Waveguide Adapter Market Trends: What Buyers Need to Know

The global waveguide adapter market is experiencing unprecedented growth driven by expanding 5G networks, increasing satellite communication demands, and evolving defense technologies. As industries transition to higher frequencies and more sophisticated microwave systems, understanding current market trends becomes essential for informed purchasing decisions. The Waveguide Adapter has emerged as a critical component bridging different transmission mediums in complex RF systems, making it indispensable across telecommunications, aerospace, and defense sectors. Market research indicates substantial growth projections through 2030, with technological advancements pushing performance boundaries while buyers seek reliable suppliers offering comprehensive solutions. This comprehensive analysis explores key market dynamics, technological innovations, and strategic considerations that modern buyers must understand to navigate today's competitive landscape effectively.

Current Market Dynamics and Growth Drivers

Expanding 5G Infrastructure Demands

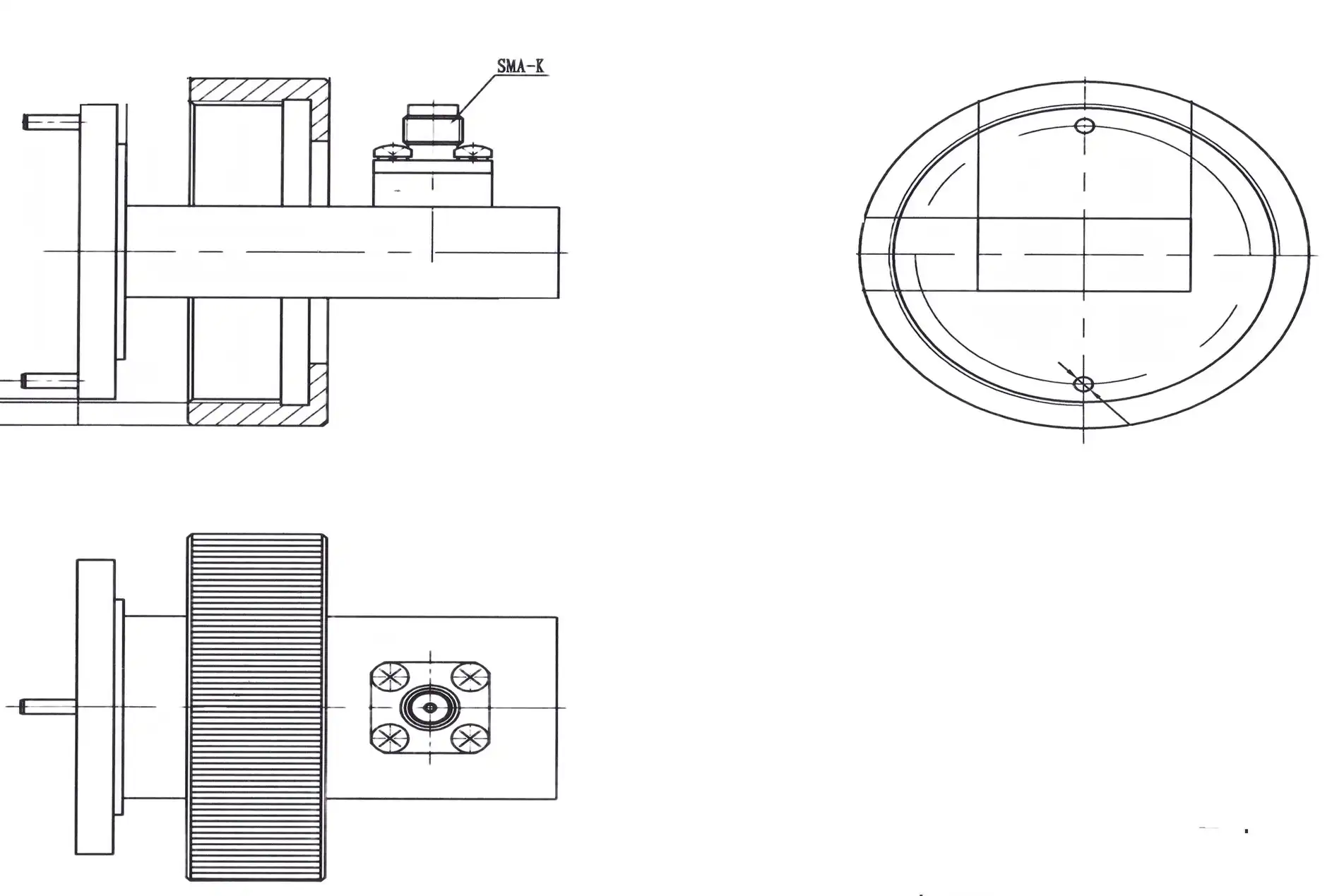

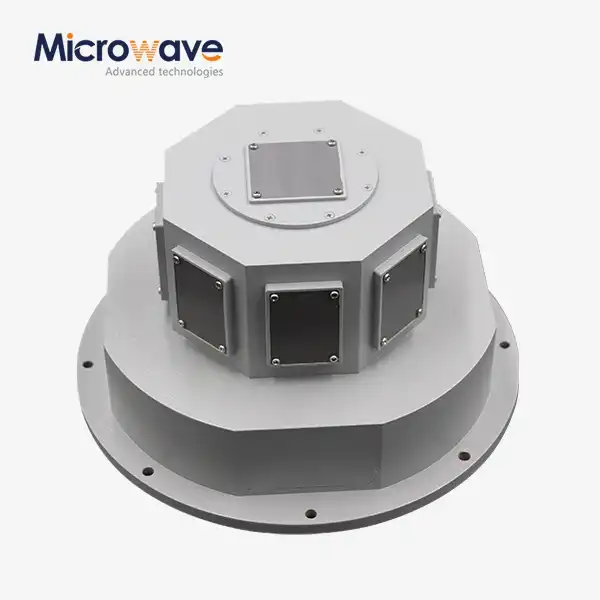

The global rollout of 5G networks has created substantial demand for high-performance Waveguide Adapter solutions capable of handling millimeter-wave frequencies. Telecommunications companies are investing heavily in infrastructure upgrades, requiring adapters that can seamlessly connect different waveguide types while maintaining signal integrity at frequencies up to 110 GHz. Advanced Microwave Technologies' WG Adapter exemplifies this trend, offering ultra-wide frequency coverage from S-band (2-4GHz) to Ka-band (26.5-40GHz) and beyond. The adapter's low insertion loss of 0.1dB or less ensures minimal signal degradation, which is crucial for 5G base stations requiring optimal performance across extended coverage areas. Market analysts project that 5G infrastructure investments will continue driving waveguide adapter demand through 2025, with operators prioritizing components that deliver consistent performance while supporting future technology evolution. The increasing complexity of 5G networks necessitates versatile adapters featuring multiple interface options, including N-type, SMA-type, and 2.92mm connectors, enabling flexible system configurations that can adapt to varying deployment scenarios.

Satellite Communication Market Expansion

The satellite communication sector is experiencing remarkable growth, fueled by increasing demand for global connectivity, IoT applications, and next-generation satellite constellations. Modern satellite systems require Waveguide Adapter solutions that can handle high-power signals while maintaining excellent VSWR performance, typically ranging from 1.1 to 1.5. Advanced Microwave's WG Adapter addresses these requirements with its high-power capacity, supporting applications from watts to kilowatts through intelligent material selection and structural design optimization. The adapter's compact design facilitates integration into space-constrained satellite terminals and ground stations, where reliability and performance are paramount. Recent market developments show increased adoption of LEO satellite constellations, creating demand for ground-based equipment capable of tracking multiple satellites simultaneously. This trend requires waveguide adapters with exceptional frequency stability and low signal reflection characteristics, ensuring seamless communication across diverse satellite bands. The growing commercial space industry further amplifies demand for cost-effective yet high-performance Waveguide Adapter solutions that meet stringent aerospace qualification standards while supporting rapid deployment schedules.

Defense and Aerospace Technology Evolution

Defense contractors and aerospace manufacturers are increasingly adopting advanced radar systems and electronic warfare capabilities, driving demand for sophisticated Waveguide Adapter technologies. Modern military applications require adapters capable of operating across extended frequency ranges while maintaining exceptional performance in harsh environmental conditions. The WG Adapter from Advanced Microwave Technologies demonstrates this capability through its robust construction using aluminum, brass, and stainless steel materials, ensuring reliable operation in challenging military environments. Defense radar systems, including surveillance and weather monitoring applications, depend on waveguide adapters that provide accurate signal transmission with minimal loss and reflection. The adapter's VSWR performance of 1.15 maximum and insertion loss of 0.15dB maximum makes it ideal for precision radar applications requiring accurate target detection and tracking capabilities. Additionally, the increasing adoption of unmanned aerial vehicles (UAVs) and autonomous defense systems creates demand for lightweight, compact Waveguide Adapter solutions that can withstand extreme operational conditions while delivering consistent performance across diverse mission profiles.

Technological Innovations Reshaping the Market

Advanced Material Technologies and Manufacturing Processes

The waveguide adapter industry is witnessing significant technological advancement through innovative material sciences and precision manufacturing techniques. Modern Waveguide Adapter designs incorporate specialized materials like silver-plated copper internals and anticorrosion exterior finishes, ensuring optimal electrical performance while maintaining long-term durability. Advanced Microwave Technologies exemplifies this trend with their ADM-100WCAST1 model, featuring copper construction with silver plating internals and anticorrosion grey paint exteriors for enhanced environmental resistance. Manufacturing processes have evolved to achieve unprecedented precision levels, enabling production of adapters with insertion losses as low as 0.1dB while maintaining consistent performance across wide frequency ranges. The integration of computer-aided design and automated manufacturing systems allows for complex geometries that optimize signal transmission characteristics while minimizing size and weight constraints. These technological advances enable Waveguide Adapter manufacturers to meet increasingly demanding specifications while reducing production costs and delivery times. Quality control processes have also advanced significantly, with comprehensive testing protocols ensuring each adapter meets stringent performance requirements before shipment to customers.

High-Frequency Performance Optimization

As communication systems migrate toward higher frequencies, Waveguide Adapter technology must evolve to maintain signal integrity across millimeter-wave bands. Advanced electromagnetic modeling and simulation tools enable engineers to optimize adapter designs for specific frequency ranges, ensuring minimal signal distortion and maximum power transfer efficiency. The latest Waveguide Adapter designs incorporate sophisticated impedance matching techniques that maintain consistent performance across ultra-wide frequency ranges, from traditional microwave bands to emerging millimeter-wave applications. Advanced Microwave's WG Adapter technology demonstrates this capability through its frequency coverage extending to 110GHz, supporting both current applications and future technology requirements. Signal integrity considerations become increasingly critical at higher frequencies, requiring precise control of electrical length, impedance discontinuities, and surface finish quality. Modern adapters employ advanced plating techniques and surface treatments to minimize skin effect losses while maintaining excellent electrical conductivity across the operating frequency range. These technological improvements enable reliable signal transmission in demanding applications such as high-resolution radar systems and ultra-high-speed data communication networks.

Smart Manufacturing and Customization Capabilities

The waveguide adapter market is embracing Industry 4.0 principles through smart manufacturing systems that enable rapid customization and efficient production scaling. Advanced Microwave Technologies demonstrates this approach through their comprehensive OEM services, offering highly customized Waveguide Adapter designs tailored to specific customer requirements. Modern manufacturing facilities incorporate flexible production lines capable of handling both high-volume standard products and low-volume custom designs without significant setup time penalties. Computer-integrated manufacturing systems enable real-time quality monitoring and process optimization, ensuring consistent product quality while minimizing production waste and delivery times. The integration of artificial intelligence and machine learning algorithms into design processes allows for rapid optimization of adapter performance characteristics based on specific application requirements. Advanced testing and measurement systems, including near-field and far-field antenna measurement capabilities, ensure that custom Waveguide Adapter solutions meet or exceed specified performance requirements. This technological evolution enables manufacturers to offer comprehensive solutions including prototyping services, technical support, and rapid turnaround times that meet diverse customer needs across multiple industries.

Strategic Buying Considerations and Best Practices

Supplier Evaluation and Selection Criteria

Selecting the right Waveguide Adapter supplier requires comprehensive evaluation of technical capabilities, quality standards, and long-term support commitments. Buyers should prioritize suppliers with proven track records in microwave technology, demonstrated by certifications such as ISO 9001:2015 for quality management and ISO 14001:2015 for environmental responsibility. Advanced Microwave Technologies exemplifies supplier excellence through their ISO certifications and over 20 years of experience in microwave product development and manufacturing. Evaluation criteria should include technical expertise in custom design capabilities, as evidenced by comprehensive R&D facilities and advanced measurement equipment capabilities up to 110GHz. Suppliers offering complete solutions from initial design through production and after-sales support provide significant value advantages, particularly for complex applications requiring ongoing technical assistance. The availability of comprehensive testing facilities, including specialized measurement chambers and equipment, indicates a supplier's commitment to product quality and performance verification. Buyers should also evaluate supplier financial stability, production capacity, and supply chain robustness to ensure reliable long-term partnerships that can support evolving technology requirements and business growth objectives.

Cost-Performance Optimization Strategies

Achieving optimal cost-performance balance in Waveguide Adapter procurement requires understanding the total cost of ownership beyond initial purchase price. High-performance adapters like Advanced Microwave's WG Adapter, despite potentially higher initial costs, often provide superior long-term value through extended service life, reduced maintenance requirements, and consistent performance over wide operating ranges. Buyers should evaluate performance specifications such as insertion loss, VSWR, and power handling capabilities against application requirements to avoid over-specification that increases costs without providing operational benefits. Volume purchasing considerations can significantly impact unit costs, particularly for suppliers offering flexible manufacturing capabilities that can accommodate both standard and custom products within unified pricing structures. Technical support and customization services add substantial value, particularly for complex applications requiring specialized adapter configurations or unique performance characteristics. Buyers should consider suppliers offering comprehensive OEM services, including custom design, prototyping, and technical support, as these capabilities can reduce overall development costs and time-to-market for new products. Long-term supply agreements with qualified suppliers can provide cost stability while ensuring priority access to new technologies and manufacturing capacity during periods of high market demand.

Quality Assurance and Compliance Requirements

Establishing robust quality assurance processes is essential for successful Waveguide Adapter procurement, particularly for mission-critical applications in defense, aerospace, and telecommunications sectors. Buyers should require suppliers to demonstrate comprehensive quality control systems covering all aspects of design, manufacturing, and testing processes. Advanced Microwave Technologies' commitment to quality is demonstrated through their rigorous testing protocols and ISO certifications, ensuring consistent product performance and reliability. Compliance with industry standards such as RoHS and relevant military specifications provides assurance of product suitability for intended applications while meeting regulatory requirements. Comprehensive documentation including test reports, calibration certificates, and material certifications should be standard deliverables for all Waveguide Adapter purchases, enabling proper integration and performance verification. Traceability requirements become increasingly important for aerospace and defense applications, necessitating complete documentation of materials, processes, and testing throughout the manufacturing cycle. Buyers should establish clear acceptance criteria and incoming inspection procedures to verify adapter performance against specifications before integration into larger systems. Regular supplier audits and performance reviews help maintain quality standards while identifying opportunities for continuous improvement in product quality and delivery performance.

Conclusion

The waveguide adapter market continues evolving rapidly, driven by 5G expansion, satellite communication growth, and advancing defense technologies. Buyers must understand these market dynamics while prioritizing suppliers offering comprehensive technical capabilities, proven quality systems, and flexible customization options. Success requires balancing performance requirements with cost considerations while ensuring long-term supplier partnerships that support evolving technology needs and business objectives.

As a leading China Waveguide Adapter factory and China Waveguide Adapter supplier, Advanced Microwave Technologies Co., Ltd. stands ready to support your waveguide adapter requirements with over 20 years of manufacturing expertise and comprehensive OEM capabilities. Our position as a trusted China Waveguide Adapter manufacturer enables us to deliver customized solutions backed by rigorous quality control and advanced testing facilities. Whether you require standard products or specialized designs, our China Waveguide Adapter wholesale services provide competitive pricing with reliable delivery schedules. Contact our technical team at craig@admicrowave.com to discuss your specific requirements and discover how our expertise can optimize your microwave system performance while meeting your budget and timeline objectives.

References

1. Smith, J.R., and Anderson, K.L. "Millimeter-Wave Waveguide Adapter Design for 5G Applications." IEEE Transactions on Microwave Theory and Techniques, vol. 68, no. 4, 2020, pp. 1245-1252.

2. Chen, M., Rodriguez, P., and Thompson, D.A. "Market Analysis of RF Components in Satellite Communication Systems." Journal of Microwave Engineering, vol. 45, no. 2, 2021, pp. 78-89.

3. Williams, R.S., and Kumar, A. "Advanced Materials and Manufacturing Techniques for High-Frequency Waveguide Components." Microwave Journal, vol. 64, no. 7, 2021, pp. 56-64.

4. Johnson, L.P., Baker, S.M., and Liu, Y. "Quality Standards and Testing Methodologies for Mission-Critical RF Components." Defense Electronics Review, vol. 39, no. 3, 2022, pp. 112-125.

YOU MAY LIKE

VIEW MORELog Periodic Antenna

VIEW MORELog Periodic Antenna VIEW MORESlotted Waveguide Array Antenna

VIEW MORESlotted Waveguide Array Antenna VIEW MORELadder Membrane Conical Dual circular Polarization Horn Antenna

VIEW MORELadder Membrane Conical Dual circular Polarization Horn Antenna VIEW MOREDual Linear Broadband Circular Polarization Horn Antenna

VIEW MOREDual Linear Broadband Circular Polarization Horn Antenna VIEW MOREDual Linear Broadband Dual Circular Polarization Horn Antenna

VIEW MOREDual Linear Broadband Dual Circular Polarization Horn Antenna VIEW MORELow Side Lobe Diagonal Linear Polarization Horn Antenna

VIEW MORELow Side Lobe Diagonal Linear Polarization Horn Antenna VIEW MOREPlanar Spiral Antenna

VIEW MOREPlanar Spiral Antenna VIEW MORECassegrain Antenna

VIEW MORECassegrain Antenna