How Does an E-Plane Tee Work in Waveguide Networks?

In microwave engineering, signal distribution demands precision engineering components that ensure minimal signal loss and consistent performance across high-frequency operations. Picture this scenario: your satellite ground station requires simultaneous signal routing to multiple antenna elements while maintaining exact phase relationships and impedance matching throughout the entire system. This is precisely where the e-plane tee becomes indispensable. An e-plane tee is a three-port waveguide junction where the auxiliary arm is attached to the broad wall of the main rectangular waveguide, positioned parallel to the electric field lines. This configuration enables the component to efficiently split or combine electromagnetic signals with controlled phase relationships, making it essential for applications ranging from radar systems to satellite communications where power division accuracy directly impacts system performance and signal integrity.

Understanding the Core Structure of E-Plane Tee in Waveguide Systems

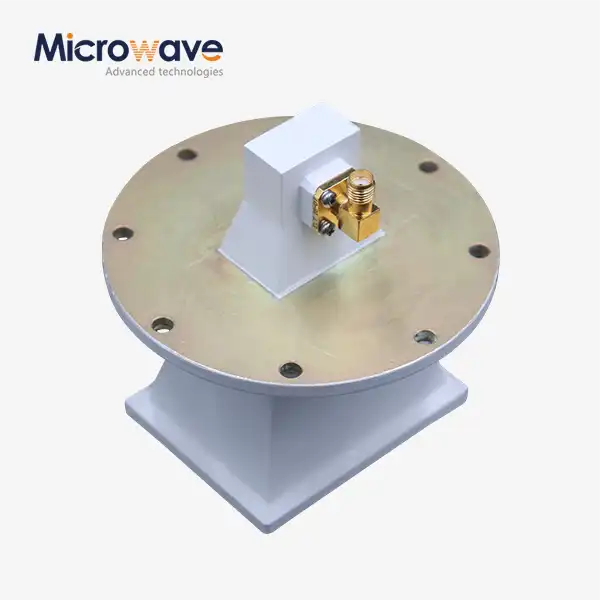

The e-plane tee represents a fundamental building block in microwave waveguide networks, distinguished by its unique T-shaped configuration that emerges from precise electromagnetic engineering principles. Advanced Microwave Technologies Co., Ltd. manufactures a wide variety of e-plane tees with meticulous attention to structural precision. The junction of the auxiliary arm is made on the broad wall of the main waveguide, creating a three-port device where two collinear ports form the main transmission path and a third port extends perpendicularly from the broad wall. This specific architectural design is not arbitrary—it directly corresponds to the orientation of electric field lines in the dominant TE₁₀ mode that propagates through rectangular waveguides. When electromagnetic waves travel through the main waveguide, the electric field oscillates perpendicular to the broad walls, and by positioning the auxiliary arm junction on this broad wall, engineers ensure that the electric field distribution remains parallel to the side arm axis, hence the designation "E-plane." This orientation fundamentally determines how the component splits and combines microwave signals, creating characteristic phase relationships between output ports that are essential for specific applications.

The physical dimensions of an e-plane tee must be precisely calculated based on the operating frequency range to ensure optimal electromagnetic performance. Advanced Microwave Technologies Co., Ltd. designs e-plane tee components with advanced measurement capabilities spanning 0.5 to 110 GHz in their state-of-the-art 24m Microwave Darkroom facility. The broad wall dimensions, narrow wall dimensions, and auxiliary arm positioning must all satisfy rigorous mathematical relationships derived from Maxwell's equations to prevent unwanted reflections and maximize power transfer efficiency. The junction geometry creates a discontinuity in the waveguide structure where electromagnetic boundary conditions must be carefully managed to minimize return loss and insertion loss. Engineers employ sophisticated electromagnetic simulation software combined with empirical testing in controlled environments to refine these dimensions, ensuring that each e-plane tee meets stringent performance specifications across its intended frequency band. The manufacturing process requires precision machining techniques capable of maintaining dimensional tolerances measured in micrometers, as even minor deviations can significantly degrade electrical performance at millimeter-wave frequencies.

Operating Principles: How E-Plane Tee Divides and Combines Signals

The fundamental operating principle of an e-plane tee centers on the controlled distribution of electromagnetic energy at the waveguide junction, governed by the interaction between incident waves and the physical structure of the component. When a signal enters through one of the collinear ports of an e-plane tee, the electromagnetic waves propagate toward the junction where the auxiliary arm intersects the main waveguide. At this critical junction point, the electric field configuration forces the incident wave to divide its energy between the two available output paths. The unique characteristic of the e-plane tee lies in the phase relationship it establishes between these divided signals—waves emerging from the two collinear ports maintain a 180-degree phase difference when the input originates from the side arm port. This phase inversion occurs because of how the electric field couples with the auxiliary arm structure positioned on the broad wall. Conversely, when signals enter through the collinear ports, they combine at the side arm with specific amplitude and phase relationships determined by the junction geometry.

The e-plane tee enables sophisticated power splitting configurations essential for modern microwave systems deployed across telecommunications, aerospace, and defense sectors. Advanced Microwave manufactures e-plane tee components engineered to handle frequencies up to 110 GHz with minimal insertion loss, ensuring that signal power is divided or combined with maximum efficiency. The component's ability to split power while maintaining controlled phase relationships makes it invaluable in phased array antenna systems where multiple radiating elements must be fed with precise phase offsets to achieve desired beam steering characteristics. In satellite ground station applications, e-plane tees distribute incoming signals from parabolic reflectors to multiple receiver channels, enabling simultaneous processing of different frequency bands or polarizations. The power handling capability of these components becomes critical in high-power radar applications where kilowatts of microwave energy must be routed through the waveguide network without causing breakdown or thermal damage. The robust construction materials and engineering design employed by Advanced Microwave Technologies Co., Ltd. ensure that e-plane tee components maintain stable electrical characteristics even under extreme power levels and environmental conditions.

The impedance matching characteristics of an e-plane tee significantly influence overall system performance, particularly in applications requiring wideband operation or minimal signal reflections. The junction where the auxiliary arm meets the main waveguide creates an impedance discontinuity that must be carefully compensated through precise dimensional control and potentially through matching elements such as inductive posts or capacitive irises. Advanced Microwave's engineering team employs sophisticated design optimization techniques to ensure superior matching performance across the entire operating frequency band. When properly designed, an e-plane tee exhibits low voltage standing wave ratio (VSWR) at all ports, minimizing reflected power that could degrade transmitter efficiency or receiver sensitivity. The scattering parameters of the device, particularly S11, S22, and S33, quantify the return loss at each port and provide measurable metrics for matching quality. In high-performance systems, return loss values exceeding 20 dB across the operating band are typically required, demanding exceptional manufacturing precision and quality control. The ISO:9001:2008 certified production processes employed by Advanced Microwave Technologies Co., Ltd. incorporate rigorous testing protocols using vector network analyzers to verify that each manufactured e-plane tee meets specified electrical parameters before shipment to customers.

Critical Applications of E-Plane Tee Across Multiple Industries

The e-plane tee serves as an indispensable component in radar systems where power distribution networks must maintain precise amplitude balance and phase relationships among multiple antenna elements or signal processing channels. Military surveillance radars deployed for threat detection and target tracking require feed networks that can distribute transmitted power to planar array antennas while maintaining the coherence necessary for synthetic aperture radar (SAR) imaging and moving target indication (MTI) processing. Advanced Microwave's custom e-plane tee solutions excel in these demanding defense applications where operational reliability under extreme conditions is non-negotiable. Air traffic control radar systems utilize e-plane tee components to create sum and difference patterns for monopulse tracking, enabling ultra-sharp beamforming that accurately determines aircraft position even in adverse weather conditions. The phase characteristics of the e-plane tee—specifically the 180-degree phase difference between collinear ports when excited from the side arm—directly support the generation of difference patterns essential for angle measurement. Weather monitoring radar networks employ these components in dual-polarization systems where separate horizontal and vertical polarization channels require isolated feed networks with minimal cross-coupling.

Satellite communication systems represent another critical application domain where e-plane tee performance directly impacts overall link quality and operational efficiency. Satellite ground stations processing multiple frequency bands simultaneously require sophisticated feed networks that can separate or combine signals with minimal insertion loss and excellent isolation between channels. Advanced Microwave Technologies Co., Ltd. provides e-plane tee components that ensure efficient signal transfer for high-definition video transmission, data relay, and voice communications in commercial satellite networks. The company's products support frequencies spanning from L-band through Ka-band and into millimeter-wave spectrum allocations being adopted for next-generation satellite constellations. In satellite payload applications, where size and weight constraints are paramount, the compact design of e-plane tee components becomes a significant advantage. These devices enable efficient power combining from multiple solid-state amplifiers or power division to multiple antenna feeds while occupying minimal volume within the spacecraft bus. The RoHS-compliant materials and robust construction ensure long-term reliability in the harsh space environment characterized by temperature extremes, radiation exposure, and vacuum conditions.

Telecommunications infrastructure increasingly relies on e-plane tee components as network operators deploy advanced antenna systems to enhance coverage and capacity in both urban and rural environments. Base station antenna arrays for 5G networks utilize complex feed networks incorporating multiple e-plane tee junctions to create the multi-beam patterns required for massive MIMO (Multiple Input Multiple Output) operation. Advanced Microwave's e-plane tee products optimize long-distance signal propagation by ensuring efficient power distribution across antenna elements with minimal losses that could degrade link budgets. In point-to-point microwave backhaul systems connecting remote cell sites to core network infrastructure, e-plane tees enable redundant path configurations that improve network resilience. Industrial IoT applications in remote locations benefit from telecommunications systems incorporating these components to bring reliable connectivity to areas where traditional wireline infrastructure is economically impractical. The low insertion loss characteristic of high-quality e-plane tee components directly translates to extended communication range or reduced transmitter power requirements, yielding both performance and economic benefits for network operators.

Design Optimization and Performance Characteristics

Achieving optimal performance from an e-plane tee requires careful attention to numerous design parameters that collectively determine electrical characteristics across the intended frequency band. The broad wall junction geometry where the auxiliary arm connects to the main waveguide represents perhaps the most critical design element, as this interface directly influences impedance matching, insertion loss, and power handling capability. Advanced Microwave Technologies Co., Ltd. engineers employ full-wave electromagnetic simulation tools to model field distributions within the junction region, enabling optimization of transition geometry to minimize discontinuity effects. The radius of curvature at junction corners, the precise angle of the auxiliary arm connection, and the thickness of connecting walls all contribute to overall electrical performance. Designers must balance competing objectives: minimizing insertion loss requires smooth field transitions, but maintaining compact dimensions may necessitate sharper transitions that increase loss. The extensive experience accumulated over more than 20 years of microwave component development enables Advanced Microwave's engineering team to navigate these tradeoffs effectively, producing e-plane tee designs that simultaneously achieve low loss, excellent matching, and practical manufacturability.

The frequency response characteristics of an e-plane tee determine its suitability for specific applications ranging from narrowband radar systems to wideband communications infrastructure. A well-designed e-plane tee exhibits relatively flat insertion loss and return loss across its specified operating band, ensuring consistent performance regardless of the instantaneous frequency of operation. However, the waveguide structure inherently imposes frequency limitations—below the waveguide cutoff frequency, propagation becomes evanescent and the component ceases to function effectively. Advanced Microwave manufactures e-plane tee components across numerous standard waveguide bands from WR-2300 through WR-10, each optimized for specific frequency ranges spanning from sub-GHz frequencies to the millimeter-wave spectrum above 75 GHz. For applications requiring operation across multiple waveguide bands, system designers may need to incorporate multiple e-plane tee components with appropriate transitions, adding complexity but ensuring optimal performance in each frequency range. The high-frequency support capability extending to 110 GHz enables Advanced Microwave's products to address emerging applications in automotive radar, wireless backhaul, and imaging systems operating at millimeter-wave frequencies where atmospheric attenuation and component losses become increasingly significant challenges.

Power handling capability represents another crucial performance parameter, particularly for transmit applications where kilowatts of RF power must be safely routed through the waveguide network. The maximum power an e-plane tee can handle without breakdown is determined by the electric field intensity within the junction region and the pressure, temperature, and cleanliness of the internal environment. Voltage breakdown occurs when the electric field strength exceeds the dielectric strength of air or other gas filling the waveguide, causing ionization and arc formation that can damage internal surfaces. Advanced Microwave designs e-plane tee components with appropriate safety margins, ensuring that peak electric fields remain well below breakdown thresholds even under worst-case standing wave conditions. For ultra-high-power applications such as particle accelerators or industrial heating systems, pressurization with SF6 gas or dry nitrogen can increase breakdown thresholds by factors of two to three times compared to atmospheric pressure air. The durable and reliable construction employed by Advanced Microwave Technologies Co., Ltd. ensures these components maintain stable performance characteristics even under the thermal stresses associated with high-power operation, where RF losses converted to heat must be effectively dissipated to prevent degradation of electrical properties or mechanical distortion of the waveguide structure.

Customization and Advanced Manufacturing Capabilities

Every microwave system presents unique requirements shaped by specific frequency bands, power levels, environmental conditions, and space constraints that demand customized component solutions rather than off-the-shelf products. Advanced Microwave Technologies Co., Ltd. offers comprehensive OEM services to tailor e-plane tee specifications to exact customer requirements, whether adjustments involve frequency range optimization, power handling enhancement, or physical configuration modifications to integrate seamlessly within constrained installation environments. The company's engineering team collaborates closely with clients throughout the design and development process, beginning with detailed requirements analysis to understand operational parameters, continuing through electromagnetic design and optimization, and concluding with prototype fabrication and rigorous testing validation. This collaborative approach ensures that each customized e-plane tee delivers optimal performance aligned precisely with system-level objectives. The extensive measurement capabilities available in Advanced Microwave's laboratory facilities, including their 24m Microwave Darkroom equipped with antenna plane near and far field measuring recombination chambers, enable comprehensive characterization of prototype designs before committing to production manufacturing.

The manufacturing processes employed to produce high-performance e-plane tee components require sophisticated machining capabilities, precision tooling, and rigorous quality control protocols to ensure that fabricated hardware faithfully realizes design intent. Advanced Microwave Technologies Co., Ltd. maintains ISO:9001:2008 certified production facilities equipped with state-of-the-art CNC machining centers capable of maintaining dimensional tolerances essential for millimeter-wave frequency operation. The broad wall junction where the auxiliary arm connects to the main waveguide demands particular attention during fabrication, as any irregularities or dimensional errors in this critical region directly degrade electrical performance. Experienced machinists combine traditional waveguide fabrication techniques with modern computer-controlled equipment to produce components meeting stringent specifications. Surface finish quality within the waveguide interior affects insertion loss, particularly at higher frequencies where skin depth becomes very small and surface roughness represents a larger fraction of penetration depth. Electroplating internal surfaces with silver or gold further reduces ohmic losses while providing oxidation resistance that maintains stable electrical characteristics throughout the component's operational lifetime. The RoHS-compliant materials and environmentally responsible manufacturing processes demonstrate Advanced Microwave's commitment to producing high-performance products that minimize environmental impact.

Quality assurance procedures implemented throughout the manufacturing process ensure that every e-plane tee component meets or exceeds specified electrical and mechanical parameters before shipment to customers. Advanced Microwave employs comprehensive testing protocols incorporating both dimensional verification and electrical characterization stages. Precision measurement tools including coordinate measuring machines (CMMs) verify that critical dimensions match design specifications within required tolerances. Electrical testing using calibrated vector network analyzers measures S-parameters across the full operating frequency range, quantifying insertion loss, return loss, and isolation performance. Components failing to meet acceptance criteria are identified and either reworked if possible or rejected to prevent substandard products from reaching customers. This commitment to quality, reinforced by ISO:9001:2008 certification and supported by over 20 years of manufacturing experience, ensures that Advanced Microwave Technologies Co., Ltd. consistently delivers e-plane tee components that perform reliably in demanding real-world applications spanning satellite communications, defense systems, aerospace platforms, and telecommunications infrastructure deployed globally.

Conclusion

The e-plane tee serves as a foundational component in waveguide networks, enabling precise signal division and combination through its unique junction geometry positioned on the broad wall of the main waveguide. Its controlled phase relationships, low insertion loss, and robust power handling capabilities make it indispensable across telecommunications, aerospace, defense, and satellite communication applications where performance and reliability are paramount.

Cooperate with Advanced Microwave Technologies Co., Ltd.

Advanced Microwave Technologies Co., Ltd. stands as a leading China e-plane tee manufacturer with over 20 years of specialized experience in microwave component development and production. As a premier China e-plane tee supplier and China e-plane tee factory, we offer High Quality e-plane tee solutions available for wholesale to global customers across aviation and aerospace, shipboard systems, weather monitoring, security check systems, UAV platforms, and direction finding applications. Our state-of-the-art 24m Microwave Darkroom equipped with antenna plane near and far field measuring recombination chamber enables precise testing across 0.5 to 110 GHz frequencies, ensuring every e-plane tee for sale meets rigorous performance standards. We provide competitive e-plane tee price structures combined with comprehensive OEM services, allowing customization of dimensions, materials, and frequency ranges tailored to your specific system requirements. Our perfect supply chain system, professional technical R&D team, and strict ISO:9001:2008 certified quality control processes guarantee fast delivery of products that are RoHS-compliant and environmentally responsible. Whether you need prototypes for evaluation or full-scale production quantities, our expert engineers provide in-depth technical support including installation guidance and troubleshooting assistance. Contact us today at craig@admicrowave.com to discuss your e-plane tee requirements and discover how our China e-plane tee wholesale solutions can optimize your waveguide network performance while delivering exceptional value and reliability for your critical microwave applications.

References

1. Pozar, David M. "Microwave Engineering, Fourth Edition." John Wiley & Sons, 2011. Chapter 4: Microwave Network Analysis and Chapter 5: Impedance Matching and Tuning.

2. Collin, Robert E. "Foundations for Microwave Engineering, Second Edition." IEEE Press, 2001. Chapter 7: Waveguide Junctions and Discontinuities.

3. Montgomery, C.G., Dicke, R.H., and Purcell, E.M. "Principles of Microwave Circuits." McGraw-Hill Book Company, 1948. MIT Radiation Laboratory Series Volume 8, Chapter 9: Waveguide Junctions.

4. Saad, Theodore S. "Microwave Engineers' Handbook, Volume 1." Artech House, 1971. Section on Waveguide Components and T-Junctions.

5. Matthaei, George L., Young, Leo, and Jones, E.M.T. "Microwave Filters, Impedance-Matching Networks, and Coupling Structures." Artech House, 1980. Chapter 16: Waveguide Directional Couplers and Power Dividers.

YOU MAY LIKE

VIEW MORELog Periodic Antenna

VIEW MORELog Periodic Antenna VIEW MOREConical Circular Polarization Horn Antenna

VIEW MOREConical Circular Polarization Horn Antenna VIEW MORELadder Membrane Square Dual Circular Polarization Horn Antenna

VIEW MORELadder Membrane Square Dual Circular Polarization Horn Antenna VIEW MOREDual Linear Broadband Circular Polarization Horn Antenna

VIEW MOREDual Linear Broadband Circular Polarization Horn Antenna VIEW MOREPyramidal Linear Polarization Horn Antenna

VIEW MOREPyramidal Linear Polarization Horn Antenna VIEW MORELow Side Lobe Diagonal Linear Polarization Horn Antenna

VIEW MORELow Side Lobe Diagonal Linear Polarization Horn Antenna VIEW MOREQuadrifilar Helix Antenna

VIEW MOREQuadrifilar Helix Antenna VIEW MORECassegrain Antenna

VIEW MORECassegrain Antenna