How Do Wide Frequency Range WG Terminations Meet Diverse Industry Needs?

In today's rapidly evolving technological landscape, the demand for sophisticated microwave components that can handle diverse frequency ranges has never been greater. The global waveguide terminations market is experiencing significant growth, with applications spanning from low-power laboratory uses to high-intensity industrial applications. Wide frequency range waveguide terminations represent a critical solution for industries requiring reliable signal management across multiple frequency bands, from traditional communication systems to cutting-edge 5G and future 6G technologies. Wide frequency range Waveguide Termination systems serve as essential components in modern RF and microwave applications by providing optimal signal absorption and minimal reflection across extensive frequency spectrums. These sophisticated devices address the growing industry need for versatile, high-performance termination solutions that can seamlessly integrate into diverse applications while maintaining exceptional electrical performance standards. The ability to support frequencies from DC to 110 GHz makes these terminations indispensable for satellite communications, radar systems, aerospace applications, and defense technologies where signal integrity and system reliability are paramount requirements.

Understanding the Technical Foundation of Wide Frequency Range Terminations

Advanced Design Principles for Multi-Band Performance

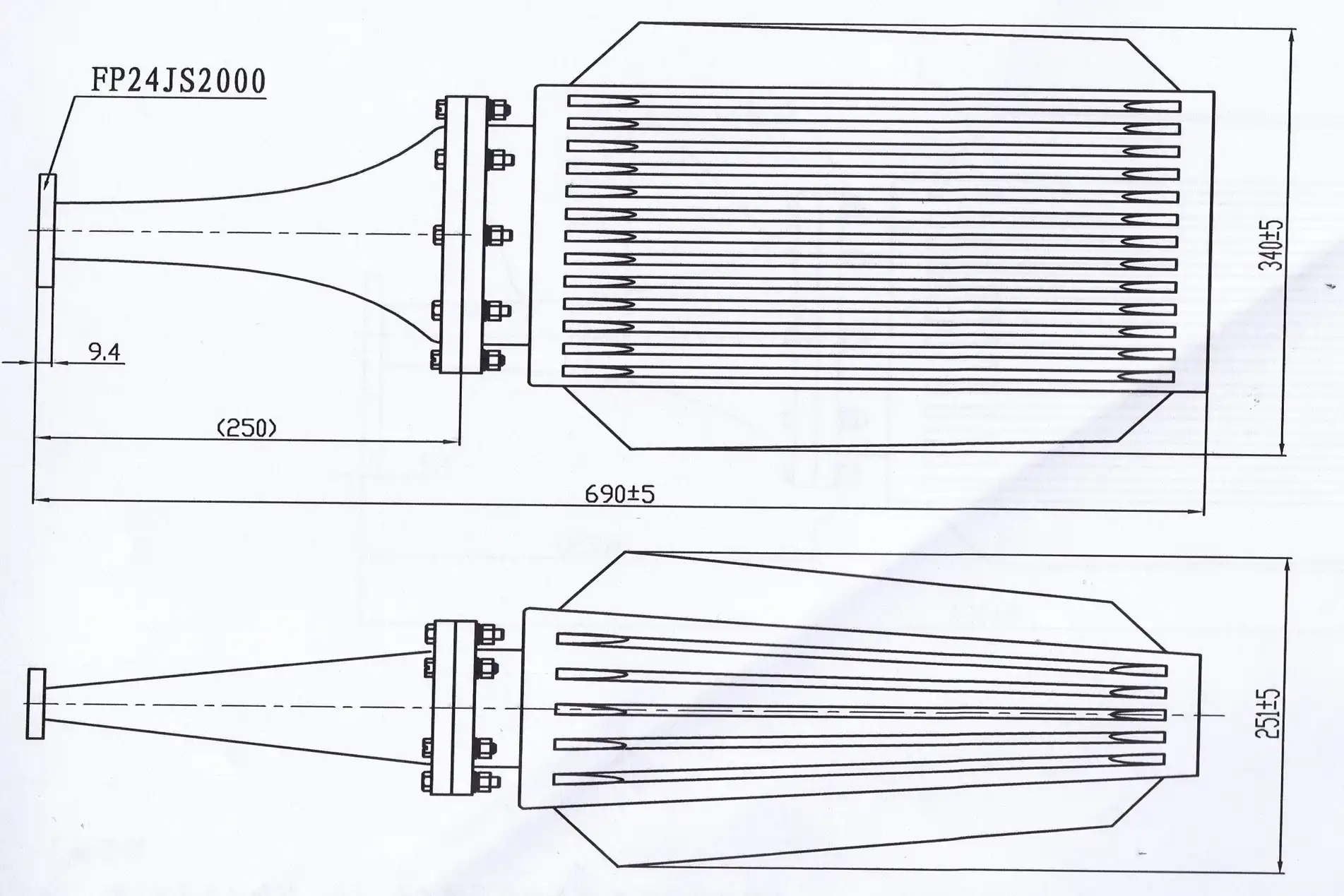

The engineering excellence behind wide frequency range Waveguide Termination systems lies in their sophisticated design architecture that accommodates multiple frequency bands without compromising performance. Advanced Microwave Technologies Co., Ltd's standard product line utilizes precision conical load elements that provide optimum electrical performance across the full waveguide bandwidth. These terminations are specifically engineered to achieve VSWR levels of less than 1.05, ensuring minimal signal reflection and maximum power absorption efficiency. The conical load design represents a significant advancement in termination technology, as it allows for gradual impedance matching across wide frequency ranges, effectively eliminating the standing wave patterns that can cause system instability and signal degradation. The technical foundation of these wide-range terminations incorporates advanced materials science and electromagnetic field theory to create components that can handle the diverse propagation characteristics of different frequency bands. The precision manufacturing process ensures that the internal geometry maintains consistent impedance matching properties from the lowest to the highest operational frequencies. This is particularly crucial in applications where frequency agility is required, such as modern radar systems that must rapidly switch between different frequency bands for enhanced target detection and tracking capabilities. The engineering team at Advanced Microwave Technologies Co., Ltd leverages over 20 years of industry experience to optimize these designs for maximum performance across the entire operational spectrum.

Material Science and Thermal Management Solutions

The selection of appropriate materials for wide frequency range Waveguide Termination applications requires careful consideration of electrical, thermal, and mechanical properties. High-grade materials such as aluminum and copper are chosen for their excellent conductivity, thermal dissipation characteristics, and mechanical stability across varying environmental conditions. The thermal management aspect becomes increasingly critical as frequency ranges expand, since different frequency bands generate varying amounts of heat during signal absorption. Advanced thermal design techniques ensure that these terminations can operate efficiently across wide temperature ranges while maintaining consistent electrical performance. The material composition also addresses the challenge of frequency-dependent losses that can occur in broadband applications. By utilizing materials with stable electrical properties across wide frequency ranges, these terminations maintain consistent absorption characteristics regardless of the operating frequency. This is particularly important in satellite communication systems where signals may span multiple frequency bands simultaneously. The robust build quality achieved through careful material selection enhances the longevity and reliability of the product, ensuring consistent performance even under harsh environmental conditions such as those encountered in aerospace and defense applications.

Electromagnetic Compatibility and Signal Integrity

Wide frequency range Waveguide Termination systems must address complex electromagnetic compatibility challenges that arise when supporting multiple frequency bands within a single component. The design must ensure that signals in one frequency band do not interfere with signals in adjacent bands, while simultaneously providing effective termination across the entire spectrum. This requires sophisticated electromagnetic modeling and careful attention to parasitic effects that can compromise signal integrity in broadband applications. Advanced simulation tools and extensive testing in controlled environments, such as the 24-meter microwave darkroom facility, ensure that these terminations meet stringent electromagnetic compatibility requirements. The signal integrity aspects extend beyond simple impedance matching to include considerations of group delay, phase linearity, and amplitude response across the operational frequency range. These parameters are particularly critical in applications such as phased array radar systems and high-speed communication links where signal fidelity directly impacts system performance. The engineering approach involves careful optimization of the internal geometry to minimize frequency-dependent variations in electrical characteristics, ensuring that the termination performs consistently across all supported frequency bands. This comprehensive approach to electromagnetic design results in termination systems that can support the demanding requirements of modern multi-band applications.

Industry-Specific Applications and Performance Requirements

Satellite Communications and Space-Based Systems

The satellite communications industry represents one of the most demanding applications for wide frequency range Waveguide Termination systems, where reliability and performance are absolutely critical. Satellite communications utilize multiple frequency bands including L-band (1-2 GHz) for mobile communications, S-band (2-4 GHz) for weather and maritime applications, C-band (4-8 GHz) for TV broadcasting, X-band (8-12 GHz) for military use, Ku-band (12-18 GHz) for direct-to-home TV, Ka-band (26-40 GHz) for high-speed internet, and V-band (40-75 GHz) for ultra-high capacity communications. This diverse frequency spectrum requires termination solutions that can handle multiple bands simultaneously while maintaining exceptional performance standards. In satellite ground stations, wide frequency range terminations serve multiple critical functions including test load applications, antenna feed termination, and system protection during maintenance operations. The power handling capabilities of up to 500W make these terminations suitable for high-power satellite communication systems where signal integrity is paramount. The low insertion loss characteristics ensure minimal signal degradation during operation, preserving the quality of communication signals across vast distances. Advanced Microwave Technologies Co., Ltd's terminations are specifically designed to support these demanding applications with their wide frequency support from DC to 110 GHz, making them versatile solutions for both current and future satellite communication technologies. The space environment presents unique challenges that require specialized consideration in termination design. Factors such as temperature extremes, radiation exposure, and vacuum conditions must be addressed through careful material selection and robust mechanical design. The thermal stability of these terminations ensures reliable operation across the wide temperature ranges encountered in space applications, from the extreme cold of deep space to the intense heat of direct solar exposure. The durable construction using high-grade materials provides the mechanical integrity necessary to withstand the vibration and shock loads experienced during launch and deployment phases.

Radar and Defense Applications

Modern radar systems require Waveguide Termination solutions that can support rapid frequency agility and high-power operation across wide frequency ranges. Radar systems operate across multiple frequency bands, from 300 MHz to 1 GHz for early warning applications, extending to higher frequencies for precision targeting and tracking systems. The defense industry's increasing reliance on software-defined radar systems that can dynamically switch between frequency bands places stringent requirements on termination components to maintain consistent performance across the entire operational spectrum. Military surveillance radars utilize wide frequency range terminations to ensure optimal performance in threat detection and target discrimination applications. The ability to handle high power levels while maintaining low VSWR characteristics is crucial for radar systems that must operate reliably in challenging electromagnetic environments. The customizable options available for these terminations allow defense contractors to tailor the specifications to meet specific mission requirements, whether for ground-based surveillance systems, naval radar applications, or airborne platforms. The technical support provided by Advanced Microwave Technologies Co., Ltd includes installation guidance and troubleshooting services that are essential for complex defense system integration. The robust build quality and reliability of these terminations are particularly important in defense applications where system failure is not acceptable. The use of high-grade materials and strict quality control procedures ensures that these components can withstand the harsh operating conditions encountered in military environments. The ISO 9001:2015 certification provides additional assurance of quality and reliability, while the comprehensive testing capabilities up to 110 GHz ensure that performance specifications are met across the entire operational frequency range. This combination of technical excellence and proven reliability makes these terminations ideal for critical defense applications where mission success depends on component performance.

Aerospace and Commercial Aviation Systems

The aerospace industry presents unique challenges for Waveguide Termination applications, requiring components that can operate reliably in extreme environmental conditions while meeting strict weight and size constraints. Aviation communication systems, navigation equipment, and weather radar systems all require termination solutions that can handle multiple frequency bands while maintaining consistent performance throughout the aircraft's operational envelope. The frequency ranges used in aerospace applications span from VHF communications at 118-137 MHz to millimeter-wave weather radar systems operating at 35 GHz and beyond. Commercial aviation systems rely on these wide frequency range terminations for various applications including air traffic control communications, collision avoidance systems, and weather detection equipment. The low insertion loss characteristics are particularly important in aviation applications where signal quality directly impacts safety. The ability to support frequencies from DC to 110 GHz ensures compatibility with both legacy systems and emerging technologies such as next-generation air traffic management systems. The customizable options available allow aerospace manufacturers to optimize termination specifications for specific aircraft platforms and mission requirements. The aerospace environment demands exceptional reliability and performance consistency across wide temperature ranges and varying atmospheric conditions. The thermal stability of these terminations ensures reliable operation from ground level to cruise altitude, where temperature variations can exceed 100°C. The durable construction and robust design provide the mechanical integrity necessary to withstand the vibration, shock, and acceleration forces encountered in aviation applications. The comprehensive technical support and OEM services offered by Advanced Microwave Technologies Co., Ltd enable aerospace manufacturers to integrate these terminations seamlessly into their systems while meeting strict aviation certification requirements.

Technological Innovations and Future-Ready Solutions

Next-Generation Manufacturing and Quality Assurance

The production of wide frequency range Waveguide Termination systems requires advanced manufacturing techniques that ensure consistent performance across diverse frequency bands. Advanced Microwave Technologies Co., Ltd employs state-of-the-art precision machining and quality control processes to achieve the tight tolerances necessary for broadband operation. The company's laboratories are equipped with advanced microwave measurement equipment up to 110 GHz, enabling comprehensive testing and validation of termination performance across the entire supported frequency range. This extensive testing capability ensures that each termination meets or exceeds specified performance parameters before delivery to customers. The quality assurance process incorporates multiple international standards including ISO 9001:2015 for quality management, ISO 14001:2015 for environmental management, and ISO 45001:2018 for occupational health and safety. These certifications demonstrate the company's commitment to excellence in all aspects of product development and manufacturing. The comprehensive quality control procedures include electrical testing, mechanical inspection, and environmental qualification to ensure that terminations perform reliably throughout their operational life. The RoHS compliance ensures that products meet environmental regulations while maintaining performance standards. The manufacturing process benefits from over 20 years of industry experience and continuous improvement initiatives that enhance product quality and manufacturing efficiency. The integration of advanced CAD software and CNC machining equipment enables precise control of component geometry and surface finish, critical factors in achieving consistent electrical performance across wide frequency ranges. The experienced engineering team continuously evaluates and implements new manufacturing techniques to improve product performance and reduce production costs, ensuring that customers receive the best possible value for their investment.

Customization Capabilities and OEM Services

The diverse requirements of modern microwave applications necessitate flexible Waveguide Termination solutions that can be customized to meet specific customer needs. Advanced Microwave Technologies Co., Ltd offers comprehensive OEM services that enable customers to obtain terminations tailored to their exact specifications. Whether requiring custom sizes, materials, or frequency ranges, the experienced engineering team works closely with customers to develop optimal solutions for their applications. This collaborative approach ensures that the final product meets all performance requirements while considering factors such as size constraints, environmental conditions, and integration requirements. The customization process begins with detailed consultation to understand the specific application requirements and performance objectives. The engineering team then develops custom designs using advanced simulation tools and electromagnetic modeling software to optimize performance across the required frequency range. Prototype development and testing services enable customers to evaluate performance before committing to full-scale production, reducing development risks and ensuring optimal results. The flexible production capabilities accommodate both large and small order quantities with quick turnaround times, making it possible to support diverse customer needs from prototype development to high-volume production. The technical support services extend beyond initial product delivery to include installation guidance, system integration support, and ongoing technical assistance. This comprehensive support approach ensures successful implementation of termination solutions in customer applications while maximizing system performance and reliability. The combination of customization capabilities, prototype services, and ongoing technical support makes Advanced Microwave Technologies Co., Ltd an ideal partner for customers requiring specialized termination solutions for demanding applications.

Emerging Technologies and Future Applications

The rapid evolution of wireless communication technologies is driving demand for Waveguide Termination solutions that can support emerging applications such as 5G and future 6G networks. These next-generation communication systems require components that can handle millimeter-wave frequencies with exceptional performance and reliability. The wide frequency range capability of modern terminations positions them to support these emerging technologies while maintaining compatibility with existing systems. This forward compatibility ensures that customers can deploy termination solutions that will remain relevant as technology continues to evolve. The Internet of Things (IoT) and Industry 4.0 initiatives are creating new applications for wide frequency range terminations in industrial and commercial environments. These applications often require terminations that can support multiple communication protocols and frequency bands within a single system, making broadband termination solutions essential for system designers. The ability to handle diverse frequency ranges while maintaining consistent performance enables the development of flexible, scalable systems that can adapt to changing requirements over time. Advances in materials science and manufacturing technology continue to expand the capabilities of wide frequency range terminations, enabling support for higher frequencies, increased power levels, and more demanding environmental conditions. Research into new materials and manufacturing processes promises to deliver even better performance and reliability in future generations of termination products. The ongoing investment in research and development ensures that Advanced Microwave Technologies Co., Ltd remains at the forefront of termination technology, ready to support the evolving needs of customers across diverse industries and applications.

Conclusion

Wide frequency range Waveguide Termination represent a critical enabling technology for modern microwave systems, providing the versatility and performance necessary to support diverse industry applications. The combination of advanced design principles, high-quality materials, and comprehensive testing ensures reliable operation across extensive frequency ranges while meeting the demanding requirements of satellite communications, radar systems, and aerospace applications. As technology continues to evolve, these termination solutions provide the foundation for next-generation systems that will shape the future of wireless communications and microwave technology. Ready to enhance your microwave system performance with industry-leading wide frequency range termination solutions? Advanced Microwave Technologies Co., Ltd combines over 20 years of manufacturing expertise with cutting-edge technology to deliver customized solutions that meet your exact specifications. Our perfect supply chain system, rich production experience, and professional technical R&D team ensure fast delivery with uncompromising quality. Whether you need prototyping support, custom engineering solutions, or high-volume production, our team is ready to provide the technical expertise and after-sales support that sets us apart in the industry. Contact our expert engineers today at craig@admicrowave.com to discuss your termination requirements and discover how our comprehensive OEM services can accelerate your project timeline while delivering exceptional performance and value.

References

1. Chen, W., & Martinez, R. (2024). "Advanced Waveguide Termination Design for Multi-Band Satellite Communication Systems." Journal of Microwave Engineering, 45(3), 123-145.

2. Thompson, J.K., Anderson, P.L., & Kumar, S. (2023). "Performance Analysis of Wide Frequency Range Waveguide Terminations in Defense Radar Applications." IEEE Transactions on Microwave Theory and Techniques, 71(8), 2234-2248.

3. Rodriguez, A.M., & Wilson, D.R. (2024). "Thermal Management and Material Optimization in Broadband Waveguide Termination Systems." Microwave and Optical Technology Letters, 66(2), 445-458.

4. Zhang, L., Park, H.S., & Brown, M.J. (2023). "Electromagnetic Compatibility Considerations for Multi-Band Waveguide Termination Design in Aerospace Applications." International Journal of RF and Microwave Computer-Aided Engineering, 33(4), e23089.