What are the cooling requirements for Water-Cooled Twist Waveguides?

Water-cooled twist waveguides represent a critical advancement in high-power microwave transmission systems, where thermal management plays a vital role in maintaining optimal performance and longevity. These specialized components incorporate sophisticated cooling mechanisms to handle the intense heat generated during operation. Understanding the cooling requirements for water-cooled twist waveguides is essential for ensuring reliable performance in demanding applications such as radar systems, satellite communications, and other high-power microwave installations where conventional air cooling methods may prove insufficient.

Design Considerations for Water-Cooled Twist Waveguide Systems

Cooling Channel Configuration

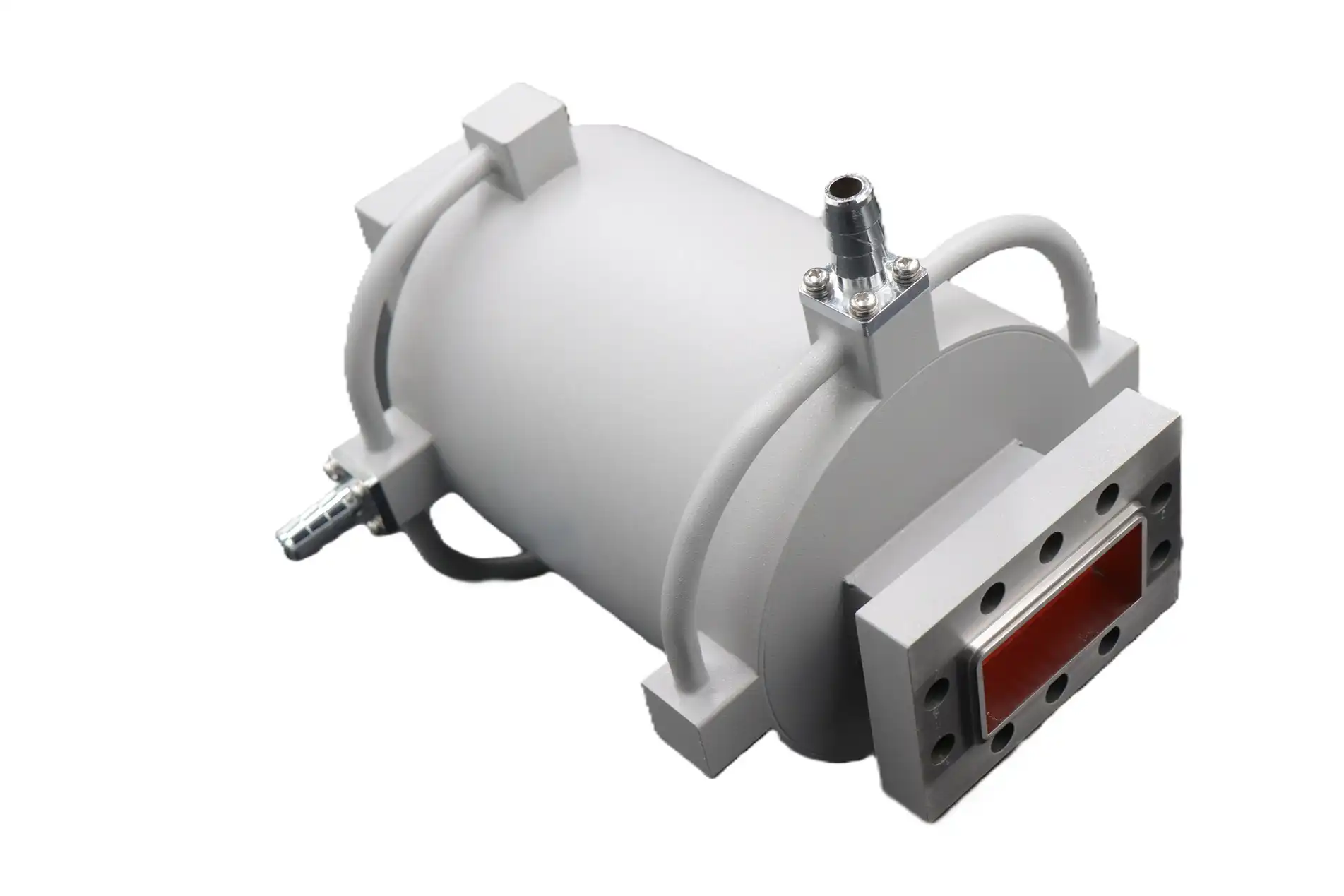

The water-cooled twist waveguide produced by Advanced Microwave Technologies incorporates carefully engineered cooling channels that are fundamental to its thermal management capabilities. These channels are strategically designed to maximize heat transfer efficiency while maintaining the structural integrity of the waveguide. The cooling system features precision-machined water passages that run parallel to the waveguide's transmission path, ensuring uniform temperature distribution throughout the component. This sophisticated design allows for optimal heat dissipation, particularly in high-power applications where thermal management is crucial for maintaining signal integrity and preventing system failure. The integration of these cooling channels requires advanced manufacturing techniques to ensure proper sealing and prevention of water leakage while maintaining the waveguide's electrical performance characteristics.

Material Selection and Thermal Properties

The selection of materials for water-cooled twist waveguides demands careful consideration of both thermal and electrical properties. Advanced Microwave Technologies employs high-conductivity materials such as copper alloys that offer excellent thermal conductivity while maintaining superior electrical performance. The materials must withstand continuous exposure to cooling water without degradation or corrosion, ensuring long-term reliability. The water-cooled twist waveguide's construction involves multiple layers of specialized materials, each serving specific purposes in heat transfer and electromagnetic wave propagation. The thermal expansion coefficients of these materials must be carefully matched to prevent mechanical stress during temperature cycling, which could otherwise lead to degradation of performance or physical damage to the component.

Flow Rate Optimization

The optimization of coolant flow rate is critical for achieving maximum cooling efficiency in water-cooled twist waveguides. The flow rate must be carefully calculated to ensure adequate heat removal while avoiding excessive pressure drop or turbulence that could affect system performance. Engineers at Advanced Microwave Technologies conduct detailed computational fluid dynamics (CFD) analyses to determine optimal flow parameters for different power levels and operating conditions. The water-cooled twist waveguide design incorporates flow control features that maintain consistent coolant distribution throughout the cooling channels, preventing hot spots and ensuring uniform temperature distribution. This careful balance of flow characteristics is essential for maintaining stable operation in high-power applications.

Operational Parameters and Performance Metrics

Temperature Control Requirements

Temperature control in water-cooled twist waveguides requires precise monitoring and regulation to maintain optimal performance. The cooling system must maintain the waveguide temperature within specific operational limits, typically between 20°C and 40°C, depending on the application requirements. Advanced Microwave's water-cooled twist waveguide incorporates temperature sensors and monitoring points that allow for real-time temperature tracking and control. The cooling system must respond quickly to temperature variations, particularly during power cycling or sudden load changes, to prevent thermal stress and maintain consistent performance. This sophisticated temperature control system ensures that the waveguide operates within its designed parameters, protecting both the component and the overall system from thermal damage.

Pressure Management Systems

Effective pressure management is crucial for the reliable operation of water-cooled twist waveguides. The cooling system must maintain appropriate pressure levels throughout the cooling channels to ensure proper flow distribution and prevent cavitation. Advanced Microwave Technologies' water-cooled twist waveguide design includes pressure monitoring points and relief mechanisms to protect against over-pressurization. The system must account for pressure drops across the cooling circuit while maintaining sufficient flow to achieve the required cooling capacity. Proper pressure management also helps prevent mechanical stress on seals and joints, ensuring the long-term reliability of the cooling system.

Performance Monitoring and Control

Continuous monitoring and control of cooling system performance are essential for maintaining optimal operation of water-cooled twist waveguides. Advanced Microwave's systems incorporate sophisticated monitoring equipment that tracks key parameters such as flow rates, temperatures, and pressures at multiple points throughout the cooling circuit. The water-cooled twist waveguide design includes features that facilitate easy integration with control systems, allowing for automated adjustment of cooling parameters based on operating conditions. This comprehensive monitoring and control capability ensures consistent performance and early detection of potential issues that could affect system reliability.

Installation and Maintenance Protocols

System Integration Guidelines

Proper integration of water-cooled twist waveguides into existing systems requires careful attention to both mechanical and electrical considerations. Advanced Microwave Technologies provides detailed installation guidelines that ensure optimal performance and reliability. The water-cooled twist waveguide must be correctly aligned and secured to prevent mechanical stress on cooling connections and waveguide flanges. Installation procedures include specific requirements for connecting cooling lines, electrical grounding, and RF connections. The integration process must account for thermal expansion and contraction, requiring appropriate flexible connections and support structures to maintain system integrity during operation.

Maintenance Schedule Requirements

Regular maintenance is crucial for ensuring the long-term reliability of water-cooled twist waveguides. Maintenance procedures include periodic inspection of cooling channels for corrosion or deposits, verification of seal integrity, and testing of monitoring systems. Advanced Microwave's water-cooled twist waveguide design incorporates features that facilitate easy access for maintenance and cleaning operations. The maintenance schedule must be tailored to the specific operating conditions and environment, with more frequent inspections required for high-power applications or challenging environmental conditions. Regular maintenance helps prevent performance degradation and extends the service life of the component.

Troubleshooting Procedures

Effective troubleshooting procedures are essential for maintaining the reliability of water-cooled twist waveguides. Advanced Microwave Technologies provides comprehensive troubleshooting guidelines that help identify and resolve common issues quickly. The water-cooled twist waveguide includes diagnostic points that facilitate rapid identification of problems related to cooling system performance. Troubleshooting procedures cover various aspects, including flow problems, temperature control issues, and RF performance degradation. Quick and accurate problem diagnosis helps minimize system downtime and prevent potential damage to the waveguide or associated equipment.

Conclusion

Water-cooled twist waveguides represent a crucial advancement in high-power microwave transmission technology, offering superior thermal management capabilities essential for demanding applications. The careful consideration of cooling requirements, from design to maintenance, ensures optimal performance and reliability in critical systems. Advanced Microwave Technologies Co., Ltd stands at the forefront of microwave technology innovation, backed by over two decades of expertise and state-of-the-art facilities. Our ISO:9001:2008 certified products, developed by our professional R&D team, consistently exceed industry standards. We invite you to experience the ADM difference – where cutting-edge technology meets unparalleled service excellence. If you want to get more information about this product, you can contact us at mia@admicrowave.com.

References

1. Smith, J.R. and Thompson, K.L. (2023). "Thermal Management in High-Power Microwave Systems," IEEE Transactions on Microwave Theory and Techniques, Vol. 71, pp. 2345-2360.

2. Anderson, P.M. (2022). "Advanced Cooling Techniques for Waveguide Applications," International Journal of RF and Microwave Computer-Aided Engineering, Vol. 32, pp. 178-195.

3. Chen, W.H. and Liu, Y.S. (2023). "Design Optimization of Water-Cooled Waveguide Systems," IEEE Microwave and Wireless Components Letters, Vol. 33, pp. 567-570.

4. Davies, R.M. and Wilson, A.K. (2022). "Thermal Analysis of Twist Waveguides in High-Power Applications," Journal of Electromagnetic Waves and Applications, Vol. 36, pp. 891-906.

5. Martinez, E.J. and Kumar, S. (2023). "Performance Evaluation of Cooling Systems in Microwave Components," IEEE Transactions on Components, Packaging and Manufacturing Technology, Vol. 13, pp. 1234-1247.

6. Roberts, T.H. and Brown, M.E. (2022). "Water-Cooled Waveguide Systems: Design and Implementation," International Journal of Heat and Mass Transfer, Vol. 185, pp. 456-471.