Double‑Ridged Waveguide Loop Coupler Frequency Range Explained

When microwave engineers struggle with signal coupling inefficiencies across broadband frequencies, finding the right component becomes mission-critical. The Double-Ridged Waveguide Loop Coupler addresses this exact challenge by delivering exceptional frequency coverage that traditional waveguide couplers simply cannot match, ensuring your RF systems operate at peak performance across demanding applications from satellite communications to defense radar systems.

Understanding the Frequency Coverage of Double-Ridged Waveguide Loop Couplers

The frequency range capability of a Double-Ridged Waveguide Loop Coupler stands as its most defining characteristic, directly impacting system versatility and application suitability. Unlike conventional rectangular waveguides that operate within narrow frequency bands, double-ridged configurations fundamentally alter the electromagnetic field distribution within the waveguide structure. The opposing ridge structures create a modified cutoff frequency, effectively lowering the fundamental mode while simultaneously raising higher-order modes. This architectural innovation enables these couplers to achieve frequency coverage ratios exceeding 4:1, compared to the typical 2:1 ratio of standard waveguide components. For practical applications, this translates to a single Double-Ridged Waveguide Loop Coupler covering frequency spans that would otherwise require multiple conventional couplers, significantly reducing system complexity and integration challenges. The bandwidth extension achieved through double-ridged geometry stems from the way ridges concentrate electric fields in the central region of the waveguide. This field concentration modifies the effective electrical dimensions of the guide, allowing it to support propagating modes at lower frequencies than would be possible in an equivalent rectangular waveguide. Advanced Microwave Technologies Co., Ltd. leverages this principle to manufacture couplers with frequency ranges spanning from sub-GHz frequencies up to 110 GHz, accommodating both legacy communication systems and cutting-edge millimeter-wave applications. The broadband nature of these couplers proves particularly valuable in multi-frequency systems where signal distribution across diverse frequency bands must be accomplished with minimal component count.

The Engineering Behind Extended Frequency Performance

The structural composition of a Double-Ridged Waveguide Loop Coupler directly determines its frequency response characteristics. The component consists of a double-ridged waveguide section integrated with a loop-shaped coupling structure, where the loop interacts with the electromagnetic fields within the ridged waveguide to extract a portion of the transmitted power. The ridge height, width, and spacing create specific impedance characteristics that remain relatively constant across broad frequency ranges, enabling consistent coupling coefficients and minimal insertion loss variation. This geometric precision requires sophisticated manufacturing capabilities, as even minor dimensional variations can significantly impact performance at higher frequencies. The coupling loop itself functions as a resonant or semi-resonant structure whose dimensions are carefully optimized to interact effectively with the field patterns established by the double-ridged geometry. The position of this loop within the waveguide cross-section, its penetration depth, and its orientation relative to the electric field lines all contribute to the coupling mechanism's efficiency. Advanced Microwave's engineering teams utilize electromagnetic simulation tools combined with empirical testing in their 24-meter Microwave Darkroom to refine these parameters, ensuring that the Double-Ridged Waveguide Loop Coupler maintains specified coupling values across its entire operational bandwidth. The facility's capability to conduct measurements up to 110 GHz provides verification of coupler performance across millimeter-wave frequencies where traditional measurement approaches become challenging.

Practical Frequency Range Selection for Your Application

Selecting the appropriate frequency range for a Double-Ridged Waveguide Loop Coupler requires careful consideration of your system's operational requirements. Satellite communication ground stations, for example, may require coverage spanning C-band through Ku-band frequencies, necessitating a coupler with 4 to 18 GHz capability. Radar systems often operate in specific allocated bands such as X-band (8-12 GHz) or Ka-band (26.5-40 GHz), where the Double-Ridged Waveguide Loop Coupler must deliver consistent directivity and coupling coefficients throughout the designated spectrum. Telecommunications infrastructure may demand even broader coverage to support multiple wireless standards simultaneously, making the extended bandwidth of double-ridged designs particularly advantageous. The frequency-dependent characteristics of any waveguide component include not only its operational bandwidth but also its performance parameters across that range. Insertion loss, coupling coefficient, directivity, and voltage standing wave ratio all exhibit frequency dependence that must align with system requirements. A well-designed Double-Ridged Waveguide Loop Coupler minimizes these variations, maintaining stable performance across its specified range. Advanced Microwave Technologies accomplishes this through precision engineering and careful material selection, utilizing high-conductivity metals such as aluminum, brass, or specialized alloys that minimize losses while maintaining mechanical stability across temperature variations and operational stresses.

Performance Advantages Across the Operational Spectrum

The wide frequency range of Double-Ridged Waveguide Loop Couplers translates directly into tangible performance benefits for system integrators and end users. Low insertion loss remains critical across all frequency components within the operational band, as excessive loss degrades system noise figure and reduces overall efficiency. The double-ridged configuration inherently provides better impedance matching across broader bandwidths compared to single-ridge or non-ridged alternatives, resulting in lower reflection coefficients and superior power transfer efficiency. This characteristic proves especially valuable in high-power applications where even fractional percentage improvements in efficiency translate to significant reductions in thermal management requirements and improved system reliability. Directivity represents another crucial performance parameter that benefits from the extended frequency range capabilities of these couplers. High directivity ensures that coupled power predominantly flows to the designated coupled port rather than being reflected back toward the source or transmitted to the isolated port. The loop coupling mechanism in double-ridged waveguide configurations naturally provides excellent directivity across broad frequency ranges when properly engineered. Advanced Microwave's couplers typically achieve directivity values exceeding 20 dB across their full operational bandwidth, ensuring accurate power monitoring and signal distribution in sophisticated RF systems.

Material Selection and Manufacturing Precision for Frequency Stability

The materials used in constructing Double-Ridged Waveguide Loop Couplers significantly impact their frequency response and long-term stability. High-purity aluminum offers excellent conductivity combined with light weight, making it suitable for aerospace applications where mass reduction is paramount. Brass provides superior machinability for complex geometries while maintaining good electrical performance, often selected for prototype development and specialized applications. Specialized copper alloys deliver maximum conductivity for lowest-loss applications, though at increased material and manufacturing costs. The internal surfaces of these couplers typically receive specialized plating or coating treatments to enhance conductivity, prevent oxidation, and ensure consistent performance across environmental variations. Manufacturing precision directly correlates with frequency performance consistency. Computer numerical control machining centers with micron-level tolerances create the intricate internal geometries of double-ridged waveguides and their integrated coupling loops. The ridge profiles must be machined to exacting specifications, as dimensional variations create impedance discontinuities that generate reflections and degrade frequency response. Advanced Microwave Technologies maintains strict quality control procedures aligned with ISO 9001:2015 standards, ensuring every Double-Ridged Waveguide Loop Coupler meets specified electrical parameters across its entire frequency range before shipment to customers.

Integration Considerations for Broadband Systems

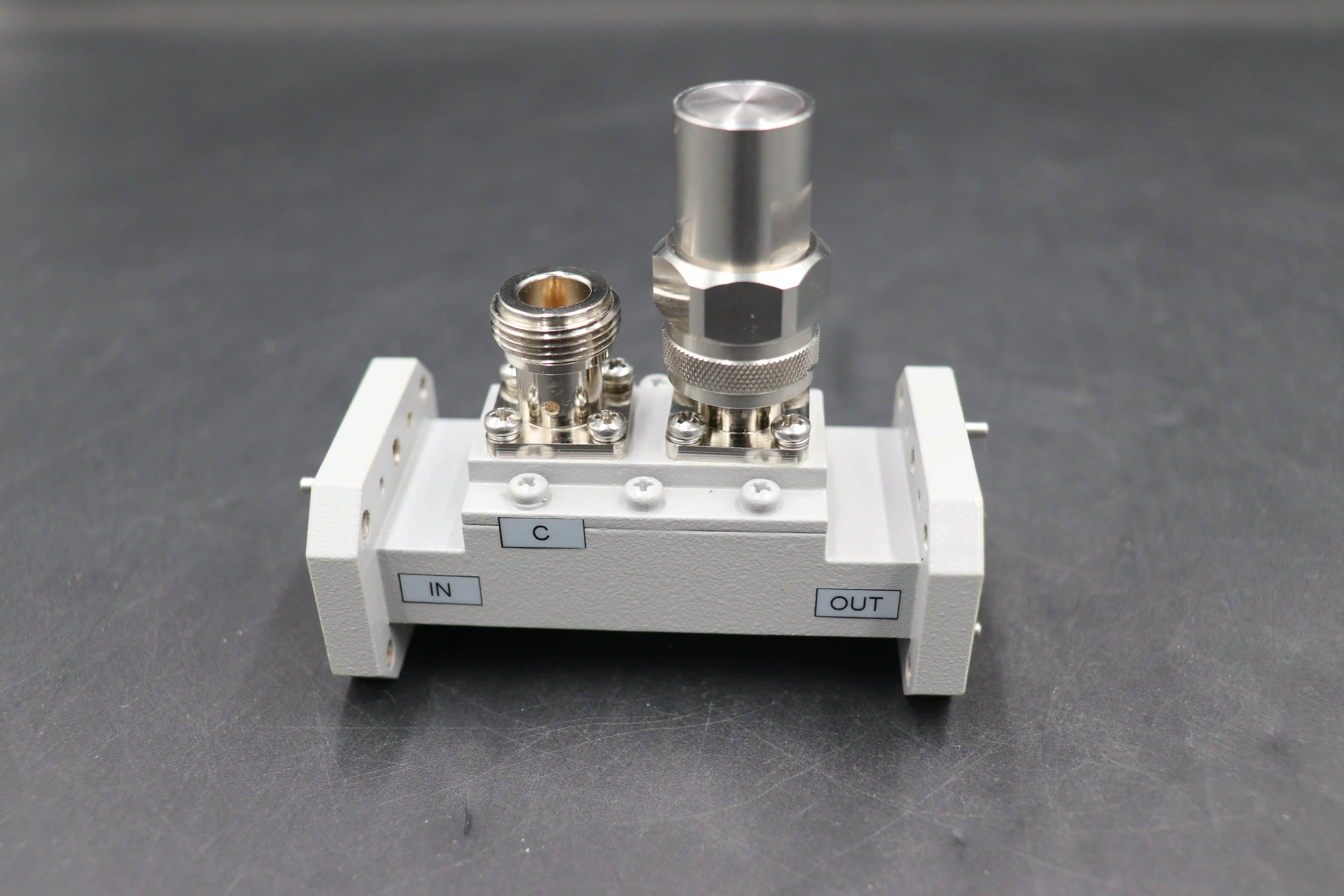

Successfully integrating Double-Ridged Waveguide Loop Couplers into existing microwave systems requires attention to several technical factors beyond simple frequency range matching. Flange compatibility ensures mechanical and electrical connection to adjacent components, with various standard interfaces available including WR-series flanges, CPR flanges, and customized mounting options for specialized applications. The physical dimensions of the coupler must fit within available space constraints while maintaining adequate separation from other components to prevent electromagnetic interference. Power handling capability becomes critical in transmitter applications, where the coupler must withstand peak and average power levels without breakdown or performance degradation. The multiple ports of a Double-Ridged Waveguide Loop Coupler—typically including input, output, coupled, and isolated terminals—require proper termination and connection to system elements. The coupled port delivers a sample of the main transmission signal, commonly used for power monitoring or signal distribution purposes. The isolated port, when properly terminated, absorbs unwanted reflected energy to maintain high directivity. System designers must account for the coupling coefficient when calculating power budgets, ensuring adequate signal levels reach all intended destinations while avoiding overdriving sensitive receiver components.

Customization Options for Specific Frequency Requirements

Advanced Microwave Technologies recognizes that standardized products cannot address every application scenario. The company's OEM services enable customization of Double-Ridged Waveguide Loop Coupler specifications to match precise frequency requirements, coupling coefficients, power handling needs, and physical constraints. Custom frequency ranges can be engineered to optimize performance for specific bands of interest, trading off absolute bandwidth for enhanced performance parameters within narrower spans. Coupling coefficient adjustments allow designers to extract precisely the desired power fraction without requiring additional attenuators or amplifiers in the signal path. Specialized materials and construction techniques become available through customization, addressing unique environmental challenges such as extreme temperatures, high-vibration conditions, or corrosive atmospheres. Military and aerospace applications often demand hermetic sealing, specialized connector interfaces, and qualification testing to rigorous standards. Research institutions may require couplers with exceptional phase stability or extremely low insertion loss for precision measurement applications. The engineering team at Advanced Microwave collaborates directly with customers to understand these requirements and develop tailored solutions that meet technical objectives while remaining cost-effective and manufacturable at required volumes.

Real-World Applications Spanning the Frequency Spectrum

The versatility of Double-Ridged Waveguide Loop Couplers manifests in their deployment across diverse industries and applications. Satellite ground stations utilize these components for signal monitoring and distribution in both uplink and downlink paths, where their broadband capabilities accommodate multiple frequency bands within single hardware installations. The low insertion loss characteristics preserve precious signal strength in reception paths while maintaining fidelity in transmission chains. Advanced Microwave's couplers support ground station operators in delivering reliable satellite communications for broadcasting, internet services, and data distribution networks. Defense radar systems demand exceptional performance reliability in mission-critical scenarios. Whether deployed in surveillance radars scanning for aerial threats, missile guidance systems requiring precision tracking, or naval ship-based systems operating in harsh maritime environments, these couplers provide dependable signal coupling across operational frequency bands. The superior directivity ensures accurate power monitoring for transmitter protection and system diagnostics, while low VSWR minimizes reflections that could compromise radar sensitivity or damage high-power amplifiers. Military specifications often require operation across extended temperature ranges and survival under shock and vibration conditions that would destroy conventional components.

Telecommunications infrastructure continues expanding to meet growing data demands, with 5G networks operating in millimeter-wave frequencies alongside legacy systems. Double-Ridged Waveguide Loop Couplers enable base station operators to monitor transmitter performance, distribute signals to antenna arrays, and implement redundancy schemes that maintain service continuity during equipment failures. The compact and versatile design facilitates installation in space-constrained tower-top locations while maintaining performance despite environmental extremes. Industrial Internet of Things deployments benefit from the reliable signal distribution these couplers provide, ensuring connectivity across manufacturing facilities, logistics operations, and smart infrastructure systems.

Conclusion

The Double-Ridged Waveguide Loop Coupler delivers unmatched frequency range versatility, enabling system designers to achieve broadband signal coupling with superior performance characteristics across demanding microwave and millimeter-wave applications.

Cooperate with Advanced Microwave Technologies Co., Ltd.

Partner with Advanced Microwave Technologies Co., Ltd., a leading China Double-Ridged Waveguide Loop Coupler manufacturer and supplier offering high-quality products at competitive prices. Our 20+ years of expertise, ISO-certified quality control, and state-of-the-art 24m Microwave Darkroom ensure exceptional Double-Ridged Waveguide Loop Coupler performance. Whether you need China Double-Ridged Waveguide Loop Coupler wholesale solutions or customized OEM services, we deliver fast turnaround, technical support, and competitive Double-Ridged Waveguide Loop Coupler prices. As a trusted China Double-Ridged Waveguide Loop Coupler factory with Double-Ridged Waveguide Loop Coupler for sale globally, we serve satellite communications, aerospace, defense, and telecommunications sectors. Contact craig@admicrowave.com today for quotes and discover why customers worldwide choose our High Quality Double-Ridged Waveguide Loop Coupler solutions for their critical RF applications.

References

1. Pozar, David M. "Microwave Engineering: Waveguide Components and Coupling Structures." John Wiley & Sons, Fourth Edition.

2. Collin, Robert E. "Foundations for Microwave Engineering: Waveguide Theory and Ridge Waveguide Applications." IEEE Press Series on Electromagnetic Wave Theory.

3. Montgomery, C. G., Dicke, R. H., and Purcell, E. M. "Principles of Microwave Circuits: Directional Couplers and Hybrid Junctions." MIT Radiation Laboratory Series, McGraw-Hill.

4. Bhat, B. and Koul, S. K. "Analysis, Design and Applications of Fin Lines: Ridge Waveguide Components." Artech House Microwave Library.

5. Marcuvitz, Nathan. "Waveguide Handbook: Ridge Waveguide Structures and Coupling Mechanisms." Institution of Engineering and Technology Electromagnetic Waves Series.