Waveguide Variable Attenuator OEM Options: Custom Solutions Guide

When your satellite ground station experiences unpredictable signal fluctuations or your radar testing lab struggles with imprecise attenuation control, the consequences can be costly—system failures, data corruption, and project delays. Finding the right Waveguide Variable Attenuator with tailored OEM specifications becomes mission-critical for engineers who demand precise signal management across ultra-high frequency ranges. This comprehensive guide reveals how custom waveguide variable attenuator solutions solve your most challenging signal control problems while delivering the performance reliability your applications require.

Understanding Waveguide Variable Attenuator Technology and Capabilities

Waveguide Variable Attenuators represent a cornerstone technology in modern microwave systems, providing engineers with dynamic control over signal strength without compromising transmission quality. Unlike fixed attenuators that offer predetermined attenuation values, variable designs enable real-time adjustments to accommodate changing operational requirements. The fundamental principle involves introducing controlled impedance into the waveguide path, allowing signal power reduction while maintaining critical parameters such as phase linearity and VSWR performance. Advanced Microwave Technologies Co., Ltd manufactures continuously variable waveguide attenuators covering an extensive frequency range from 33 GHz to 110 GHz across five distinct bands, addressing applications from legacy communication systems to cutting-edge millimeter-wave technologies. These precision instruments utilize micrometer-driven adjustment mechanisms that enable repeatable settings with exceptional accuracy—a feature particularly valuable during prototype development and system optimization phases where engineers must systematically evaluate performance across multiple signal strength scenarios.

The operational characteristics of modern Waveguide Variable Attenuator designs reflect decades of engineering refinement. Contemporary units achieve attenuation ranges from 0 to 30 dB across specified frequency bands while maintaining flat response characteristics that ensure consistent performance throughout the operating spectrum. Insertion loss values remain remarkably low, typically below 0.5 dB in the bypass position, preserving signal integrity even when minimal attenuation is required. The micrometer adjustment feature distinguishes professional-grade attenuators from basic models, providing calibrated control that technicians can document and reproduce during extended test sequences. Engineers conducting antenna pattern measurements, receiver sensitivity testing, or system integration verification depend on this repeatability to generate reliable data sets. The broad frequency coverage accommodates diverse application requirements, from Ka-band satellite communications operating around 30 GHz to W-band radar systems functioning above 75 GHz, while maintaining performance specifications that meet stringent military and commercial standards.

Critical Performance Parameters for OEM Applications

When selecting Waveguide Variable Attenuator components for integration into original equipment manufacturer systems, several technical specifications demand careful consideration beyond basic frequency range and attenuation capability. Power handling capacity determines whether an attenuator can withstand the continuous wave or pulsed power levels present in your specific application without degradation or failure. Advanced designs accommodate up to 1 kilowatt of continuous power, making them suitable for high-performance radar transmitters, satellite communication ground stations, and industrial heating applications. VSWR performance directly impacts signal reflection characteristics—superior attenuators maintain values below 1.15:1 across their operating bands, ensuring minimal energy reflection that could disturb sensitive measurement equipment or compromise system efficiency. Temperature stability represents another crucial consideration, particularly for outdoor installations or thermally demanding environments where ambient conditions fluctuate significantly. Premium Waveguide Variable Attenuator units incorporate materials and construction techniques that maintain calibration accuracy across temperature ranges from -40°C to +85°C, eliminating the need for frequent recalibration in challenging deployment scenarios.

The mechanical design aspects of variable attenuators significantly influence long-term reliability and operational convenience. Rotational mechanisms must withstand thousands of adjustment cycles without developing backlash, hysteresis, or calibration drift that would compromise measurement integrity. Advanced Microwave Technologies employs precision manufacturing processes and rigorous quality control protocols to ensure each unit meets ISO 9001:2015 standards for consistent mechanical performance. Waveguide flange specifications must precisely match system requirements—whether you need UG-series, WR-series, or custom interface configurations, proper mechanical compatibility ensures reliable connections that maintain electrical performance over years of service. Environmental sealing capabilities become essential for military, aerospace, and outdoor telecommunications applications where moisture ingress, dust contamination, or corrosive atmospheres threaten component longevity. RoHS-compliant materials and conformal coating options protect internal components while meeting international environmental regulations that increasingly govern equipment deployment worldwide.

Customization Options for Specialized Applications

The true value of partnering with an experienced China Waveguide Variable Attenuator manufacturer emerges when standard catalog products cannot satisfy unique application requirements. Custom frequency band support enables designers to optimize attenuator performance for narrow-band applications where catalog units covering broader ranges might introduce unnecessary compromise. A satellite ground station operating exclusively at 14.0-14.5 GHz benefits from an attenuator specifically tuned for X-band uplink frequencies rather than a unit specified across the entire 8-12 GHz range. Advanced Microwave Technologies' engineering team collaborates directly with OEM customers to define precise frequency boundaries, attenuation characteristics, and electrical specifications that align with system-level performance objectives. This consultative approach identifies opportunities to enhance functionality beyond basic signal attenuation—integrated power monitoring taps, remote motorization interfaces, or specialized waveguide transitions that simplify system integration while reducing component count and associated connection losses.

Material selection represents another critical customization dimension that significantly impacts performance, cost, and longevity. Aluminum alloy construction offers excellent mechanical properties and thermal conductivity at modest cost, making it ideal for laboratory instruments and commercial communication equipment. Brass alternatives provide superior machinability for complex geometries while delivering adequate performance for many applications. When deployment environments demand exceptional corrosion resistance—maritime radar systems, coastal telecommunications infrastructure, or chemical processing facilities—stainless steel or specialized coating options prevent material degradation that could compromise electrical performance or structural integrity. The internal attenuating elements themselves offer customization possibilities, with resistive film compositions, carbon-loaded absorber materials, or hybrid designs selected based on power handling requirements, frequency response characteristics, and expected service life. Advanced Microwave Technologies maintains comprehensive material science expertise developed over 20 years of microwave component manufacturing, enabling informed recommendations that balance performance requirements against budget constraints and production timelines.

Mechanical Interface and Integration Considerations

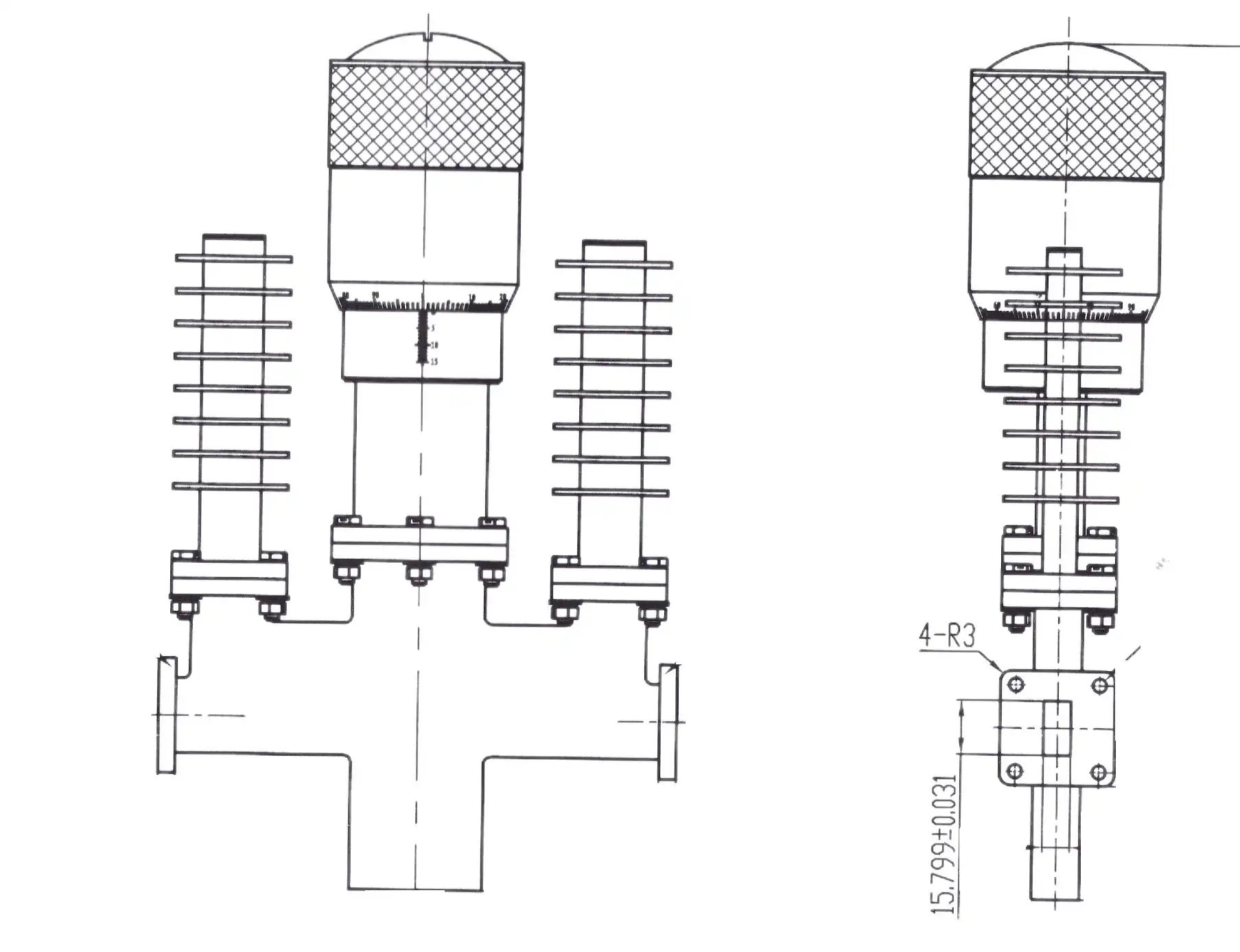

Beyond basic waveguide flange configurations, OEM customers frequently require specialized mechanical features that facilitate integration into larger system assemblies. Mounting bracket designs must accommodate specific chassis configurations, rack-mount dimensions, or environmental enclosure requirements unique to each application. Custom bracket patterns, threaded insert locations, or anti-vibration mounting provisions ensure secure installation that maintains alignment precision throughout years of service. When Waveguide Variable Attenuator units must operate within automated test systems or remotely controlled installations, motorized drive mechanisms replace manual adjustment knobs. Stepper motor or servo-controlled designs accept digital command signals that enable computer-controlled attenuation settings, position feedback for verification, and integration with SCADA systems or laboratory automation platforms. The motorization process requires careful engineering to maintain the precision and repeatability characteristics of manual designs while adding remote control capabilities—a specialization where experienced manufacturers demonstrate clear advantages over generic suppliers attempting to retrofit automation onto existing manual designs.

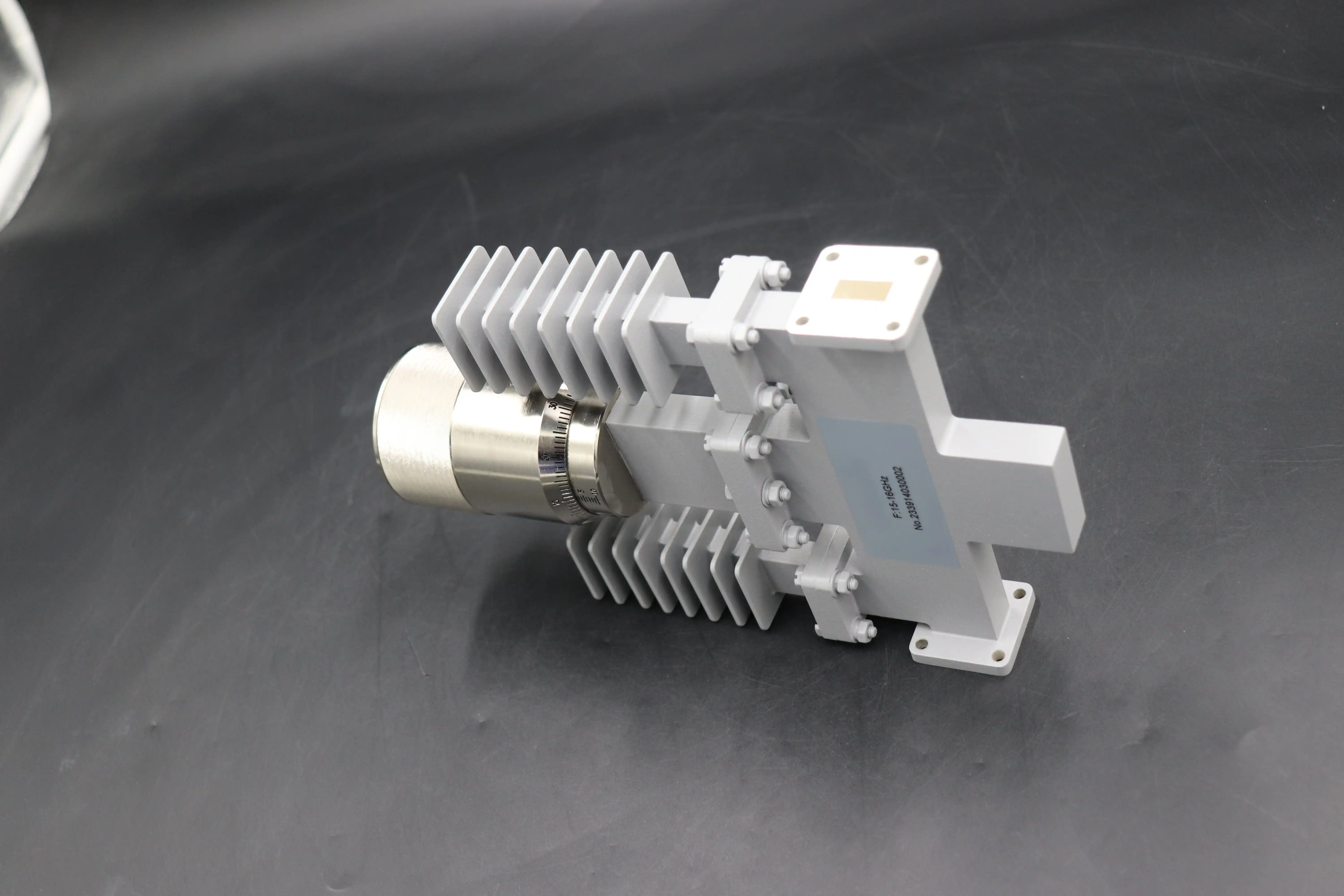

Thermal management considerations influence mechanical design when attenuators operate in high-power applications or thermally constrained environments. Effective heat dissipation prevents temperature-induced drift in attenuation characteristics while protecting internal components from thermal stress that could shorten service life. Advanced designs incorporate finned heat sink structures, thermal interface materials that efficiently conduct heat to mounting surfaces, or provisions for forced-air cooling when ambient convection proves insufficient. The 24m Microwave Darkroom operated by Advanced Microwave Technologies enables comprehensive thermal characterization under realistic power loading conditions, validating that custom designs maintain specified performance across their intended operating temperature ranges. For space-constrained installations common in aircraft, unmanned aerial vehicles, or compact test equipment, dimensional optimization reduces footprint while preserving electrical performance—a capability requiring extensive electromagnetic simulation capability and fabrication expertise that distinguishes leading China Waveguide Variable Attenuator supplier operations from commodity component providers.

OEM Services and Manufacturing Capabilities

Partnering with a qualified China Waveguide Variable Attenuator factory involves far more than simply purchasing components from a catalog. Comprehensive OEM services begin during the conceptual design phase, where experienced engineers help customers translate system requirements into specific component specifications. This consultative engineering approach identifies potential performance bottlenecks, suggests alternative solutions that might offer cost or schedule advantages, and ensures that proposed designs remain manufacturable at required volumes without compromising quality standards. Advanced Microwave Technologies' technical team brings extensive domain expertise spanning satellite communications, defense radar systems, navigation equipment, and emerging 5G infrastructure—knowledge that informs design recommendations and prevents costly mistakes during development. The prototyping phase follows initial design approval, delivering functional units that engineers can evaluate in actual system configurations before committing to production tooling. Quick turnaround on prototype fabrication accelerates development schedules while providing opportunities to refine specifications based on empirical testing rather than relying solely on theoretical predictions.

Production scalability represents a critical consideration when evaluating potential Waveguide Variable Attenuator manufacturer partners. Suppliers must demonstrate capacity to support initial prototype quantities, transition smoothly to pilot production runs that validate manufacturing processes, and ultimately scale to full production volumes while maintaining consistent quality and delivery reliability. Advanced Microwave Technologies operates dedicated manufacturing facilities equipped with precision machining centers, automated assembly stations, and quality control systems that support production volumes from single prototypes to thousands of units annually. The company's robust supply chain management ensures access to raw materials and specialized components without delays that could disrupt customer production schedules. ISO 9001:2015 certification provides documented evidence of process control capabilities, while ISO 14001:2015 and ISO 45001:2018 standards demonstrate commitment to environmental responsibility and worker safety—factors increasingly important to multinational corporations subject to comprehensive supplier qualification requirements.

Quality Assurance and Testing Protocols

Every High Quality Waveguide Variable Attenuator delivered by Advanced Microwave Technologies undergoes rigorous testing before shipment to verify compliance with specified electrical and mechanical parameters. The testing sequence begins with dimensional verification using precision measurement equipment that confirms critical features meet drawing tolerances. Waveguide flange interfaces receive particular attention since even minor dimensional deviations can cause poor mating characteristics, increased insertion loss, or degraded VSWR performance when installed in customer systems. Electrical characterization follows mechanical inspection, employing vector network analyzers and specialized test fixtures to measure insertion loss, attenuation accuracy, VSWR, and return loss across specified frequency ranges. Advanced Microwave Technologies' laboratories feature measurement capability extending to 110 GHz, enabling comprehensive characterization even for millimeter-wave designs operating at frequencies where many competitors lack proper test equipment.

The Antenna Plane Near and Far Field Measuring Recombination Chamber provides capabilities beyond basic electrical parameter verification, enabling assessment of how attenuators perform within complete antenna systems or complex signal chains. This system-level testing identifies interaction effects that might not appear during isolated component characterization—knowledge that proves invaluable when supporting customers developing sophisticated applications where multiple microwave components must function harmoniously. Temperature cycling tests subject Waveguide Variable Attenuator samples to thermal extremes representative of actual deployment conditions, verifying that performance remains within specification despite environmental stress. Vibration and shock testing validates mechanical robustness for mobile platforms, transportation scenarios, or high-vibration industrial environments. Documentation accompanying each shipment includes calibration data, test reports, and certificates of conformance that customers require for their own quality assurance processes or regulatory compliance obligations. This comprehensive approach to quality assurance differentiates professional China Waveguide Variable Attenuator wholesale operations from opportunistic suppliers offering questionable components at seemingly attractive Waveguide Variable Attenuator price points.

Application-Specific Design Considerations

Understanding how Waveguide Variable Attenuators function within specific applications enables more effective customization that addresses real operational challenges rather than simply meeting generic specifications. Satellite communication ground stations employ variable attenuators to compensate for signal strength variations caused by atmospheric conditions, satellite position changes, or link budget adjustments required when switching between different orbital assets. The ability to precisely control received signal strength prevents receiver saturation during strong signal conditions while optimizing signal-to-noise ratio during marginal link scenarios. Custom designs for these applications might incorporate weatherproof enclosures, lightning protection features, or remote monitoring capabilities that enable operators to adjust attenuation settings from climate-controlled control rooms rather than requiring physical access to outdoor equipment locations. The frequency stability and low insertion loss characteristics prove particularly critical since satellite links often operate near their theoretical capacity limits where even small additional losses directly impact data throughput or service quality.

Aerospace and defense radar systems present entirely different requirements that drive alternative customization approaches. Radar receiver protection represents a primary concern since powerful transmit pulses can damage sensitive receiver components if proper isolation does not exist during transmission periods. Waveguide Variable Attenuator designs for these applications often incorporate fast-acting switching mechanisms or PIN diode protection circuits that instantly increase attenuation when transmit pulses occur, then restore low-loss signal paths during receive intervals. Military specifications typically mandate operation across extreme temperature ranges, resistance to electromagnetic interference, and reliable performance despite shock and vibration levels that would destroy commercial components. Advanced Microwave Technologies' experience supporting defense contractors worldwide informs design decisions that ensure Waveguide Variable Attenuator units meet stringent MIL-STD requirements while remaining cost-effective for procurement at scale. The ability to provide comprehensive documentation including reliability predictions, failure mode analysis, and long-term availability commitments proves equally important as technical performance when supporting programs with multi-decade service life expectations.

Laboratory and Research Applications

Research institutions and development laboratories represent significant markets for specialized Waveguide Variable Attenuator configurations optimized for measurement accuracy rather than rugged environmental performance. Scientists characterizing novel materials, engineers optimizing antenna designs, or physicists conducting fundamental electromagnetic research require attenuators that introduce known, stable signal reductions without adding measurement uncertainty from their own imperfections. Calibration traceability becomes paramount in these applications—users need documented evidence that attenuation values correspond to recognized standards maintained by national metrology institutes. Advanced Microwave Technologies provides calibration services traceable to international standards, delivering documentation that satisfies quality management system requirements and enables customers to maintain their own measurement uncertainties within acceptable bounds. The micrometer-driven adjustment mechanism proves particularly valuable in laboratory settings where technicians must repeatedly set specific attenuation values, document system responses, then adjust to different values for comparative measurements—a workflow where manual adjustment precision directly impacts research productivity and data quality.

Telecommunications infrastructure applications increasingly rely on Waveguide Variable Attenuator technology as 5G networks expand into millimeter-wave frequency bands where traditional coaxial components become impractical. Base station installations require precise signal level control to optimize coverage patterns, prevent interference with adjacent cells, and accommodate varying subscriber densities throughout daily usage cycles. Custom designs for telecommunications might emphasize compact dimensions that simplify installation within space-constrained equipment shelters, low power consumption for battery-backed sites, or extended temperature ranges for rooftop deployments experiencing direct solar heating. The ability to provide Waveguide Variable Attenuator for sale with telecommunications-specific features demonstrates a manufacturer's commitment to understanding diverse market requirements rather than attempting one-size-fits-all solutions that compromise performance across multiple application domains.

Conclusion

Selecting the right Waveguide Variable Attenuator with appropriate OEM customization delivers precise signal control that enhances system performance across satellite communications, aerospace, telecommunications, and research applications while meeting demanding specifications for frequency range, power handling, and environmental resilience.

Cooperate with Advanced Microwave Technologies Co., Ltd.

As a leading China Waveguide Variable Attenuator factory, Advanced Microwave Technologies Co., Ltd. combines over 20 years of microwave expertise with ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018 certifications to deliver exceptional custom solutions. Our China Waveguide Variable Attenuator supplier capabilities include comprehensive OEM services from rapid prototyping to full-scale production, supported by advanced measurement facilities reaching 110 GHz. Whether you need High Quality Waveguide Variable Attenuator components for demanding applications or competitive Waveguide Variable Attenuator price quotes with fast delivery, our experienced engineering team provides the technical support and manufacturing excellence your projects demand. As a trusted China Waveguide Variable Attenuator manufacturer and China Waveguide Variable Attenuator wholesale partner, we offer customizable Waveguide Variable Attenuator for sale that perfectly matches your specifications. Contact craig@admicrowave.com today to discuss your requirements and discover how our perfect supply chain system, professional technical R&D team, and strong after-sales capability can optimize your microwave system performance. Save this guide for future reference when evaluating attenuator solutions for your next project.

References

1. Pozar, David M. Microwave Engineering (Fourth Edition). John Wiley & Sons, 2011.

2. Collin, Robert E. Foundations for Microwave Engineering (Second Edition). IEEE Press, 2001.

3. Marcuvitz, Nathan. Waveguide Handbook. Institution of Engineering and Technology, 1986.

4. Rizzi, Peter A. Microwave Engineering: Passive Circuits. Prentice Hall, 1988.

5. Saad, Theodore S. Microwave Engineers' Handbook (Volume 1). Artech House Publishers, 1971.