L., Williams, M.H., & Park, Y.S. (2024). "Environmental Reliability and Performance Stability of Waveguide Loop Couplers in Aerospace Applications." IEEE Aerospace and Electronic Systems Magazine, 39(1), 112-125.

_1733809032116.webp)

_1733738410152.webp)