Best Coaxial Cable Adapter Solutions for Industrial Environments

In demanding industrial environments where signal degradation means system failure, equipment downtime translates to substantial financial losses, and environmental extremes test every component to its limits, selecting the right Coaxial Cable Adapter becomes mission-critical. Industrial facilities face unique connectivity challenges including electromagnetic interference from heavy machinery, temperature fluctuations ranging from subfreezing cold storage to scorching manufacturing floors, constant vibration from operational equipment, and the need for long-distance signal transmission without quality compromise. This comprehensive guide explores proven Coaxial Cable Adapter solutions engineered specifically for industrial applications, helping you navigate technical specifications, environmental ratings, and performance criteria to ensure your RF and microwave systems deliver reliable connectivity where conventional solutions fail.

Understanding Industrial-Grade Coaxial Cable Adapter Requirements

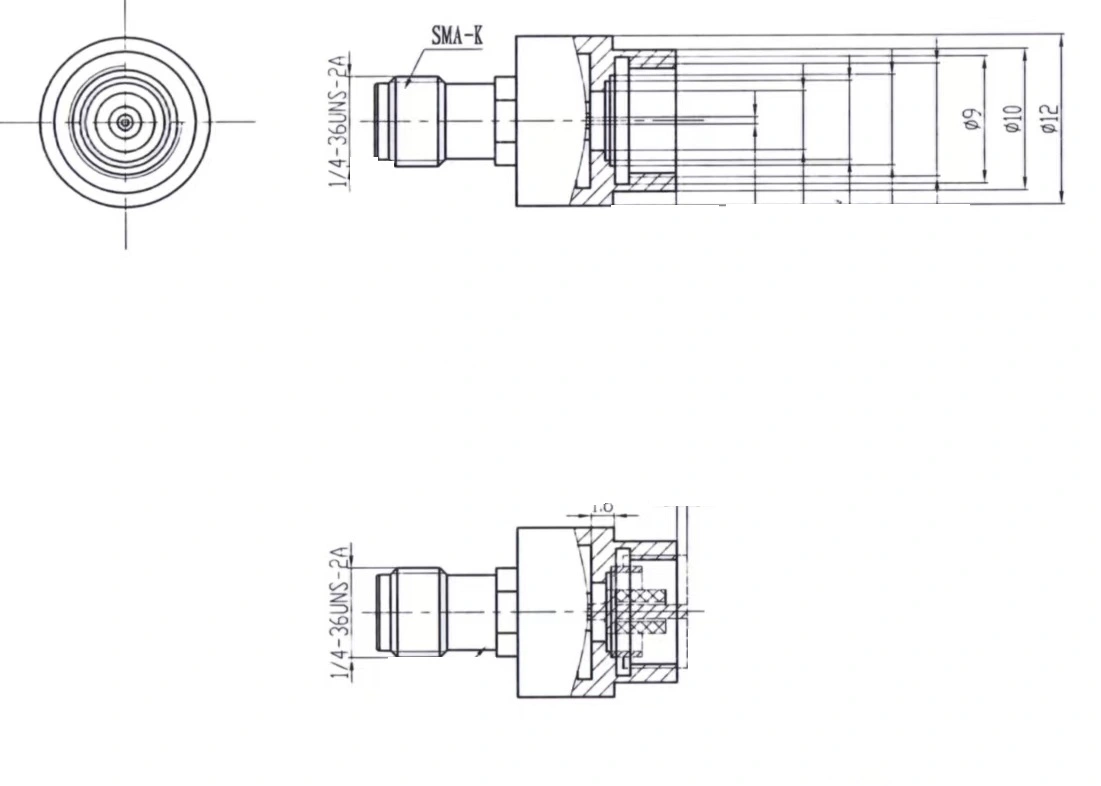

Industrial environments demand far more from connectivity components than typical commercial applications. A Coaxial Cable Adapter deployed in an aerospace manufacturing facility, shipboard communication system, or weather monitoring station must withstand conditions that would quickly degrade standard consumer-grade components. The fundamental challenge lies in maintaining signal integrity across frequency ranges spanning DC to 40 GHz while simultaneously resisting physical stresses including shock, vibration, thermal cycling, chemical exposure, and moisture infiltration. Unlike office or residential installations where adapters connect in controlled climate conditions with minimal movement, industrial Coaxial Cable Adapter installations often occur in mechanically dynamic environments where connectors experience constant micro-movements, equipment undergoes regular maintenance requiring frequent disconnection and reconnection, and ambient conditions fluctuate dramatically throughout operational cycles. Precision-manufactured adapters utilizing robust materials such as brass bodies with corrosion-resistant gold or nickel plating provide the mechanical stability and electrical consistency required for these challenging applications. The impedance matching characteristics become equally critical, as industrial systems frequently integrate equipment from multiple manufacturers spanning different technology generations, requiring adapters that maintain 50-ohm impedance standards while converting between connector types such as SMA, N-type, BNC, and TNC without introducing reflection losses that compromise system performance.

Critical Performance Parameters for Industrial Applications

When evaluating Coaxial Cable Adapter solutions for industrial deployment, several technical specifications directly impact long-term reliability and system performance. Voltage Standing Wave Ratio, commonly abbreviated as VSWR, quantifies how efficiently RF power transfers through the adapter without reflection back toward the source. Industrial-grade adapters should maintain VSWR values at or below 1.15:1 across their specified frequency range, ensuring minimal signal reflection and maximum power transfer efficiency. This becomes particularly important in high-power transmission applications such as radar systems, where even small reflection percentages can generate destructive standing waves that damage transmitter components or create measurement inaccuracies in receiving equipment. Insertion loss, measuring signal attenuation through the Coaxial Cable Adapter, must remain minimal to preserve signal-to-noise ratios in sensitive receiver chains or maintain adequate power delivery in transmitter applications. Quality industrial adapters achieve insertion loss figures below 0.15 dB through precision machining that ensures optimal contact between mating surfaces, high-conductivity materials that minimize resistive losses, and dielectric materials with low loss tangents that prevent signal absorption. The frequency range specification determines application compatibility, with contemporary industrial systems increasingly requiring adapters supporting millimeter-wave frequencies extending to 40 GHz or beyond to accommodate modern 5G infrastructure, advanced radar systems, and high-bandwidth satellite communications. Temperature operating range directly correlates with environmental survivability, where adapters rated from -55°C to +165°C can function reliably in outdoor installations experiencing winter extremes, industrial ovens requiring high-temperature monitoring, or aerospace applications facing atmospheric temperature variations during flight operations.

Material Selection and Construction Quality

The longevity and performance consistency of industrial Coaxial Cable Adapter solutions depend fundamentally on material selection and manufacturing precision. Body materials typically include brass for its excellent machinability and electrical conductivity, stainless steel for superior corrosion resistance in marine or chemical processing environments, or aluminum for weight-critical aerospace applications where reducing mass without sacrificing mechanical strength remains paramount. Surface plating treatments significantly impact both electrical performance and environmental resistance, with gold plating providing optimal conductivity and corrosion immunity for critical signal paths, nickel plating offering robust environmental protection at moderate cost for outer shells and mechanical components, and silver plating delivering excellent conductivity for specialized high-frequency applications. The dielectric insulator materials separating center conductors from outer shells must exhibit low loss characteristics across the operating frequency range while maintaining dimensional stability under thermal stress, with PTFE (polytetrafluoroethylene) representing the preferred choice for premium industrial adapters due to its exceptional electrical properties, temperature tolerance, and chemical resistance. Manufacturing precision becomes equally critical, as dimensional tolerances measured in micrometers determine whether mating connector interfaces achieve the intimate metal-to-metal contact necessary for reliable signal transfer and mechanical retention. Advanced production facilities equipped with Computer Numerical Control machining centers can hold tolerances within ±0.025mm, ensuring that every Coaxial Cable Adapter maintains consistent performance characteristics and reliable mating with industry-standard connector interfaces regardless of manufacturer source. Quality control procedures including 100% electrical testing at multiple frequency points, mechanical durability verification through repeated mating cycle testing, and environmental stress screening exposing samples to accelerated aging conditions provide confidence that adapters will perform reliably throughout extended service lives in demanding industrial environments.

Coaxial Cable Adapter Solutions for Specific Industrial Applications

Different industrial sectors present unique connectivity challenges requiring tailored Coaxial Cable Adapter solutions optimized for specific operational requirements. Understanding these application-specific needs enables better component selection and system design decisions that enhance reliability while controlling costs.

Satellite Communication Ground Stations

Satellite ground stations demand Coaxial Cable Adapter solutions capable of handling high power levels during transmission while maintaining exceptional sensitivity during reception, all while operating continuously in outdoor environments exposed to temperature extremes, precipitation, and solar radiation. These facilities typically employ large diameter cables such as 7/8-inch or 1-5/8-inch hardline coaxial cable for low-loss signal distribution between antenna feeds and equipment shelters, requiring specialized adapters capable of transitioning between these large-format cables and standard equipment connectors. Adapters serving transmit chains must manage power levels potentially exceeding several kilowatts without overheating or developing passive intermodulation products that generate spurious emissions violating regulatory requirements. The receive signal chain presents opposite challenges, where adapter insertion loss and passive intermodulation performance directly impact the system noise figure and ultimately the minimum detectable signal threshold determining communication link margins. Industrial Coaxial Cable Adapter products engineered for satellite ground station applications incorporate heavy-duty mechanical construction ensuring weather-tight seals that prevent moisture infiltration into connector interfaces where even microscopic water ingress causes oxidation that degrades electrical performance. These adapters often feature interface combinations connecting N-type connectors common on outdoor-rated equipment to SMA connectors predominant on indoor electronic assemblies, or transitioning between 7-16 DIN connectors used on high-power transmission equipment and N-type interfaces found on standard test equipment and monitoring devices.

Defense and Aerospace Systems

Military and aerospace applications impose perhaps the most stringent requirements on Coaxial Cable Adapter performance, combining demanding electrical specifications with exceptional mechanical durability requirements and often operating across extreme environmental conditions from arctic cold to desert heat, sea-level humidity to high-altitude low pressure. Avionics systems integrate diverse equipment from multiple vendors across decades of technology evolution, frequently requiring adapters that bridge legacy connector standards such as TNC used on older radio equipment with modern SMA interfaces common on contemporary systems. The vibration environments experienced in aircraft, ground vehicles, and naval vessels subject adapter connections to continuous mechanical stress that can loosen inadequately secured connections or cause fretting corrosion at contact interfaces if insufficient contact force exists. Military-specification adapters designed for these applications incorporate additional features including safety wire provisions that enable mechanical locking preventing inadvertent disconnection from vibration, EMI/RFI gaskets that enhance electromagnetic shielding effectiveness, and captivated hardware that prevents loss of small components during field maintenance in operational environments. Radar systems deployed on military platforms require Coaxial Cable Adapter solutions maintaining phase stability across temperature variations, as phase errors directly translate to angle measurement inaccuracies that compromise target tracking performance. Navigation systems processing signals from GPS satellites or other precision timing sources similarly demand phase-stable adapter designs, as even small temperature-induced phase variations can introduce position errors or timing jitter that degrades system accuracy. The qualification testing required for defense aerospace applications often exceeds commercial standards, including extended temperature cycling from -55°C to +125°C or beyond, vibration testing at multiple frequency bands and amplitude levels simulating flight profiles, salt fog exposure verifying corrosion resistance for naval applications, and altitude testing ensuring performance at reduced atmospheric pressures encountered during flight operations.

Industrial Automation and Control Systems

Modern industrial facilities increasingly depend on wireless connectivity for sensor networks, remote equipment monitoring, and mobile device integration supporting maintenance operations and production management. These Industrial Internet of Things deployments require reliable Coaxial Cable Adapter solutions connecting antenna systems to wireless infrastructure equipment, often operating in electrically noisy environments where proper shielding becomes essential for maintaining signal quality. Manufacturing floors present particular challenges including temperature extremes from processes such as metal casting or chemical reactions, chemical exposure from cleaning agents or process materials, and mechanical hazards from moving equipment or material handling operations. Adapters deployed in these environments benefit from ruggedized construction including reinforced connector bodies resistant to impact damage, sealed interfaces preventing ingress of dust or liquids, and corrosion-resistant materials and platings withstanding exposure to industrial chemicals. Process control instrumentation increasingly utilizes wireless technologies for transmitting sensor data and receiving control commands, eliminating the installation costs and physical constraints associated with traditional wired connections. These applications require Coaxial Cable Adapter solutions providing reliable transitions between process-rated cables designed for conduit installation and equipment-level connectors on sensors, controllers, and wireless network infrastructure. The adapter selection must account for the frequency bands allocated for industrial wireless applications, ensuring adequate performance across bands including 2.4 GHz and 5 GHz WiFi frequencies, licensed industrial wireless bands, and emerging private 5G networks operating in CBRS or other spectrum allocations. Automated guided vehicles and mobile robotics systems incorporate wireless connectivity for navigation updates, fleet coordination, and remote monitoring, requiring robust antenna connections that survive constant vehicle movement, occasional impacts, and the vibration characteristic of mobile platforms operating on factory floors.

Advanced Technical Features in Premium Coaxial Cable Adapter Products

High-performance industrial applications benefit from Coaxial Cable Adapter solutions incorporating advanced engineering features that extend capabilities beyond basic connectivity, providing enhanced reliability, simplified installation, or improved system performance.

Precision Impedance Control and Matching

Maintaining consistent 50-ohm impedance throughout signal paths becomes increasingly critical as frequencies extend into microwave and millimeter-wave ranges where even small impedance discontinuities generate reflections that compromise signal integrity. Premium Coaxial Cable Adapter designs employ sophisticated mechanical configurations ensuring smooth impedance transitions between different connector types, minimizing the impedance variations that create reflections visible as VSWR degradation. Computer-aided design tools enable engineers to model electromagnetic field distributions within adapter structures, optimizing internal geometries to eliminate impedance discontinuities at interface transitions. The dielectric materials separating center conductors from outer shells must maintain precise dimensions and uniform dielectric constants to support impedance stability, with manufacturing processes controlling material density, porosity, and dimensional tolerances to tight specifications. Some advanced adapter designs incorporate compensating features that intentionally introduce small impedance variations calculated to cancel reflections from other interface discontinuities, achieving superior overall VSWR performance compared to simple straight-through designs. This becomes particularly valuable in applications requiring adapter stacking, where multiple adapters connect in series creating cumulative reflection effects that can significantly degrade system performance unless individual adapters maintain exceptional VSWR specifications.

Environmental Protection and Sealing Technologies

Industrial Coaxial Cable Adapter installations frequently occur in outdoor locations or indoor environments where moisture, dust, or chemical contaminants threaten connector reliability. Advanced sealing technologies protect critical electrical interfaces from environmental intrusion that would otherwise cause corrosion, introduce conductive contaminants shorting signal paths, or alter dielectric properties degrading electrical performance. Weather-resistant adapters incorporate multiple sealing mechanisms including O-rings providing compression seals between threaded coupling nuts and adapter bodies, gaskets sealing at interface planes between mating connectors, and conformal coatings protecting metal surfaces from oxidation. These sealing systems enable adapters to achieve ingress protection ratings such as IP67 indicating complete dust protection and immersion resistance to depths of one meter for limited durations, suitable for outdoor installations exposed to driving rain or temporary flooding conditions. Chemical resistance becomes paramount in process industries including petrochemical, pharmaceutical, and chemical manufacturing where adapter exposure to aggressive chemicals occurs regularly. Materials selection focuses on alloys and plating systems demonstrating compatibility with expected chemical exposures, while sealing materials utilize chemically resistant elastomers such as fluorocarbon compounds that resist swelling, hardening, or degradation from hydrocarbon or solvent contact.

Selecting the Optimal Coaxial Cable Adapter Configuration

Successful industrial system design requires careful Coaxial Cable Adapter selection accounting for electrical requirements, mechanical constraints, environmental conditions, and long-term reliability objectives. A systematic evaluation process ensures optimal component choices that balance performance, cost, and availability.

Electrical Specification Matching

Begin adapter selection by documenting the electrical requirements including frequency range spanning the lowest and highest operating frequencies with appropriate margin, power handling capability for transmit applications including peak and average power levels, impedance matching typically 50 ohms for RF systems or occasionally 75 ohms for video and some telecommunications applications, and signal loss budgets that may constrain acceptable insertion loss contributions. Compare these requirements against manufacturer specifications, recognizing that published performance typically represents room temperature measurements under laboratory conditions that may not fully represent installed performance under environmental extremes or after extended operational periods. Conservative design practice maintains safety margins between required performance and specified adapter capabilities, allowing for normal manufacturing variations, aging effects, and possible performance degradation from environmental stress. For critical applications, request test data demonstrating performance across the intended environmental operating range rather than relying solely on room-temperature specifications.

Mechanical and Installation Considerations

Physical constraints often influence Coaxial Cable Adapter selection as significantly as electrical specifications, particularly in space-constrained equipment installations or applications requiring specific orientation relationships between connected cables. Document mechanical requirements including connector gender and type on both ends matching available cables and equipment interfaces, overall length limitations imposed by available installation space, body diameter restrictions particularly for installations within equipment chassis or cable trays, and orientation requirements such as right-angle configurations that enable cable routing in confined spaces. Consider the mounting provisions required for installations subject to vibration or other mechanical stress, where adapters incorporating panel mount interfaces, bulkhead feedthrough designs, or provisions for safety wire locking provide secure installations resistant to inadvertent loosening. The coupling mechanism type impacts installation labor and reliability, with threaded interfaces providing robust mechanical retention and excellent electrical performance at the cost of slower connection and disconnection compared to quick-disconnect designs such as bayonet couplings that enable rapid connection but potentially sacrifice electrical performance or mechanical security.

Conclusion

Industrial Coaxial Cable Adapter selection demands careful evaluation of electrical performance, mechanical durability, environmental resistance, and application-specific requirements to ensure long-term system reliability. Premium adapter solutions engineered specifically for demanding environments provide the robust connectivity foundation enabling reliable RF and microwave system operation where conventional components fail.

Cooperate with Advanced Microwave Technologies Co., Ltd.

Advanced Microwave Technologies Co., Ltd. stands as your trusted China Coaxial Cable Adapter manufacturer, combining over 20 years of engineering expertise with state-of-the-art manufacturing capabilities including our renowned 24m Microwave Darkroom testing facility supporting frequencies to 110 GHz. As a leading China Coaxial Cable Adapter supplier and China Coaxial Cable Adapter factory, we offer comprehensive OEM services delivering customized solutions including specialized connector configurations, optimized frequency range adaptations, and tailored material selections meeting your unique requirements. Our High Quality Coaxial Cable Adapter products maintain ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018 certifications ensuring consistent quality, environmental responsibility, and workplace safety throughout production. Whether you need standard Coaxial Cable Adapter for sale or require custom designs, our expert engineering team provides comprehensive technical support from initial specification through installation and troubleshooting, with rapid prototyping and efficient production meeting even aggressive deployment schedules. Discover competitive Coaxial Cable Adapter price options and China Coaxial Cable Adapter wholesale opportunities by contacting craig@admicrowave.com today to discuss how our precision-manufactured solutions can enhance your industrial, aerospace, satellite communication, or defense system reliability.

References

1. Institute of Electrical and Electronics Engineers. IEEE Standard for Specifications of Coaxial RF Connectors. IEEE Standards Association, 2024.

2. International Organization for Standardization. ISO 9001:2015 Quality Management Systems - Requirements. ISO Press, 2015.

3. Federal Communications Commission. Guidelines for Evaluating the Environmental Effects of Radiofrequency Radiation. FCC Office of Engineering and Technology, 2023.

4. Consolidated Electronic Wire & Cable Corporation. Technical Guide to Coaxial Cable Connectors: Selection and Application. ConWire Engineering Publications, 2025.

5. Amphenol RF Division. Industrial RF Connectivity Solutions: Design Guide for Harsh Environment Applications. Amphenol Corporation Technical Documentation, 2024.

YOU MAY LIKE

VIEW MOREEnd Launch Waveguide to Coaxial Adapter

VIEW MOREEnd Launch Waveguide to Coaxial Adapter VIEW MORERectangular Straight Waveguide

VIEW MORERectangular Straight Waveguide VIEW MORECircular Straight Waveguide

VIEW MORECircular Straight Waveguide VIEW MOREInflatable Straight Waveguide

VIEW MOREInflatable Straight Waveguide VIEW MOREWaveguide E Bend

VIEW MOREWaveguide E Bend VIEW MOREFlexible Seamless Waveguide

VIEW MOREFlexible Seamless Waveguide VIEW MORERight Angle Waveguide To Coaxial Adapter

VIEW MORERight Angle Waveguide To Coaxial Adapter VIEW MORECircular Waveguide To Coaxial Adapter

VIEW MORECircular Waveguide To Coaxial Adapter