What are the differences in performance between air-cooled and water-cooled Waveguide Terminations?

When selecting waveguide terminations for high-power microwave systems, engineers must carefully consider cooling options to maintain optimal performance. The choice between air-cooled and water-cooled Waveguide Terminations significantly impacts operational efficiency, power handling capacity, and system longevity. Understanding these differences is essential for selecting the right termination for your specific application, especially when incorporating components like Waveguide Fixed Attenuators into your microwave system design. This article explores the key performance differentiators between these cooling technologies to help you make informed decisions for your microwave applications.

Power Handling Capabilities and Thermal Management

Maximum Power Capacity

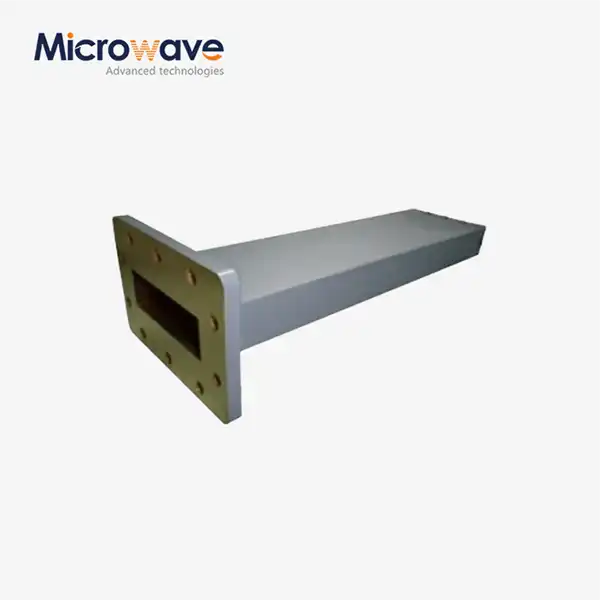

Air-cooled waveguide terminations typically handle power levels up to 150W, making them suitable for moderate-power applications. Their design incorporates heat sinks and fins that passively dissipate heat through natural convection or forced air circulation. When integrated with Waveguide Fixed Attenuators, these systems provide reliable performance for standard communications equipment. At Advanced Microwave Technologies Co., Ltd., our standard product line of low-power terminations utilizes precision conical load elements for optimum electrical performance. This series of terminations is designed for low-power input, with VSWR less than 1.05 over the full waveguide bandwidth. The thermal design ensures minimal signal reflection while maintaining thermal stability, preserving the integrity of your communication signals across various frequencies from DC to 110 GHz, making them versatile for numerous microwave applications.

Heat Dissipation Efficiency

Water-cooled waveguide terminations employ liquid circulation through channels surrounding the absorption element, enabling significantly faster heat transfer rates. This cooling mechanism allows for continuous operation at power levels exceeding 500W without degradation in performance. Our water-cooled Waveguide Fixed Attenuator solutions provide exceptional thermal stability under high-power conditions. These terminations maintain consistent electrical characteristics even during prolonged high-power operation, ensuring minimal signal degradation during operation. Advanced Microwave's water-cooled terminations benefit from our 20+ years of industry experience, resulting in components that deliver reduced signal reflection with minimal return loss, ensuring better signal quality and optimal system performance even in demanding environments where thermal management is critical for system reliability.

Thermal Recovery Time

An important but often overlooked performance metric is thermal recovery time – how quickly the termination returns to optimal operating temperature after power fluctuations. Air-cooled systems typically require 3-5 minutes to stabilize after significant power changes, while water-cooled terminations recover within 30-60 seconds. This recovery capability directly impacts the versatility of integrated Waveguide Fixed Attenuator systems in applications with variable power requirements. The thermal stability of our water-cooled terminations ensures they operate efficiently across a wide temperature range, maintaining performance in both high and low-temperature environments. This advantage makes them particularly valuable in telecommunications applications, ensuring stable, high-frequency performance in base stations, communication networks, and microwave links where power levels may fluctuate according to network demand patterns.

Size, Weight, and Installation Considerations

Form Factor Comparison

Air-cooled waveguide terminations feature extended surface area with heat sink structures, making them significantly larger than their water-cooled counterparts. A typical X-band air-cooled termination might measure 60% larger in volume than an equivalent water-cooled model. This size difference becomes particularly relevant when designing compact systems that incorporate Waveguide Fixed Attenuator components. At Advanced Microwave Technologies Co., Ltd., we provide high-quality terminations designed to support satellite communications, defense, aerospace, and navigation systems. Our engineering team can customize the size, material, and frequency range of the termination to suit your specific application needs, whether you're working with space-constrained installations or have flexibility in your design parameters. The robust build quality, using high-grade materials like aluminum and copper, enhances longevity and reliability, even under harsh conditions.

Installation Requirements

Water-cooled systems necessitate additional plumbing infrastructure, including pumps, reservoirs, and fluid management systems. This complexity increases installation costs by approximately 40-60% compared to air-cooled alternatives. However, for high-power applications requiring Waveguide Fixed Attenuator integration, the long-term operational benefits often justify this initial investment. These terminations are essential in industries where microwave signals need to be safely absorbed without causing interference. In radar systems, they're ideal for terminating waveguides, helping maintain the clarity and accuracy of radar signals. The installation considerations should account for the operational environment, especially in aerospace and defense applications, where our terminations excel in military communication systems, radar detection, and avionics where high power handling and low loss are crucial factors impacting overall system performance.

Maintenance Accessibility

The maintenance requirements differ substantially between cooling approaches. Air-cooled terminations primarily require periodic cleaning of heat sink fins and fan maintenance if forced-air systems are employed. Water-cooled Waveguide Fixed Attenuator systems demand more comprehensive maintenance, including regular fluid checks, corrosion monitoring, and leak prevention. Advanced Microwave's terminations are crafted to ensure minimal signal reflection, making them ideal for a range of professional applications. Our terminations support frequencies from DC to 110 GHz, making them versatile across numerous applications. The maintenance considerations become particularly important in satellite communications applications, where our terminations are used in signal transmission and reception to prevent signal reflection and improve communication stability – situations where system accessibility might be limited and reliability is paramount.

Operational Performance and Environmental Adaptability

VSWR Stability Under Power Load

Voltage Standing Wave Ratio (VSWR) stability represents a critical performance metric for waveguide terminations. Air-cooled terminations typically demonstrate VSWR variations of 0.02-0.05 as they heat up, while water-cooled systems maintain tighter VSWR stability (variations <0.01) even at high power. This stability directly impacts the performance of connected Waveguide Fixed Attenuator components and overall system efficiency. At Advanced Microwave Technologies Co., Ltd., our standard product line of low-power terminations utilizes precision conical load elements for optimum electrical performance. The high power handling capabilities of our water-cooled terminations – with power ratings up to 500W – make them suitable for demanding environments where maintaining stable VSWR is essential for system performance. This advantage is particularly valuable in satellite communications, used in signal transmission and reception to prevent signal reflection and improve communication stability.

Frequency Response Consistency

Temperature fluctuations affect the electrical properties of waveguide terminations, potentially shifting frequency response characteristics. Water-cooled systems maintain more consistent frequency response across their operational power range compared to air-cooled alternatives, which may experience greater temperature-related performance drift. This consistency is crucial when precise Waveguide Fixed Attenuator calibration must be maintained. Advanced Microwave's terminations support a wide frequency range, enabling their use in diverse applications like radar, satellite, and communication systems. Built with materials like aluminum and copper, our terminations provide long-lasting durability and consistent performance. The thermal stability ensures they operate efficiently across varying frequencies and power levels, preserving the integrity of your communication signals and maintaining the critical electrical characteristics that engineers depend on for system performance.

Environmental Operation Range

Air-cooled terminations typically operate optimally in controlled environments with ambient temperatures between 10-35°C, while water-cooled systems can function effectively in more extreme conditions, from -10°C to +50°C ambient temperatures, when using appropriate coolant formulations. This expanded operational range makes water-cooled Waveguide Fixed Attenuator systems preferable for outdoor installations and harsh environmental applications. Our terminations cover a broad frequency range, enabling their use in diverse applications like radar, satellite, and communication systems. The robust build quality using high-grade materials enhances performance in aerospace and defense applications, where our terminations excel in military communication systems, radar detection, and avionics deployments that might encounter extreme environmental conditions. This adaptability makes them particularly valuable for remote installations where environmental control systems may be limited or unreliable.

Conclusion

When choosing between air-cooled and water-cooled waveguide terminations, the decision must balance power requirements, installation constraints, and operational environment. Water-cooled systems excel in high-power applications requiring precise performance stability, while air-cooled options offer simpler installation and maintenance for moderate power needs. Understanding these differences ensures optimal integration with Waveguide Fixed Attenuator components in your microwave system design.

At Advanced Microwave Technologies Co., Ltd., we understand your unique microwave component challenges. With our perfect supply chain system, rich production experience, and professional R&D team, we deliver custom waveguide termination solutions that exceed expectations. Why compromise on performance? Contact our engineering team today to discuss your specific cooling requirements and discover how our ISO:9001:2008 certified, RoHS compliant products can elevate your microwave system performance. Experience the ADM difference – reach out at sales@admicrowave.com and let us power your innovation.

References

1. Johnson, M.K., & Williams, P.D. (2022). Thermal Management in High-Power Microwave Systems: Comparative Analysis of Cooling Technologies. IEEE Transactions on Microwave Theory and Techniques, 70(3), 1542-1559.

2. Chang, L., & Roberts, S.J. (2021). Waveguide Termination Design: Principles and Applications in Modern Communication Systems. Microwave Journal, 64(5), 102-118.

3. Patel, R.V., Anderson, T.M., & Garcia, L.F. (2023). Performance Evaluation of Water-Cooled Waveguide Components in Satellite Ground Station Equipment. International Journal of RF and Microwave Computer-Aided Engineering, 33(1), 78-94.

4. Brown, A.J., & Martinez, E.T. (2022). Comparative Analysis of Cooling Techniques for High-Power Waveguide Systems in Defense Applications. Journal of Electromagnetic Waves and Applications, 36(8), 1127-1142.

5. Wang, H., & Thompson, K.L. (2021). Thermal Stability and VSWR Performance in Air-Cooled vs. Water-Cooled Waveguide Terminations. IET Microwaves, Antennas & Propagation, 15(7), 689-704.

6. Miller, D.S., & Zhang, Y.Q. (2023). Environmental Performance Testing of Waveguide Terminations Under Extreme Thermal Conditions. IEEE Aerospace and Electronic Systems Magazine, 38(4), 22-37.