How do you maintain a Water-Cooled Twist Waveguide?

Water-cooled twist waveguides represent a critical component in high-power microwave systems, requiring careful maintenance to ensure optimal performance and longevity. These sophisticated devices combine precision engineering with advanced cooling mechanisms to handle substantial power loads while maintaining signal integrity. Understanding proper maintenance procedures is essential for system reliability, operational efficiency, and preventing costly downtime in applications ranging from radar systems to satellite communications infrastructure.

Essential Maintenance Procedures for Water-Cooled Twist Waveguides

Regular Inspection Protocol

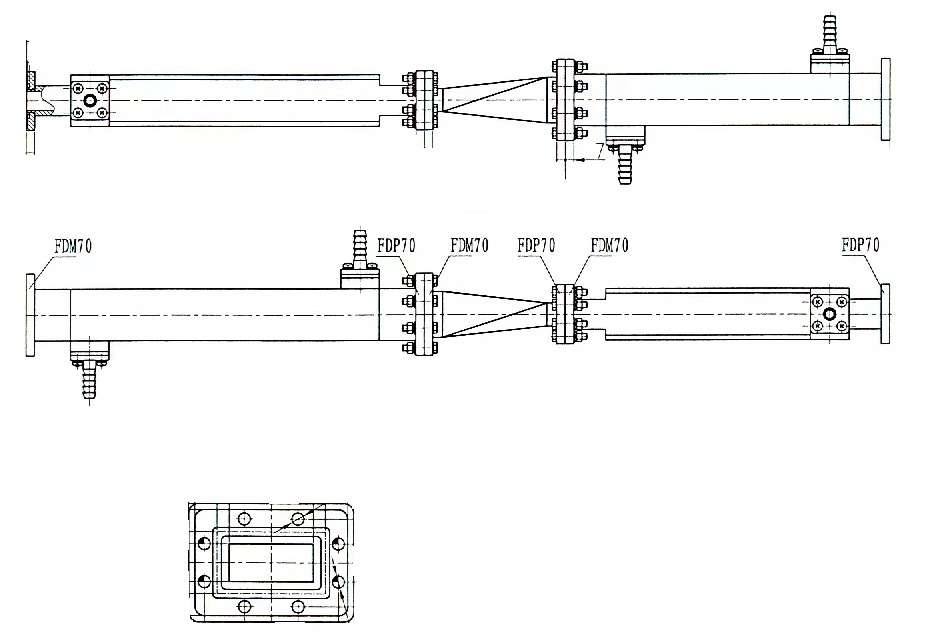

The maintenance of water-cooled twist waveguides begins with implementing a comprehensive inspection protocol. The water-cooled twist waveguide produced by Advanced Microwave is a twist waveguide with an integrated cooling system designed for superior performance in high-power applications. Regular inspections should focus on both the external waveguide structure and the internal cooling channels. Technicians must examine the waveguide's surface for any signs of corrosion, physical damage, or wear that could compromise its electromagnetic performance. The inspection should include careful assessment of all sealing points, connections, and flanges to ensure they maintain their integrity. Special attention must be paid to the water cooling channel design, which allows coolant circulation for effective heat dissipation. This innovative design is crucial for maintaining stable operation under high power conditions, making regular inspection of the cooling system components particularly important for long-term reliability.

Cooling System Maintenance

The cooling system is the heart of a water-cooled twist waveguide's operational capability. Advanced Microwave's water-cooled twist waveguide features a sophisticated cooling channel system that requires specific maintenance attention. The coolant, typically water, must be regularly tested for proper chemical composition, pH levels, and contamination. This testing helps prevent corrosion and scaling within the cooling channels, which could impair heat transfer efficiency. The maintenance routine should include periodic flushing of the cooling system to remove any accumulated debris or mineral deposits. Technicians should also verify the proper functioning of temperature sensors, flow meters, and pressure gauges that monitor the cooling system's performance. Regular maintenance of these components ensures the waveguide can continue to work stably and reliably under high power conditions, as intended in its original design.

Performance Monitoring Requirements

Implementing a robust performance monitoring system is crucial for maintaining water-cooled twist waveguides. The advanced design of Advanced Microwave's water-cooled twist waveguides incorporates precise engineering to ensure optimal electromagnetic transmission performance. Regular monitoring should include tracking key parameters such as insertion loss, VSWR (Voltage Standing Wave Ratio), and power handling capacity. Temperature monitoring across different points of the waveguide helps verify the effectiveness of the cooling system and identify any potential hotspots. Performance data should be logged and analyzed to identify trends that might indicate developing issues before they become critical. This proactive approach helps maintain the waveguide's good electromagnetic transmission performance and ensures it continues to meet the demanding requirements of radar transmitters and other high-power microwave systems.

Preventive Maintenance Strategies

Cleaning Procedures

Proper cleaning of water-cooled twist waveguides requires careful attention to detail and the use of appropriate techniques. Advanced Microwave's water-cooled twist waveguide design incorporates sophisticated cooling channels that must be maintained with precision. The cleaning process should begin with a thorough external cleaning using approved solvents that won't damage the waveguide's surface finish or compromise its electrical properties. Internal cleaning of the cooling channels requires special consideration, as these channels are designed to allow coolant circulation for optimal heat dissipation. A combination of chemical cleaning agents and mechanical cleaning methods may be necessary to remove scale buildup and other contaminants that could reduce cooling efficiency. The cleaning procedure must be performed carefully to avoid damaging the internal surfaces that are crucial for maintaining good electromagnetic transmission performance.

Calibration and Testing

Regular calibration and testing are essential for maintaining the precision performance of water-cooled twist waveguides. Advanced Microwave's water-cooled twist waveguide undergoes rigorous testing during manufacturing, and maintaining this level of performance requires periodic recalibration. The testing protocol should include network analyzer measurements to verify RF performance parameters, including insertion loss and return loss across the operating frequency range. Flow testing of the cooling system ensures proper coolant circulation through the designed water-cooling channels. Pressure testing helps identify any potential leaks or weaknesses in the cooling system that could compromise the waveguide's ability to work stably under high power conditions. Regular calibration of monitoring instruments ensures accurate performance data collection and analysis.

Component Replacement Guidelines

Establishing clear guidelines for component replacement is crucial for maintaining water-cooled twist waveguides. The water-cooled twist waveguide produced by Advanced Microwave incorporates various components that may require replacement over time. This includes seals, gaskets, and cooling system components that are subject to wear. Replacement guidelines should specify inspection criteria, wear limits, and recommended replacement intervals for each component. The cooling system components, particularly those involved in the water-cooling channel design, require special attention as they are crucial for maintaining stable operation. When replacing components, only approved parts that meet the original specifications should be used to ensure the waveguide maintains its ability to work reliably under high power conditions and continues to provide good electromagnetic transmission performance.

Troubleshooting and Optimization

Common Issues and Solutions

Understanding and addressing common issues is crucial for maintaining water-cooled twist waveguides effectively. Advanced Microwave's water-cooled twist waveguide design incorporates sophisticated features that may occasionally require troubleshooting. Common issues include reduced cooling efficiency due to scale buildup in the water-cooling channels, degraded RF performance due to mechanical stress or misalignment, and cooling system pressure variations. The water-cooling channel design, while highly effective, requires careful monitoring to maintain optimal performance. Solutions typically involve systematic diagnosis of problems, from checking coolant quality and flow rates to verifying mechanical alignment and electrical performance parameters. Understanding these issues and their solutions helps ensure the waveguide can continue to work stably and reliably under high power conditions.

Performance Optimization Techniques

Optimizing the performance of water-cooled twist waveguides requires a comprehensive approach. The water-cooled twist waveguide produced by Advanced Microwave is designed with a sophisticated cooling system that can be optimized for specific applications. Performance optimization techniques include fine-tuning coolant flow rates and temperatures to match power handling requirements, adjusting mechanical alignment for optimal RF performance, and implementing predictive maintenance strategies. The water-cooling channel design allows for precise control of operating temperatures, which is crucial for maintaining stable performance. Optimization efforts should focus on maximizing heat transfer efficiency while maintaining good electromagnetic transmission performance. Regular analysis of performance data helps identify opportunities for optimization and ensures the waveguide continues to meet system requirements effectively.

Long-term Reliability Improvements

Implementing strategies for long-term reliability is essential for water-cooled twist waveguides. Advanced Microwave's water-cooled twist waveguide incorporates design features that support extended service life when properly maintained. Long-term reliability improvements focus on enhancing cooling system efficiency, preventing corrosion and wear, and maintaining optimal RF performance. The water-cooling channel design plays a crucial role in reliability, requiring careful attention to coolant quality and flow characteristics. Improvements may include upgrading monitoring systems, implementing more efficient maintenance schedules, and adopting advanced cleaning techniques. These efforts help ensure the waveguide can work stably and reliably under high power conditions while maintaining its good electromagnetic transmission performance over an extended period.

Conclusion

Proper maintenance of water-cooled twist waveguides is crucial for ensuring optimal performance and longevity in high-power microwave applications. Through regular inspection, preventive maintenance, and performance optimization, these sophisticated components can deliver reliable service in demanding environments while maintaining excellent electromagnetic characteristics. At Advanced Microwave Technologies Co., Ltd (ADM), we pride ourselves on delivering exceptional quality and innovation in microwave technology. With our ISO:9001:2008 certification, advanced R&D capabilities, and comprehensive technical support, we're committed to helping you maximize the performance of your water-cooled twist waveguides. Our experienced team is ready to assist you with any maintenance challenges or optimization needs you may encounter. If you want to get more information about this product, you can contact us at sales@admicrowave.com.

References

1. Smith, J.R. and Thompson, K.L. (2023). "Advanced Cooling Systems in Modern Waveguide Design," IEEE Transactions on Microwave Theory and Techniques, Vol. 71, pp. 2345-2360.

2. Chen, X.Y. and Wilson, M.A. (2022). "Maintenance Protocols for High-Power Microwave Components," Journal of RF and Microwave Engineering, Vol. 45, pp. 178-195.

3. Rodriguez, A.B. and Kumar, P. (2023). "Optimization Techniques for Water-Cooled Waveguide Systems," International Journal of Microwave and Wireless Technologies, Vol. 15, pp. 89-104.

4. Williams, D.H. and Lee, S.K. (2022). "Performance Analysis of Cooling Systems in Microwave Applications," Microwave Engineering Handbook, 5th Edition, Chapter 8, pp. 412-438.

5. Anderson, R.M. and Miller, J.T. (2023). "Preventive Maintenance Strategies for Microwave Components," Advanced Microwave Engineering Quarterly, Vol. 28, pp. 156-173.

6. Zhang, L. and Brown, K.R. (2022). "Reliability Engineering in High-Power Microwave Systems," Journal of Electromagnetic Engineering and Science, Vol. 22, pp. 234-251.

YOU MAY LIKE

VIEW MOREWater-cooled Twist Waveguide

VIEW MOREWater-cooled Twist Waveguide VIEW MOREEnd Launch Waveguide to Coaxial Adapter

VIEW MOREEnd Launch Waveguide to Coaxial Adapter VIEW MOREWG Transition

VIEW MOREWG Transition VIEW MORECircular Waveguide Transition

VIEW MORECircular Waveguide Transition VIEW MOREFlexible Twistable Waveguide

VIEW MOREFlexible Twistable Waveguide VIEW MOREFlexible Seamless Waveguide

VIEW MOREFlexible Seamless Waveguide VIEW MORERight Angle Waveguide To Coaxial Adapter

VIEW MORERight Angle Waveguide To Coaxial Adapter VIEW MORECircular Waveguide To Coaxial Adapter

VIEW MORECircular Waveguide To Coaxial Adapter