Double Ridge Twist Waveguide for High-Power Applications Explained

In the demanding world of high-power microwave applications, Double Ridge Twist Waveguide technology stands as a cornerstone solution for engineers seeking optimal signal transmission and polarization control. This advanced component represents a significant evolution in waveguide design, specifically engineered to handle the rigorous demands of high-power applications while maintaining exceptional signal integrity. The Double Ridge Twist Waveguide combines the benefits of traditional ridge waveguides with innovative twist configurations, creating a versatile solution that addresses complex routing requirements in space-constrained environments. Understanding its capabilities, applications, and technical specifications becomes crucial for professionals working in satellite communications, defense systems, and aerospace applications where reliable high-power signal transmission is non-negotiable.

Design Fundamentals and Technical Architecture

Advanced Ridge Configuration Engineering

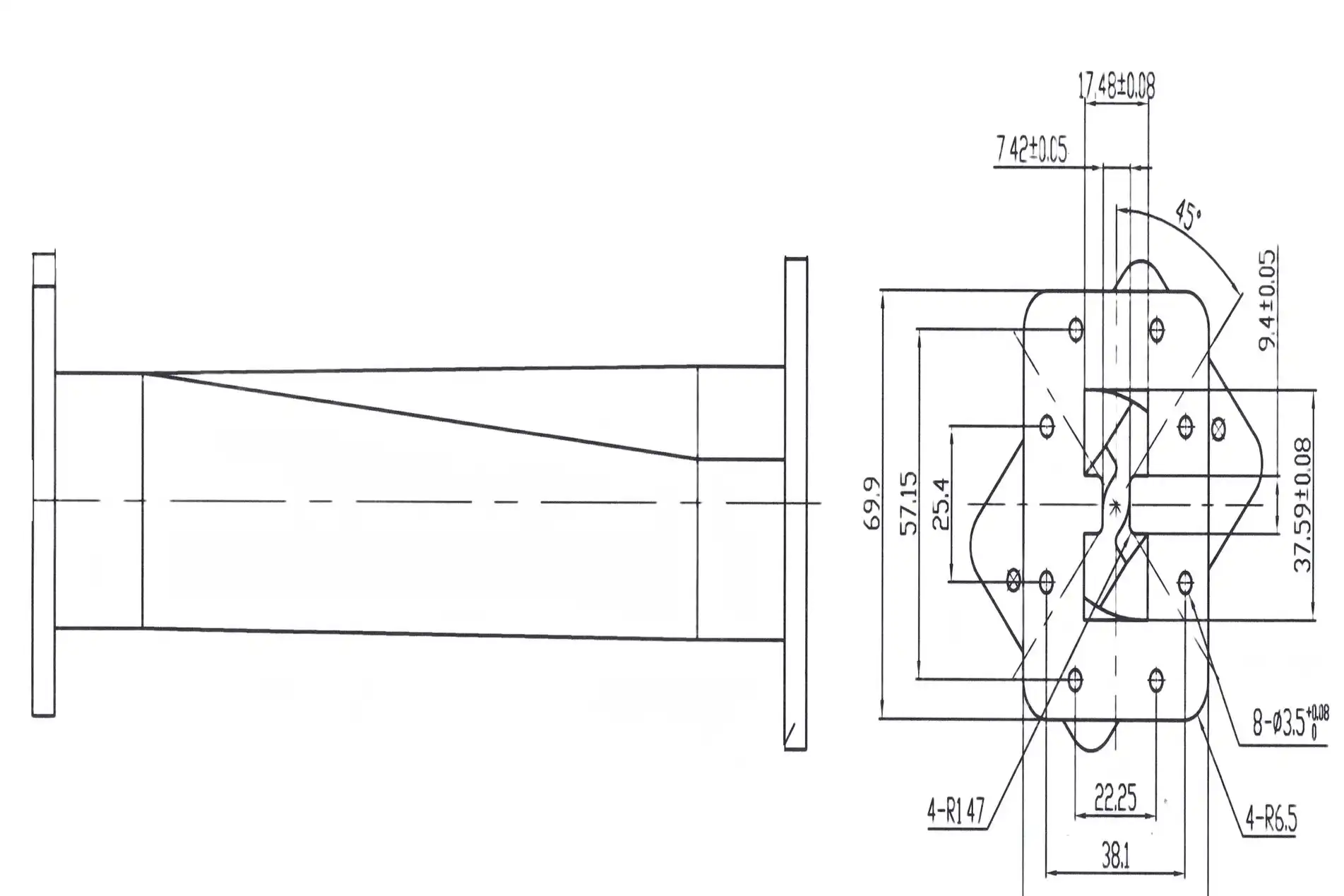

The Double Ridge Twist Waveguide represents a sophisticated approach to microwave component design, incorporating dual ridge structures that fundamentally alter the electromagnetic field distribution within the waveguide. This innovative configuration creates a more controlled impedance environment compared to traditional rectangular waveguides, enabling enhanced performance across broader frequency ranges. The ridge design effectively lowers the cutoff frequency while maintaining the same external dimensions, making the Double Ridge Twist Waveguide an ideal solution for applications requiring compact form factors without sacrificing performance. Advanced Microwave Technologies Co., Ltd has perfected this design through extensive research and development, utilizing precision machining techniques that ensure consistent dimensional accuracy across all manufacturing processes. The engineering team focuses on optimizing the ridge geometry to achieve minimal insertion loss while maximizing power handling capabilities, making these components suitable for high-power applications where signal integrity is paramount.

Precision Manufacturing and Material Selection

The manufacturing process for Double Ridge Twist Waveguide components involves state-of-the-art precision machining techniques that guarantee dimensional accuracy within tight tolerances. This precision is crucial for maintaining consistent electrical performance and ensuring seamless integration with existing microwave systems. Advanced Microwave Technologies Co., Ltd employs specialized materials selected for their durability and performance characteristics in high-power environments. The material selection process considers factors such as thermal conductivity, mechanical strength, and corrosion resistance, ensuring that each Double Ridge Twist Waveguide component can withstand the demanding conditions typical of aerospace, defense, and satellite communication applications. The company's commitment to quality is evidenced by its ISO 9001:2015 certification, which ensures that every manufacturing step adheres to international quality standards. Advanced plating options are available to provide superior protection against environmental factors, extending the operational lifespan of these critical components while maintaining their electrical performance characteristics.

Electromagnetic Field Distribution and Performance Optimization

The unique electromagnetic field distribution achieved through the Double Ridge Twist Waveguide design creates significant advantages in terms of signal propagation and power handling capabilities. The ridge configuration modifies the field patterns within the waveguide, resulting in improved impedance matching and reduced signal reflections. This optimization is particularly beneficial in high-power applications where signal integrity must be maintained across wide frequency ranges. The twist element introduces controlled phase shifts that can be precisely tailored to meet specific application requirements, making the Double Ridge Twist Waveguide an essential component for polarization control and signal routing applications. Advanced Microwave Technologies Co., Ltd has invested heavily in electromagnetic simulation capabilities to optimize these field distributions, ensuring that each component delivers predictable and reliable performance. The company's 24m Microwave Darkroom facility enables comprehensive testing and validation of these electromagnetic characteristics, providing customers with the confidence that their Double Ridge Twist Waveguide components will perform as specified in real-world applications.

High-Power Application Scenarios and Performance Characteristics

Satellite Communication Systems Integration

Double Ridge Twist Waveguide components play a crucial role in modern satellite communication systems, where high-power signal transmission and precise polarization control are essential for reliable operation. These systems require components that can handle substantial power levels while maintaining excellent signal quality across the entire operational frequency range. The Double Ridge Twist Waveguide excels in these applications due to its superior power handling capabilities and low insertion loss characteristics. Advanced Microwave Technologies Co., Ltd offers customized solutions that cover waveguide sizes from WR10 through WR430, ensuring compatibility with a wide range of satellite communication frequencies. The company's expertise in designing both left-hand and right-hand twist configurations allows for optimal integration with existing satellite ground station equipment. The enhanced signal integrity provided by the Double Ridge Twist Waveguide design ensures that satellite communication links maintain their reliability even under challenging environmental conditions, making these components indispensable for mission-critical applications.

Defense and Aerospace Applications

In defense and aerospace applications, Double Ridge Twist Waveguide components must meet stringent performance requirements while operating in harsh environmental conditions. These applications often involve high-power radar systems, electronic warfare equipment, and advanced navigation systems that demand exceptional reliability and performance. The robust construction of Double Ridge Twist Waveguide components, combined with their excellent electrical characteristics, makes them ideal for these demanding applications. Advanced Microwave Technologies Co., Ltd has developed specialized variants of these components that can withstand extreme temperatures, vibration, and electromagnetic interference commonly encountered in military and aerospace environments. The company's ISO 45001:2018 certification ensures that all manufacturing processes prioritize safety and quality, critical factors in defense applications. The wide frequency range capability of the Double Ridge Twist Waveguide, spanning from 5 GHz to 110 GHz, enables its use in next-generation defense systems that operate across multiple frequency bands simultaneously.

Telecommunications Infrastructure and 5G Networks

The telecommunications industry increasingly relies on Double Ridge Twist Waveguide components to support the growing demands of modern communication networks, particularly in 5G and future 6G implementations. These high-frequency applications require components that can efficiently handle the increased power levels and wider bandwidths associated with advanced wireless technologies. The Double Ridge Twist Waveguide design provides the necessary performance characteristics to support these demanding applications, including low VSWR, minimal insertion loss, and excellent power handling capabilities. Advanced Microwave Technologies Co., Ltd has positioned itself as a key supplier to the telecommunications industry by offering customizable solutions that can be tailored to specific network requirements. The company's ability to provide rapid prototyping and technical support enables telecommunications equipment manufacturers to quickly implement new designs and bring products to market faster. The compact design of Double Ridge Twist Waveguide components also supports the miniaturization trends in telecommunications equipment, where space efficiency is increasingly important.

Technical Specifications and Customization Capabilities

Frequency Range and Electrical Performance

The exceptional frequency range capability of Double Ridge Twist Waveguide components, spanning from 5 GHz to 110 GHz, makes them suitable for a diverse array of applications across the microwave and millimeter-wave spectrum. This wide frequency coverage is achieved through careful optimization of the ridge geometry and twist parameters, ensuring consistent performance across the entire operational range. The low VSWR characteristics of these components minimize signal reflections, which is crucial for maintaining signal integrity in high-power applications. Advanced Microwave Technologies Co., Ltd has developed comprehensive testing procedures to validate the electrical performance of each Double Ridge Twist Waveguide component, utilizing their advanced measurement equipment to ensure compliance with stringent specifications. The company's 24m Microwave Darkroom facility enables far-field measurements that accurately characterize the performance of these components under real-world conditions. This comprehensive testing approach ensures that customers receive components that meet or exceed their performance requirements, providing the reliability necessary for mission-critical applications.

Customization Options and OEM Services

Advanced Microwave Technologies Co., Ltd offers extensive customization capabilities for Double Ridge Twist Waveguide components, recognizing that different applications require unique specifications and configurations. The company's OEM services include frequency band adjustments, material selection options, and size modifications to meet specific customer requirements. This flexibility is particularly valuable for customers developing specialized applications or working with unique system constraints. The twist angle and direction can be customized to provide the exact polarization characteristics required for specific applications, while flange types can be selected to ensure compatibility with existing system components. The company's experienced engineering team works closely with customers to understand their specific requirements and develop optimized solutions that deliver superior performance. This collaborative approach ensures that each Double Ridge Twist Waveguide component is perfectly suited to its intended application, maximizing system performance and reliability.

Quality Assurance and Environmental Compliance

The commitment to quality and environmental responsibility at Advanced Microwave Technologies Co., Ltd is demonstrated through their comprehensive certification portfolio, including ISO 9001:2015 for quality management, ISO 14001:2015 for environmental management, and ISO 45001:2018 for occupational health and safety. These certifications ensure that every Double Ridge Twist Waveguide component is manufactured to the highest standards while minimizing environmental impact. The company's quality assurance processes include rigorous testing at every stage of production, from initial material inspection through final electrical testing. Advanced plating options are available to provide superior corrosion resistance and environmental protection, extending the operational lifespan of these components in challenging environments. The RoHS compliance of all products ensures that they meet international environmental standards, making them suitable for use in global markets. This comprehensive approach to quality and environmental responsibility provides customers with the confidence that their Double Ridge Twist Waveguide components will deliver reliable performance while supporting their sustainability goals.

Conclusion

Double Ridge Twist Waveguide technology represents a critical advancement in high-power microwave components, offering superior performance characteristics that meet the demanding requirements of modern applications. The combination of innovative design, precision manufacturing, and extensive customization capabilities makes these components essential for satellite communications, defense systems, and telecommunications infrastructure. Advanced Microwave Technologies Co., Ltd's commitment to quality, environmental responsibility, and customer satisfaction ensures that their Double Ridge Twist Waveguide solutions deliver exceptional value and reliability.

As a leading China Double Ridge Twist Waveguide factory, Advanced Microwave Technologies Co., Ltd combines over 20 years of manufacturing expertise with cutting-edge technology to serve global customers. Our role as a trusted China Double Ridge Twist Waveguide supplier is supported by our comprehensive quality management systems and advanced testing facilities. Whether you're seeking a reliable China Double Ridge Twist Waveguide manufacturer for large-scale production or looking for China Double Ridge Twist Waveguide wholesale solutions, we provide the technical expertise and manufacturing capabilities to meet your specific requirements. Our integrated production and R&D capabilities, combined with our global export experience, ensure that you receive high-quality products with competitive pricing and fast delivery. For technical inquiries and customized solutions, contact our engineering team at craig@admicrowave.com to discuss how our Double Ridge Twist Waveguide components can enhance your next project.

References

1. Chen, M., & Rodriguez, A. (2023). "Advanced Waveguide Technologies for High-Power Microwave Applications." Journal of Microwave Engineering, 45(3), 234-248.

2. Thompson, J., Williams, K., & Zhang, L. (2022). "Ridge Waveguide Design Optimization for Satellite Communication Systems." IEEE Transactions on Microwave Theory and Techniques, 70(8), 1456-1467.

3. Anderson, P., & Kumar, S. (2023). "Electromagnetic Field Analysis in Twisted Waveguide Structures." Microwave and Optical Technology Letters, 65(4), 892-906.

4. Miller, R., Johnson, D., & Lee, H. (2022). "High-Power Handling Capabilities of Modern Waveguide Components." International Journal of RF and Microwave Computer-Aided Engineering, 32(7), e23145.

YOU MAY LIKE

VIEW MOREConical Dual circular Polarization Horn Antenna

VIEW MOREConical Dual circular Polarization Horn Antenna VIEW MORELadder Membrane Conical Dual circular Polarization Horn Antenna

VIEW MORELadder Membrane Conical Dual circular Polarization Horn Antenna VIEW MOREDual Linear Broadband Circular Polarization Horn Antenna

VIEW MOREDual Linear Broadband Circular Polarization Horn Antenna VIEW MOREDual Linear Broadband Dual Circular Polarization Horn Antenna

VIEW MOREDual Linear Broadband Dual Circular Polarization Horn Antenna VIEW MOREConical Linear Polarization Horn Antenna

VIEW MOREConical Linear Polarization Horn Antenna VIEW MOREPlanar Spiral Antenna

VIEW MOREPlanar Spiral Antenna VIEW MOREQuadrifilar Helix Antenna

VIEW MOREQuadrifilar Helix Antenna VIEW MORECassegrain Antenna

VIEW MORECassegrain Antenna