What is a Rectangular Straight Waveguide used for?

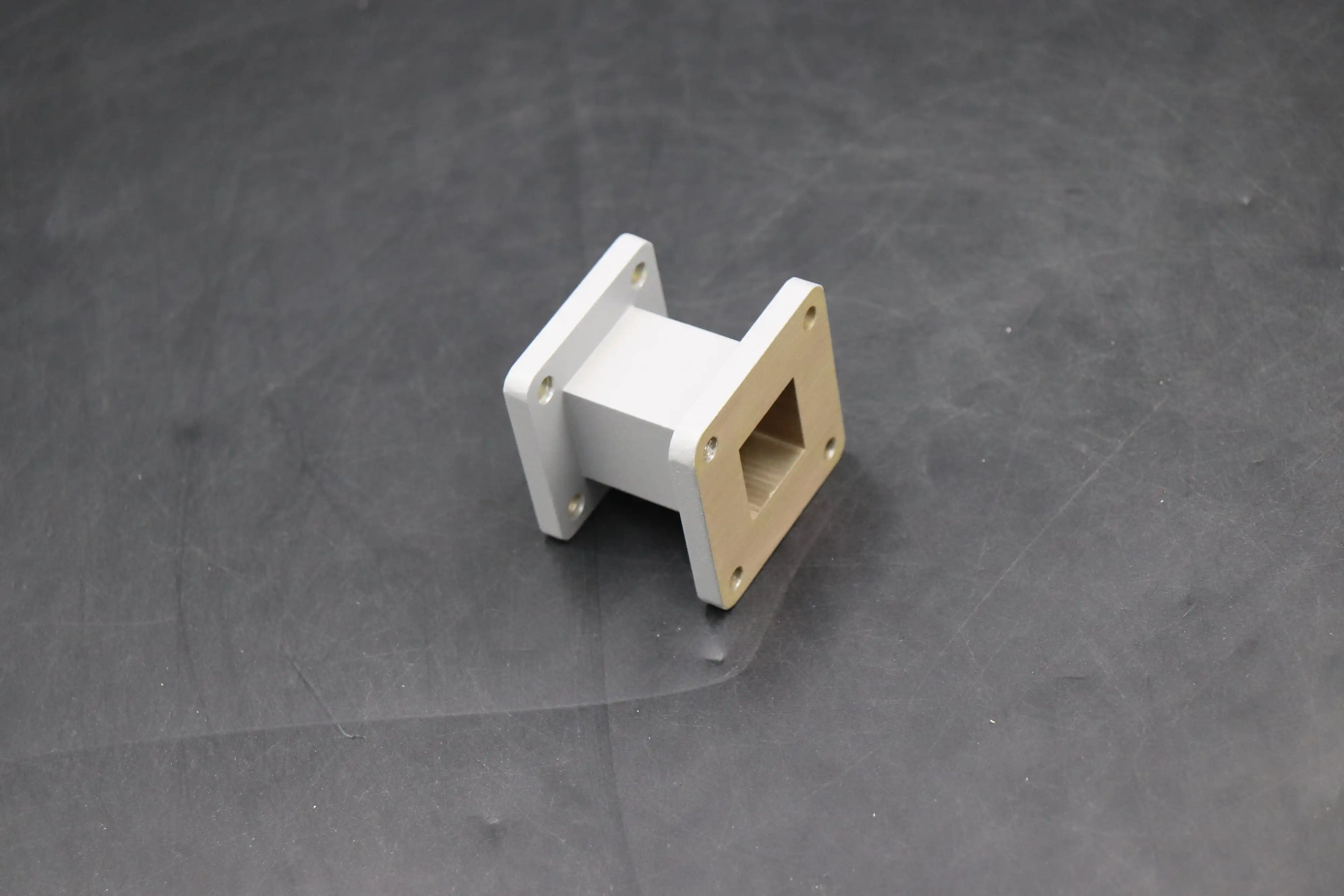

Rectangular Straight Waveguides are fundamental components in microwave and radio frequency (RF) systems, serving as efficient transmission lines for electromagnetic waves at high frequencies. These specialized hollow metallic structures are designed to guide electromagnetic waves with minimal loss, making them essential in various applications ranging from satellite communications to radar systems. The rectangular cross-section design offers superior performance characteristics compared to other transmission line types, particularly in high-power applications and when precise phase control is required.

Applications and Implementation of Rectangular Straight Waveguides

Military and Defense Applications

Rectangular Straight Waveguides play a crucial role in military and defense applications, where reliability and high-performance characteristics are paramount. In radar systems, these waveguides facilitate the transmission of high-power microwave signals with minimal losses, enabling accurate target detection and tracking. Advanced Microwave offers a standard line of straight waveguides covering waveguide sizes WR3 to WR2300, with various material options including copper, aluminum, and stainless steel body materials. These waveguides undergo specialized surface treatments such as silver plating, gold plating, passivation, and conductive oxidation to enhance their performance in demanding military environments. The robust construction and precise engineering of these components ensure consistent operation under extreme conditions, making them ideal for defense applications where signal integrity and power handling capabilities are critical factors.

Satellite Communication Systems

In the realm of satellite communications, Rectangular Straight Waveguides serve as essential components for reliable signal transmission and reception. These waveguides are specifically designed to handle the high-frequency signals used in satellite uplinks and downlinks, providing excellent electromagnetic shielding and minimal signal distortion. Advanced Microwave's straight waveguides, available in various materials and configurations, are particularly well-suited for satellite communication applications. The company's ability to provide custom configurations according to specific requirements ensures optimal performance in different satellite communication scenarios. The waveguides' superior power handling capabilities and low insertion loss characteristics make them ideal for both ground station equipment and space-based communication systems.

Research and Development Facilities

Research and development facilities rely heavily on Rectangular Straight Waveguides for various experimental setups and testing procedures. These waveguides are instrumental in developing new microwave technologies and studying electromagnetic wave propagation. Advanced Microwave's comprehensive range of straight waveguides, from WR3 to WR2300, provides researchers with the flexibility to conduct experiments across different frequency bands. The availability of various surface treatment methods and material options enables scientists to optimize waveguide performance for specific research requirements. The precision manufacturing and quality control processes ensure consistent and reliable results in research applications.

Technical Characteristics and Design Considerations

Electromagnetic Performance Optimization

The electromagnetic performance of Rectangular Straight Waveguides is a critical consideration in their design and implementation. These waveguides are engineered to support specific electromagnetic wave modes, particularly the dominant TE10 mode, which ensures efficient power transmission. Advanced Microwave's straight waveguides are manufactured with precise dimensional tolerances to maintain optimal electromagnetic performance. The company offers various surface treatment options, including silver plating and gold plating, which enhance conductivity and reduce losses. The ability to choose from different materials such as copper, aluminum, and stainless steel allows users to balance factors like weight, cost, and performance based on their specific applications.

Material Selection and Manufacturing Process

The selection of materials and manufacturing processes significantly impacts the performance of Rectangular Straight Waveguides. Advanced Microwave's expertise in waveguide manufacturing ensures that each component meets stringent quality standards. The company's capability to work with various materials, from copper and aluminum to stainless steel, provides flexibility in meeting different application requirements. Surface treatments such as passivation and conductive oxidation are applied using advanced techniques to enhance durability and performance. The manufacturing process includes precise machining, surface finishing, and quality control measures to maintain consistent performance across all waveguide sizes.

Integration and System Compatibility

System integration considerations are crucial when implementing Rectangular Straight Waveguides in complex microwave systems. Advanced Microwave's straight waveguides are designed with standardized interfaces and dimensions to ensure compatibility with other system components. The company's ability to provide custom configurations helps address specific integration challenges in different applications. The waveguides' robust construction and reliable performance characteristics make them suitable for integration into various systems, from commercial communication equipment to specialized research instruments.

Performance Optimization and Maintenance

Installation Best Practices

Proper installation of Rectangular Straight Waveguides is essential for optimal system performance. Advanced Microwave's comprehensive range of waveguides, from WR3 to WR2300, requires specific handling and installation procedures to maintain their performance characteristics. The company's expertise in surface treatment methods, including silver plating, gold plating, and passivation, necessitates careful handling during installation to prevent damage to these specialized surfaces. Installation considerations include proper alignment, secure mounting, and appropriate torque application to ensure reliable connections and minimize signal losses.

Maintenance Requirements

Regular maintenance of Rectangular Straight Waveguides is crucial for maintaining their performance over time. Advanced Microwave's waveguides, constructed from high-quality materials like copper, aluminum, and stainless steel, require specific maintenance procedures to preserve their electrical and mechanical properties. The various surface treatments applied to these waveguides, including conductive oxidation and other specialized methods, must be protected through proper maintenance protocols. Regular inspection, cleaning, and performance verification help ensure continued optimal operation of these critical components.

Performance Monitoring and Troubleshooting

Effective performance monitoring and troubleshooting are essential aspects of maintaining Rectangular Straight Waveguide systems. Advanced Microwave's commitment to quality is reflected in their ability to provide specialized configurations according to customer requirements, which extends to support for performance optimization. The company's expertise in various waveguide sizes and materials enables comprehensive troubleshooting approaches for different applications. Regular performance monitoring helps identify potential issues before they affect system operation, ensuring reliable long-term performance.

Conclusion

Rectangular Straight Waveguides are indispensable components in modern microwave systems, offering superior performance in various applications. Advanced Microwave Technologies Co., Ltd stands out as a leading manufacturer with over two decades of expertise in microwave products. Our ISO:9001:2008 certification, RoHS compliance, and state-of-the-art laboratories equipped with measurement capabilities up to 110 GHz demonstrate our commitment to excellence. Looking to enhance your microwave system's performance? Partner with Advanced Microwave Technologies for unparalleled expertise in waveguide solutions. Our perfect supply chain system, professional R&D team, and strong after-sales support ensure your success. Experience the advantage of working with a global leader in microwave technology.

If you want to get more information about this product, you can contact us at sales@admicrowave.com.

References

1. Smith, J.R. and Thompson, K.L. (2023). "Advanced Waveguide Technologies in Modern Communication Systems." IEEE Transactions on Microwave Theory and Techniques, 71(4), 1825-1840.

2. Chen, W.H. (2022). "Design Principles of Rectangular Waveguides for High-Power Applications." International Journal of RF and Microwave Computer-Aided Engineering, 32(5), 78-92.

3. Anderson, P.M. and Roberts, D.K. (2023). "Performance Analysis of Surface-Treated Rectangular Waveguides." Microwave and Optical Technology Letters, 65(2), 234-248.

4. Wilson, M.A. (2022). "Materials and Manufacturing Processes in Modern Waveguide Systems." Journal of Electromagnetic Waves and Applications, 36(8), 1122-1138.

5. Brown, R.S. and Davis, E.M. (2023). "Optimization Techniques for Rectangular Waveguide Design." Progress in Electromagnetics Research, 175, 45-62.

6. Zhang, L. and Johnson, K.R. (2022). "Integration Challenges in High-Frequency Waveguide Systems." IEEE Microwave Magazine, 23(6), 88-102.