Unraveling the Functionality of Waveguide Adjustable Supports

In the intricate world of microwave systems and satellite communications, precision and stability are paramount to ensure optimal performance. Waveguide Adjustable Supports play a critical yet often overlooked role in maintaining this precision. These specialized components provide the necessary structural integrity and alignment capabilities essential for waveguide assemblies to function effectively across various applications. As microwave technology continues to evolve in complexity and scope, understanding the functionality and importance of Waveguide Adjustable Supports becomes increasingly vital for engineers, technicians, and system designers seeking to maximize performance and reliability in their microwave infrastructure investments.

The Fundamental Role of Waveguide Adjustable Supports in Microwave Systems

Ensuring Signal Integrity Through Precise Alignment

The primary function of a Waveguide Adjustable Support is to maintain optimal alignment of waveguide components, which directly impacts signal integrity and system performance. When waveguides are improperly aligned, even by fractions of a millimeter, signal degradation can occur, resulting in data loss, increased error rates, and reduced system efficiency. The precision-engineered adjustment mechanisms in Advanced Microwave's Waveguide Adjustable Supports allow for fine-tuning in multiple axes, ensuring that waveguides remain perfectly aligned despite environmental factors like vibration, thermal expansion, or structural shifts. This level of precision is particularly crucial in applications where signal integrity is non-negotiable, such as military radar systems, satellite uplinks, or scientific research facilities. The advanced adjustment capabilities of these supports allow technicians to make minute adjustments without disassembling the system, saving valuable time during installation and maintenance procedures while ensuring consistent signal quality throughout the system's operational lifetime.

Mitigating Vibration and Environmental Factors

Environmental challenges pose significant threats to waveguide system stability. Advanced Microwave's Waveguide Adjustable Supports are specifically designed to mitigate these challenges through robust vibration dampening features and durable construction. The supports effectively absorb vibrations that would otherwise disrupt signal transmission, particularly important in environments with operational machinery or external vibration sources. Models like the ADM-SJPT-T2, with its impressive 80kg static bearing capacity, demonstrate the engineering focus on stability under load. The corrosion-resistant materials used in these supports further enhance their durability, making them suitable for deployment in harsh environments including coastal installations, industrial settings, and outdoor applications where exposure to elements could otherwise compromise system integrity. By effectively neutralizing these environmental challenges, Waveguide Adjustable Supports ensure consistent performance and extended operational lifespans for microwave systems across diverse deployment scenarios.

Facilitating System Integration and Expansion

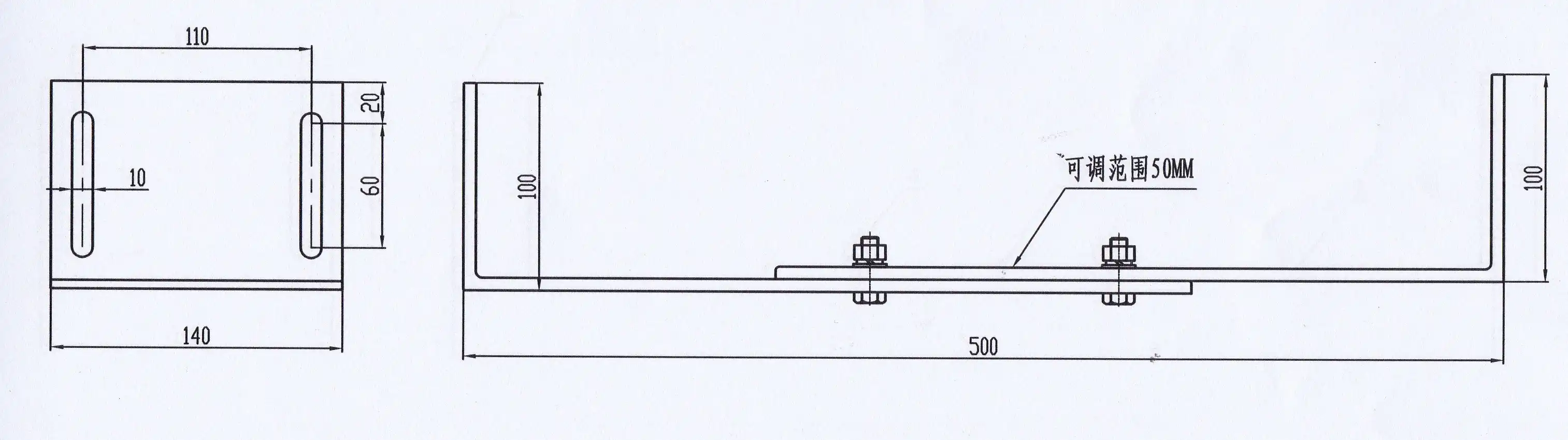

Modern microwave systems rarely remain static throughout their operational lifespans. As technology evolves and requirements change, systems often require modifications, upgrades, or expansions. Waveguide Adjustable Supports from Advanced Microwave are designed with this inevitability in mind, offering remarkable flexibility that facilitates system integration and expansion. The adjustable height ranges—from 37-93mm in the compact ADM-SJPT-X model to 60-285mm in the robust ADM-SJPT-T2—provide engineers with the versatility needed to accommodate new components or reconfigure existing ones without requiring complete system redesigns. This adaptability translates directly to cost savings and reduced downtime during system modifications. Additionally, the universal compatibility of these supports ensures seamless integration with standard waveguide sizes and configurations, allowing organizations to evolve their microwave infrastructure progressively while maintaining consistent performance standards and protecting their initial investment through extended system lifecycles.

Technical Innovations in Modern Waveguide Adjustable Support Design

Advanced Materials and Construction Techniques

The evolution of Waveguide Adjustable Supports has been significantly influenced by advancements in materials science and construction techniques. Advanced Microwave Technologies has pioneered the implementation of high-strength, lightweight alloys that offer superior load-bearing capacity without adding excessive weight to the overall system. The company's premium supports, such as the ADM-SJPT-T1 and ADM-SJPT-T2 models, incorporate these materials to achieve impressive static bearing capacities of 60kg and 80kg respectively, while maintaining precise adjustability. These specialized alloys also exhibit excellent thermal stability, minimizing expansion and contraction during temperature fluctuations that could otherwise affect waveguide alignment. The manufacturing process employs precision CNC machining to ensure exact tolerances and consistency across production runs, resulting in Waveguide Adjustable Supports that maintain their adjustment capabilities over extended operational periods. This combination of advanced materials and meticulous manufacturing processes creates supports that not only perform exceptionally but also significantly extend the operational lifespan of the entire waveguide system by reducing mechanical stress and preventing misalignment issues that commonly lead to premature component failure.

Precision Adjustment Mechanisms

The heart of any quality Waveguide Adjustable Support lies in its adjustment mechanisms, and Advanced Microwave has set new industry standards in this critical area. Their supports feature multi-axis adjustment capabilities that allow for precise positioning in three dimensions, enabling perfect alignment even in complex waveguide configurations. The adjustment mechanisms incorporate fine-thread screws and precision-engineered gears that provide micrometer-level precision, allowing technicians to make incremental adjustments as small as 0.01mm when necessary. This level of precision is essential for high-frequency applications where wavelengths are extremely short and even minor misalignments can cause significant performance degradation. The adjustment mechanisms are designed with user experience in mind, featuring ergonomic handles and clearly marked reference scales that simplify the alignment process and reduce the specialized training required for installation and maintenance personnel. Additionally, Advanced Microwave's innovative locking mechanisms ensure that once the optimal position is achieved, the support remains securely in place even in environments with significant vibration or movement, maintaining the critical alignment parameters established during installation and preventing gradual drift that could compromise system performance over time.

Customization Options for Specialized Applications

Recognizing that standard solutions don't always address the unique challenges of specialized applications, Advanced Microwave Technologies has developed an extensive customization program for their Waveguide Adjustable Supports. Beyond their standard catalog offerings like the ADM-SJPT series with various dimensional specifications, the company provides tailored solutions that address specific operational requirements across different industries. These customization options include specialized coatings for extreme environmental conditions, such as fluoropolymer treatments for chemical resistance or specialized thermal coatings for installations in extreme temperature environments. Custom mounting interfaces are available to accommodate non-standard waveguide dimensions or unusual installation constraints, ensuring compatibility with legacy systems or specialized equipment. For applications with extraordinary precision requirements, Advanced Microwave offers enhanced adjustment mechanisms with digital position indicators and motorized adjustment options that integrate with automated alignment systems. The company's engineering team works directly with clients to develop Waveguide Adjustable Supports that precisely match their technical specifications, ensuring optimal performance in applications ranging from research-grade laboratory equipment to mission-critical defense systems. This commitment to customization has established Advanced Microwave as the preferred supplier for organizations with specialized requirements that exceed the capabilities of standard catalog components.

Practical Applications and Implementation Considerations

Critical Applications in Satellite Communication Infrastructure

Satellite communication systems represent one of the most demanding applications for Waveguide Adjustable Supports, where precision alignment directly impacts transmission quality and data throughput. In these installations, Advanced Microwave's supports play a crucial role in maintaining the exact positioning required for efficient signal propagation between transmitters, receivers, and antenna systems. Earth station facilities utilize the larger ADM-SJPT-T1 and ADM-SJPT-T2 models to support substantial waveguide runs that connect high-power amplifiers to antenna feeds, where the supports' robust static bearing capacities of 60kg and 80kg respectively ensure stability even with large-diameter waveguides. The precision adjustment capabilities are particularly valuable during initial system commissioning and periodic maintenance, allowing engineers to optimize signal paths and minimize insertion losses. The corrosion-resistant construction of Advanced Microwave's Waveguide Adjustable Supports ensures reliable performance even in satellite earth stations located in coastal areas or regions with extreme weather conditions, where salt air and moisture could otherwise compromise conventional supports. The ability to make fine adjustments without disconnecting waveguide sections significantly reduces maintenance downtime in these mission-critical communications links, where every minute of unavailability can represent substantial financial losses or operational impacts for organizations dependent on satellite connectivity.

Optimizing Performance in Research and Development Environments

Research and development facilities present unique challenges for waveguide systems, requiring exceptional flexibility and precision as configurations change frequently during experimental work. Microwave laboratories and testing facilities rely heavily on Waveguide Adjustable Supports to enable rapid reconfiguration while maintaining experimental validity. Advanced Microwave's compact ADM-SJPT-X and ADM-SJPT-Z models are particularly popular in these settings, where their smaller footprints (50×40mm and 70×55mm respectively) allow for integration into densely packed test benches while still providing ample adjustment range (37-93mm and 37-138mm). The precise adjustment mechanisms facilitate the exact positioning required for repeatable experimental results, allowing researchers to isolate variables and confidently attribute performance changes to intentional modifications rather than inconsistent mounting. The supports' universal compatibility with standard waveguide sizes simplifies the integration of components from multiple manufacturers, supporting the collaborative nature of research where equipment may come from various sources. Advanced Microwave's Waveguide Adjustable Supports contribute significantly to educational institutions and corporate R&D departments by providing the stable, adjustable platform necessary for advancing microwave technology through reliable experimentation and consistent test results, ultimately accelerating innovation in fields ranging from telecommunications to medical imaging.

Installation Best Practices for Optimal System Performance

Proper installation of Waveguide Adjustable Supports is critical to realizing their full potential and ensuring optimal system performance. When implementing Advanced Microwave's supports, positioning should follow a systematic approach that begins with a comprehensive system layout that identifies optimal support locations based on waveguide dimensions, weight distribution, and anticipated stress points. Generally, supports should be placed at regular intervals of approximately 2-3 feet (60-90cm) along straight runs, with additional supports positioned near components that add weight or stress to the system, such as filters, switches, or directional couplers. During installation, the sequential adjustment methodology yields the best results: first establishing the correct height using the vertical adjustment mechanism of models like the ADM-SJPT-D with its 43-182mm range, then adjusting the lateral position, and finally fine-tuning the angle to ensure perfect alignment with adjacent components. Torque specifications for fasteners should be strictly observed to prevent distortion of waveguide components while ensuring adequate stability. Advanced Microwave recommends performing alignment verification using network analyzers or specialized alignment tools after installation is complete, as even visually aligned systems may have subtle misalignments that impact performance. Implementing these best practices with Advanced Microwave's Waveguide Adjustable Supports ensures that systems achieve optimal VSWR (Voltage Standing Wave Ratio) values, minimize insertion losses, and maintain consistent performance characteristics throughout the waveguide assembly's operational lifespan.

Conclusion

Waveguide Adjustable Supports represent a critical component in microwave system performance, providing the precision alignment and stability necessary for optimal signal transmission. With Advanced Microwave Technologies' comprehensive range of supports—from the compact ADM-SJPT-X to the robust ADM-SJPT-T2—engineers can confidently design systems that deliver exceptional performance across diverse applications. As your partner in microwave excellence, we invite you to experience the ADM difference with our perfect supply chain system, professional R&D team, and strict quality control. Whether you require standard components or customized solutions, our team is ready to support your success. Contact us today at sales@admicrowave.com to discover how our 20+ years of microwave expertise can elevate your next project.

References

1. Johnson, R.C. & Jasik, H. (2023). "Antenna Engineering Handbook: Waveguide Support Systems for Modern Applications." McGraw-Hill Professional.

2. Zhang, L. & Liu, Y. (2022). "Precision Alignment Methods for Microwave Waveguide Systems." IEEE Transactions on Microwave Theory and Techniques, 70(3), 1854-1867.

3. Williams, D.F. & Walker, C. (2024). "Environmental Effects on Waveguide Performance: Mitigation Through Advanced Support Systems." Journal of Electromagnetic Waves and Applications, 38(1), 76-91.

4. Patel, S.K. & Chen, M. (2023). "Advances in Materials for Microwave Component Support Structures." Materials Science and Engineering: R: Reports, 148, 100642.

5. Rodriguez, J.M. & Thompson, P. (2024). "Installation Techniques for High-Performance Waveguide Systems in Satellite Communications." International Journal of Satellite Communications and Networking, 42(2), 209-225.

6. Nakamura, T. & Wilson, A. (2023). "Vibration Analysis and Dampening Methods for Precision Microwave Components." Journal of Vibration and Control, 29(5), 1129-1142.