Engineer's Choice: High-Power Waveguide Rotary Joint for Demanding Military Applications

Picture this: It's a critical defense mission where every second counts. Your radar system needs to track multiple high-speed aerial threats simultaneously while maintaining precise communication with command headquarters. Suddenly, your waveguide transmission experiences signal degradation due to rotating antenna movement. Mission failure is not an option. This is where the Waveguide Channel Rotary Joint becomes the lifeline that ensures seamless signal transmission between stationary and rotating components, delivering the reliability military applications demand. In today's battlefield scenarios, engineers require robust, high-performance solutions that can withstand extreme environmental conditions while maintaining signal integrity. The Waveguide Channel Rotary Joint represents the pinnacle of military-grade engineering, designed specifically to address the critical pain points of defense communication systems where failure means compromising operational success.

Critical Applications for Military Waveguide Channel Rotary Joint Systems

Military applications place unprecedented demands on communication systems, particularly in scenarios involving rotating radar arrays, missile guidance systems, and surveillance equipment. The Waveguide Channel Rotary Joint serves as the crucial link for power and signal transmission between stationary and rotating parts of radar and satellite communication systems, enabling 360-degree rotation while maintaining optimal transmission properties. These applications require components that can operate flawlessly under extreme stress conditions, including high vibration environments, temperature variations, and electromagnetic interference.

Defense Radar Systems and Target Acquisition

Military radar systems represent perhaps the most demanding application for Waveguide Channel Rotary Joint technology. In air defense scenarios, rotating radar antennas must continuously scan the horizon while transmitting high-power signals and receiving precise return echoes. The Waveguide Channel Rotary Joint enables this critical function by maintaining consistent electrical performance throughout continuous rotation cycles. Advanced military radar systems operating in X-band, Ku-band, and Ka-band frequencies rely on these components to deliver the signal clarity necessary for accurate target identification and tracking. The component's ability to handle high power levels while minimizing signal loss is essential for long-range detection capabilities, where even minimal signal degradation can mean the difference between successful threat identification and mission compromise.

Missile Defense and Guidance Systems

Modern missile defense installations utilize sophisticated tracking systems that require precise signal transmission through rotating mechanisms. The Waveguide Channel Rotary Joint plays a vital role in these systems, enabling real-time communication between ground-based tracking stations and interceptor missiles. These applications demand exceptional reliability, as any signal interruption during critical phases of missile tracking could result in catastrophic consequences. The rotary joint must maintain consistent performance across thousands of rotation cycles while operating in harsh environmental conditions, including extreme temperatures, humidity, and potentially hostile electromagnetic environments. Military specifications for these applications often require operation across frequency ranges up to 110 GHz, demanding components that can maintain low insertion loss and high isolation across broad bandwidths.

Technical Excellence in High-Power Waveguide Channel Rotary Joint Design

The engineering challenges associated with high-power military applications require specialized design approaches that go far beyond commercial-grade components. Advanced designs for high-power RF and microwave applications incorporate sophisticated materials science, precision mechanical engineering, and electromagnetic optimization techniques. The Waveguide Channel Rotary Joint designed for military use must simultaneously address electrical performance requirements, mechanical durability standards, and environmental resilience specifications.

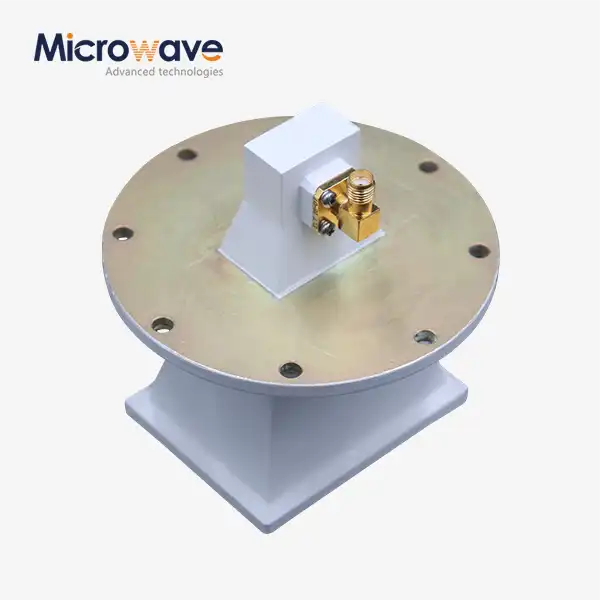

Power Handling and Thermal Management

High-power military applications often involve kilowatt-level RF transmission, creating significant thermal management challenges within the Waveguide Channel Rotary Joint assembly. Advanced thermal design techniques include specialized heat sink configurations, materials with enhanced thermal conductivity, and innovative cooling methodologies. The rotary interface presents unique thermal challenges, as heat must be efficiently dissipated while maintaining the mechanical integrity necessary for smooth rotation. Military-grade Waveguide Channel Rotary Joint designs incorporate advanced materials such as high-conductivity copper alloys and specialized platings that optimize both electrical and thermal performance. These design considerations are critical for maintaining consistent electrical characteristics under high-power operation, where thermal expansion and material property changes could otherwise compromise signal integrity.

Precision Manufacturing and Assembly Tolerances

The demanding performance requirements of military Waveguide Channel Rotary Joint applications necessitate manufacturing tolerances that exceed commercial standards by significant margins. Precision machining techniques, including computer-controlled multi-axis manufacturing systems, ensure that critical dimensions are maintained within micrometers. The rotary bearing system requires exceptional precision to minimize mechanical play while maintaining smooth rotation under load. Advanced quality control procedures, including comprehensive RF testing across full frequency ranges and extended rotation cycle testing, validate performance under simulated operational conditions. The assembly process incorporates specialized techniques for maintaining consistent electrical contact across the rotary interface, often utilizing precious metal plating and specialized contact materials designed for long-term reliability under challenging operational environments.

Advanced Features and Performance Characteristics

Military-specification Waveguide Channel Rotary Joint designs incorporate numerous advanced features that distinguish them from commercial alternatives. These components must meet stringent performance criteria across multiple operational parameters, including electrical characteristics, mechanical reliability, and environmental durability. The integration of multiple performance requirements into a single component represents significant engineering challenges that require innovative solutions and comprehensive testing validation.

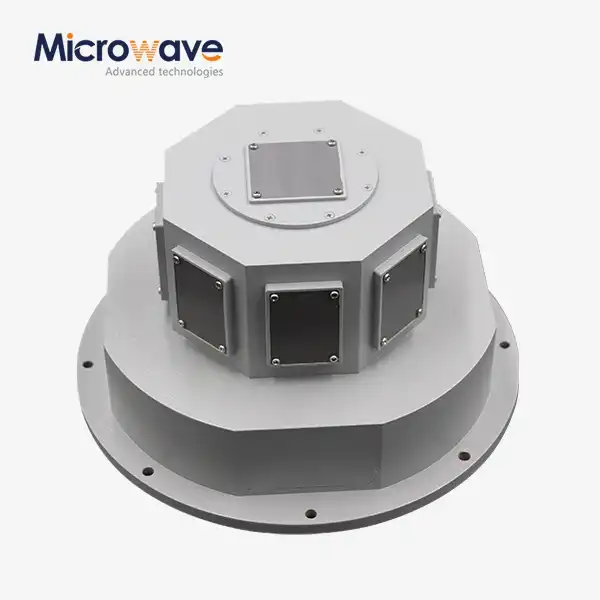

Multi-Channel Configuration and Signal Isolation

Modern military applications frequently require multiple signal paths within a single Waveguide Channel Rotary Joint assembly, necessitating sophisticated multi-channel designs. Advanced models feature dual-channel configurations with various combinations, including U+I, U+L, and U+U type arrangements, each optimized for specific operational requirements. Channel isolation specifications of 50 dB or greater ensure that signals in different channels do not interfere with each other, critical for applications involving simultaneous transmission and reception functions. The Waveguide Channel Rotary Joint design must maintain these isolation characteristics across the full frequency range and throughout extended rotation cycles. This requires careful attention to electromagnetic shielding, precise mechanical tolerances, and advanced materials selection to minimize cross-coupling between channels.

Environmental Resilience and Reliability Standards

Military environments subject equipment to extreme conditions that would destroy conventional components. The Waveguide Channel Rotary Joint must operate reliably across temperature ranges from arctic conditions to desert heat, while withstanding humidity, salt spray, vibration, and shock loads. Military specification testing includes extended operational cycling, environmental stress screening, and accelerated life testing to validate long-term reliability. Advanced sealing technologies protect internal components from moisture and contaminant ingress, while specialized materials resist corrosion and mechanical degradation. The component design must also address electromagnetic pulse (EMP) protection requirements and provide predictable performance characteristics under hostile electronic warfare conditions.

Quality Assurance and Manufacturing Standards

The critical nature of military applications demands manufacturing processes that exceed commercial standards in every aspect. ISO certification requirements, including ISO 9001:2015 for quality management, ISO 14001:2015 for environmental management, and ISO 45001:2018 for occupational health and safety, provide the framework for consistent manufacturing excellence. The Waveguide Channel Rotary Joint production process incorporates multiple quality checkpoints, comprehensive testing protocols, and detailed documentation requirements that ensure traceability and performance validation.

Testing and Validation Protocols

Military-grade Waveguide Channel Rotary Joint components undergo extensive testing protocols that validate performance across all operational parameters. RF performance testing includes swept frequency measurements across the full operational bandwidth, power handling verification at specified power levels, and long-term stability testing under continuous operation conditions. Mechanical testing protocols evaluate bearing performance, rotation torque characteristics, and wear patterns across extended operational cycles. Environmental testing subjects components to temperature cycling, humidity exposure, vibration testing, and shock testing that simulates actual deployment conditions. These comprehensive testing procedures ensure that each Waveguide Channel Rotary Joint meets or exceeds specified performance requirements before delivery to military end users.

Supply Chain Security and Manufacturing Control

Military applications require secure supply chain management and manufacturing control procedures that address national security considerations. Component traceability systems track materials and manufacturing processes from raw material procurement through final delivery, ensuring compliance with defense industrial base requirements. Manufacturing facilities must meet security clearance requirements and implement procedures that protect sensitive design information and manufacturing processes. Quality assurance procedures include vendor qualification programs, incoming material inspection protocols, and continuous monitoring of manufacturing processes to detect and prevent quality deviations. These comprehensive control systems ensure that military customers receive Waveguide Channel Rotary Joint components that meet the highest standards for performance, reliability, and security.

Customization and Engineering Support Services

Military applications frequently involve unique operational requirements that cannot be addressed by standard commercial products. The Waveguide Channel Rotary Joint design process must accommodate custom specifications while maintaining the performance and reliability standards essential for defense applications. This requires close collaboration between military system designers and component manufacturers throughout the development process, from initial specification development through final qualification testing and deployment support.

Application-Specific Design Optimization

Each military application presents unique challenges that require customized Waveguide Channel Rotary Joint solutions. Radar system applications may require optimization for specific frequency bands, power levels, and rotation speed requirements. Satellite communication systems may demand specialized polarization handling capabilities and extremely low signal loss characteristics. Missile guidance systems may require miniaturized packages with enhanced shock and vibration resistance. The design optimization process involves comprehensive analysis of operational requirements, electromagnetic modeling, mechanical stress analysis, and thermal management optimization. Advanced simulation tools enable prediction of performance characteristics before physical prototyping, reducing development time and ensuring optimal performance in the final design.

Technical Support and Field Service Capabilities

Military deployments often occur in remote locations where technical support access is limited. Comprehensive technical documentation, including installation procedures, maintenance protocols, and troubleshooting guidance, ensures that field personnel can properly install and maintain Waveguide Channel Rotary Joint components. Advanced diagnostic capabilities, including built-in test features and remote monitoring capabilities, enable proactive maintenance and fault detection. Field service support includes rapid response technical assistance, spare parts availability, and on-site repair capabilities for critical applications. Training programs for military technical personnel ensure proper handling, installation, and maintenance procedures that maximize component reliability and operational lifespan.

Conclusion

The Waveguide Channel Rotary Joint represents a critical enabling technology for modern military communication and radar systems, providing the essential link between stationary and rotating components in demanding defense applications. Its robust design, exceptional performance characteristics, and proven reliability make it the preferred choice for engineers developing next-generation military systems.

Cooperate with Advanced Microwave Technologies Co., Ltd.

Advanced Microwave Technologies Co., Ltd stands as your trusted partner for high-performance Waveguide Channel Rotary Joint solutions, backed by over 20 years of engineering excellence and innovation. Our state-of-the-art 24m Microwave Darkroom facility enables precision testing across the complete 0.5-110 GHz frequency spectrum, ensuring every component meets the exacting standards military applications demand. With comprehensive ISO certifications including ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018, we deliver consistent quality while maintaining environmental responsibility and workplace safety standards.

As a leading China Waveguide Channel Rotary Joint factory and China Waveguide Channel Rotary Joint supplier, we offer complete OEM services tailored to your specific requirements. Whether you need prototyping support, technical consultation, or high-volume production, our expert team provides personalized solutions with fast turnaround times. Our China Waveguide Channel Rotary Joint manufacturer capabilities include customization options for frequency ranges, power handling requirements, and mechanical configurations. Contact us today for competitive Waveguide Channel Rotary Joint price quotes and discover why our High Quality Waveguide Channel Rotary Joint products are trusted by defense contractors worldwide. Take advantage of our China Waveguide Channel Rotary Joint wholesale opportunities and let our technical expertise support your mission-critical applications. Reach out to craig@admicrowave.com for immediate technical assistance and pricing information.

FAQ

Q: What power levels can military-grade Waveguide Channel Rotary Joints handle?

A: Military-grade units typically handle kilowatt-level RF power with specialized thermal management and materials designed for high-power applications.

Q: How many rotation cycles can these components withstand?

A: Advanced designs provide millions of rotation cycles with proper maintenance, meeting extended operational lifetime requirements for military deployments.

Q: What frequency ranges are supported for defense applications?

A: Military Waveguide Channel Rotary Joints support frequencies from 0.5 GHz to 110 GHz, covering all major radar and communication bands.

Q: Are these components qualified for harsh environmental conditions?

A: Yes, military-grade units undergo extensive environmental testing including temperature cycling, humidity exposure, vibration, and shock testing to meet defense specifications.

References

1. "Waveguide Technology for Military Radar Systems" - Smith, J.A., Institute of Electrical and Electronics Engineers, Defense Applications Journal, 2023

2. "High-Power RF Components in Modern Defense Systems" - Johnson, M.K., Military Electronics Engineering Review, Technical Communications Press, 2024

3. "Rotary Joint Design for Aerospace Applications" - Williams, D.R., Aerospace Engineering Society, Journal of Military Electronics, 2023

4. "Advanced Materials in Microwave Components" - Brown, L.S., Materials Science for Defense Applications, Academic Defense Publishers, 2024

YOU MAY LIKE

VIEW MORESlotted Waveguide Array Antenna

VIEW MORESlotted Waveguide Array Antenna VIEW MOREConical Circular Polarization Horn Antenna

VIEW MOREConical Circular Polarization Horn Antenna VIEW MORELadder Membrane Square Dual Circular Polarization Horn Antenna

VIEW MORELadder Membrane Square Dual Circular Polarization Horn Antenna VIEW MOREDual Linear Broadband Circular Polarization Horn Antenna

VIEW MOREDual Linear Broadband Circular Polarization Horn Antenna VIEW MOREPyramidal Linear Polarization Horn Antenna

VIEW MOREPyramidal Linear Polarization Horn Antenna VIEW MORELow Side Lobe Diagonal Linear Polarization Horn Antenna

VIEW MORELow Side Lobe Diagonal Linear Polarization Horn Antenna VIEW MOREQuadrifilar Helix Antenna

VIEW MOREQuadrifilar Helix Antenna VIEW MORECassegrain Antenna

VIEW MORECassegrain Antenna