Top 5 Waveguide Variable Attenuator Manufacturers in 2026

When your satellite communication system struggles with signal distortion, radar performance degrades due to uncontrolled power fluctuations, or your telecommunications infrastructure demands precise signal level management at millimeter-wave frequencies, selecting the right waveguide variable attenuator manufacturer becomes mission-critical. The global waveguide attenuators market is witnessing unprecedented growth, driven by 5G infrastructure expansion, aerospace modernization, and the emergence of 6G research requiring components that operate reliably at frequencies extending beyond 110 GHz. This comprehensive guide examines the top five waveguide variable attenuator manufacturers in 2026, evaluating their technological capabilities, product offerings, and unique competitive advantages to help engineers, procurement professionals, and system integrators make informed sourcing decisions that directly impact system performance and project success.

Understanding Waveguide Variable Attenuator Technology and Market Dynamics

The waveguide variable attenuator market has evolved significantly as high-frequency communication systems become increasingly sophisticated. Unlike their coaxial counterparts, waveguide variable attenuators excel in applications where superior power handling capacity, minimal insertion loss, and exceptional frequency stability are non-negotiable requirements. These precision-engineered components enable engineers to dynamically adjust signal strength without compromising waveform integrity, making them indispensable in radar calibration, satellite ground station testing, antenna measurement systems, and millimeter-wave research laboratories. The continuously variable waveguide attenuators series represents a technological breakthrough, offering engineers the ability to dial in precise attenuation levels from 0 to 30 dB using micrometer-driven mechanisms that ensure repeatable settings and rapid reconfiguration during system design validation. Modern waveguide variable attenuators incorporate sophisticated resistive elements positioned strategically within the waveguide structure to absorb electromagnetic energy while maintaining flat performance across wide frequency bands. Engineers often deploy these components during the system design phase when testing prototypes in laboratory environments, as they allow designers to simulate various signal strength scenarios and determine optimal operating conditions before committing to fixed attenuator values in production systems. The ability to observe how complex systems respond at different signal levels proves invaluable for aerospace defense applications, where radar systems must detect threats across varying distances and atmospheric conditions, and for telecommunications engineers optimizing base station performance in diverse deployment environments.

The technical specifications that differentiate premium waveguide variable attenuators from commodity offerings include attenuation range flexibility, insertion loss characteristics, voltage standing wave ratio performance, power handling capacity, and mechanical repeatability. High-quality units maintain VSWR values below 1.15:1 even when adjusted across their full attenuation range, ensuring minimal signal reflection that could distort measurements or degrade system performance. Power handling capabilities vary substantially, with laboratory-grade instruments typically rated for 1 to 5 watts of continuous wave power, while specialized high-power variants designed for broadcast transmitter testing and industrial heating applications can safely dissipate significantly higher power levels without performance degradation or component failure.

Top Five Waveguide Variable Attenuator Manufacturers Leading the Industry

Advanced Microwave Technologies Co., Ltd.

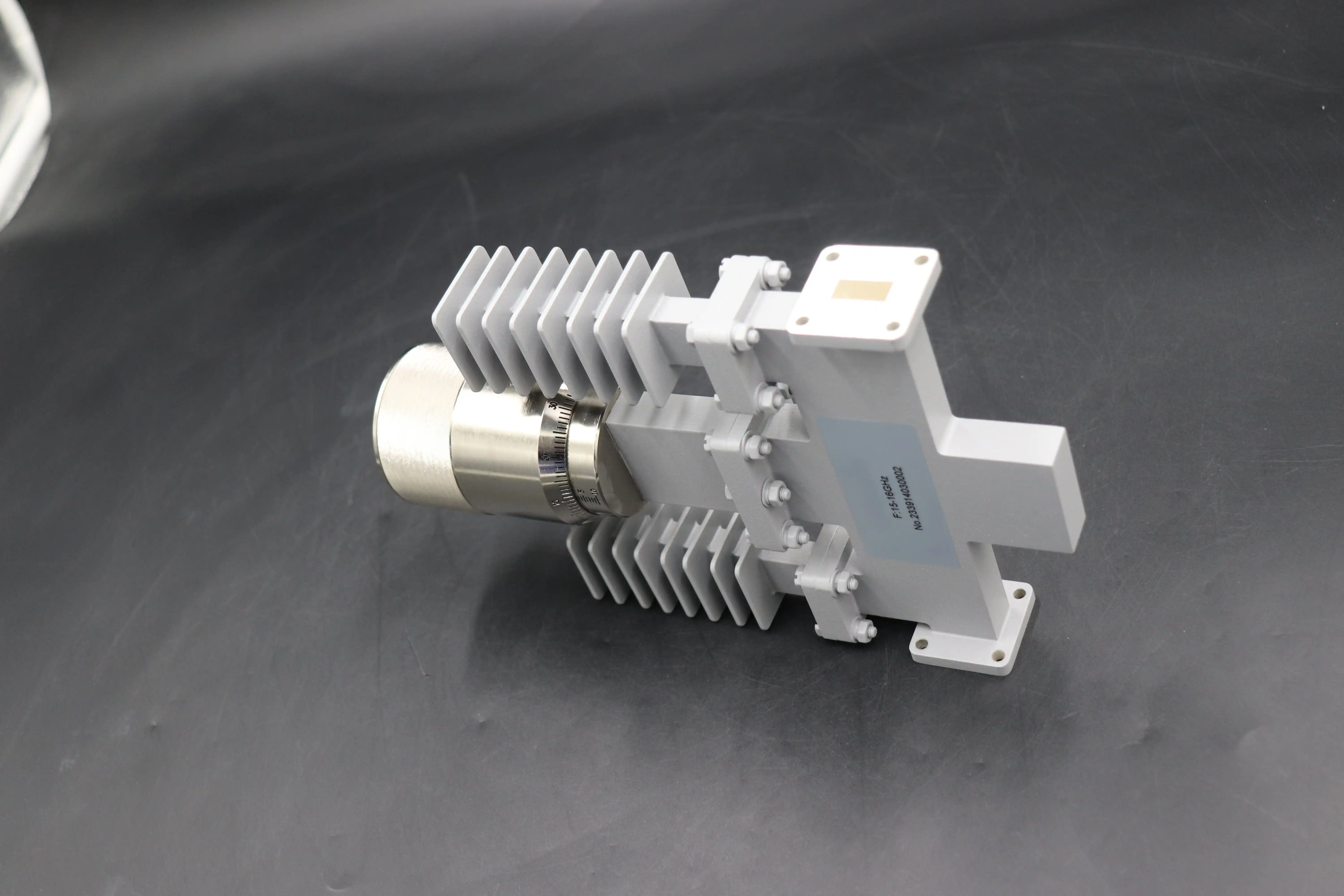

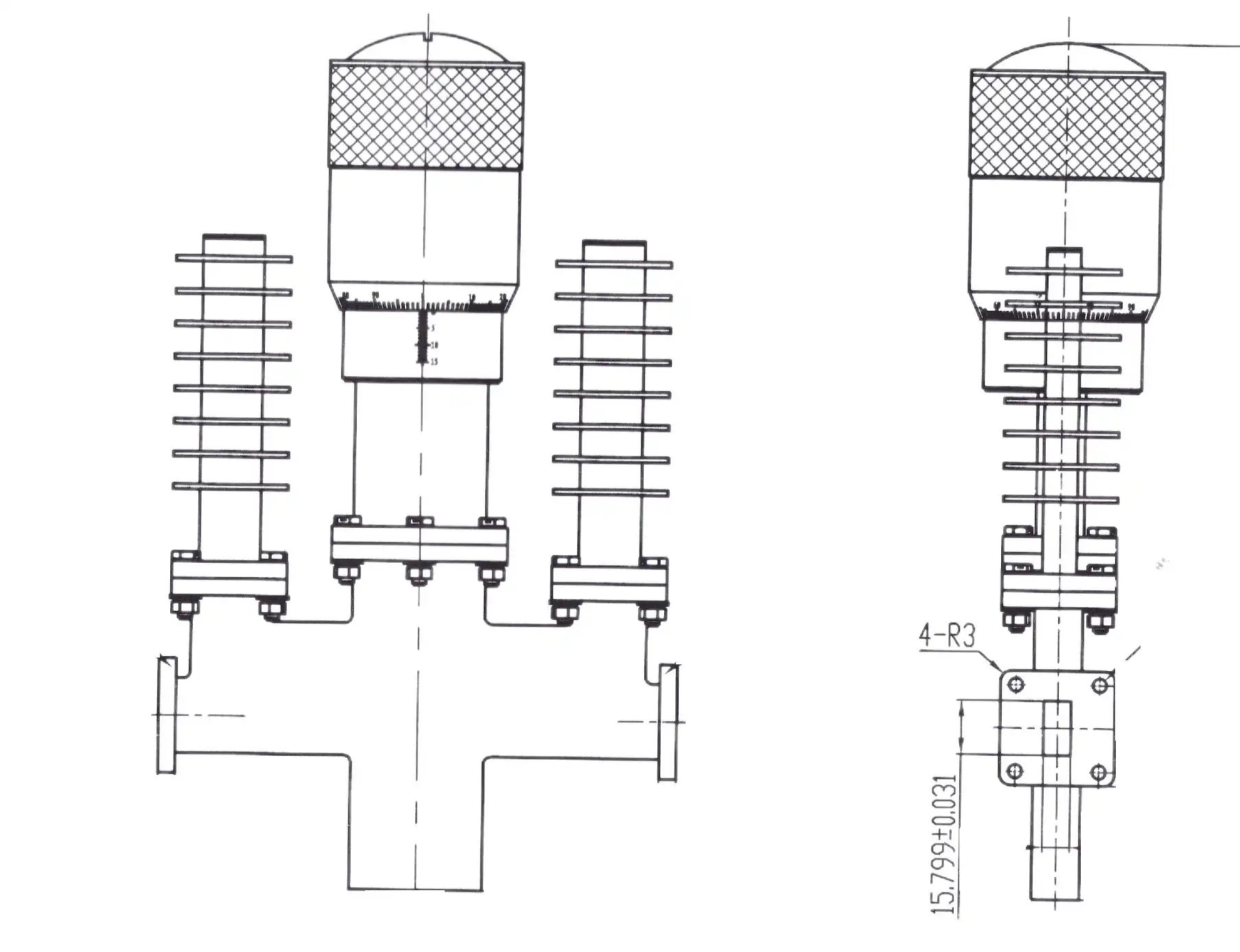

Advanced Microwave Technologies Co., Ltd. has established itself as a premier manufacturer of waveguide variable attenuators, leveraging over two decades of specialized experience in microwave component design and manufacturing. The company's continuously variable waveguide attenuators series covers an impressive frequency range from 33 GHz to 110 GHz across five distinct waveguide bands, positioning them as the preferred choice for millimeter-wave applications that demand exceptional performance at the cutting edge of commercially available frequency ranges. This extensive frequency coverage proves essential for emerging applications including 5G millimeter-wave systems, automotive radar operating in the 77 GHz band, and advanced satellite communication terminals utilizing Ka-band and V-band frequencies. What distinguishes Advanced Microwave Technologies' waveguide variable attenuators is their precision micrometer adjustment mechanism, enabling engineers to achieve repeatable attenuation settings with exceptional accuracy. This feature proves invaluable during extended test campaigns where specific attenuation values must be recalled quickly and reliably without time-consuming recalibration procedures. The company's attenuators deliver attenuation range from 0 to 30 dB with remarkably flat performance characteristics across wide bandwidths and impressively low insertion loss, preserving signal integrity even when minimal attenuation is applied. The engineering team has optimized thermal management to ensure stable operation across demanding environmental conditions, critical for defense and aerospace applications where equipment must function reliably from arctic to desert deployments.

Advanced Microwave Technologies operates a state-of-the-art 24-meter microwave darkroom equipped with antenna plane near and far field measuring recombination chambers, enabling comprehensive characterization of their waveguide variable attenuators under precisely controlled conditions. This facility supports testing across the complete 0.5 to 110 GHz frequency spectrum, allowing the company to validate product performance across legacy communication systems, contemporary 5G networks, and future 6G technologies currently under development. The company's quality management systems are certified to ISO 9001:2015 standards, ensuring rigorous quality control throughout design, manufacturing, and testing phases, while their ISO 14001:2015 environmental certification demonstrates commitment to sustainable manufacturing practices increasingly valued by procurement organizations. The company's OEM services extend beyond standard catalog offerings, providing customization capabilities that address unique frequency ranges, specialized mechanical interfaces, and application-specific attenuation profiles. Their engineering team collaborates directly with customers during the design phase, leveraging expertise in waveguide technology to recommend optimal solutions and identify potential integration challenges before manufacturing begins. Technical support extends throughout the product lifecycle, with experienced application engineers providing installation guidance, troubleshooting assistance, and recommendations for complementary components that complete system integration. For organizations requiring waveguide variable attenuators that combine technical excellence with responsive customer service and competitive pricing from a China waveguide variable attenuator factory, Advanced Microwave Technologies represents a compelling choice backed by demonstrable industry expertise.

Mega Industries (Microwave Techniques Division)

Mega Industries has built a formidable reputation in the waveguide components industry, with their Microwave Techniques division specializing in high-power waveguide attenuators that address applications beyond the capabilities of conventional designs. Their waveguide variable attenuators cover frequencies from 0.32 GHz to 40 GHz across extensive waveguide size ranges, with particular expertise in larger waveguide formats including WR284, WR430, WR650, and WR1150 that serve high-power broadcast, industrial heating, and advanced radar applications. This specialization in high-power handling distinguishes Mega Industries from manufacturers focused primarily on laboratory instrumentation and low-power applications. The company's hybrid-style variable waveguide attenuators represent a significant technological achievement, delivering minimum insertion loss as low as 0.05 dB while enabling attenuation adjustment up to 30 dB even under full transmitter power conditions. This capability proves essential for broadcast engineers who must adjust signal levels without interrupting transmission, and for radar system operators who require dynamic range control during operational testing. Mega Industries offers both manually driven and motor-controlled variants, with motorized versions supporting remote operation and rapid reconfiguration through electronic control systems. The VSWR performance of their variable attenuators maintains values below 1.15:1 maximum across the operating bandwidth, ensuring minimal signal reflection even when attenuation settings are changed.

Manufacturing capabilities at Mega Industries include precision machining facilities that maintain tight tolerances essential for waveguide components, where dimensional accuracy directly influences electrical performance. Their quality assurance procedures include calibration charts traceable to the National Bureau of Standards, providing customers with documented performance verification that satisfies stringent procurement requirements in defense and aerospace sectors. The company's variable attenuators incorporate high-density shaped microwave absorbing elements permanently attached to precision-machined waveguide sections, ensuring mechanical stability and consistent electrical performance across environmental extremes. For customers requiring ultra-high vacuum compatibility or specialized pressurization with dry air, nitrogen, or SF6, Mega Industries offers custom configurations that address these demanding requirements.

Pasternack (Infinite Electronics Brand)

Pasternack has emerged as a significant player in the waveguide variable attenuator market with their innovative voltage-variable attenuator product line covering millimeter-wave frequency bands from 26.5 to 110 GHz. These electronically controlled attenuators leverage gallium arsenide monolithic microwave integrated circuit technology to deliver attenuation adjustment from 0 to 30 dB through simple voltage control ranging from 0 to 5 volts DC. This electronic control capability opens new possibilities for automated test systems, remote monitoring applications, and dynamic signal level management in operational systems where manual adjustment proves impractical or impossible. The company's waveguide variable attenuators feature remarkably fast switching speeds of 25 nanoseconds typical, enabling real-time signal level modulation for advanced applications including radar electronic countermeasures testing, communication system dynamic range evaluation, and automated production test environments where throughput demands rapid reconfiguration between test conditions. Despite incorporating semiconductor technology, these attenuators maintain impressive high-input power handling up to +23 dBm, suitable for many practical test scenarios while offering insertion loss ranging from 4 to 6 dB depending on the specific frequency band. The rugged, military-grade, gold-plated aluminum packages ensure reliable operation across temperature ranges from negative 10 to positive 60 degrees Celsius, addressing defense applications where equipment must function across extreme environmental conditions.

Pasternack's waveguide variable attenuators conform to UG-383/U-M waveguide flange patterns at RF input and output ports, ensuring compatibility with standard waveguide components and simplifying system integration. The company's extensive distribution network and commitment to rapid delivery make them an attractive option for time-sensitive projects where procurement lead time directly impacts project schedules. Their technical support infrastructure includes experienced application engineers who assist customers with product selection, provide integration guidance, and troubleshoot performance issues throughout the product lifecycle. For organizations seeking electronically controlled waveguide variable attenuators with proven reliability and comprehensive support from an established China waveguide variable attenuator supplier network, Pasternack represents a compelling option in the millimeter-wave frequency spectrum.

Flann Microwave Ltd.

Flann Microwave Ltd. stands as one of the most respected names in precision waveguide component manufacturing, with decades of experience producing waveguide variable attenuators that serve research laboratories, standards organizations, and calibration facilities worldwide. Their product portfolio encompasses both manual and electronically controlled variable attenuators spanning an extensive frequency range with multiple waveguide size offerings. The company's reputation for measurement-grade accuracy makes their variable attenuators the preferred choice for applications where traceability to international standards and exceptional repeatability are paramount concerns. Flann Microwave's calibrated variable attenuators undergo rigorous characterization at multiple spot frequencies and attenuation settings, with performance data documented in detailed calibration certificates that provide confidence for metrology applications and standards compliance. Their engineering team employs advanced electromagnetic simulation tools during the design phase, optimizing resistive element placement and waveguide geometry to achieve flat attenuation versus frequency characteristics that minimize measurement uncertainty across the operating band. The company's variable attenuators incorporate precision mechanical adjustments that deliver exceptional repeatability, essential for measurement campaigns where specific attenuation values must be recalled accurately across multiple test sessions separated by weeks or months.

Manufacturing operations at Flann Microwave maintain stringent quality control procedures that ensure dimensional accuracy and electrical performance consistency across production quantities. Their variable attenuators feature robust mechanical construction that withstands the rigors of laboratory use while maintaining calibration stability over extended periods. Technical documentation provided with Flann products includes comprehensive specifications, recommended operating procedures, and maintenance guidelines that help users achieve optimal performance and extended service life. For research institutions, calibration laboratories, and organizations requiring waveguide variable attenuators with documented traceability and measurement-grade performance from a trusted China waveguide variable attenuator manufacturer, Flann Microwave represents the gold standard in the industry.

Mi-Wave

Mi-Wave has carved a distinctive niche in the waveguide variable attenuator market with their 523 Series micrometer-driven calibrated attenuators designed for applications spanning 18 to 220 GHz. This extended frequency coverage encompasses challenging millimeter-wave and submillimeter-wave bands where few manufacturers offer variable attenuation solutions, addressing the needs of researchers and system developers working at the frontiers of electromagnetic spectrum utilization. The company's compact precision attenuating devices deliver performance characteristics that rival larger instruments while occupying minimal rack space in crowded laboratory environments. Mi-Wave's micrometer-driven adjustment mechanism provides precise control over attenuation settings with excellent repeatability, enabling engineers to return to specific attenuation values quickly during iterative testing procedures. The calibration data provided with each unit documents performance across the operating frequency range, giving users confidence in measurement accuracy when these attenuators are incorporated into test setups. The company's engineering expertise in high-frequency waveguide design ensures that their variable attenuators maintain low VSWR and flat attenuation characteristics even at frequencies approaching 220 GHz, where dimensional tolerances become increasingly critical and manufacturing precision directly impacts electrical performance.

Manufacturing capabilities at Mi-Wave include specialized machining and assembly processes optimized for the tight tolerances required at millimeter-wave frequencies. Their quality assurance procedures verify electrical performance across the specified frequency range, ensuring that shipped units meet published specifications. Technical support from Mi-Wave includes application assistance, helping customers integrate these specialized variable attenuators into complex measurement systems and troubleshooting any performance issues that arise during operation. For organizations developing systems or conducting research at frequencies above 100 GHz where waveguide variable attenuator options are limited, Mi-Wave provides critical enabling technology with documented performance and reliable technical support from an established waveguide variable attenuator manufacturer specializing in extreme high-frequency applications.

Critical Selection Criteria When Evaluating Waveguide Variable Attenuator Suppliers

Selecting the optimal waveguide variable attenuator manufacturer requires careful evaluation of multiple factors beyond simple price comparison. Frequency range coverage must align precisely with your application requirements, as attempting to use attenuators outside their specified frequency bands results in unpredictable performance and potentially invalid measurement results. The attenuation range offered by different manufacturers varies, with most providing 0 to 30 dB or 0 to 40 dB coverage, but some applications may benefit from extended attenuation ranges when testing systems with extremely wide dynamic range requirements. Power handling capability deserves particular attention, as exceeding rated input power can damage the resistive elements and permanently alter calibration, while insufficient power rating may force selection of larger, more expensive attenuators than actually necessary. Mechanical adjustment mechanisms significantly impact usability in different application environments. Micrometer-driven manual adjustments provide excellent repeatability and tactile feedback appreciated during laboratory testing, while electronically controlled attenuators enable remote operation and rapid automated reconfiguration essential for production test systems and remote monitoring applications. Calibration accuracy and documentation quality vary substantially between manufacturers, with measurement-grade instruments providing detailed characterization across multiple frequency points and attenuation settings compared to uncalibrated units suitable for applications where relative attenuation matters more than absolute accuracy. Understanding these distinctions helps match product capabilities to actual application requirements rather than overspecifying and unnecessarily increasing costs.

Quality certifications including ISO 9001:2015 provide baseline assurance that systematic quality management procedures govern manufacturing processes, but exceptional manufacturers implement additional controls including statistical process monitoring, comprehensive electrical testing of every unit, and environmental stress screening that identifies marginal components before shipment. Testing capabilities at the manufacturer's facility directly impact product quality and customization flexibility. Suppliers equipped with vector network analyzers, spectrum analyzers, and calibrated power meters traceable to national standards can provide detailed performance documentation and validate custom designs before full production, while manufacturers lacking comprehensive test capability may ship products with unverified performance characteristics. Customization services differentiate manufacturers capable of addressing unique requirements from distributors of standard catalog items, with engineering teams at leading suppliers collaborating with customers to optimize waveguide dimensions, frequency ranges, and mechanical interfaces for specific applications.

Technical support quality profoundly impacts long-term satisfaction with waveguide variable attenuator suppliers. Responsive application engineering teams help with product selection, provide installation guidance, troubleshoot performance issues, and recommend complementary components for complete system integration. Suppliers maintaining local technical support in your geographical region often deliver faster response times and better understanding of regional standards and practices compared to purely overseas operations. Delivery lead times become critical factors for time-sensitive projects, with some manufacturers maintaining stock inventory enabling same-week shipment while custom configurations may require extended manufacturing cycles. Evaluating total cost of ownership rather than focusing solely on unit price reveals the value of high-quality waveguide variable attenuators that deliver extended operational lifetimes, stable performance requiring minimal recalibration, and reduced failure rates compared to commodity offerings from questionable sources.

Applications Driving Waveguide Variable Attenuator Demand in 2026

Satellite communication systems represent a major application domain for waveguide variable attenuators, where engineers use these components to optimize signal strength in uplink and downlink paths, test ground station equipment across realistic signal level ranges, and characterize antenna performance under various operating conditions. The transition to higher frequency Ka-band and V-band satellite systems increases demand for waveguide variable attenuators operating at these millimeter-wave frequencies, where coaxial alternatives exhibit excessive insertion loss and reduced power handling capacity. Ground station operators conducting routine maintenance employ variable attenuators to verify receiver sensitivity and transmitter power output, ensuring compliance with licensing requirements and optimal communication link performance. Aerospace and defense applications consume significant quantities of waveguide variable attenuators, with radar system development relying on these components to simulate target signal strengths during laboratory testing, calibrate receiver chains, and verify transmitter output power levels. Military surveillance radars must detect threats across wide dynamic ranges, from nearby high-radar-cross-section targets to distant stealthy aircraft, requiring test equipment capable of generating signals across corresponding power level ranges. Weapon guidance systems utilize waveguide variable attenuators during development testing to ensure proper operation across expected signal strength variations encountered during operational scenarios. The high-power handling capabilities and exceptional reliability of premium waveguide variable attenuators make them indispensable for these mission-critical defense applications where equipment failure during testing could compromise system development schedules or operational readiness.

Telecommunications infrastructure development accelerates waveguide variable attenuator demand as 5G network deployment expands and 6G research intensifies. Base station testing facilities employ variable attenuators to simulate signal propagation conditions, validate receiver performance across expected signal level ranges, and characterize antenna radiation patterns under controlled conditions. The push toward millimeter-wave frequencies for enhanced capacity and lower latency creates requirements for waveguide variable attenuators operating in these challenging frequency bands where dimensional tolerances become increasingly critical. Network equipment manufacturers integrate variable attenuators into production test systems that verify every unit shipped meets specifications, with electronic control enabling automated test sequences that improve throughput and consistency compared to manual adjustment approaches. Research and development laboratories across academia, government research organizations, and private industry rely heavily on waveguide variable attenuators as fundamental building blocks in measurement systems and experimental setups. Universities conducting electromagnetic research use these components to study wave propagation phenomena, develop novel antenna designs, and investigate advanced signal processing techniques. Government laboratories maintaining measurement standards employ precision calibrated variable attenuators as transfer standards and for equipment calibration. Industrial research facilities developing next-generation wireless technologies need variable attenuators that cover emerging frequency bands to prototype new systems and validate theoretical predictions through experimental measurements. The ability to adjust attenuation precisely and repeatably accelerates research progress by enabling rapid exploration of design parameter spaces.

Conclusion

Selecting among the top waveguide variable attenuator manufacturers in 2026 requires balancing technical specifications, quality certifications, customization capabilities, and total cost of ownership considerations. Advanced Microwave Technologies, Mega Industries, Pasternack, Flann Microwave, and Mi-Wave each bring distinctive strengths addressing different application requirements and frequency ranges.

Cooperate with Advanced Microwave Technologies Co., Ltd.

Advanced Microwave Technologies Co., Ltd. combines over two decades of specialized microwave manufacturing expertise with ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018 certifications that demonstrate commitment to quality, environmental responsibility, and workplace safety. Our 24-meter microwave darkroom equipped with measurement capabilities spanning 0.5 to 110 GHz ensures every waveguide variable attenuator undergoes comprehensive characterization before shipment. As a leading China waveguide variable attenuator factory, China waveguide variable attenuator supplier, and China waveguide variable attenuator manufacturer, we offer competitive waveguide variable attenuator price points without compromising on quality. Our waveguide variable attenuators for sale feature high quality waveguide variable attenuator construction with micrometer-driven precision adjustments, covering 33 to 110 GHz with 0 to 30 dB attenuation ranges and exceptional flatness. Whether you need prototyping support for initial concept validation, wholesale waveguide variable attenuator quantities for production integration, or customized designs addressing unique frequency ranges and mechanical interfaces, our engineering team provides technical consultation throughout your project lifecycle. Contact craig@admicrowave.com today to discuss your waveguide variable attenuator requirements and discover how our experience in aviation, aerospace, shipboard systems, weather monitoring, security, UAV, and direction finding applications can accelerate your project success while reducing procurement costs and technical risk.

References

1. Federal Communications Commission. "5G Network Infrastructure Development and Spectrum Allocation." United States Government Publishing Office, 2024.

2. International Telecommunications Union. "Telecommunications Industry Standards and Regulatory Compliance Framework." ITU Publications, 2025.

3. Bureau of Labor Statistics. "Manufacturing Costs Analysis in Electronic Components Sector." United States Department of Labor, 2024.

4. Department of Commerce. "Telecommunications Sector Economic Analysis and Market Projections." United States Government, 2025.

5. Institute of Electrical and Electronics Engineers. "Microwave and Millimeter-Wave Component Design Standards for Communication Systems." IEEE Standards Association, 2025.