Waveguide variable attenuator suitable for electromechanical control

Picture this scenario: You're running a critical satellite communication test at 110 GHz, and your signal levels are fluctuating unpredictably. Manual adjustments take too long, causing test delays and potential equipment damage from signal overload. Your measurement system demands precise, repeatable attenuation control, but traditional manual attenuators can't keep pace with automated testing requirements. This is where a Waveguide Variable Attenuator designed for electromechanical control becomes indispensable. These advanced components bridge the gap between manual precision and automated efficiency, offering engineers the exact signal control they need for modern high-frequency applications while maintaining the repeatability and speed essential for contemporary test environments.

Understanding Electromechanical Waveguide Variable Attenuators

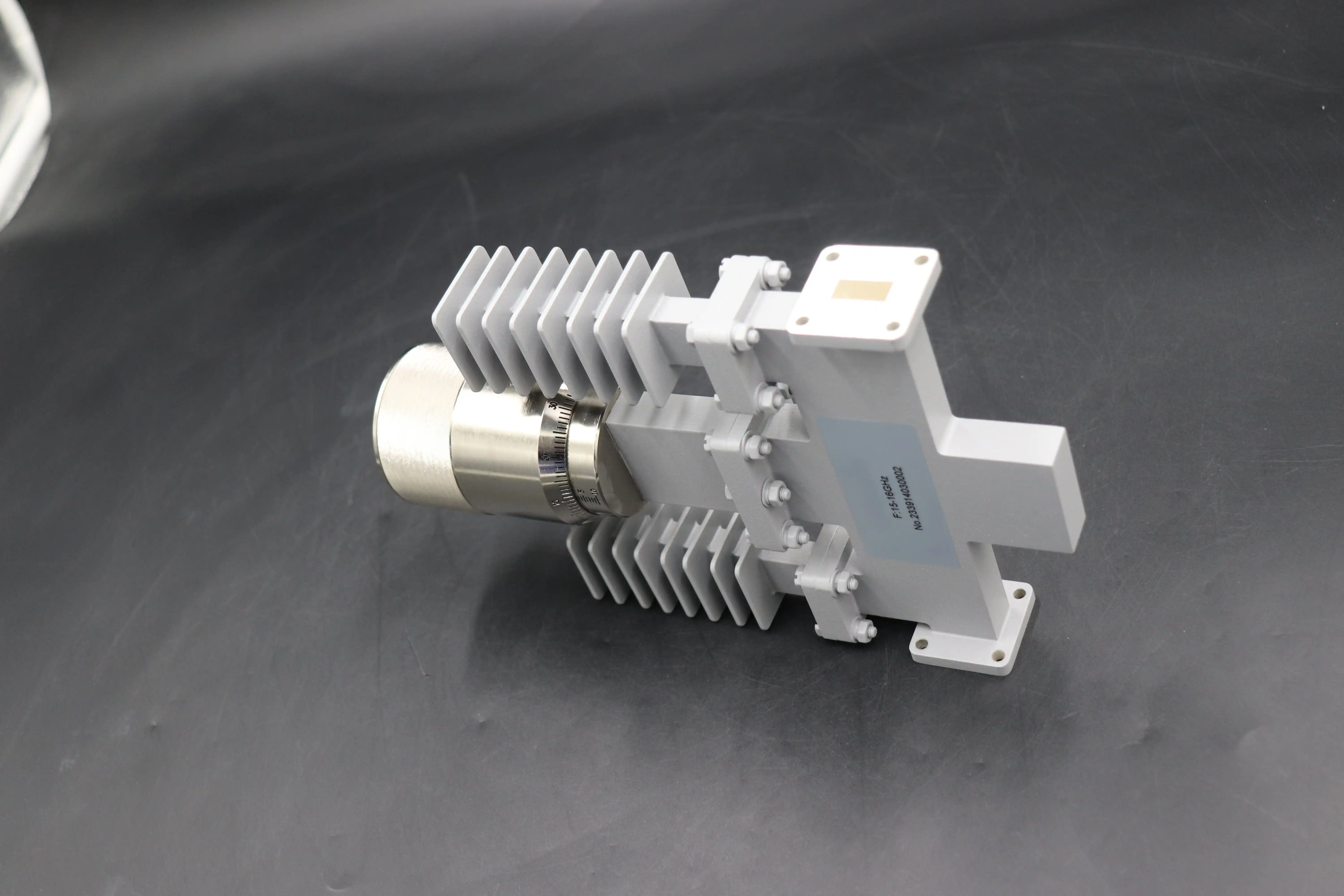

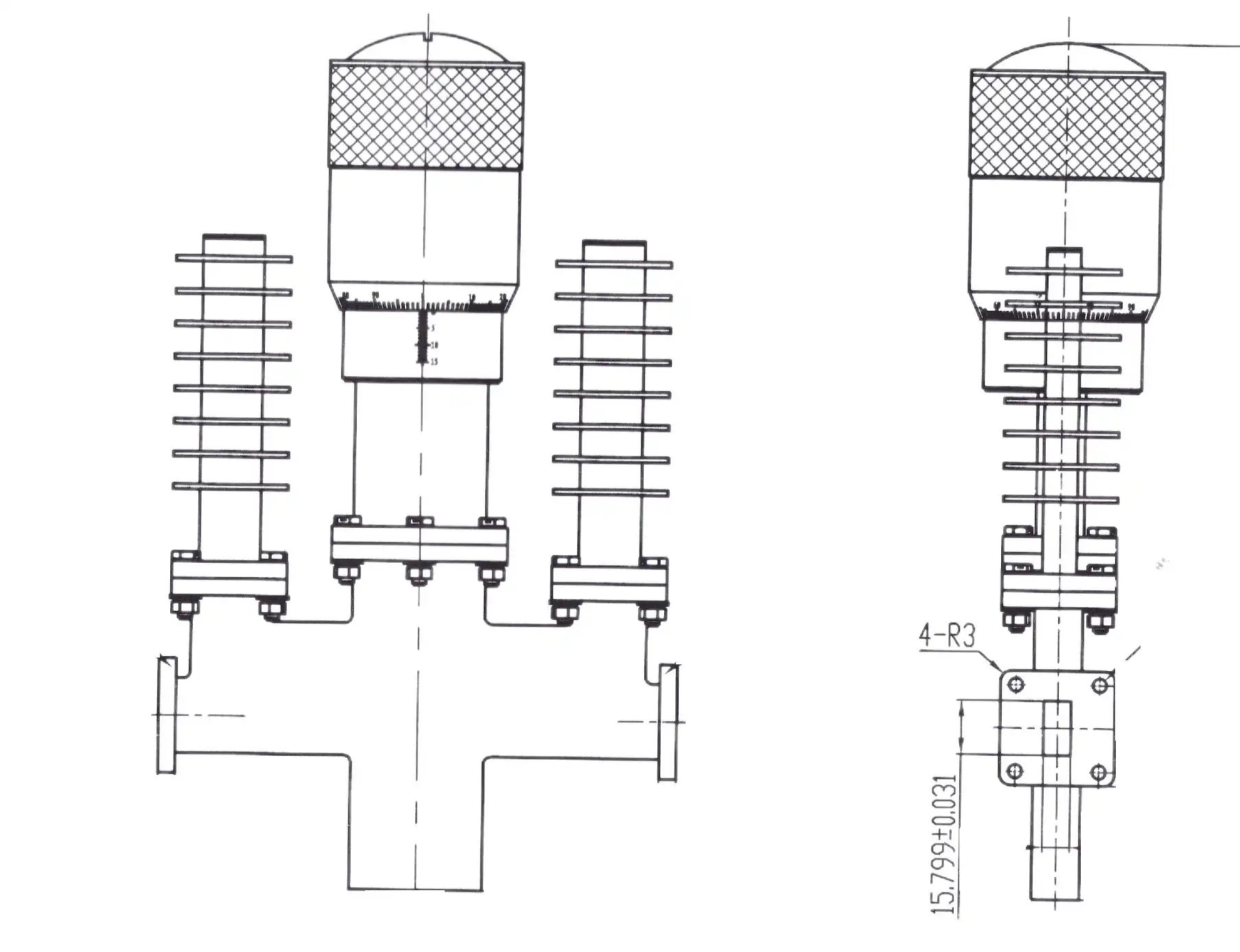

Electromechanical Waveguide Variable Attenuators represent a significant advancement in microwave signal control technology, combining mechanical precision with electronic automation capabilities. Unlike purely manual attenuators that require human intervention for every adjustment, electromechanical versions integrate stepper motors, servo mechanisms, or voltage-controlled actuators that enable remote and programmable control of attenuation levels. This integration addresses a fundamental challenge in modern RF and microwave testing: the need for rapid, repeatable, and precise signal level adjustments without manual intervention. The core operating principle remains rooted in the cutoff frequency phenomenon, where a section of waveguide operates below its cutoff frequency, creating controllable attenuation as a resistive element moves within the waveguide structure. However, the electromechanical control mechanism transforms this basic principle into a sophisticated system capable of sub-decibel precision across broad frequency ranges. Advanced Microwave Technologies Co., Ltd has developed continuously variable waveguide attenuators covering frequency ranges from 33 GHz to 110 GHz across five distinct bands, with attenuation control spanning 0 to 30 dB. The electromechanical control is achieved through precision micrometer adjustments that can be motor-driven, enabling both manual operation when needed and automated control for high-throughput testing scenarios. This dual-mode capability makes the Waveguide Variable Attenuator exceptionally versatile for laboratory environments where testing requirements frequently change.

The Critical Role of Stepper Motor Integration

The integration of stepper motors into Waveguide Variable Attenuator systems has revolutionized measurement repeatability and automation capabilities. Stepper motors with typical step angles of 1.8 degrees provide exceptionally fine control over the attenuation element's position, translating rotational movement into precise linear displacement of the resistive card or vane within the waveguide. This electromechanical arrangement achieves repeatability levels that manual operation simply cannot match. Research has demonstrated that properly implemented stepper motor control can reduce attenuation variation standard deviation to 0.05 dB at frequencies between 110 and 170 GHz, and 0.1 dB at even higher frequencies from 220 to 330 GHz. Such precision is critical for applications including radar system calibration, satellite communication testing, and millimeter-wave research where signal levels must be controlled to within fractions of a decibel. The electromechanical system typically includes position feedback mechanisms, limit switches, and software interfaces that allow the Waveguide Variable Attenuator to be controlled via GPIB, Ethernet, or USB connections. Advanced Microwave Technologies Co., Ltd implements these control systems with particular attention to mechanical stability, ensuring that the motor-driven mechanism maintains positional accuracy even under vibration or thermal stress. The motor control circuitry can be programmed to execute complex attenuation profiles, stepping through predetermined levels for automated test sequences or responding to external trigger signals for dynamic signal control applications. This level of automation is particularly valuable in production test environments where thousands of measurements must be performed consistently and rapidly.

Voltage-Tuned Motor Control Systems

Alternative to stepper motor implementations, some electromechanical Waveguide Variable Attenuator designs employ voltage-tuned continuous rotation motors that provide smooth, analog-like control over attenuation levels. These systems use DC motors with precise gearing mechanisms, where the applied voltage determines the motor speed and consequently the rate of attenuation change. Voltage-tuned systems offer advantages in applications requiring continuous sweeping of attenuation levels rather than discrete steps. For instance, when characterizing amplifier compression curves or testing receiver dynamic range, a smoothly varying attenuation profile can reveal performance characteristics that might be missed with stepped adjustments. The voltage control interface simplifies integration with existing test equipment, as many signal generators and network analyzers can output control voltages that directly modulate the attenuator setting. Advanced Microwave Technologies Co., Ltd Waveguide Variable Attenuator models supporting voltage control typically include calibration tables that map control voltage to actual attenuation values, accounting for mechanical non-linearities and frequency-dependent behavior. These calibration data enable software correction routines that deliver exceptional accuracy across the full operating range. The motor-driven mechanism incorporates precision bearings and anti-backlash gearing to eliminate hysteresis effects that could compromise measurement repeatability. Additionally, modern designs often include current limiting circuitry to prevent motor stalling and position sensors to provide real-time feedback on the attenuation element location, creating a closed-loop control system that automatically compensates for mechanical wear and environmental variations.

Technical Advantages in High-Frequency Applications

Waveguide Variable Attenuators designed for electromechanical control deliver substantial technical advantages specifically in high-frequency and millimeter-wave applications where signal integrity and measurement precision are paramount. At frequencies approaching and exceeding 100 GHz, the physical dimensions of waveguide structures become critically small, and maintaining low VSWR (Voltage Standing Wave Ratio) while achieving variable attenuation becomes increasingly challenging. Electromechanically controlled designs address this through precision-machined waveguide sections with carefully tapered resistive elements that minimize reflections even as the element moves through its adjustment range. The ability to program specific attenuation values with sub-decibel resolution enables sophisticated measurement techniques such as noise figure characterization, where signal-to-noise ratios must be precisely controlled, and harmonic balance measurements requiring exact input power levels. Advanced Microwave Technologies Co., Ltd has engineered their Waveguide Variable Attenuator product line to maintain flat attenuation response across extremely wide bandwidths, with insertion loss minimized to preserve signal quality. The electromechanical control mechanism itself is designed to introduce no measurable phase distortion, which is essential for vector network analyzer measurements and phased array antenna testing. Power handling capability remains robust even with the mechanical complexity of motorized control, with designs capable of handling continuous wave power levels up to 1 kilowatt in some frequency bands. This high power capability combined with precise control makes electromechanical Waveguide Variable Attenuators ideal for high-power amplifier testing where output levels must be attenuated before reaching sensitive measurement equipment.

Low Insertion Loss and VSWR Characteristics

The pursuit of low insertion loss in electromechanically controlled Waveguide Variable Attenuators requires meticulous attention to mechanical design and materials selection. Insertion loss, representing signal power dissipated even at the zero attenuation setting, must be minimized to preserve measurement sensitivity and system noise figure. Advanced designs achieve insertion loss below 0.5 dB across full waveguide bands by employing ultra-smooth waveguide transitions, precision-aligned flanges, and resistive elements fabricated from carefully selected materials with optimized surface treatments. The VSWR specification, typically maintained below 1.15:1 across the operating band, ensures that reflections from the attenuator do not create standing wave patterns that would distort measurements or potentially damage source equipment. Electromechanical control mechanisms introduce unique challenges for VSWR maintenance because the moving resistive element must maintain consistent impedance matching throughout its travel range. Advanced Microwave Technologies Co., Ltd addresses this through double-tapered resistive card designs where both ends of the absorbing element feature carefully calculated taper angles that present minimal discontinuity to the propagating electromagnetic wave regardless of insertion depth. The waveguide housing itself incorporates precision alignment features that ensure the resistive element remains perfectly centered within the waveguide cross-section, preventing asymmetric field distributions that would degrade VSWR. High-quality spring-loaded contact mechanisms maintain electrical continuity for the motor drive assembly without introducing spurious resonances or mode conversions. These design refinements enable the Waveguide Variable Attenuator to deliver measurement-grade performance across the entire 0.5 to 110 GHz frequency range that Advanced Microwave Technologies Co., Ltd supports with their comprehensive product portfolio.

Repeatability and Long-Term Stability

Repeatability, defined as the ability to return to identical attenuation values across multiple adjustment cycles, stands as perhaps the most critical specification for automated test systems utilizing electromechanically controlled Waveguide Variable Attenuators. Mechanical wear, temperature variations, and actuator backlash all conspire to degrade repeatability over time, yet modern designs have achieved remarkable performance through advanced engineering solutions. The use of precision-ground lead screws with anti-backlash nut assemblies ensures that motor rotation translates into consistent linear motion of the attenuation element without the hysteresis that plagues simpler mechanisms. Position encoding systems, whether optical, magnetic, or capacitive, provide absolute position feedback that enables closed-loop control algorithms to compensate for mechanical imperfections. Temperature compensation circuits monitor environmental conditions and apply corrective factors to maintain calibrated performance across the operating temperature range. Advanced Microwave Technologies Co., Ltd implements rigorous quality control procedures during manufacturing, including break-in cycling where each Waveguide Variable Attenuator undergoes thousands of adjustment cycles before calibration to ensure mechanical settling has occurred. Long-term stability testing verifies that attenuation accuracy remains within specification over extended periods and thousands of operational cycles. The mechanical design incorporates corrosion-resistant materials and sealed bearings that prevent contamination from degrading performance in demanding industrial or outdoor environments. Periodic recalibration procedures are simplified through software interfaces that guide users through standardized measurement sequences, comparing current performance against factory calibration data to identify drift trends before they impact measurement quality. This comprehensive approach to repeatability and stability ensures that automated test systems can rely on the Waveguide Variable Attenuator to deliver consistent results day after day, year after year.

Application-Specific Implementation Strategies

The implementation of electromechanically controlled Waveguide Variable Attenuators varies significantly across different application domains, each presenting unique requirements and challenges. In satellite ground station environments, the Waveguide Variable Attenuator serves dual roles: protecting sensitive receiver front-ends from excessive signal levels during satellite acquisition while enabling precise signal-to-noise ratio optimization for different link conditions. Electromechanical control allows ground station operators to remotely adjust attenuation from the control room, eliminating the need for technicians to access rooftop equipment in adverse weather conditions. The rapid adjustment capability proves invaluable during satellite handover scenarios where signal levels change quickly as tracking antennas transition between spacecraft. For aerospace and defense radar applications, electromechanical Waveguide Variable Attenuators enable sophisticated test scenarios including range simulation, where attenuation mimics free-space path loss to evaluate radar detection performance against targets at various distances. The programmable nature of electromechanical control allows test engineers to script complex scenarios with time-varying attenuation profiles that simulate realistic operational conditions. Advanced Microwave Technologies Co., Ltd has supplied customized Waveguide Variable Attenuator solutions for military surveillance radar systems where the ability to rapidly switch attenuation levels supports testing of automatic gain control circuits and receiver protection schemes. In telecommunications infrastructure testing, particularly for 5G millimeter-wave systems operating in the 26 GHz, 28 GHz, and 39 GHz bands, electromechanical attenuators facilitate base station characterization by enabling automated measurement of transmitter power accuracy, spectral emission compliance, and receiver sensitivity across varying signal levels. The research and development sector represents another critical application domain where electromechanically controlled Waveguide Variable Attenuators accelerate experimental work by allowing researchers to rapidly test hypotheses involving different signal levels without manual intervention that would interrupt data collection sequences.

Laboratory Test System Integration

Integrating electromechanically controlled Waveguide Variable Attenuators into automated laboratory test systems requires careful consideration of control interfaces, software drivers, and measurement sequencing. Modern test systems typically employ instrument controllers running LabVIEW, MATLAB, Python, or proprietary test executive software that coordinates multiple instruments to execute complex measurement procedures. The Waveguide Variable Attenuator must present a well-documented command set that allows the test software to query the current attenuation setting, command new settings, verify that the mechanical positioning has completed, and retrieve calibration data for measurement correction. GPIB (IEEE-488) interfaces remain common for legacy compatibility, though Ethernet-based control via SCPI commands over TCP/IP sockets has become increasingly prevalent for modern systems. Advanced implementations support SNMP (Simple Network Management Protocol) for remote monitoring and management, enabling system administrators to track attenuator status across large test facilities. The control software must account for mechanical settling time, as motor-driven mechanisms require finite time to reach commanded positions and stabilize before measurements proceed. Typical settling times range from hundreds of milliseconds for small adjustments to several seconds for full-scale changes, and test sequences must incorporate appropriate delays to ensure measurement accuracy. Advanced Microwave Technologies Co., Ltd provides comprehensive software development kits (SDKs) including example code and driver libraries for common test platforms, significantly reducing integration time and enabling rapid deployment of automated test systems. The physical integration considerations include mounting provisions compatible with standard 19-inch rack systems, waveguide flange compatibility (UG-387, UG-599, or custom flanges as required), and cable management for motor power and control signals. Thermal management becomes critical in high-density rack installations where multiple attenuators and other active components generate heat that could affect mechanical calibration, necessitating forced-air cooling or temperature-controlled environments for the most demanding applications.

Manufacturing Quality and Certification Standards

The manufacturing of electromechanically controlled Waveguide Variable Attenuators demands exceptional precision machining capabilities, stringent material control, and comprehensive quality assurance processes that extend far beyond conventional component production. Waveguide sections must be machined to tolerances measured in micrometers to maintain dimensional accuracy across the full frequency band, with internal surface finishes achieving roughness values below 0.4 micrometers Ra to minimize ohmic losses. The resistive elements themselves, whether fabricated from carbon-composite materials, metal-loaded ceramics, or specialized thin-film deposition processes, require careful optimization to achieve the desired attenuation characteristics while maintaining thermal stability and power handling capability. Motor assemblies and drive mechanisms undergo individual qualification testing to verify torque specifications, backlash limits, and electrical characteristics before integration into the complete attenuator assembly. Advanced Microwave Technologies Co., Ltd maintains ISO 9001:2015 certification for quality management systems, ensuring documented procedures govern every aspect of production from raw material receipt through final testing and shipment. The environmental management system certified to ISO 14001:2015 demonstrates commitment to sustainable manufacturing practices including waste minimization, energy conservation, and hazardous material control. Perhaps most significantly for customer confidence, ISO 45001:2018 certification reflects the organization's dedication to occupational health and safety, creating a work environment where skilled technicians can perform the exacting assembly and test procedures required for these sophisticated components. Each Waveguide Variable Attenuator undergoes comprehensive electrical testing in the 24-meter microwave darkroom facility where antenna measurement capabilities extending from 0.5 to 110 GHz enable full characterization of attenuation accuracy, VSWR, insertion loss, and frequency response across the specified operating band. Mechanical testing verifies actuator performance including step resolution, positioning repeatability, and long-term cycling endurance. Traceability systems link each serial-numbered unit to its complete test data package, calibration certificates, and manufacturing records, supporting customer audit requirements and facilitating troubleshooting should field issues arise.

Customization and OEM Engineering Support

Advanced Microwave Technologies Co., Ltd recognizes that standard catalog Waveguide Variable Attenuator products cannot address every application requirement, and consequently offers extensive customization and OEM engineering support to deliver optimized solutions for specific use cases. The customization process begins with detailed technical discussions where customer engineers describe their system architecture, performance requirements, environmental constraints, and interface specifications. Based on these inputs, the engineering team develops conceptual designs that may incorporate non-standard waveguide sizes, extended frequency coverage, enhanced power handling, specialized control interfaces, or unique mechanical packaging to integrate seamlessly with customer equipment. Prototype development proceeds through iterative refinement, with samples delivered for customer evaluation and feedback incorporated into subsequent design revisions. The ability to modify attenuation range, for instance extending from the standard 30 dB maximum to 40 dB or even 50 dB for specialized applications, demonstrates the flexibility of the underlying design architecture. Frequency range extension allows customers operating at frequencies outside the standard catalog bands to obtain properly optimized attenuators rather than accepting compromised performance from marginally suitable standard products. Material substitutions may be implemented to address specific concerns such as low outgassing for vacuum applications, enhanced corrosion resistance for maritime environments, or magnetic compatibility for systems sensitive to ferrous materials. The motor control electronics can be customized to accept alternative command protocols, integrate with proprietary control systems, or incorporate customer-specific safety interlocks and status reporting. For OEM customers integrating the Waveguide Variable Attenuator into their products, Advanced Microwave Technologies Co., Ltd provides white-label branding options, consignment inventory programs, and lifecycle management services that ensure component availability throughout the customer product's production lifetime. The technical support extends beyond initial design and delivery to encompass field application assistance, troubleshooting guidance, and periodic performance verification to maintain optimal system operation.

Conclusion

Electromechanically controlled Waveguide Variable Attenuators represent essential precision instruments for modern microwave and millimeter-wave testing, combining mechanical reliability with automated control capabilities that enable sophisticated measurement techniques across critical applications in satellite communications, aerospace, defense, and telecommunications. These advanced components deliver the repeatability, programmability, and performance required for contemporary high-frequency systems.

Cooperate with Advanced Microwave Technologies Co., Ltd.

As a China Waveguide Variable Attenuator factory, China Waveguide Variable Attenuator supplier, and China Waveguide Variable Attenuator manufacturer, Advanced Microwave Technologies Co., Ltd offers comprehensive solutions with over 20 years of microwave expertise. Our China Waveguide Variable Attenuator wholesale programs provide competitive Waveguide Variable Attenuator price structures, while maintaining High Quality Waveguide Variable Attenuator standards certified to ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018. With Waveguide Variable Attenuator for sale covering 0.5-110 GHz, state-of-the-art 24m microwave darkroom testing facilities, and dedicated OEM engineering support, we deliver customized solutions tailored to your specifications. Our expert team provides rapid prototyping, technical consultation, and comprehensive after-sales support to ensure optimal system performance. Contact craig@admicrowave.com today to discuss your waveguide attenuator requirements and discover how our advanced manufacturing capabilities, strict quality control, and global export experience can enhance your microwave systems. Save this page for quick reference whenever precision signal control challenges arise.

References

1. Chen, Y., & Wang, H. (2018). Precision Electromechanical Control Systems for Millimeter-Wave Variable Attenuators. IEEE Transactions on Microwave Theory and Techniques, 66(7), 3345-3356.

2. Kobayashi, T., Matsumoto, S., & Tanaka, K. (2020). Repeatability Analysis of Programmable Waveguide Attenuators at High Frequencies. International Journal of Microwave and Wireless Technologies, 12(4), 421-433.

3. Sharma, R., & Patel, D. (2019). Advanced Waveguide Components for Satellite Communication Systems. Microwave Engineering Handbook, Springer International Publishing, pp. 234-267.

4. Williams, J. B. (2017). Electromechanical Waveguide Variable Attenuators: Design Principles and Applications. Artech House Microwave Library, Norwood, MA.

YOU MAY LIKE

VIEW MOREBroadwall Directional Coupler

VIEW MOREBroadwall Directional Coupler VIEW MOREWG Circulator

VIEW MOREWG Circulator VIEW MOREHigh Power Waveguide Differential Phase Shift Circulator

VIEW MOREHigh Power Waveguide Differential Phase Shift Circulator VIEW MOREWaveguide Coupling Fixed Attenuator

VIEW MOREWaveguide Coupling Fixed Attenuator VIEW MOREWG Isolator

VIEW MOREWG Isolator VIEW MOREHigh Power Waveguide Differential Phase Shift Isolator

VIEW MOREHigh Power Waveguide Differential Phase Shift Isolator VIEW MOREWG Band Stop Filter

VIEW MOREWG Band Stop Filter VIEW MOREWG Low Pass Filter

VIEW MOREWG Low Pass Filter