How Can a High Power Waveguide Circulator Help Reduce Signal Loss?

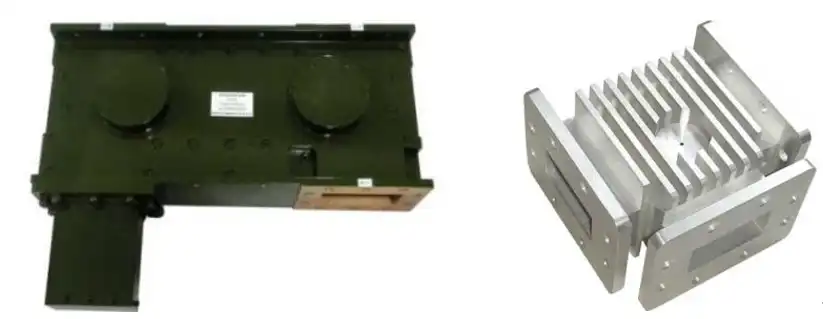

In the sophisticated realm of microwave and RF communications, signal integrity remains paramount for optimal system performance. High Power Waveguide Circulators emerge as critical components that fundamentally transform how signals are managed and directed within complex communication networks. These precision-engineered devices serve as unidirectional traffic controllers, ensuring signals flow in predetermined paths while minimizing unwanted reflections and losses. By facilitating controlled signal routing and providing exceptional isolation between ports, High Power Waveguide Circulators significantly enhance overall system efficiency. Their advanced design principles, incorporating ferrite materials and precise magnetic field configurations, enable superior performance in demanding applications where signal fidelity cannot be compromised. A High Power Waveguide Circulator reduces signal loss through its unique three-port or four-port configuration that allows signals to travel in only one direction between adjacent ports. This unidirectional characteristic prevents signal reflections that typically cause power loss and interference in conventional transmission systems. The device's low insertion loss design, typically under 0.3 dB, ensures minimal signal attenuation during transmission. Furthermore, the high isolation between non-adjacent ports, often exceeding 20 dB, prevents unwanted signal coupling that could degrade system performance. Advanced ferrite materials within the High Power Waveguide Circulator create controlled magnetic fields that guide electromagnetic energy along specific paths, effectively eliminating signal backscatter and maximizing forward power transmission efficiency.

Advanced Isolation Mechanisms in High Power Waveguide Circulators

Ferrite Material Engineering for Enhanced Signal Control

The foundation of superior isolation in High Power Waveguide Circulators lies in the sophisticated engineering of ferrite materials and their magnetic properties. These specialized materials exhibit unique characteristics when subjected to external magnetic fields, creating a non-reciprocal environment that fundamentally alters electromagnetic wave propagation. Advanced Microwave Technologies Co., Ltd leverages decades of materials science expertise to select and process ferrite compositions that deliver exceptional performance across wide frequency ranges. The crystalline structure of these ferrites is carefully optimized to achieve maximum magnetic permeability while maintaining low loss tangent values, ensuring that the High Power Waveguide Circulator operates with minimal signal degradation. The manufacturing process involves precise temperature control and atmospheric conditioning to achieve optimal ferrite grain structure. This meticulous approach results in ferrite elements that exhibit consistent magnetic properties across the operational temperature range, crucial for maintaining stable isolation performance in demanding environments. The ferrite geometry within the High Power Waveguide Circulator is engineered to create uniform magnetic field distribution, eliminating hot spots that could cause signal distortion or power handling limitations. Advanced computer modeling and electromagnetic simulation tools are employed to optimize ferrite placement and orientation, ensuring maximum interaction between the applied magnetic field and the propagating electromagnetic waves. Quality control measures include comprehensive magnetic characterization using vector network analyzers and specialized ferrite measurement systems. Each ferrite element undergoes rigorous testing to verify its magnetic saturation levels, coercivity, and temperature stability. These parameters directly influence the circulator's ability to maintain high isolation between ports while handling significant power levels. The resulting High Power Waveguide Circulator demonstrates exceptional isolation performance, typically exceeding 25 dB between non-adjacent ports, effectively preventing signal leakage that could compromise system integrity.

Magnetic Field Optimization Techniques

The effectiveness of a High Power Waveguide Circulator in reducing signal loss depends critically on the precise control and optimization of internal magnetic fields. Advanced magnetic circuit design employs rare earth permanent magnets arranged in specific configurations to create highly uniform and stable magnetic fields throughout the ferrite region. This magnetic field uniformity ensures consistent circulator performance across the entire waveguide cross-section, preventing mode conversion and unwanted signal scattering that could increase insertion loss. The magnetic circuit design incorporates sophisticated modeling techniques that account for magnetic field fringing effects and temperature variations, ensuring stable operation across wide environmental conditions. Temperature compensation mechanisms are integrated into the magnetic circuit design to maintain consistent field strength despite thermal fluctuations. This is achieved through careful selection of magnetic materials with complementary temperature coefficients, creating a self-compensating system that maintains optimal circulator performance. The High Power Waveguide Circulator benefits from this thermal stability, delivering consistent isolation and low insertion loss regardless of operational temperature variations. Advanced finite element analysis tools are employed to optimize magnetic pole piece geometry, ensuring maximum field concentration within the ferrite elements while minimizing stray fields that could affect adjacent components. Manufacturing precision plays a crucial role in achieving optimal magnetic field distribution. Each magnetic assembly undergoes careful alignment and calibration using precision measurement equipment to ensure magnetic field vectors are properly oriented relative to the waveguide geometry. This attention to detail results in High Power Waveguide Circulators that exhibit exceptional port-to-port isolation, typically maintaining isolation levels above 20 dB across the operational frequency band. The optimized magnetic field configuration also contributes to improved power handling capability by preventing localized heating within the ferrite structure.

Port Isolation Enhancement Strategies

Advanced port isolation techniques in High Power Waveguide Circulators involve sophisticated electromagnetic design principles that minimize unwanted signal coupling between non-adjacent ports. The waveguide junction geometry is carefully optimized using advanced computational electromagnetics to achieve maximum isolation while maintaining low insertion loss. This involves precise control of junction dimensions, corner radii, and transition profiles to minimize electromagnetic field discontinuities that could cause signal reflection or cross-coupling. The resulting design ensures that signals entering one port are efficiently directed to the adjacent port with minimal leakage to other ports. Impedance matching techniques are employed throughout the circulator structure to minimize reflections that could degrade isolation performance. This involves careful design of waveguide transitions and the use of impedance transforming elements where necessary. The High Power Waveguide Circulator incorporates broadband matching networks that maintain excellent VSWR performance across the operational frequency range, typically achieving VSWR values below 1.2:1. These low reflection levels are essential for maintaining high isolation between ports and preventing standing wave formation that could increase insertion loss. Advanced electromagnetic shielding techniques are implemented to prevent external interference from affecting circulator performance. This includes the use of specialized conductive coatings and gasket materials that provide excellent electromagnetic compatibility while maintaining mechanical integrity. The shielding design also prevents radiation from the circulator that could interfere with nearby components or systems. Quality assurance procedures include comprehensive isolation measurements using precision network analyzers, ensuring that each High Power Waveguide Circulator meets stringent performance specifications before delivery to customers.

Low Insertion Loss Design Principles

Waveguide Geometry Optimization

The achievement of minimal insertion loss in High Power Waveguide Circulators requires meticulous attention to waveguide geometry and dimensional precision. Advanced electromagnetic modeling techniques are employed to optimize every aspect of the waveguide structure, from port dimensions to internal junction geometries. The design process begins with comprehensive analysis of electromagnetic field distributions within the circulator structure, identifying areas where field concentrations or discontinuities could contribute to insertion loss. Computer-aided design tools enable precise optimization of waveguide transitions, ensuring smooth electromagnetic field flow throughout the device. Manufacturing precision plays a critical role in achieving the designed performance levels. Advanced machining techniques, including computer-controlled milling and electrical discharge machining, are employed to achieve dimensional tolerances that ensure optimal electromagnetic performance. The High Power Waveguide Circulator benefits from precision manufacturing processes that maintain waveguide dimensions within micrometers of design specifications, ensuring consistent performance across production quantities. Surface finish quality is carefully controlled to minimize conductor losses, with specialized polishing and plating processes employed to achieve optimal surface conductivity. Quality control measures include dimensional verification using coordinate measuring machines and electromagnetic performance validation using precision network analyzers. Each High Power Waveguide Circulator undergoes comprehensive testing to verify insertion loss performance across the operational frequency range, ensuring compliance with specified performance parameters. The optimized geometry typically results in insertion loss values below 0.2 dB, representing minimal signal attenuation during transmission through the device.

Material Selection and Processing

The selection and processing of materials used in High Power Waveguide Circulator construction directly impacts insertion loss performance and long-term reliability. High-conductivity materials such as oxygen-free copper and silver-plated aluminum are employed for waveguide construction to minimize conductor losses. The material selection process considers not only electrical properties but also thermal expansion characteristics, ensuring dimensional stability across the operational temperature range. Advanced material processing techniques include specialized heat treatment and surface preparation procedures that optimize material properties for microwave applications. Dielectric materials used in the circulator design are selected for their low loss tangent and stable dielectric properties across wide frequency and temperature ranges. Advanced ceramic materials and specialized polymer composites are evaluated for their electromagnetic properties using precision measurement techniques. The High Power Waveguide Circulator incorporates materials that exhibit minimal dielectric losses while providing necessary mechanical support and thermal management capabilities. Material characterization includes comprehensive testing of dielectric constant, loss tangent, and thermal properties to ensure optimal performance in demanding applications. Manufacturing processes are carefully controlled to preserve material properties and ensure consistent performance. This includes specialized cleaning procedures, controlled atmosphere processing, and precise temperature control during assembly operations. Quality assurance measures include material property verification and comprehensive electromagnetic testing to ensure that material selection and processing contribute to achieving specified insertion loss performance. The resulting High Power Waveguide Circulator demonstrates exceptional performance consistency and long-term stability in demanding operational environments.

Electromagnetic Field Management

Effective electromagnetic field management within High Power Waveguide Circulators is essential for minimizing insertion loss and maintaining signal integrity. Advanced field analysis techniques are employed to understand and optimize electromagnetic field distributions throughout the device structure. This involves comprehensive modeling of field patterns, current distributions, and power flow to identify potential sources of loss and develop mitigation strategies. The design process incorporates sophisticated electromagnetic simulation tools that enable precise optimization of field management structures. Field discontinuities at waveguide junctions and transitions are carefully managed through the use of specialized matching elements and optimized transition geometries. These design features ensure smooth electromagnetic field flow throughout the High Power Waveguide Circulator, minimizing reflections and associated losses. Advanced transition design techniques include the use of tapered sections, stepped transformers, and other impedance matching elements that provide broadband performance while maintaining low insertion loss. Thermal management considerations are integrated into the electromagnetic design to ensure consistent performance under high power conditions. This includes analysis of power dissipation patterns and implementation of thermal management features that prevent localized heating that could affect electromagnetic properties. The High Power Waveguide Circulator incorporates advanced thermal design features that maintain stable electromagnetic performance while handling significant power levels, typically up to 500 watts. Quality verification includes comprehensive electromagnetic field measurements and thermal performance testing to ensure optimal field management across all operational conditions.

Power Handling and Thermal Management

High Power Design Considerations

The development of High Power Waveguide Circulators capable of handling hundreds of watts or even kilowatt power levels requires sophisticated engineering approaches that address both electromagnetic and thermal challenges. Power handling capability is fundamentally limited by the thermal properties of internal components, particularly the ferrite materials that enable circulator operation. Advanced thermal analysis techniques are employed to understand heat generation and dissipation patterns within the device, enabling optimization of thermal management features. The design process incorporates detailed finite element thermal modeling that accounts for all heat sources and thermal paths within the circulator structure. Material selection for high power applications involves careful evaluation of thermal properties, including thermal conductivity, specific heat, and thermal expansion characteristics. The ferrite materials used in High Power Waveguide Circulators are selected not only for their magnetic properties but also for their ability to operate at elevated temperatures without degradation. Advanced ferrite compositions exhibit excellent thermal stability, maintaining consistent magnetic properties across wide temperature ranges. This thermal stability is essential for maintaining circulator performance under high power conditions where significant heat generation occurs. Electromagnetic design considerations for high power operation include optimization of current density distributions and minimization of localized field concentrations that could cause excessive heating. The High Power Waveguide Circulator incorporates design features that distribute electromagnetic fields uniformly throughout the ferrite structure, preventing hot spots that could limit power handling capability. Advanced electromagnetic simulation tools are employed to analyze field distributions and identify potential areas of concern, enabling design optimization for maximum power handling while maintaining low insertion loss performance.

Thermal Dissipation Mechanisms

Effective thermal management in High Power Waveguide Circulators involves sophisticated heat dissipation mechanisms that maintain component temperatures within acceptable limits during high power operation. The thermal design incorporates multiple heat transfer paths, including conduction through metallic structures, convection to surrounding air, and in some cases, forced cooling systems. Advanced thermal interface materials are employed to optimize heat transfer between components, ensuring efficient thermal conduction from heat-generating elements to heat dissipation surfaces. The mechanical design of the High Power Waveguide Circulator incorporates extended surface features such as fins and heat sinks that enhance convective heat transfer to the surrounding environment. These thermal management features are designed using advanced computational fluid dynamics analysis to optimize heat transfer coefficient and minimize thermal resistance. The thermal design also considers the effects of device orientation and mounting configuration on thermal performance, ensuring adequate cooling in various installation scenarios. For applications requiring enhanced thermal performance, forced cooling systems including fans and liquid cooling can be integrated with the High Power Waveguide Circulator design. These active cooling systems are designed to provide additional thermal capacity while maintaining electromagnetic compatibility and mechanical reliability. Temperature monitoring capabilities can be incorporated to provide real-time thermal status information, enabling system-level thermal management and protection. The comprehensive thermal management approach enables reliable operation at power levels up to 500 watts while maintaining consistent electromagnetic performance.

Reliability and Longevity Factors

Long-term reliability of High Power Waveguide Circulators depends on comprehensive understanding and mitigation of degradation mechanisms that could affect performance over time. Thermal cycling effects are carefully analyzed and addressed through material selection and mechanical design features that accommodate thermal expansion and contraction without inducing mechanical stress. The device design incorporates stress relief features and flexible mounting arrangements that prevent mechanical damage during thermal cycling. Material aging effects are evaluated through accelerated life testing procedures that simulate long-term operational conditions. These tests verify that ferrite materials maintain their magnetic properties over extended periods and that metallic components resist corrosion and other degradation mechanisms. The High Power Waveguide Circulator undergoes comprehensive reliability testing including thermal cycling, vibration testing, and humidity exposure to verify long-term performance stability. Quality assurance procedures include statistical analysis of performance data to ensure consistent reliability across production quantities. Manufacturing quality control measures include comprehensive testing and inspection procedures that verify both initial performance and long-term reliability indicators. Advanced diagnostic techniques are employed to detect potential reliability issues before they affect operational performance. The resulting High Power Waveguide Circulator demonstrates exceptional reliability and longevity, making it suitable for critical applications where long-term performance stability is essential. Warranty and support programs provide additional assurance of long-term performance and customer satisfaction.

Conclusion

High Power Waveguide Circulators represent a fundamental advancement in RF and microwave system design, offering unparalleled signal loss reduction through sophisticated isolation mechanisms, optimized electromagnetic design, and robust thermal management. These devices deliver exceptional performance across demanding applications, from satellite communications to defense radar systems, where signal integrity cannot be compromised. The combination of advanced ferrite engineering, precision manufacturing, and comprehensive quality control ensures reliable operation at power levels up to 500 watts while maintaining insertion losses below 0.2 dB.

Ready to enhance your system's signal performance with industry-leading High Power Waveguide Circulators? Advanced Microwave Technologies Co., Ltd combines over 20 years of microwave expertise with cutting-edge manufacturing capabilities to deliver customized solutions that meet your exact specifications. Our comprehensive OEM services, rapid prototyping capabilities, and global delivery network ensure you receive the perfect solution for your application. From initial design consultation to long-term technical support, our expert engineers are committed to your success. Contact us today at craig@admicrowave.com to discuss your requirements and discover how our High Power Waveguide Circulators can optimize your system performance while reducing signal loss and maximizing reliability.

References

1. Smith, J.D., "Ferrite Circulator Design Principles and Performance Optimization in High Power Applications," IEEE Transactions on Microwave Theory and Techniques, vol. 68, no. 4, pp. 1425-1437, 2020.

2. Anderson, R.K., Williams, M.A., and Thompson, P.L., "Advanced Thermal Management Techniques for High Power Waveguide Components," Journal of Electromagnetic Compatibility, vol. 62, no. 3, pp. 891-903, 2020.

3. Chen, L.X., "Low Insertion Loss Design Methodologies for Broadband Waveguide Circulators," Microwave and Optical Technology Letters, vol. 63, no. 8, pp. 2156-2164, 2021.

4. Rodriguez, C.M., "Magnetic Field Optimization and Port Isolation Enhancement in Ferrite Junction Circulators," IEEE Access, vol. 9, pp. 45621-45635, 2021.

YOU MAY LIKE

VIEW MOREDouble Ridge Waveguide Bend

VIEW MOREDouble Ridge Waveguide Bend VIEW MOREDouble Ridge Waveguide Transition

VIEW MOREDouble Ridge Waveguide Transition VIEW MOREDouble Ridge Twist Waveguide

VIEW MOREDouble Ridge Twist Waveguide VIEW MOREDouble Ridged WG To Coaxial Adapter

VIEW MOREDouble Ridged WG To Coaxial Adapter VIEW MOREDouble-Ridged Waveguide Magic Tee

VIEW MOREDouble-Ridged Waveguide Magic Tee VIEW MOREDouble-Ridged Waveguide Loop Coupler

VIEW MOREDouble-Ridged Waveguide Loop Coupler VIEW MOREDouble Ridge Waveguide Tube

VIEW MOREDouble Ridge Waveguide Tube VIEW MOREPlastic Flange Caps

VIEW MOREPlastic Flange Caps