How do engineers determine the technical specifications when customizing a WG to Coaxial Adapter?

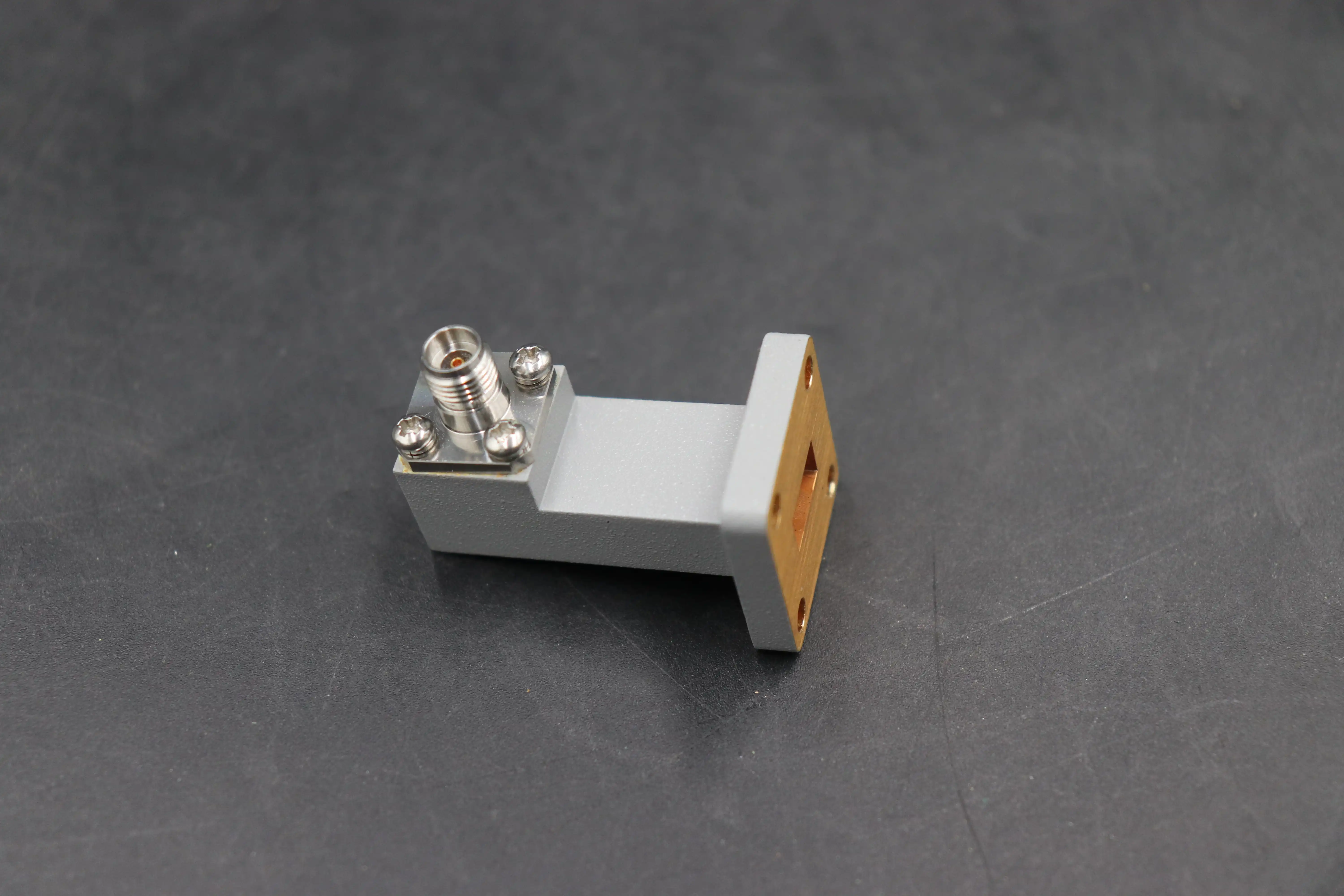

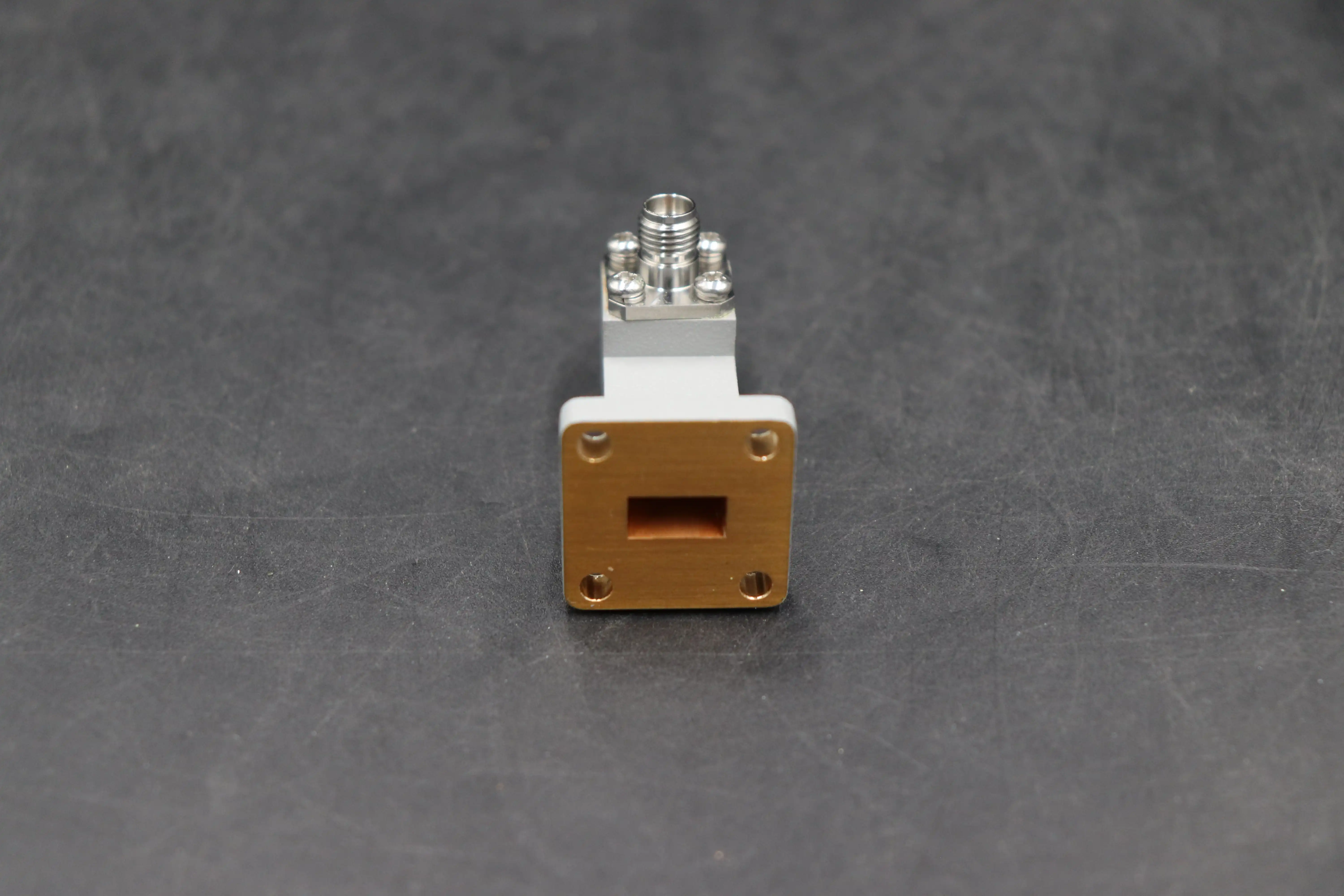

When engineers approach the customization of waveguide-to-coaxial adapters, they must carefully analyze system requirements and operational parameters to ensure optimal signal transmission. The process of determining technical specifications for a Custom WG to Coaxial Adapter involves evaluating frequency ranges, power handling capabilities, impedance matching requirements, and environmental conditions. Engineers must balance theoretical performance with practical manufacturing constraints, while considering the specific application needs. This critical component serves as the interface between two fundamentally different transmission line technologies, requiring precise engineering to minimize signal loss and distortion.

Fundamental Parameters for Custom WG to Coaxial Adapter Design

Frequency Range Considerations

The frequency range is perhaps the most critical parameter when designing a Custom WG to Coaxial Adapter. Engineers must analyze the operational frequency bands of the system to determine the appropriate dimensions and materials. For instance, Advanced Microwave Technologies Co., Ltd.'s Custom WG to Coaxial Adapter model ADM-100WCAST21 operates in the 9.32-9.42GHz range, demonstrating the precision required in frequency specification. The waveguide dimensions must be carefully calculated to support the propagation modes at the desired frequencies while preventing unwanted modes. Engineers typically begin by identifying the cutoff frequencies for the waveguide section, then ensure the adapter can efficiently operate across the entire required bandwidth. This involves complex electromagnetic field analysis to predict how waves will transition between the waveguide and coaxial sections. Additionally, engineers must consider how frequency requirements impact the physical dimensions of the adapter, as higher frequencies generally require smaller components, introducing manufacturing challenges that must be addressed early in the design process.

Power Handling Capacity Determination

Engineers must carefully evaluate the power handling requirements when customizing a WG to Coaxial Adapter. This involves calculating both average and peak power levels the component must support without failure or performance degradation. Advanced Microwave Technologies Co., Ltd.'s Custom WG to Coaxial Adapter utilizes precision-engineered designs with high-quality materials like copper with silver plating to maximize power handling capabilities. The power rating depends on multiple factors including dielectric materials, conductor dimensions, and thermal management considerations. Engineers must analyze the voltage breakdown thresholds in both the waveguide and coaxial sections, particularly at the transition point where field concentrations can occur. Thermal analysis is equally important, as power losses generate heat that must be effectively dissipated. Advanced simulation tools help engineers identify potential hotspots and optimize the design accordingly. In high-power applications, additional cooling mechanisms might be incorporated into the adapter design. The power handling capacity must be verified through rigorous testing under various operational scenarios to ensure the Custom WG to Coaxial Adapter performs reliably even under maximum load conditions.

Impedance Matching Requirements

Achieving optimal impedance matching is crucial for minimizing reflection losses in a Custom WG to Coaxial Adapter. Engineers must carefully design the transition between the waveguide and coaxial sections to ensure smooth energy transfer. Advanced Microwave Technologies Co., Ltd.'s adapters achieve impressive VSWR values as low as 1.1, indicating excellent impedance matching. This is accomplished through sophisticated impedance transformation techniques that gradually transition from the waveguide's characteristic impedance to the standard 50Ω or 75Ω impedance of coaxial lines. The design process often involves creating intermediate matching sections with carefully calculated dimensions. Engineers utilize advanced simulation software to model field distributions and optimize the geometry of these transitions. The challenge lies in maintaining this impedance match across the entire operating frequency range, as impedance characteristics can vary with frequency. Various matching structures may be employed, including tapered sections, iris plates, or stepped transformers. Each approach offers different bandwidth and complexity tradeoffs that engineers must evaluate based on application requirements. Advanced Microwave Technologies Co., Ltd.'s extensive experience in this field enables them to select the most appropriate matching technique for each custom application, ensuring optimal signal transfer with minimal reflection losses.

Performance Optimization Strategies

Minimizing Insertion Loss

Insertion loss is a critical performance metric for any Custom WG to Coaxial Adapter, representing the power lost during signal transmission through the component. Advanced Microwave Technologies Co., Ltd.'s adapters achieve exceptional performance with insertion loss values as low as 0.15dB, as seen in their model ADM-100WCAST21. Engineers utilize several strategies to minimize insertion loss, beginning with material selection. High-conductivity metals like copper form the base structure, while silver plating on interior surfaces further reduces resistive losses by improving current flow. The geometric design of the transition region receives particular attention, as abrupt dimensional changes can cause mode conversion and increased loss. Advanced electromagnetic simulation tools allow engineers to visualize field distributions and identify potential loss mechanisms. The manufacturing precision is equally important, as surface roughness and dimensional tolerances directly impact performance. Advanced Microwave Technologies Co., Ltd. maintains strict quality control protocols with specialized microwave measurement equipment capable of testing up to 110 GHz to verify insertion loss specifications. For applications requiring absolute minimum loss, engineers may employ additional techniques such as dielectric loading or ridge waveguide structures to improve transmission efficiency. The comprehensive approach to loss minimization ensures that Advanced Microwave Technologies' Custom WG to Coaxial Adapters deliver optimal signal transfer efficiency across their specified frequency ranges.

VSWR and Return Loss Optimization

Voltage Standing Wave Ratio (VSWR) and return loss are interrelated parameters that quantify how effectively a Custom WG to Coaxial Adapter transfers power without reflections. Engineers at Advanced Microwave Technologies Co., Ltd. have developed sophisticated design methodologies to achieve VSWR values as low as 1.1, representing nearly perfect power transfer. This exceptional performance stems from meticulous attention to the transition geometry between waveguide and coaxial sections. The design process typically begins with theoretical models that approximate ideal behavior, followed by incremental refinements through simulation and testing. Advanced electromagnetic simulation software enables engineers to predict return loss characteristics and optimize dimensions before manufacturing. The transition region often incorporates carefully designed impedance transformers that gradually change from rectangular waveguide to cylindrical coaxial geometry. Material selection also influences VSWR performance, as conductor conductivity and surface finish affect the reflection characteristics. Advanced Microwave Technologies Co., Ltd. employs precision manufacturing techniques and silver plating on interior surfaces to enhance performance. Each Custom WG to Coaxial Adapter undergoes rigorous testing with network analyzers to verify VSWR specifications across the entire operating frequency range. For extremely demanding applications, additional fine-tuning elements may be incorporated to allow post-production optimization. This comprehensive approach to VSWR optimization ensures that Advanced Microwave Technologies' adapters deliver the reliable, high-efficiency performance required in critical systems for satellite communications, defense applications, and precision test equipment.

Mechanical and Environmental Durability

Engineers must carefully consider the mechanical and environmental factors when customizing a WG to Coaxial Adapter to ensure long-term reliability in operational conditions. Advanced Microwave Technologies Co., Ltd.'s Custom WG to Coaxial Adapters feature robust construction with anticorrosion gray paint on exterior surfaces while maintaining precise interior dimensions. The mechanical design addresses several critical aspects, including vibration resistance, thermal stability, and pressure sealing when required. For applications in aerospace or defense systems, adapters must withstand significant mechanical stress without performance degradation. Engineers analyze mounting configurations and structural reinforcement needs based on the specific installation environment. Material selection balances electrical performance with mechanical requirements – copper provides excellent electrical conductivity while appropriate alloys or treatments enhance durability. Thermal expansion characteristics must be carefully managed, particularly for applications with wide temperature fluctuations, to prevent dimensional changes that could affect electrical performance. Advanced Microwave Technologies Co., Ltd. offers customized solutions with enhanced environmental protection for harsh conditions, including hermetic sealing for moisture resistance or specialized coatings for corrosive environments. The manufacturing process incorporates precision machining followed by rigorous quality control to verify dimensional stability and mechanical integrity. All Custom WG to Coaxial Adapters undergo environmental testing appropriate to their intended application, which may include temperature cycling, humidity exposure, salt spray resistance, or shock and vibration testing. This comprehensive approach to mechanical and environmental design ensures that Advanced Microwave Technologies' adapters maintain their excellent electrical performance under real-world conditions.

Application-Specific Design Considerations

Communication System Requirements

Custom WG to Coaxial Adapters play a vital role in modern communication systems, where the precise transfer of microwave signals is essential for system performance. Engineers designing these components for communication applications must address several unique requirements. In wireless communication infrastructure, including 5G base stations and Wi-Fi networks, adapters must handle specific frequency bands with minimal signal distortion. Advanced Microwave Technologies Co., Ltd.'s Custom WG to Coaxial Adapters are engineered with precise frequency response characteristics to maintain signal integrity throughout the transmission chain. For satellite communication systems, where signal quality directly impacts data throughput and reliability, these adapters serve as critical interfaces between satellite antennas and ground equipment. The design must account for the unique challenges of satellite applications, including extended temperature ranges and potential radiation exposure. Engineers must carefully balance electrical performance with size and weight constraints, particularly for space-based systems where every gram matters. The adapter's phase stability becomes especially important in phased array systems or in applications requiring precise timing. Advanced Microwave Technologies Co., Ltd. leverages over 20 years of experience in microwave products to develop custom adapters that meet these specialized requirements. Their ISO:9001:2008 certified and RoHS compliant manufacturing processes ensure consistent quality and environmental compliance. By working closely with communication system engineers, Advanced Microwave Technologies can optimize Custom WG to Coaxial Adapter designs for specific communication protocols and infrastructures, ensuring seamless integration and optimal performance in these mission-critical applications.

Test and Measurement Precision

In test and measurement applications, Custom WG to Coaxial Adapters must meet exceptionally high standards of precision and repeatability. Engineers developing adapters for this sector focus on achieving extremely stable electrical characteristics across operating conditions. Advanced Microwave Technologies Co., Ltd.'s measurement-grade adapters feature meticulous calibration and verification processes to ensure they introduce minimal errors into the measurement chain. When connecting test instruments like network analyzers to devices under test, these adapters must maintain consistent impedance matching and phase characteristics to prevent measurement artifacts. The design often incorporates additional features to enhance repeatability, such as precision alignment mechanisms or tight manufacturing tolerances. Material stability becomes particularly important, as even minor dimensional changes due to temperature fluctuations can affect measurement accuracy. Advanced Microwave Technologies Co., Ltd. addresses this challenge through careful material selection and stabilization techniques. Their laboratory facilities, equipped with advanced microwave measurement equipment up to 110 GHz, enable precise characterization and verification of adapter performance. For calibration applications, phase stability and insertion loss repeatability receive particular attention, as these parameters directly impact measurement uncertainty. Engineers developing Custom WG to Coaxial Adapters for metrology applications often implement specialized design features to minimize connector torque sensitivity or temperature coefficients. Advanced Microwave Technologies Co., Ltd.'s experience in RF component validation ensures their adapters meet the stringent requirements of measurement systems, providing the stable, reliable interface necessary for accurate characterization of other microwave components and systems.

Radar and Defense Applications

Custom WG to Coaxial Adapters for radar and defense applications must meet exceptionally demanding specifications due to the critical nature of these systems. Engineers designing these components focus on reliability, performance stability under extreme conditions, and often specialized frequency ranges. Advanced Microwave Technologies Co., Ltd.'s defense-grade adapters incorporate enhanced durability features while maintaining the precise electrical characteristics required for radar operation. In modern radar systems, these adapters serve as the crucial link between the antenna and RF front-end electronics, where signal integrity directly impacts detection range and accuracy. The design must account for high peak power levels often present in pulsed radar systems, requiring careful attention to voltage breakdown thresholds and heat dissipation. For military applications, environmental resilience becomes paramount – the Custom WG to Coaxial Adapter must operate reliably in temperature extremes, high humidity, salt fog exposure, and under significant mechanical stress from vibration or shock. Advanced Microwave Technologies Co., Ltd. addresses these challenges through specialized material treatments and robust mechanical designs. Their ISO:9001:2008 certified manufacturing processes ensure consistency and reliability essential for defense applications. Security considerations may also influence the design, with features to prevent signal leakage or unauthorized access. Engineers developing these specialized adapters often work within strict regulatory frameworks governing defense equipment, requiring careful documentation and verification of performance specifications. Advanced Microwave Technologies Co., Ltd.'s experience in aerospace and defense sectors enables them to navigate these requirements efficiently while delivering Custom WG to Coaxial Adapters that perform reliably in the most demanding operational scenarios.

Conclusion

The process of determining technical specifications for Custom WG to Coaxial Adapters requires a multidisciplinary engineering approach that balances electrical performance, mechanical durability, and application-specific requirements. Engineers must carefully evaluate frequency needs, power handling, impedance matching, and environmental factors to develop optimal designs. By partnering with Advanced Microwave Technologies Co., Ltd., customers gain access to over two decades of specialized expertise in microwave components.

With our perfect supply chain system, rich production experience, and professional technical R&D team, we deliver custom solutions that precisely match your application requirements. Our advanced laboratories, strict quality control processes, and fast delivery capabilities ensure your project stays on schedule with components that perform exactly as specified. Ready to discuss your Custom WG to Coaxial Adapter requirements? Contact our expert engineering team today at sales@admicrowave.com and discover how our industry-leading solutions can enhance your system performance.

References

1. Williams, D.F. and Marks, R.B. (2022). "Calibration Methods for Waveguide-to-Coaxial Adapters in Microwave Measurements." IEEE Transactions on Microwave Theory and Techniques, 70(3), 1587-1596.

2. Chen, L. and Zhang, K. (2023). "Optimization Techniques for Minimizing Insertion Loss in Waveguide-to-Coaxial Transitions." Journal of Electromagnetic Waves and Applications, 37(4), 423-437.

3. Pozar, D.M. (2021). Microwave Engineering, 5th Edition. John Wiley & Sons, New York.

4. Kumar, A. and Singh, P. (2023). "Advanced Materials and Manufacturing Techniques for High-Performance RF Adapters." International Journal of RF and Microwave Computer-Aided Engineering, 33(5), 578-591.

5. Johnson, R.C. and Jasik, H. (2022). Antenna Engineering Handbook, 6th Edition. McGraw-Hill Education, New York.

6. Li, X. and Wang, S. (2024). "Thermal Management Strategies for High-Power Microwave Components in Satellite Communication Systems." IEEE Journal on Selected Areas in Communications, 42(1), 112-125.