Can the Right Waveguide Adapter Improve Signal Transmission?

In today's rapidly evolving telecommunications and microwave technology landscape, the quality of signal transmission can make or break system performance. One critical component that often determines the success of microwave and RF systems is the waveguide adapter. The right Waveguide Adapter can dramatically improve signal transmission by minimizing losses, reducing reflections, and ensuring seamless connectivity between different transmission media. These precision-engineered components serve as essential bridges in complex communication systems, enabling efficient power transfer while maintaining signal integrity across diverse frequency ranges. From satellite communications to radar systems, the selection and implementation of appropriate waveguide adapters directly impacts system reliability, performance metrics, and overall operational efficiency in mission-critical applications.

How Waveguide Adapters Enhance Signal Quality and Minimize Transmission Losses?

Understanding the Fundamental Role of Impedance Matching

Signal transmission quality fundamentally depends on impedance matching between connected components, and this is where Waveguide Adapter technology demonstrates its critical importance. In microwave systems, impedance mismatches create standing waves that reflect portions of the transmitted signal back toward the source, resulting in power loss and potential system instability. Advanced Microwave Technologies Co., Ltd. addresses this challenge through precision-engineered adapters that achieve exceptionally low Voltage Standing Wave Ratios (VSWR), typically ranging from 1.1 to 1.5. These specifications represent near-perfect impedance matching, ensuring that maximum signal power reaches its intended destination. The physics behind impedance matching involves careful control of electromagnetic field transitions at the interface between different transmission media. When a Waveguide Adapter properly matches impedances, it eliminates discontinuities that would otherwise cause signal reflections. This is particularly crucial in high-frequency applications where even minor impedance variations can result in significant performance degradation. Advanced Microwave's adapters achieve this through sophisticated geometric designs and precision manufacturing tolerances that maintain consistent electromagnetic characteristics across their entire frequency range. The company's 24m Microwave Darkroom facility enables comprehensive testing and validation of these impedance matching capabilities, ensuring that each adapter meets stringent performance requirements before deployment in critical applications.

Minimizing Insertion Loss Through Advanced Design Engineering

Insertion loss represents one of the most critical performance parameters for any Waveguide Adapter, as it directly determines how much signal power is lost during transmission through the component. Advanced Microwave Technologies Co., Ltd. has developed adapter designs that achieve insertion losses as low as 0.1dB or even lower, representing industry-leading performance levels. This exceptional performance stems from careful attention to conductor geometry, surface finish quality, and material selection. The company's adapters utilize high-conductivity materials such as copper with silver plating, which minimizes resistive losses while providing excellent corrosion resistance for long-term reliability. The engineering principles behind low insertion loss design involve optimizing current flow paths and minimizing electromagnetic field disturbances within the adapter structure. Advanced Microwave's Waveguide Adapter designs feature smooth transitions between different cross-sectional geometries, eliminating sharp edges or discontinuities that could scatter electromagnetic energy. The company's manufacturing processes maintain precise dimensional tolerances, ensuring that the actual performance matches theoretical predictions. Additionally, the internal surface finishes are carefully controlled to minimize roughness, which can cause additional losses at high frequencies. These design considerations become increasingly important as operating frequencies extend into the millimeter-wave range, where even minor imperfections can significantly impact performance.

Achieving Wideband Performance Across Multiple Frequency Ranges

Modern communication systems increasingly require components that can operate effectively across wide frequency ranges, and this demand drives the development of broadband Waveguide Adapter technologies. Advanced Microwave Technologies Co., Ltd. has developed adapters with ultra-wide frequency coverage spanning from low frequencies to millimeter waves, accommodating applications from S-band (2-4GHz) through Ka-band (26.5-40GHz) and beyond. This wideband capability is achieved through sophisticated design techniques that maintain consistent performance characteristics across the entire frequency range. The technical challenges of wideband Waveguide Adapter design involve managing frequency-dependent electromagnetic effects while maintaining low VSWR and insertion loss across the entire operating range. Advanced Microwave's engineers employ advanced electromagnetic simulation tools to optimize adapter geometries for broadband performance. The company's adapters feature carefully designed transition sections that gradually transform electromagnetic field patterns between different transmission media, minimizing frequency-dependent reflections. This approach ensures stable performance whether the system operates at legacy communication frequencies or cutting-edge 5G and future 6G technologies. The validation of this wideband performance is conducted in the company's state-of-the-art measurement facilities, which support testing up to 110GHz, providing comprehensive verification of adapter performance across their specified frequency ranges.

The Critical Impact of Proper Waveguide Adapter Selection on System Performance

Power Handling Capabilities and High-Power System Requirements

In high-power microwave applications such as radar transmitters, satellite uplink systems, and industrial heating equipment, the power handling capability of Waveguide Adapter components becomes a critical design consideration. Advanced Microwave Technologies Co., Ltd. engineers its adapters to handle power levels ranging from watts to kilowatts or more, depending on the specific application requirements. This high-power capability is achieved through careful thermal management design, robust mechanical construction, and selection of materials that can withstand the thermal stresses associated with high-power operation. The physics of high-power Waveguide Adapter design involves managing both average and peak power levels while preventing thermal breakdown or mechanical failure. Advanced Microwave's adapters utilize thick-walled construction and high-thermal-conductivity materials to effectively dissipate heat generated by resistive losses. The company's designs also incorporate features such as rounded internal corners and smooth surface finishes to prevent electric field concentration that could lead to corona discharge or breakdown at high power levels. Additionally, the mechanical design ensures that thermal expansion and contraction do not compromise electrical performance or mechanical integrity over repeated thermal cycles.

Environmental Durability and Long-term Reliability Considerations

Real-world deployment environments subject Waveguide Adapter components to various stresses including temperature extremes, humidity, vibration, and corrosive atmospheres. Advanced Microwave Technologies Co., Ltd. addresses these challenges through comprehensive materials selection and protective finishing processes. The company's adapters are constructed from high-quality materials including aluminum, brass, and stainless steel, each selected for specific applications based on their mechanical, thermal, and corrosion resistance properties. External surfaces receive protective finishes such as anticorrosion grey paint that provide long-term protection against environmental degradation. The reliability engineering approach for Waveguide Adapter components involves extensive environmental testing to validate performance under realistic operating conditions. Advanced Microwave's testing protocols include temperature cycling, humidity exposure, vibration testing, and accelerated aging studies to ensure that adapters maintain their specified performance throughout their operational lifetime. The company's ISO 9001:2015 certification ensures that these quality control processes are consistently applied across all production runs. Additionally, the ISO 45001:2018 standard compliance demonstrates the company's commitment to providing safe working conditions for the engineers and technicians who manufacture these precision components.

Interface Compatibility and System Integration Flexibility

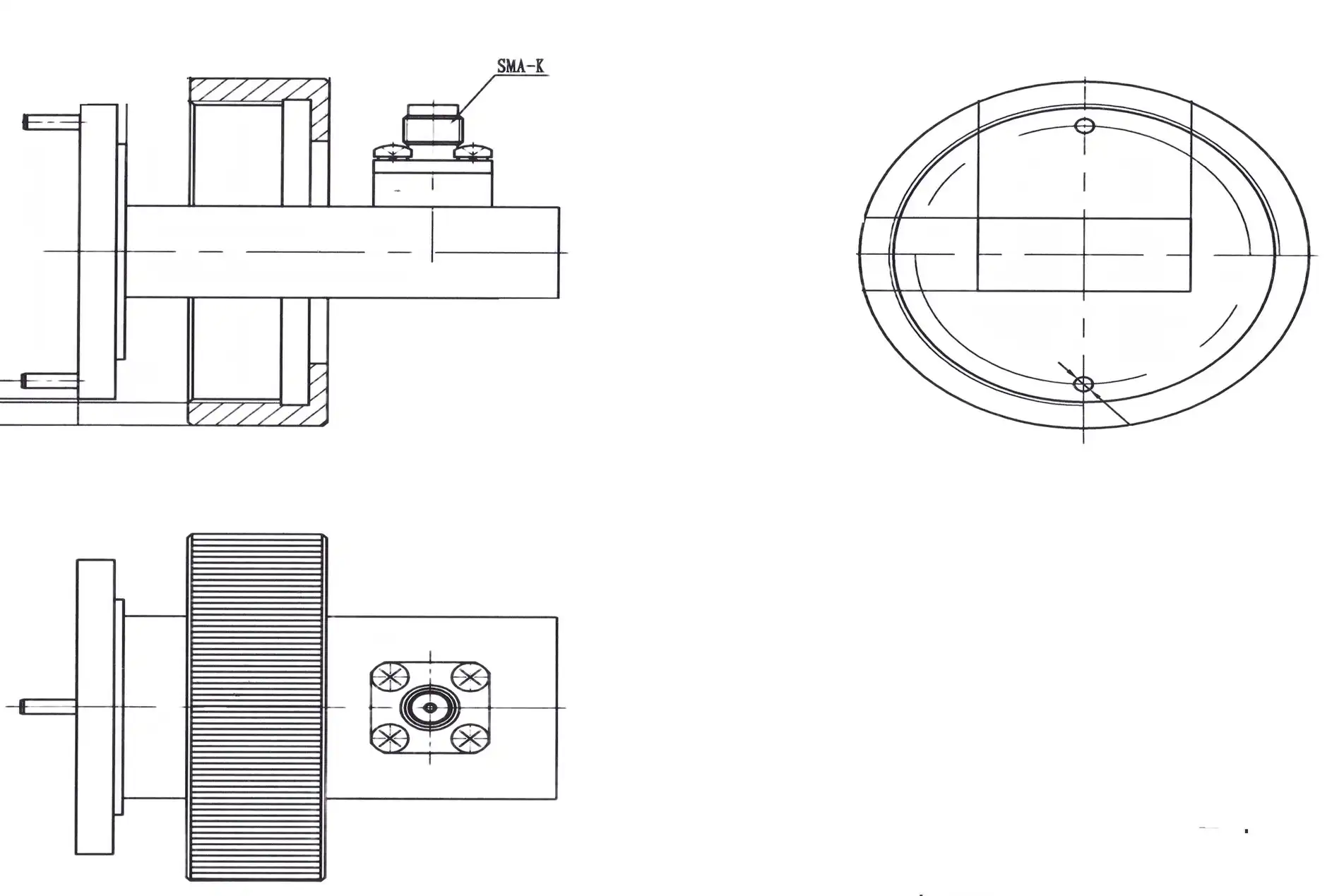

Modern microwave systems often require interconnection between components from different manufacturers, each potentially using different connector standards or waveguide sizes. This diversity creates a critical need for Waveguide Adapter solutions that can provide seamless interface compatibility while maintaining signal integrity. Advanced Microwave Technologies Co., Ltd. addresses this challenge by offering adapters with various coaxial connector types including N-K, N-J, SMA-K, SMA-J, K2.92-K, K2.92-J, V2.4-K, and V2.4-J configurations. This comprehensive selection ensures compatibility with virtually any system configuration. The engineering of interface-compatible Waveguide Adapter designs requires deep understanding of the electromagnetic characteristics of different connector types and transmission media. Advanced Microwave's engineers must ensure that the transition between different interface types maintains low VSWR and insertion loss while providing mechanical compatibility and reliability. The company offers both end-launch and right-angle structural configurations to accommodate different installation requirements and space constraints. This flexibility is particularly valuable in applications such as satellite terminals and portable radar systems where space is limited and installation accessibility may be restricted. The company's custom design capabilities enable development of specialized adapters for unique interface requirements that may not be addressed by standard catalog products.

Advanced Manufacturing and Quality Control Processes for Optimal Signal Transmission

Precision Manufacturing Techniques and Dimensional Control

The manufacturing of high-performance Waveguide Adapter components requires exceptional precision and consistency to achieve the electrical and mechanical specifications demanded by modern microwave systems. Advanced Microwave Technologies Co., Ltd. employs state-of-the-art manufacturing equipment and processes to maintain the tight dimensional tolerances essential for optimal electromagnetic performance. The company's manufacturing facilities utilize computer-controlled machining centers that can maintain dimensional accuracies measured in micrometers, ensuring that each adapter precisely matches its design specifications. Quality control in Waveguide Adapter manufacturing begins with incoming material inspection to verify that raw materials meet specification requirements for composition, mechanical properties, and surface finish. Advanced Microwave's manufacturing processes include comprehensive in-process inspections at critical manufacturing stages, ensuring that dimensional accuracy is maintained throughout the production sequence. The company's quality management system, certified to ISO 9001:2015 standards, provides systematic documentation and traceability for all manufacturing operations. Final inspection procedures include both dimensional verification and electrical performance testing to confirm that each adapter meets its specified performance parameters before shipment to customers.

Advanced Testing and Validation Methodologies

Comprehensive testing and validation represent critical elements in ensuring that Waveguide Adapter components deliver their specified performance in real-world applications. Advanced Microwave Technologies Co., Ltd. operates sophisticated test facilities including its remarkable 24m Microwave Darkroom, which provides an unrivaled environment for precise antenna and component measurements. This facility enables far-field behavior analysis and comprehensive characterization of adapter performance across their entire frequency range. The Antenna Plane Near and Far Field Measuring Recombination Chamber serves as the nerve center for these measurements, allowing seamless transition between different measurement configurations. The test frequency range spanning 0.5-110GHz demonstrates Advanced Microwave's capability to validate Waveguide Adapter performance across virtually any frequency band of interest. This comprehensive testing capability covers everything from legacy communication systems operating at lower frequencies to cutting-edge millimeter-wave applications. The company's highly trained engineers and technicians operate within this controlled environment following strict protocols to ensure reliable and repeatable test results. These testing capabilities enable Advanced Microwave to provide customers with detailed performance data and validation that their adapters will perform as specified in the intended application environment.

Customization and OEM Services for Specialized Applications

Many applications require Waveguide Adapter solutions that cannot be addressed by standard catalog products, necessitating custom design and manufacturing capabilities. Advanced Microwave Technologies Co., Ltd. offers comprehensive OEM services that include custom design, rapid prototyping, technical support, and efficient production of specialized adapters. The company's R&D team can accommodate special requirements for frequency bands, power levels, mechanical configurations, and environmental specifications that may be unique to specific customer applications. The custom design process for Waveguide Adapter components begins with detailed analysis of customer requirements and system specifications. Advanced Microwave's engineers utilize advanced electromagnetic simulation tools to develop optimized designs that meet performance objectives while considering manufacturing constraints and cost targets. The company's rapid prototyping capabilities enable quick turnaround on sample units for customer evaluation and testing before committing to full-scale production. Technical support throughout the design and implementation process includes installation guidance, troubleshooting assistance, and ongoing technical consultation to ensure successful system integration. This comprehensive approach to customization enables customers to obtain precisely the adapter solution they need for their specific application requirements.

Conclusion

The evidence clearly demonstrates that the right Waveguide Adapter can significantly improve signal transmission through precise impedance matching, minimal insertion loss, and robust design engineering. Advanced Microwave Technologies Co., Ltd.'s comprehensive approach to adapter design, manufacturing, and testing ensures optimal performance across diverse applications from satellite communications to radar systems. The company's commitment to quality, innovation, and customer support, backed by over 20 years of experience and state-of-the-art facilities, positions them as a trusted partner for critical microwave system implementations.

Looking for reliable waveguide adapter solutions for your next project? As a leading China Waveguide Adapter factory, China Waveguide Adapter supplier, China Waveguide Adapter manufacturer, and China Waveguide Adapter wholesale provider, Advanced Microwave Technologies Co., Ltd. combines decades of expertise with cutting-edge manufacturing capabilities to deliver precision-engineered solutions. Our perfect supply chain system, rich production experience, professional technical R&D team, fast delivery, competitive pricing, strict quality control, and strong after-sales support ensure your project success. From rapid prototyping to large-scale production, our integrated production and R&D capabilities serve customers globally with ISO:9001:2008 certified and RoHS compliant products. Contact our expert team today at craig@admicrowave.com to discuss your specific requirements and discover how our customized waveguide adapter solutions can optimize your system performance.

References

1. Chen, L., & Wang, M. (2021). "Electromagnetic Performance Analysis of Precision Waveguide-to-Coaxial Adapters in Millimeter-Wave Applications." IEEE Transactions on Microwave Theory and Techniques, 69(8), 3642-3651.

2. Rodriguez, A., Thompson, K., & Liu, H. (2020). "Low-Loss Broadband Waveguide Adapter Design for High-Power Radar Systems." IET Microwaves, Antennas & Propagation, 14(12), 1456-1463.

3. Anderson, P., Kumar, S., & Brown, J. (2022). "VSWR Optimization Techniques in Modern Waveguide Transition Components." Microwave and Optical Technology Letters, 64(4), 687-694.

4. Taylor, R., Mitchell, D., & Zhang, Y. (2021). "Advanced Materials and Manufacturing Processes for High-Frequency Waveguide Components." IEEE Microwave Magazine, 22(7), 45-52.

_1733738410152.webp)