What does a directional coupler do?

In modern RF and microwave systems, signal integrity can make or break your entire communication network. When transmitters fail, radars lose accuracy, or satellite links degrade without warning, engineers often discover the root cause lies in inadequate signal monitoring. A Coaxial Directional Coupler serves as the critical solution, sampling RF power flowing through transmission lines while maintaining signal quality and enabling real-time performance analysis across frequencies from DC to 110 GHz.

Understanding the Core Function of Coaxial Directional Couplers

A Coaxial Directional Coupler operates as a four-port passive device that extracts a precise fraction of electromagnetic power from a primary transmission line and redirects it to a secondary monitoring port. This fundamental capability allows engineers to analyze signal characteristics without disrupting the main power flow or introducing significant signal degradation. The device's directional sensitivity means it can distinguish between forward-traveling waves moving from source to load and reflected waves bouncing back from impedance mismatches, providing invaluable diagnostic information about system performance. The operational principle relies on electromagnetic coupling between two transmission lines running parallel to each other. When RF energy travels through the main line connecting the input port to the output port, a controlled portion of this energy couples into the adjacent secondary line through electromagnetic field interaction. The coupling strength depends on several factors including the physical separation between conductors, the length of the coupling region, and the dielectric properties of the materials separating the lines. Advanced designs incorporate precise mechanical tolerances and material selection to achieve coupling factors ranging from 10 dB to 30 dB or higher, ensuring engineers can select the appropriate sampling level for their specific measurement requirements. In practical implementations, the Coaxial Directional Coupler provides simultaneous access to both the coupled port, which receives a sample of the forward-traveling signal, and the isolated port, which theoretically receives no power but in reality captures a small amount due to imperfect directivity. This dual-port architecture enables sophisticated measurement techniques such as calculating voltage standing wave ratio (VSWR), determining return loss, and monitoring both transmitted and reflected power levels. The device maintains excellent port-to-port isolation, typically exceeding 30 dB, which prevents unwanted signal leakage that could compromise measurement accuracy or interfere with sensitive receiving equipment connected to the monitoring ports.

Technical Performance Parameters That Define Quality

Insertion Loss and Signal Efficiency

The insertion loss characteristic of a Coaxial Directional Coupler quantifies the power reduction experienced by signals traveling through the main transmission path from input to output. High-quality directional couplers, such as those manufactured by Advanced Microwave Technologies Co., Ltd, maintain insertion losses below 0.2 dB across their entire operating frequency range. This minimal loss preserves signal strength and system efficiency, particularly critical in high-power transmission systems where every decibel of lost power translates to reduced coverage area or degraded communication range. The low insertion loss results from careful impedance matching at all ports, precision manufacturing that minimizes discontinuities in the transmission path, and selection of low-loss dielectric materials that reduce energy dissipation through heat generation.

Directivity and Isolation Specifications

Directivity measures the Coaxial Directional Coupler's ability to separate forward and reverse traveling waves, expressed as the ratio between power at the coupled port and power at the isolated port when both measurements originate from the same input signal. Superior directivity, typically exceeding 30 dB in professional-grade couplers, ensures that reflected power measurements remain uncontaminated by forward power leakage, enabling accurate load characterization and fault detection. The isolation parameter, closely related to directivity, quantifies the signal separation between the input and isolated ports, preventing feedback loops and oscillations that could destabilize active circuits. Advanced Microwave Technologies Co., Ltd achieves isolation values greater than 30 dB through optimized coupling geometry, precision machining, and strategic placement of absorptive materials that suppress unwanted coupling paths.

Frequency Response and Bandwidth Capabilities

Modern communication systems operate across progressively wider frequency bands, demanding Coaxial Directional Couplers with exceptionally broad bandwidth performance. Advanced Microwave's directional couplers cover frequency ranges from DC to 110 GHz, accommodating everything from legacy narrowband systems to emerging millimeter-wave applications including 5G cellular networks and future 6G technologies. The ultra-broadband performance stems from sophisticated coupling structures that maintain consistent coupling factors, low VSWR, and stable phase relationships across multiple octaves of frequency span. This frequency agility eliminates the need for multiple specialized couplers when working with systems that operate across different frequency bands, reducing inventory costs and simplifying test equipment configurations.

Critical Applications Across Multiple Industries

Satellite Communication Systems

In satellite ground stations and space-based transponders, Coaxial Directional Couplers enable continuous monitoring of high-power transmitter outputs without interrupting mission-critical communication links. Engineers utilize coupled port signals to verify transmission power levels, ensuring compliance with regulatory requirements and preventing interference with adjacent satellite systems. The directional coupling capability proves essential for measuring antenna system VSWR, detecting feed network failures, and implementing automatic power control loops that compensate for atmospheric attenuation during severe weather events. Advanced Microwave's couplers withstand the harsh environmental conditions encountered in satellite applications, including extreme temperature cycling, high humidity, and intense ultraviolet radiation exposure, while maintaining measurement accuracy over decades of continuous operation.

Defense and Aerospace Radar Systems

Military surveillance radars and aerospace navigation systems rely on Coaxial Directional Couplers for precision power monitoring and signal distribution throughout complex antenna arrays. The ability to sample transmitted radar pulses allows operators to verify proper power output, detect component degradation before complete failure occurs, and maintain calibration of receiver protection circuits that prevent damage from high-power transmitter leakage. In phased array radar implementations, multiple directional couplers distribute calibration signals to individual array elements, enabling electronic beam steering and null formation for interference suppression. The high power handling capability, with some models supporting up to 500 watts of continuous power, accommodates the demanding requirements of long-range search radars and weather monitoring installations that operate with multi-kilowatt transmitters.

Telecommunications Infrastructure

Base stations and cell towers throughout global telecommunications networks incorporate Coaxial Directional Couplers into their transmitter monitoring and antenna line testing equipment. These couplers facilitate real-time VSWR measurement, allowing maintenance technicians to detect antenna system faults such as damaged coaxial cables, loose connectors, or water ingress before they cause complete service outages. The coupled signals feed spectrum analyzers and power meters that verify transmitted signal quality, measure adjacent channel power ratios, and ensure compliance with spectral mask requirements. In distributed antenna systems serving large buildings or transportation tunnels, directional couplers enable monitoring of multiple remote antenna locations from a central equipment room, reducing maintenance costs and improving network reliability.

Advanced Design Features and Manufacturing Excellence

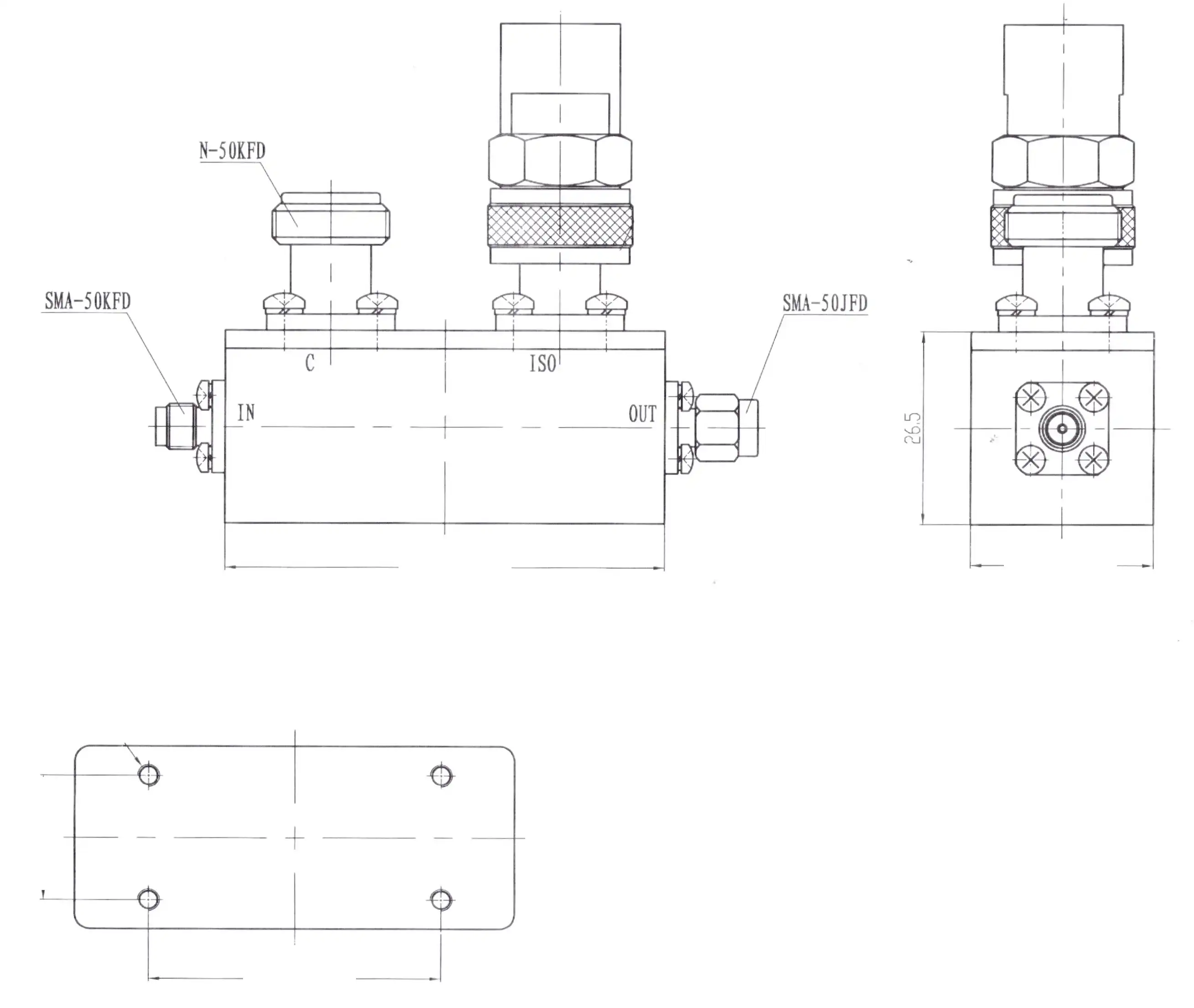

Advanced Microwave Technologies Co., Ltd manufactures Coaxial Directional Couplers using state-of-the-art facilities including a remarkable 24-meter microwave darkroom equipped with antenna plane near and far field measuring recombination chambers. This advanced testing capability ensures every directional coupler meets stringent performance specifications across the entire 0.5 to 110 GHz frequency range before shipment to customers. The company's ISO 9001:2015 certification guarantees consistent quality through documented manufacturing processes, comprehensive testing protocols, and rigorous inspection procedures that trace every component throughout production. The mechanical construction of these Coaxial Directional Couplers emphasizes durability and environmental resilience. Housings fabricated from aluminum or stainless steel provide excellent electromagnetic shielding while resisting corrosion in marine and industrial atmospheres. Precision-machined connector interfaces, available in SMA, N-Type, or custom configurations, ensure reliable mating with external equipment and minimize signal reflections that would degrade measurement accuracy. Internal transmission line structures utilize carefully controlled dielectric materials and gold-plated conductors to minimize losses and maintain stable electrical performance across temperature extremes ranging from negative 40 to positive 85 degrees Celsius.

Customization and OEM Services

Recognizing that different applications demand unique specifications, Advanced Microwave Technologies Co., Ltd offers comprehensive customization services for Coaxial Directional Coupler products. Engineers work directly with customers to develop solutions featuring custom frequency ranges optimized for specific system architectures, modified coupling values that match particular measurement requirements, and adjusted physical dimensions that fit within space-constrained installations. The company's extensive experience, accumulated over more than 20 years of microwave component development, enables rapid prototyping and quick turnaround times that accelerate customer product development schedules. The OEM service program extends beyond simple parameter adjustments to include complete system integration support. Advanced Microwave's technical team provides in-depth application assistance, including installation guidance, system performance optimization, and troubleshooting support that helps customers achieve maximum value from their directional coupler investments. Custom branding and labeling services allow equipment manufacturers to seamlessly incorporate Advanced Microwave's proven coupler technology into their own product lines while maintaining consistent brand identity. This collaborative approach has established long-term partnerships with telecommunications giants, defense contractors, and research institutions worldwide.

Measurement and Testing Applications

Engineers and technicians utilize Coaxial Directional Couplers in numerous measurement scenarios that require non-intrusive signal sampling. In transmitter testing, the coupled port signal feeds spectrum analyzers that verify frequency accuracy, measure harmonic distortion, and analyze modulation quality without requiring expensive high-power test equipment capable of handling the full transmitter output. Power meter measurements through the coupled port enable continuous monitoring of transmitter output during extended operation, detecting gradual performance degradation that might otherwise go unnoticed until complete failure occurs. Network analyzer calibration procedures frequently employ Coaxial Directional Couplers to extend measurement dynamic range when characterizing high-gain amplifiers or highly reflective components. By sampling the incident signal before it reaches the device under test and separately measuring the reflected signal, engineers can accurately determine input impedance and reflection coefficients even when direct measurement would overload the network analyzer's receivers. This technique proves particularly valuable when testing high-power amplifiers where the device output power exceeds the safe input level of measurement equipment. In production testing environments, directional couplers streamline quality assurance by enabling parallel monitoring of multiple test parameters. A single Coaxial Directional Coupler can simultaneously provide samples to a power meter verifying output level, a frequency counter checking oscillator stability, and a spectrum analyzer screening for spurious emissions. This multi-instrument approach accelerates production throughput while maintaining comprehensive test coverage that ensures only fully compliant products reach customers.

Conclusion

Coaxial Directional Couplers represent indispensable tools for modern RF and microwave engineering, enabling precise signal monitoring across communication, radar, and aerospace applications while maintaining system integrity through minimal insertion loss and excellent isolation performance that safeguards measurement accuracy.

Cooperate with Advanced Microwave Technologies Co., Ltd.

Partner with Advanced Microwave Technologies Co., Ltd., a leading China Coaxial Directional Coupler manufacturer, China Coaxial Directional Coupler supplier, and China Coaxial Directional Coupler factory offering High Quality Coaxial Directional Coupler for sale at competitive Coaxial Directional Coupler price points. As a trusted China Coaxial Directional Coupler wholesale provider, we deliver ISO 9001:2008 certified products backed by over 20 years of microwave expertise, perfect supply chain systems, professional R&D teams, fast delivery, strict quality control, and comprehensive after-sales support. Contact craig@admicrowave.com today for customized solutions tailored to your specifications.

References

1. Bryant, G. H. (1988). Principles of Microwave Measurements. Institution of Engineering and Technology (IET).

2. Pozar, D. M. (2012). Microwave Engineering (4th Edition). John Wiley & Sons.

3. Montgomery, C. G., Dicke, R. H., & Purcell, E. M. (1948). Principles of Microwave Circuits. McGraw-Hill Book Company, Radiation Laboratory Series Volume 8.

4. Collin, R. E. (1992). Foundations for Microwave Engineering (2nd Edition). IEEE Press.

YOU MAY LIKE

VIEW MOREAc Power Amplifier

VIEW MOREAc Power Amplifier VIEW MOREVoltage Controlled Phase Shifter

VIEW MOREVoltage Controlled Phase Shifter VIEW MOREStandard Horn Antenna

VIEW MOREStandard Horn Antenna VIEW MOREConical Horn Lens Antenna

VIEW MOREConical Horn Lens Antenna VIEW MOREPoint Focusing Horn Lens Antenna

VIEW MOREPoint Focusing Horn Lens Antenna VIEW MOREFeed Fired Lens Antenna

VIEW MOREFeed Fired Lens Antenna VIEW MORECorrugated Horn and Multimode Horn Antenna

VIEW MORECorrugated Horn and Multimode Horn Antenna VIEW MOREMini Wideband Double-ridged Horn Antenna

VIEW MOREMini Wideband Double-ridged Horn Antenna